|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

Atlas 6-inch Lathe Mk. 1

Atlas Mk. 1 6-inch Page 2 Atlas Mk. 1 6-inch Page 3

Atlas 6-inch Lathe Accessories Atlas Mk. 2 6-inch

Atlas 6-inch Mk. 2 Atlas Home Page Atlas 6-inch Mk. 1 Photographs

Atlas 9, 10 & 12-inch Lathes Atlas Milling Machine Atlas Shaper

Atlas 6-inch with Screwcutting Gearbox A Restored Model 612

A complete Data Pack is available for the Atlas 6-inch lathe

Styled to closely resemble its larger brother, the "10-inch", the Atlas 'Model 618' 6" x 18" (3.5" centre height) backgeared and screwcutting lathe was in production from 1936 until 1974 and then, in Mk. 2 form, until 1980. Enormously popular in America - it was affordable and with a specification that allowed it to undertake the majority of jobs likely to be encountered in a home workshop - its likely that the lathe made its first appearance not as an Atlas but badged for the mail-order company Sears,Roebuck under their Craftsman identification tab as the 101.07300. This initial Craftsman model, which carried an inadequate 3/4" x 16 t.p.i. spindle thread, a headstock that lacked backearing and a countershaft unit and belt-tensioning arrangements of a very elementary, lightweight design, was sold at the very competitive price of $42. However, it was made for one year only before being replaced by the much better specified 101.07301--as listed in the post 1938 catalogs shown here

Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Atlas 6" x 18" (3" centre height) - 1941 version with the taller, Mk. 2 countershaft with the swing-head hanging down backwards and the V belt passing between the uprights.

Continued:

As few appear on the used market, the number of early versions produced must have been limited and later machines (commonly seen as Craftsman Series 101.73**) are much more frequently encountered. Like all Atlas lathes, the 6-inch was mass produced, with costs kept down by the use of parts in Zamak - a pressure die-cast metal. However, despite its modest price, it was offered with a wide range of useful accessories and enjoyed a number of desirable features: the No. 2 Morse taper, 17/32" bore headstock spindle had a 1" x 8 t.p.i. thread (later 1" x 10 t.p.i.), was fitted with a 60-hole indexing ring on the face of the backgear bullwheel and ran in Timken taper-roller bearings with part numbers: #07079 left bearing, #07100 right bearing and #07196 for the two bearing cups. However, one example of the lathe, Serial Number 1006, has been found with a most unusual fitting, a spindle with a 1.25" x 14 t.p.i. nose; could this have a been a sort-run batch for some specific task, possibly production use and the lathe originally fitted with a capstan unit ?

In another case, an owner discovered that when he removed the spindle bearings from his Atlas 10100, both cups were # 07196 and both cones were Timken # 07100. Might these have been supplied to Atlas because Timkin ran out of the other type, could they have been installed at a bearing change by a previous owner?

Drive on all models was by proper, full-size V-belts, Z-section (about 0.4" or 10 mm across the top) on both motor and headstock drives. The spindle carried a 4-step pulley, driven by 2-step pulleys on motor and countershaft - a combination that gave a remarkably wide range of 16 speeds between approximately 54 and 3225 r.p.m. using a standard 60 Hz 1700 r.p.m. American specification motor. On the few examples to make it to Europe these speeds were somewhat reduced by the 50 Hz, 1425 r.p.m. motors used there. If the motor pulley is missing (it's a pressure die-casting and relatively fragile) the larger diameter was 33/16" and the smaller 111/16". Very occasionally an example of the lathe is found with a 3-step headstock pulley - together with a commensurately wider A-section (1/2") V-belt - and it is thought that these might have been WW2 specials, constructed either for heavier-duty work or made to match a contract specification from the military or Government. After 1958 the headstock and spindle were shortened by approximately one-inch and the spindle nose made more secure by the use of a 10 t.p.i. thread. At a time when most small English lathes were without any form of guard covering either changewheels or belts, the little Atlas was comprehensively protected with covers (found in both aluminium and cast iron) thus keeping stray fingers safe. So neatly designed was the lathe that it must (together with details from the 10-inch) have provided inspiration for the designer of the well-known, very popular and long-lived just post-WW2 Myford ML7.

Although the basic lathe remained almost unchanged during its production run the drive system underwent several alterations. The original set-up consisted of a very simple, short countershaft unit in cast-iron with all-V-belt drive and the spindle running in Oilite bearings. It bolted to the bench behind the lathe, lacked any form of motor-mounting plate and had the top of the unit (the swing-head assembly) arranged to hinge under the influence of a simple lever-operated cam - with two adjuster screws for fine setting of the countershaft-to-headstock belt tension.

Lathes supplied for fitting to the maker's narrow, wooden-topped, cast-iron leg stand were equipped with an entirely different drive unit Because the lathe carried its backgear across the full length of the spindle, the line of the drive belt could only be moved slightly from the horizontal and, to get the drive line correct, the top section of the countershaft that carried the spindle and pulleys - the 'swing-head' - was arranged to hang down backwards with the V-belt passing between the uprights. After two years of production the original bench-type countershaft was abandoned and a version of the more robust stand-type countershaft used instead - though without a motor-mounting plate. The motor (as on the early countershaft) was simply fastened to the bench with the belt-adjustment system loosening and tightening both belts simultaneously.. If an owner wished to mount a lathe prior to number M1975 on the maker's stand, a special intermediate bracket Part No. 86-M10 was offered that incorporated a hinge point for a motor-mounting platform. Surprisingly, this assembly was never shown in any catalogue, but a photograph can be seen below. One other, much rarer drive system was produced, a countershaft that bolted to the back of the headstock-end bed foot--yet lacked any means of mounting the motor. In what was otherwise an especially well-specified lathe, it appears odd that Atlas never thought to market the machine (as they did the 10-inch) in a ready-to-run form where it could be bolted to the owner's bench, plugged in and used without further ado.

If any reader has photographs of different Atlas 6-inch spindle or drive system fittings, the writer would be very interested to hear from you.

Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Atlas 6" lathe specially configured for armature reconditioning. A variety of specifications was available, all based on the use of a special set of Jacobs chucks, one of which contained a bearing to support to tail end of the armature, and the electrically-driven mica under-cutter head.

|

|

|

|

|

|

|

|

Continued:

During the early 1940s, as industry switched over to war production, several variations on the standard lathe were produced including Craftsman-badged versions built to the better Atlas specification that included (instead of plain bearings) two different types of roller-bearing headstock: one was a standard Atlas unit with just a badge change and the other a specially-made headstock that resembled (with its frontal bulge) the shape of the ordinary Craftsman plain-bearing unit. For more details of the Craftsman versions, including departures from the official specification, click here.

Tumble reverse was fitted as standard to the changewheel drive, so allowing the spindle to run freely or to cut right and left-hand threads by just lifting or lowering a lever into spring-plunger indented positions. Because the lathe was capable of very high spindle speeds, the small-diameter tumble-reverse gears ran quickly enough to be unacceptably noisy; to cure this late-model machines (from some unspecified date) used plastic gears to engage with the spindle - this fitting also having the benefit (as no shear-pin incorporated in the drive) of providing some degree of sacrificial protection for the relatively fragile ZAMAK gear train. Changewheels on all versions of the 6-inch were 24DP with a 14.5-degree pressure angle.

A simple but adequate single-sided apron with proper twin clasp nuts and a "geared-down" drive from the handwheel to the Acme-form leadscrew was used and remained unchanged for the life of the machine. Like that used on all other Atlas lathes the cross slide was of the "short" type that tended to wear the ways in their middle section, though it did carry a sheet metal cover at the rear to protect the feed screw. No attempt was ever made to market, as an accessory, a T-slotted cross slide or boring table, both being useful and common fittings at the time on many British small lathes yet virtually never used in America. The top slide could be rotated through 360º and, happily, was T-slotted - so easing the fitment of alternative toolposts to the simple and traditional single holder fitted as standard. Unfortunately both the feed screw micrometer dials and handles were tiny though by way of compensation all the carriage hand controls, even the leadscrew clasp-nut handle, were chrome plated. The leadscrew was threaded 0.5" Acme and a dial-thread indicator included in the standard equipment.

Although the headstock carried a No. 2 Morse-taper centre, the tailstock was only a No. 1 - possibly, together with the tiny feed-screw micrometer dials, the only real specification failings in an otherwise well-designed machine. A shorter-bed version, the "Model 612", with just 12 inches between centres, was also manufactured - but this seems to be a comparatively rare machine, despite the undeniable attraction of being light enough to be lifted by one person from under the stairs onto the temporary workbench in the living room.

Unfortunately no data about Serial Numbers exists - it seems not to have been recorded (or saved) by either Atlas or Sears on the Craftsman versions of the lathe. In addition, while its possible to obtain an approximate date from the numbers engraved on the headstock bearings of the larger lathes, these are not present (so far as is known) on any of those fitted to the 6-inch machines until around 1958. As the highest known Atlas Serial number is 027421, does one assume that figure represents the total for both Atlas and Craftsman branded lathes,, or just Atlas? For a country with the population of the United Stated, 30,000 or so Atlas versions would seem to be a reasonable figure, so it's entirely possible that a similar number of Craftsman versions were also sold.

Although they are very different, confusion has arisen in the past between the Atlas/Craftsman 6-inch, and two other lathes sold be Sears (but made by the AA Company) the "109" and the later "Craftsman 80". The lathes produced by AA were very simple, minimalist machines and, in comparison with the Atlas, very inexpensive: in the mid 1950s an AA Craftsman 80 cost just $48 - compared to over $160 for the very much better Atlas/Craftsman.

In view of the lathe's excellent specification, its compact dimensions and neat, built-on countershaft, it remains surprising that, unlike its 10-inch brother, the lathe was not widely cloned overseas. One exception in post-WW2 years was the Swedish Högbo - a machine that copied the earlier rather than later countershaft design. On some versions of the Högbo the bed was longer and given a V-way at the front and a flat at the rear - and other detailed changes incorporated as well.

In the early 1970s Atlas introduced a Mk. 2 version of the lathe; this was styled in a very "square" fashion and, with the traditional separate speed-reducing countershaft removed, had a very compact drive system with its eight speeds taken directly from the motor by a tensioned V-belt to a multi-step pulley mounted outboard of the left-hand end of the headstock spindle. A wide range of accessories was listed for the Atlas 6-inch, these being reproduced in their entirety here.

Many owners of small lathes tend to be inventive types and it's not unusual to find examples of lathes owned by them heavily modified and equipped with a number of useful improvements and upgrades.. Two Atlas 6-inch lathes have been found with what might be considered the ultimate accessory, a screwcutting gearbox..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roller-bearing headstock with flip-top oilers - adequate for this model, but not for the plain bearing of the "Craftsman" specification model which would have been safer with proper, continuous-drip oilers - or restricted to owners with a good memory and a conscientious character…..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early bench-type countershaft unit used from the lathe's introduction until some point in 1940 when a modified version of the more robust stand-type was used instead.

|

|

|

|

|

|

|

|

|

|

|

The carriage assembly - with its 360 degree rotating top slide - remained unchanged during the machine's production life. Even though a T-slotted cross slide would have greatly expanded the lathe's versatility, and been a popular addition, Atlas never bothered to offer one.

|

|

|

|

|

|

|

|

|

|

|

|

|

Simple but adequate single-sided apron with proper twin clasp nuts (in Zamak)

and a "geared-down" drive from the handwheel to the leadscrew.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

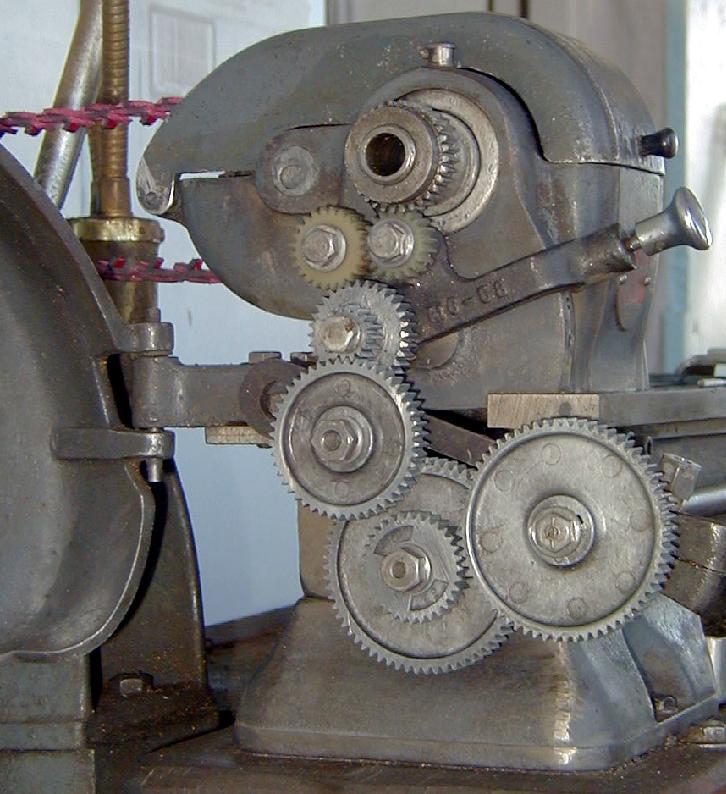

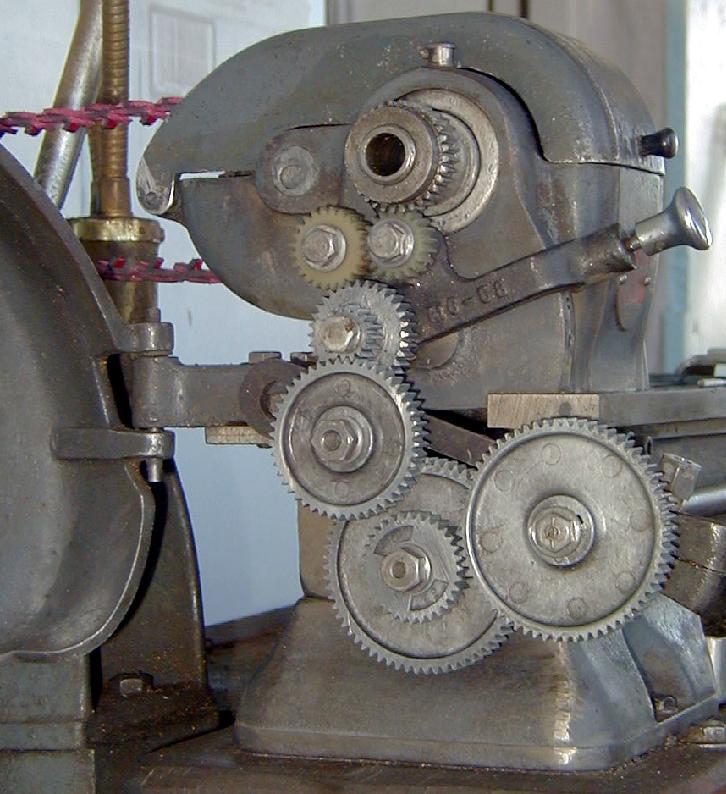

Carriage drive gears, carried on a Zamak housing, that gave

a reduction between apron handwheel and bed-mounted rack.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Changewheels with quieter-running Nylon gears on the tumble-reverse drive. Both the

changewheel guard and the headstock belt cover have been found in aluminum and cast iron.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seldom found - but oh-so-useful - the Atlas line-shaft clutch that could be used to drive not only a lathe and drill-press but other machine tools mounted on one bench

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|