Frank N. Wood "Trucut" Armature

and Undercutter Lathe Models B10 & B15

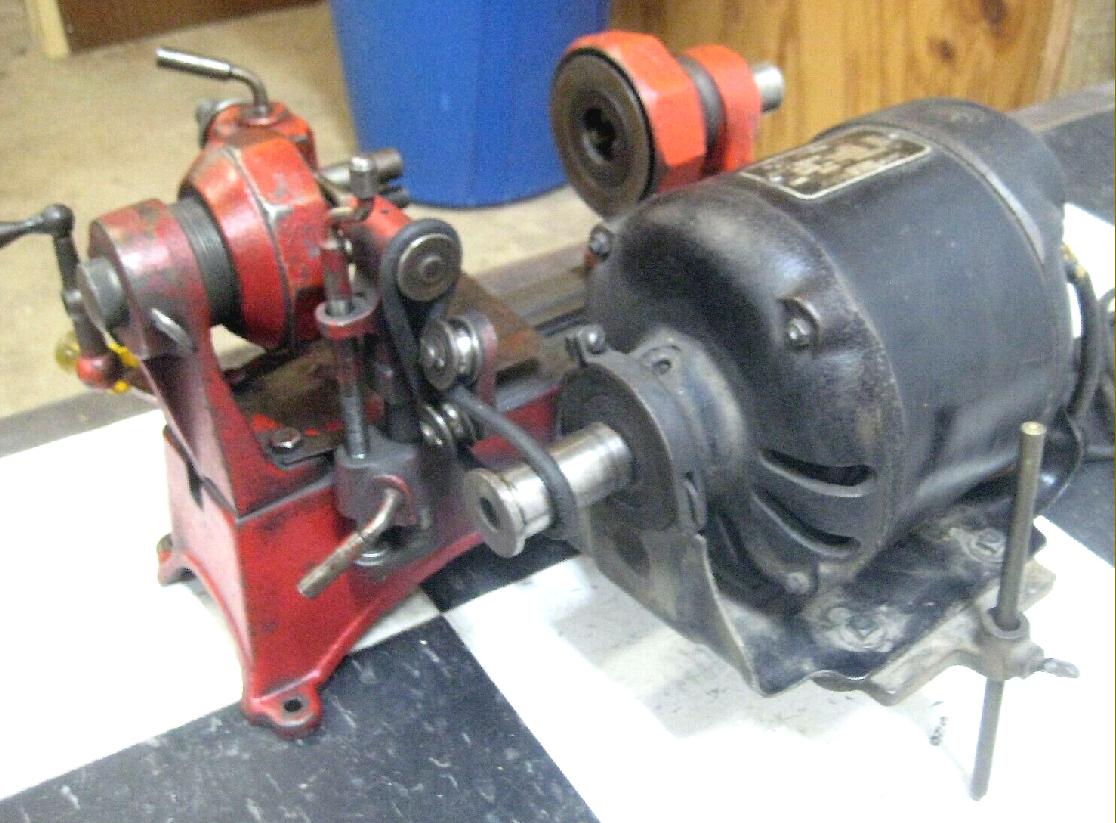

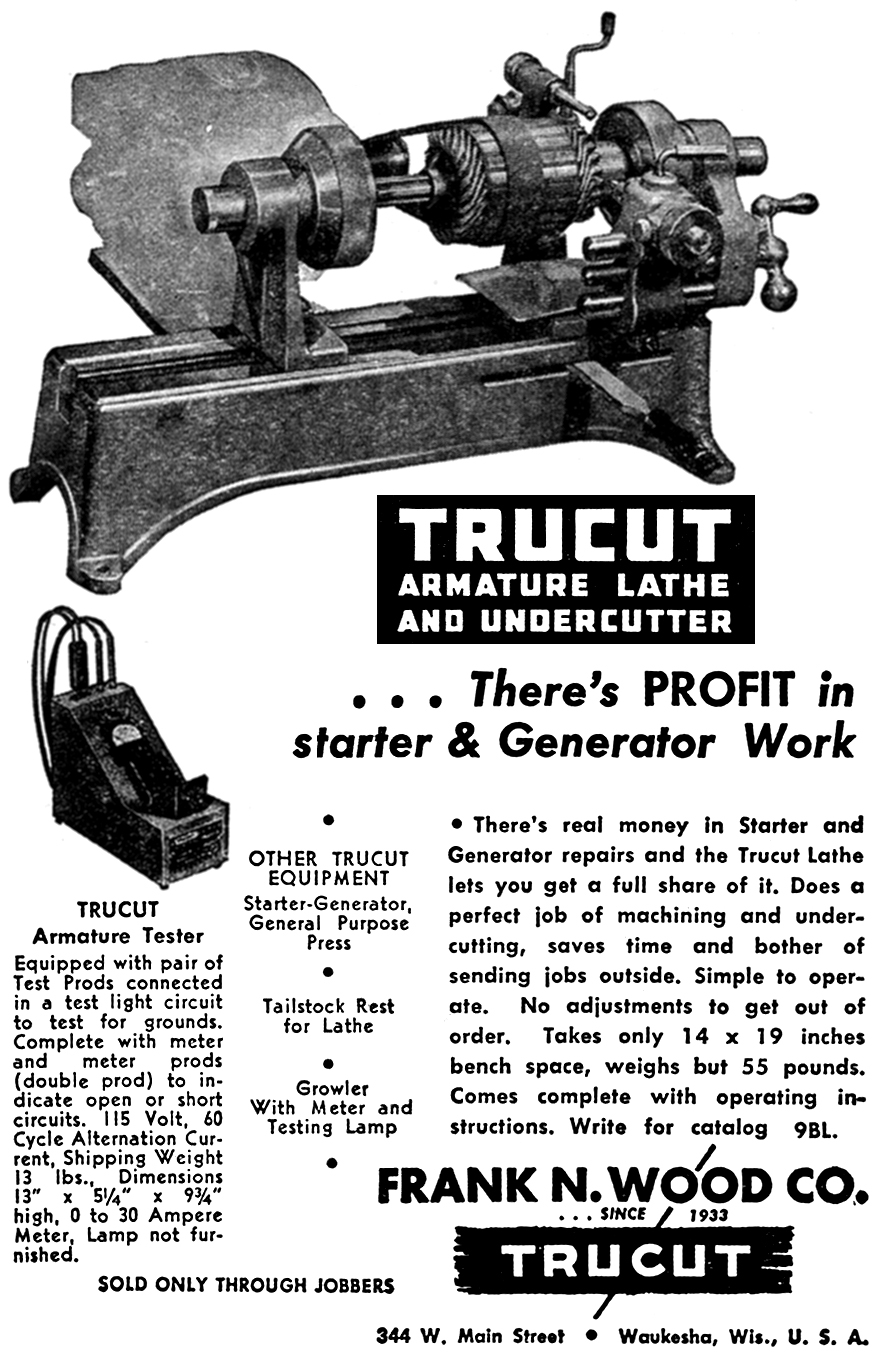

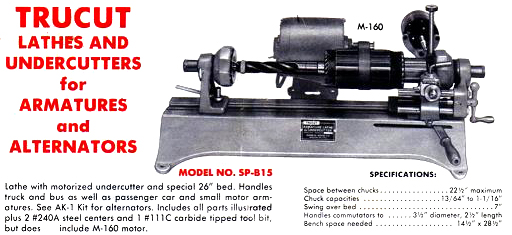

Dedicated to the single task of refurbishing electric-motor and alternator armatures, the ingeniously designed "Trucut" lathe was manufactured by Frank N. Wood Co. of 344 W.Main Street, Waukesha, Wisconsin. The lathe was built in at least three models: the basic B-10, the B-15 and the SP-815. The B-15 was identical to the B-10 save for its undercutter spindle being formed as part of the shaft of a separate motor. The SP-815 was probably the last version to be made, this being advertised as also suitable for work on alternators. While, for many decades, it had been common practice to use an ordinary centre lathe for armature work - some makers, such as Atlas with the 6-inch model, even offering special kits to make the job easier and other companies, such as Zoerman-Clark, providing third-party adaptations of inexpensive lathes of the type sold to amateurs - in a busy electrical workshop having a properly set-up, special-purpose machine would have been a good investment.

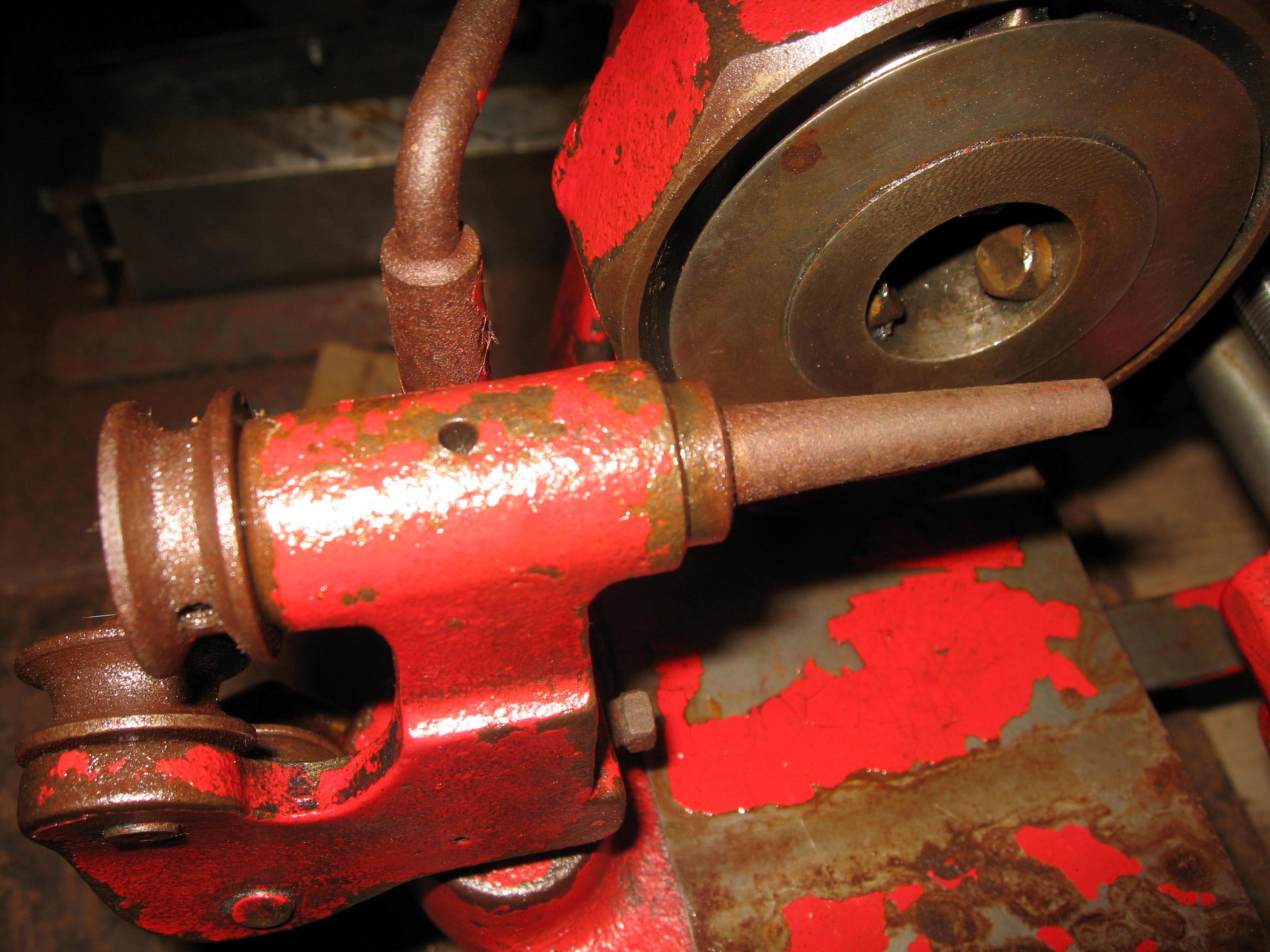

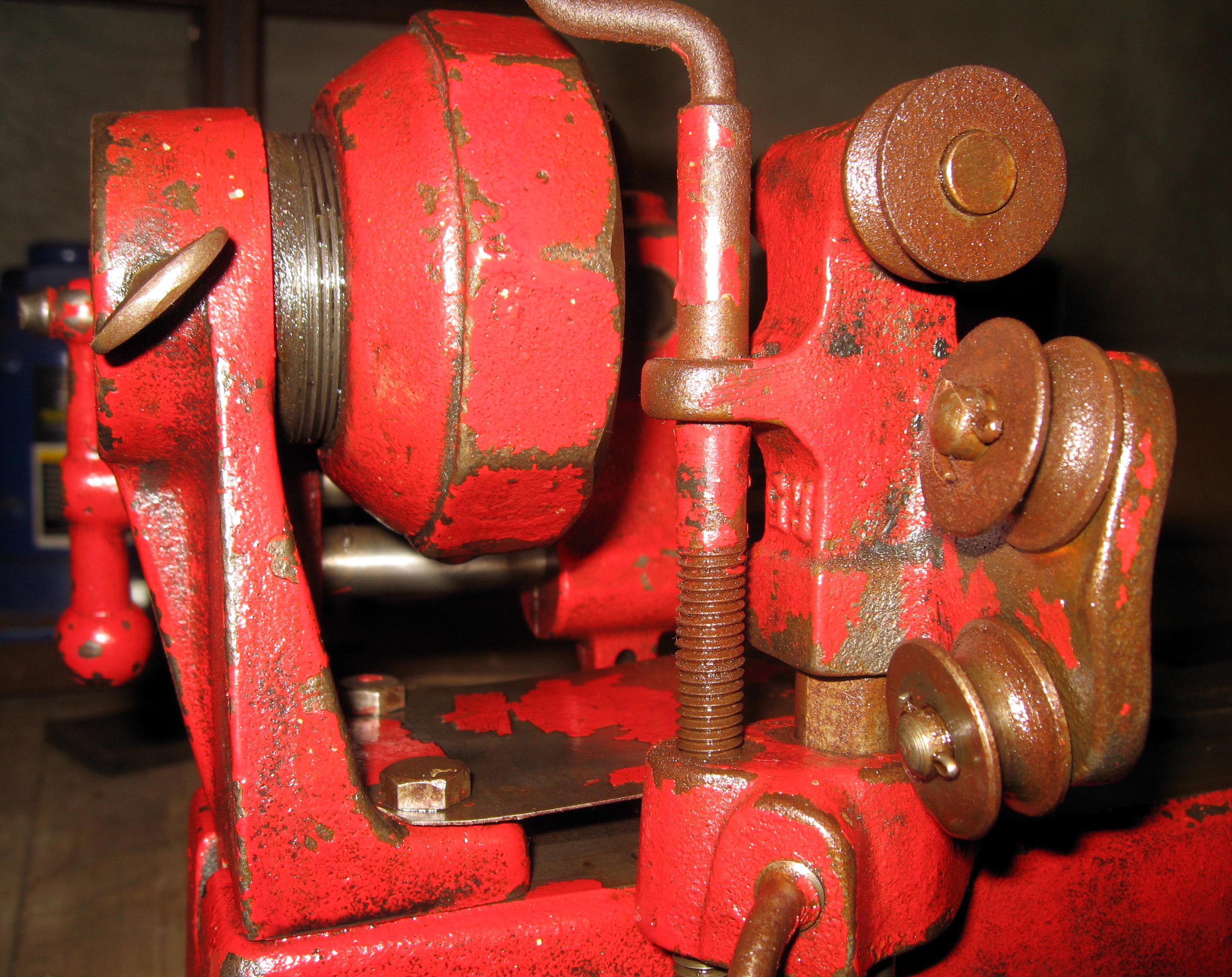

The normal way of holding an armature in the Trucut was to employ a simple 3-jaw chuck at each end, the jaws being opened and closed by a large external ring nut. However, the makers also offered several accessories to hold armatures that were awkwardly shaped, extra long or very short - while also allowing some to be turned with or without their bearings in place. The front tool holder was adjustable longitudinally on two steel bars set one above the other, drive being by a balanced handwheel turning a screw thread set between them. The cutting tool was brought up to the job by turning a threaded ring surrounding its holder, the amount of cut able to be set not only quickly but also to close limits - the assembly being not unlike the sort of micrometer-adjustable carriage stop found on the bed of some lathes.

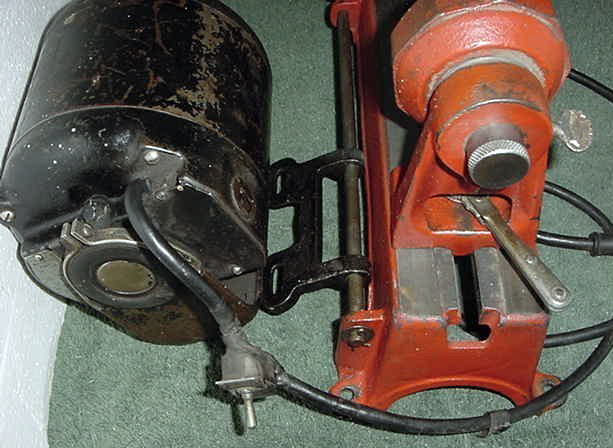

Mounted at the back of the unit, the motor was bolted to a framework - some a simple flat plate, others a stamped-out skeleton type - that was arranged to slide along a round bar so that the flat-belt drive pulley could be brought into the correct position; the drive from the motor turned the job by the simplest possible means: a belt wrapped around the armature's core. So that the whole weight of the motor was not taken by the armature, a simple screw-locked support rod was provided that passed through the back of the motor mounting plate to contact the bench - this arrangement allowing the belt tension to be set "just so".

After an armature is cleaned up, the mica that separates the segments is usually level with the surface - and has to be cut away so that it lies below. This "undercutting" action was performed on the "Trucut" by a tool carried in a height-adjustable casting, the whole assembly being carried on a plate fastened to the bed and able to be slide along it using a lever that protruded through the bed's front face; a simple sheet-steel plate was provided to cover the bed at this point to prevent wear from the shavings of copper. On the B-10, lacking the integral mot of the B15, to get the run direction correct, the round drive belt (driven from the main motor pulley) was inveigled into position by being threaded around pairs of jockey pulleys and the depth of cut altered by a handle-equipped vertical screwed rod. If any reader has a complete and functioning Frank Wood armature lathe, the writer would be interested in hearing from you.

High-resolution pictures - may take time to open