|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools for Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues Belts Books Accessories

Favorite No. 3 Precision Lathe

Favorite No. 3 lathe continued on page 2

Favorite Home Page Lathe No. 2 - Page 2 Favorite Geneva Type No. 1

Copies of Favorite Sales & Technical Specification Literature are available

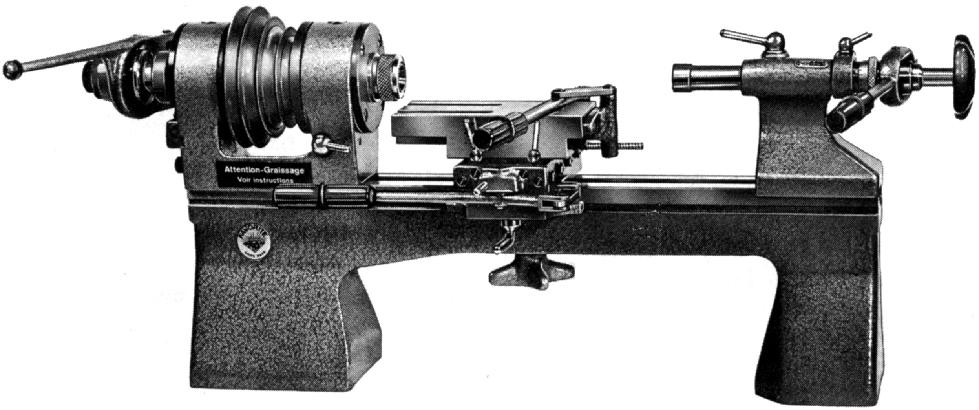

As a larger-capacity, high-precision lathe the No. 3 was, like the English IME Model 300, able to tackle a much wider variety of jobs than even the traditional, heavier WW type watchmakers' lathe. In addition, unlike many other small, high-quality lathes (including the Favorite No. 2) whose headstocks only had room for the usual type of compact, plain bearings, the No. 3's hardened and ground spindle ran in a double-row ball bearing on one end and a roller bearing at the other. Sufficient grease was packed into the bearings for over 1000 hours of running and, when driven by the right countershaft and motor system, speeds of up to 12,000 r.p.m. were possible. The left-hand face of the headstock pulley was provided with two concentric circles of indexing holes numbering 48 and 60 respectively whilst the right-hand face had 12 holes for use by a stop bolt (engaged by a lever below the front bearing) to aid changes of chucks and other spindle fittings. Like the No. 2 the bed was flat on top, with 90-degree sides, and headstock, tool rests and tailstock clamped in place by a central fitting. However, unlike the No. 2 the No. 3 was nearly always supplied with two bed feet and so without the option of a quick-release fitting at the headstock end. However, although not listed in the sales catalogues, a single-foot, short-bed model of the cantilever type was also made - and equipped with the quick-release fitting. Tailstocks, like those offered for the Model 2, avoided a screw-feed arrangement, the makers providing either a traditional "push" barrel or one operated by a lever, the latter judged to have superior feel for delicate drilling work.

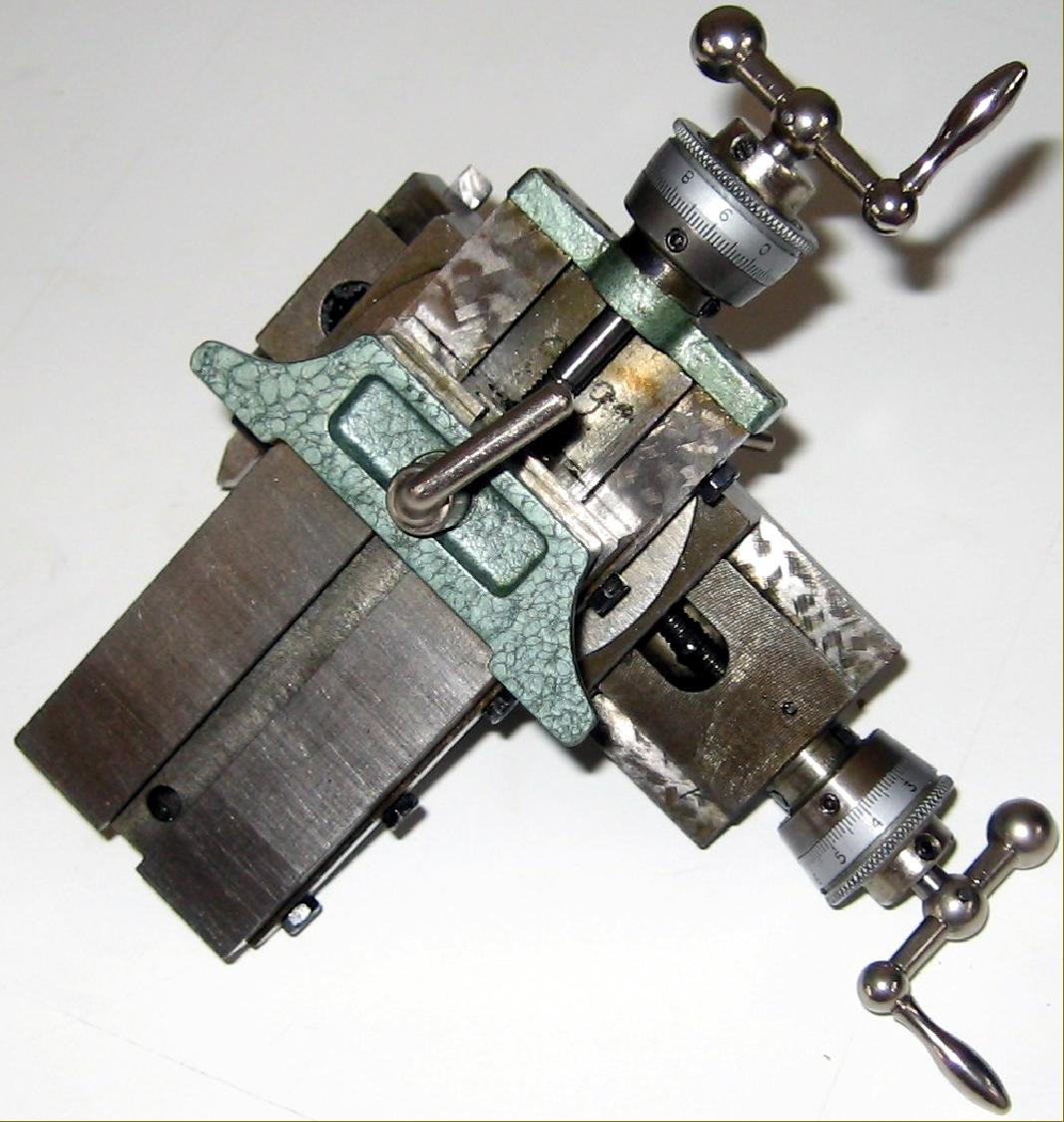

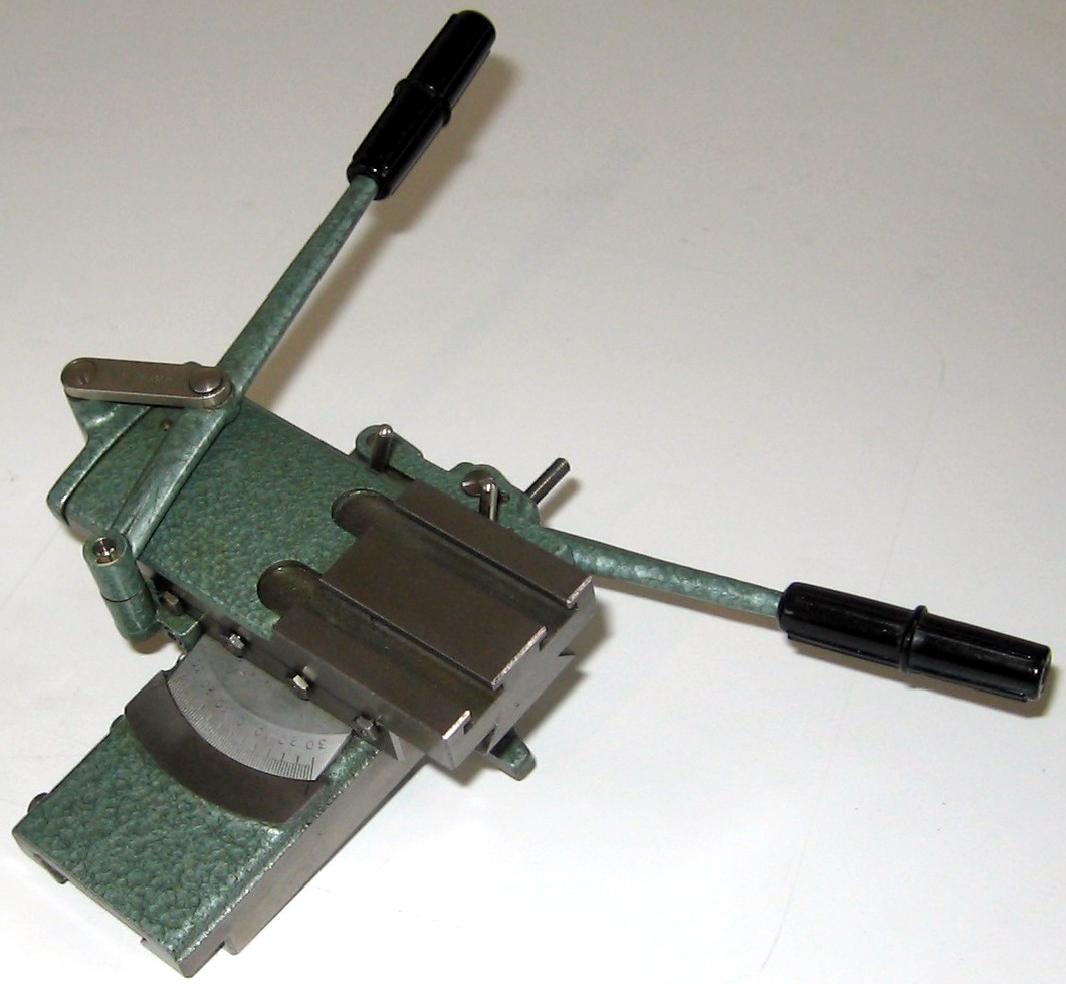

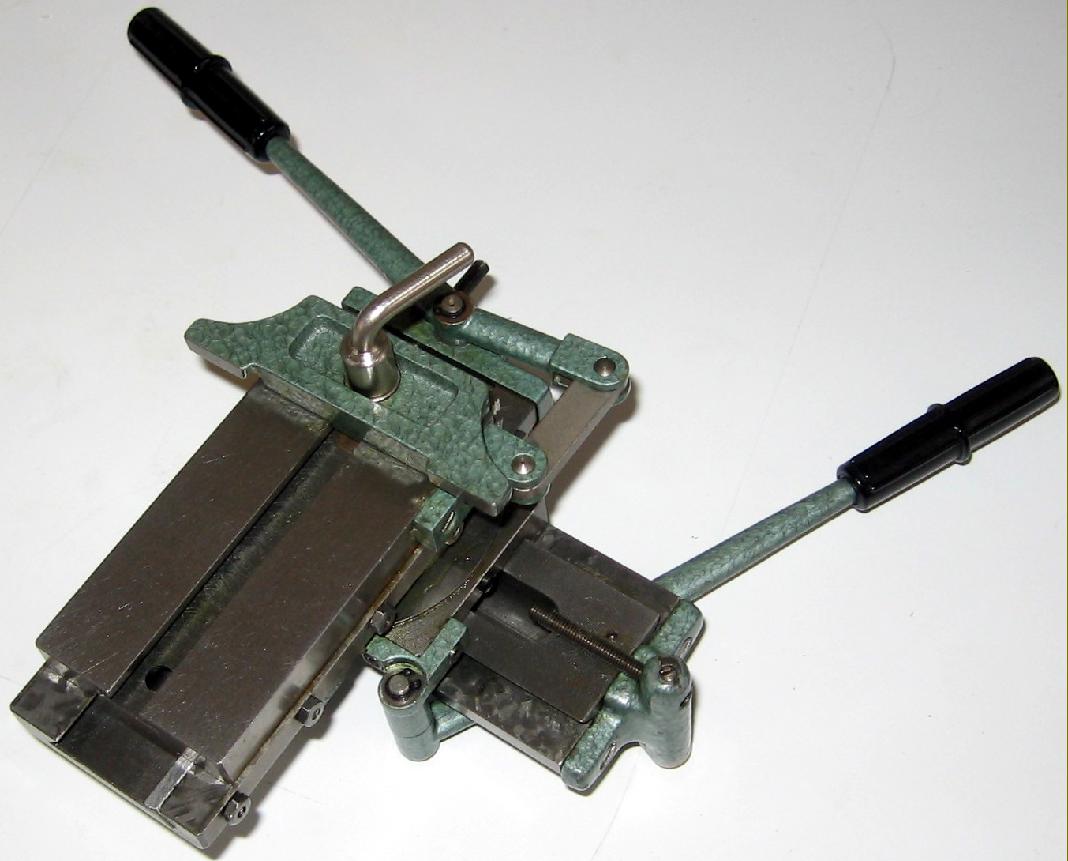

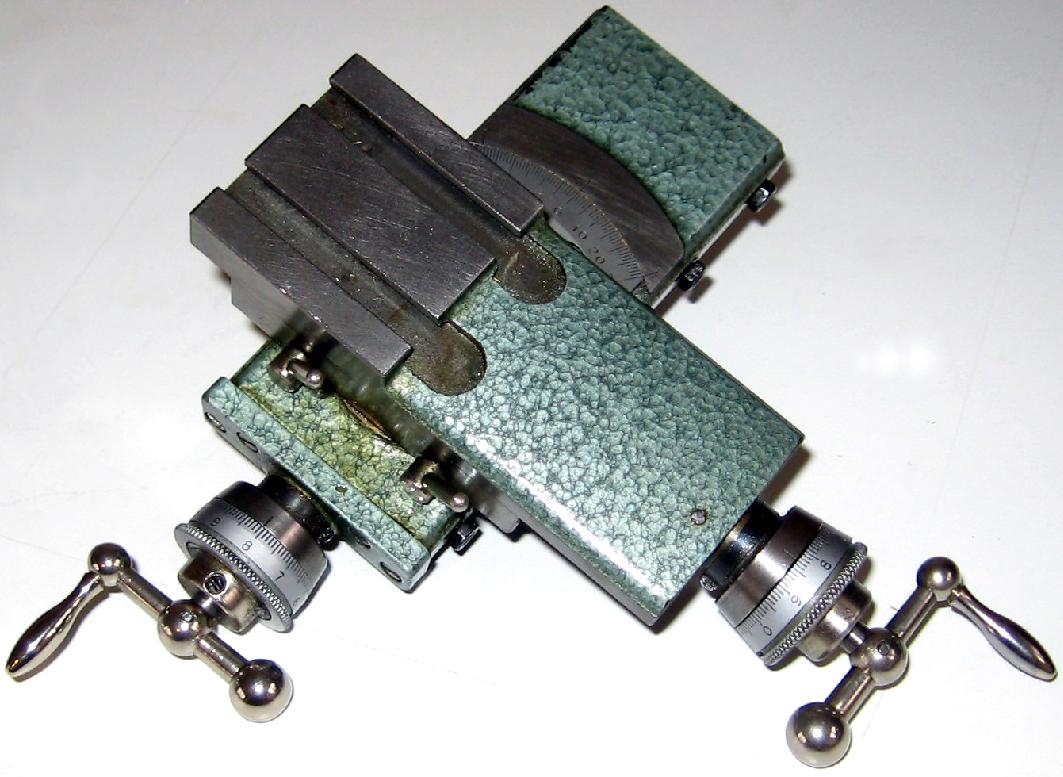

Besides the accessories illustrated on this page other smaller ones, as used on the Favorite 2, could also be employed as could an item that - like the short-bed lathe - might not have been listed: a compound slide-rest assembly with a screw-feed cross slide but lever action to the top. The aim of this assembly was to aid gear cutting where the micrometer dial on the feed screw used to advance the slide - and the attached vertical slide holding the gear-cutting job - and the lever used for repeatedly to cut the teeth..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

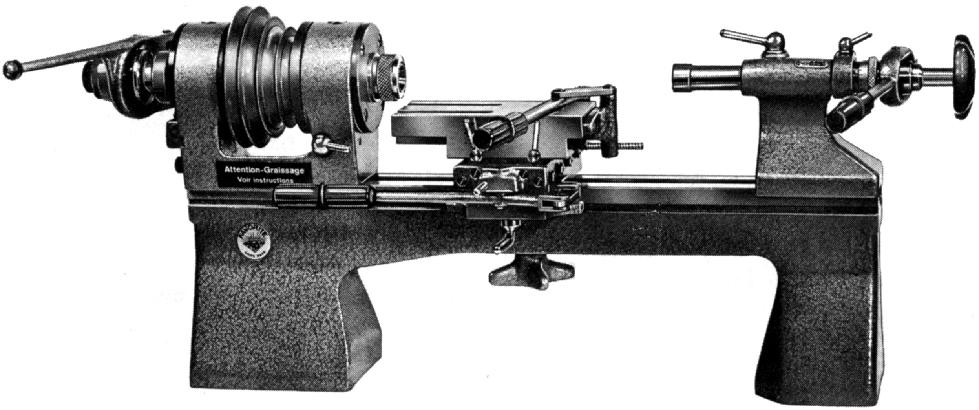

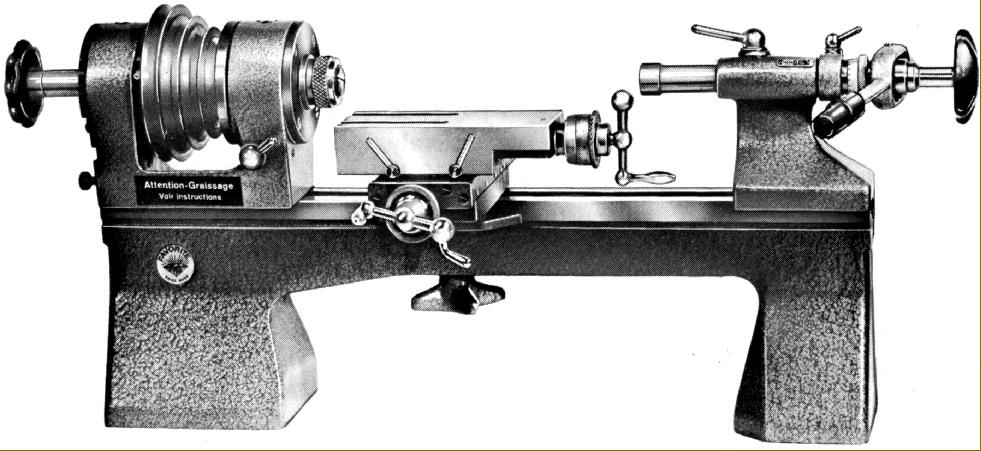

Swiss made Favorite 3 lathe shown fitted with the lever-feeds on all the main controls

|

|

|

|

|

|

|

|

|

|

|

|

|

|

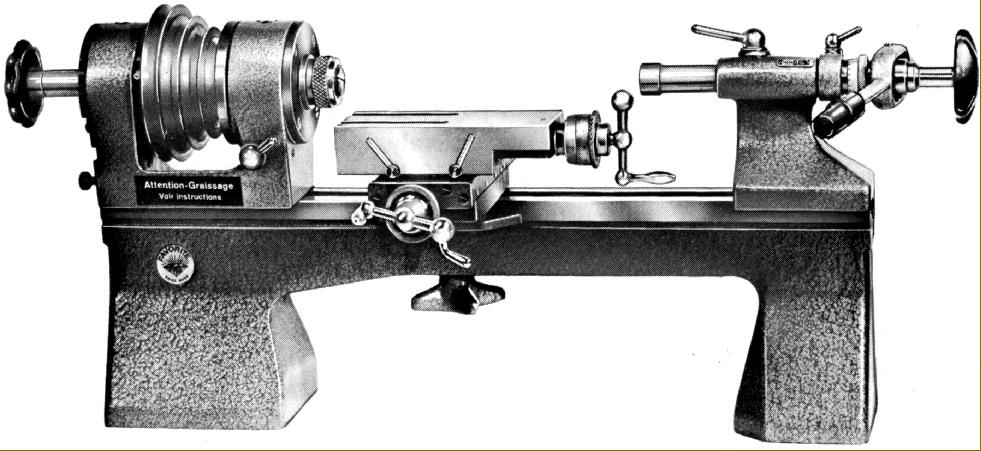

Favorite 3 with screw-feed compound slide rest and draw-tube collet closer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Favorite 3 plain and simple--with just the tip-up tool rest

|

|

|

|

|

|

|

|

|

|

|

|

|

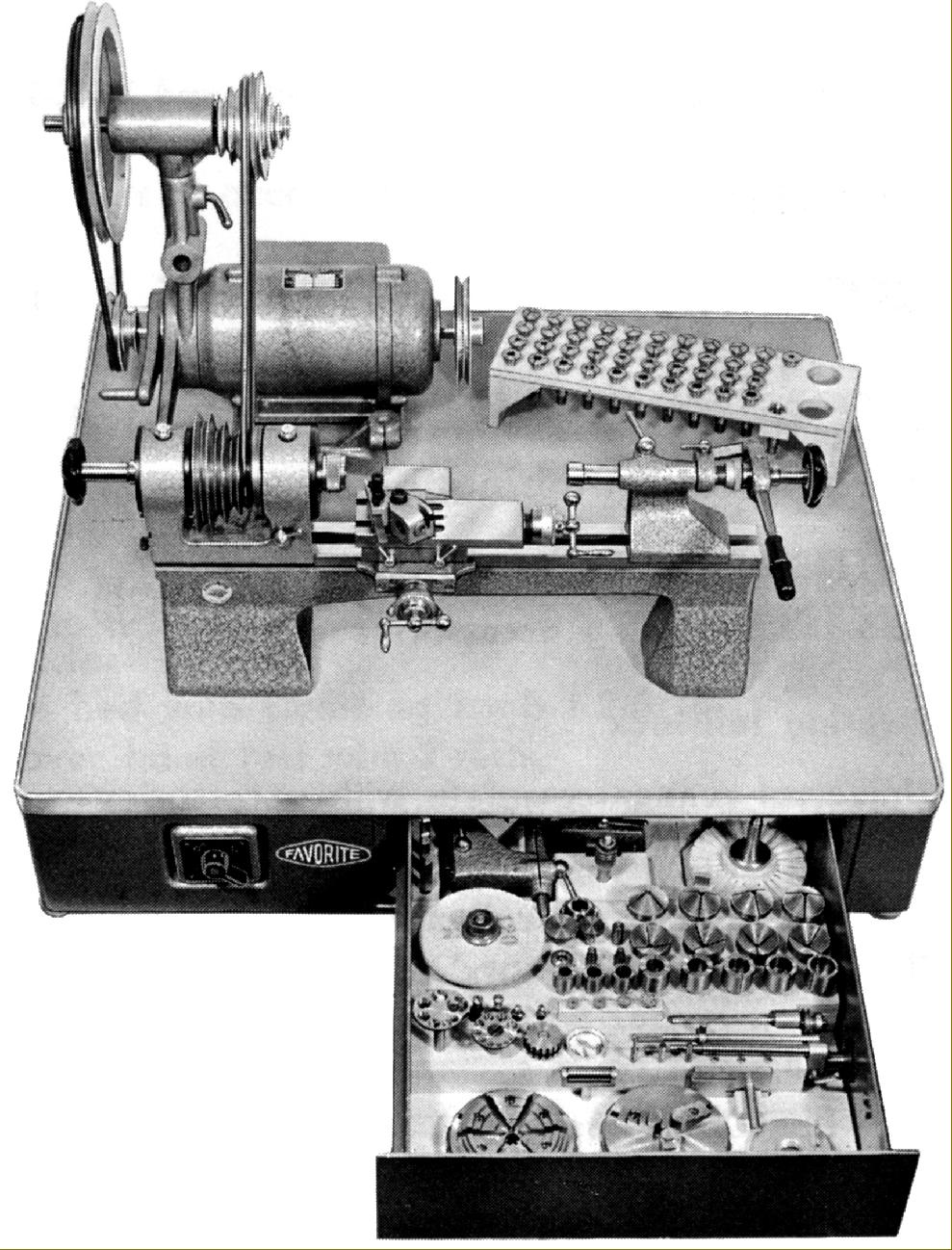

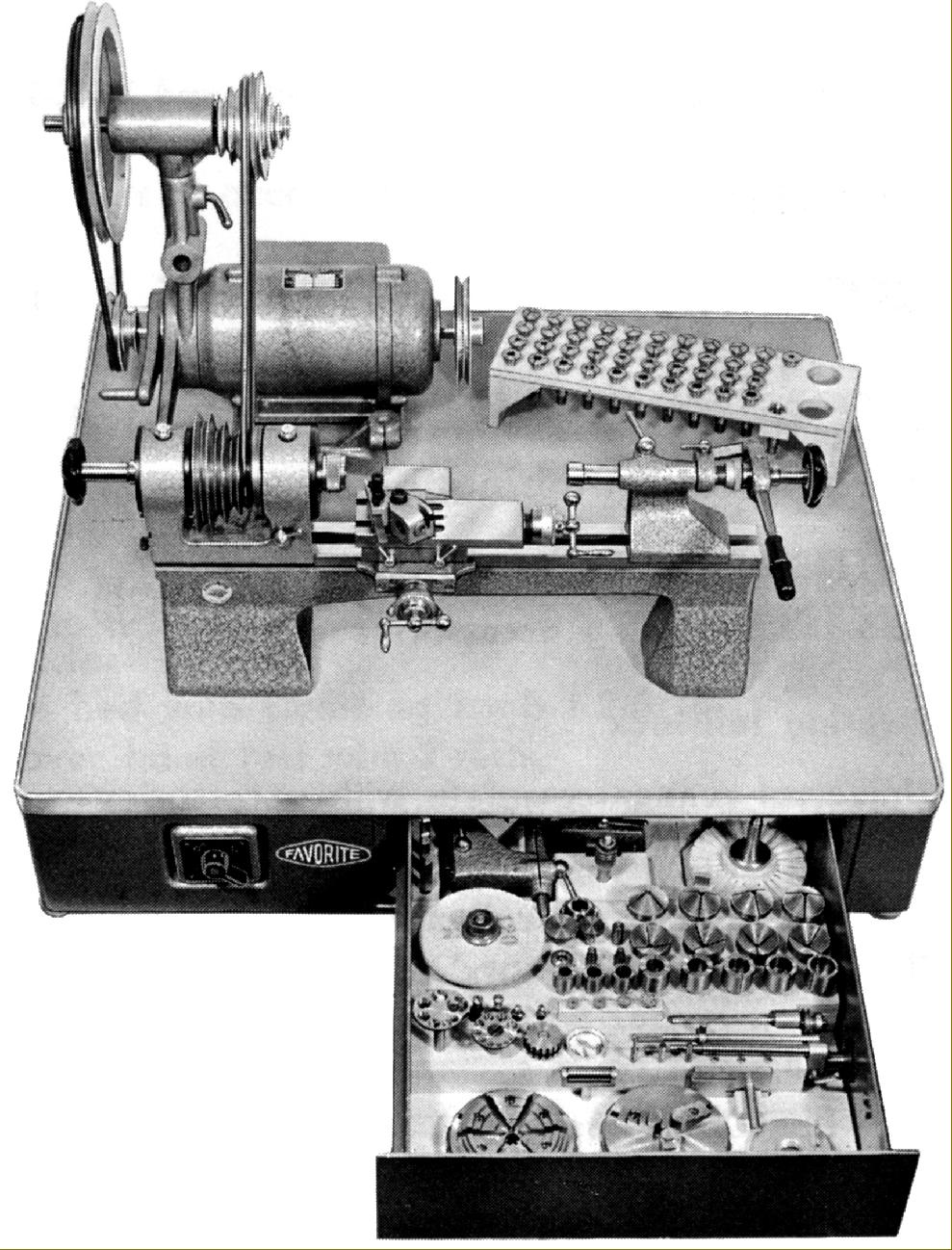

Favorite 3 lathe on maker's base with optional extras Set 18633A-B

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

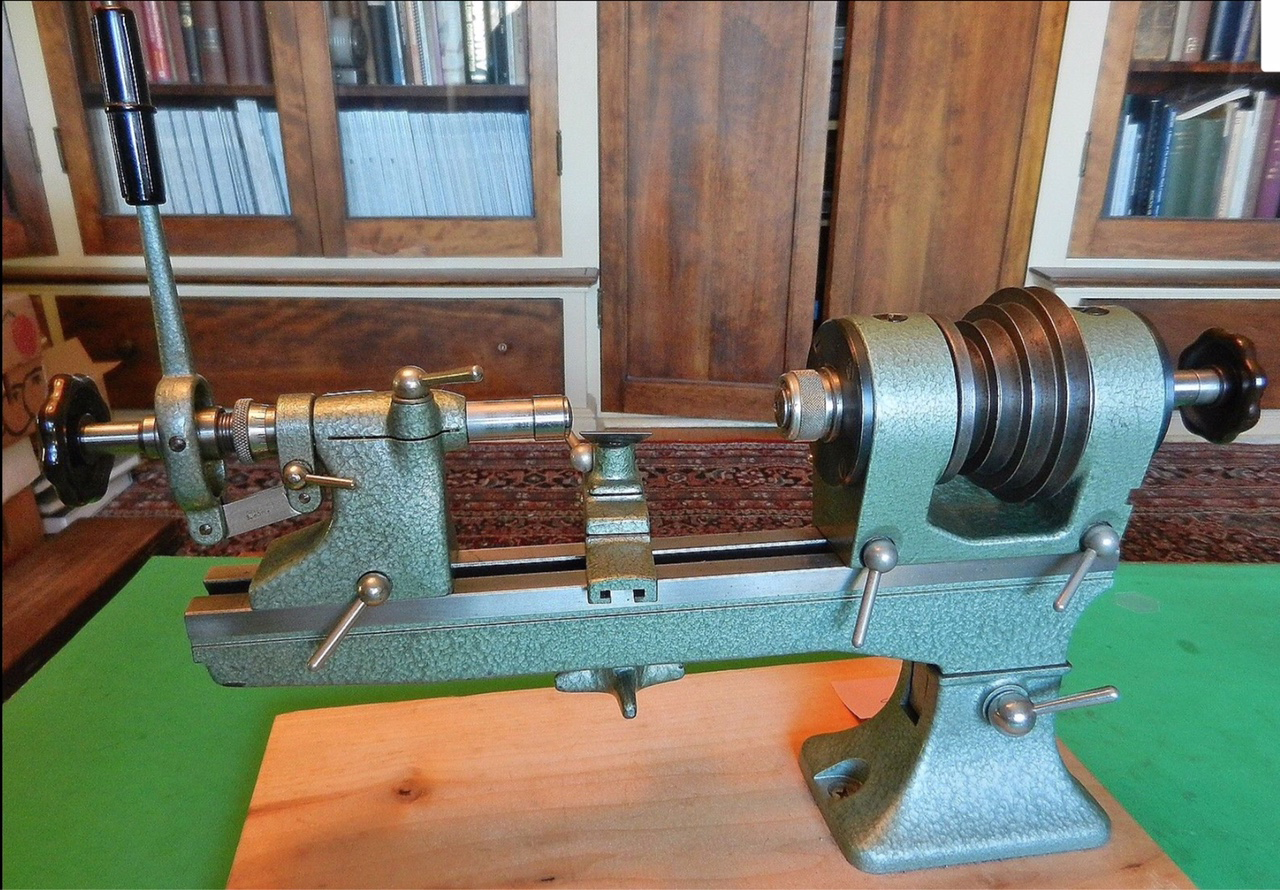

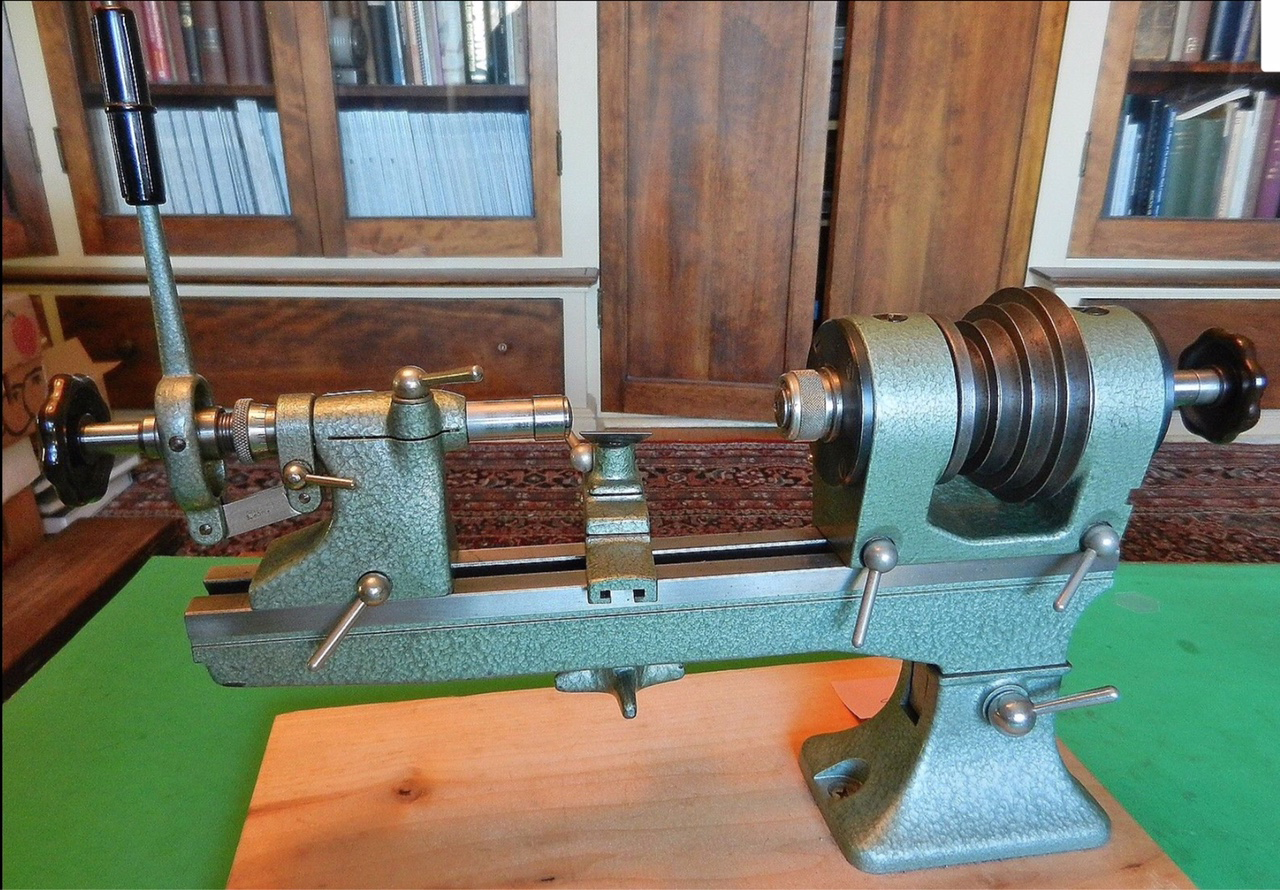

Although not listed in any known sales catalogues, a single-foot, short-bed model of the Favorite 3 was also made

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Favorite 3 Accessories for cutting gear wheels and pinions comprising the vertical milling attachment Part 20, quill with drawbar Part 21, dividing plate equipped with proper alidades (sighting arms) and mobile pointer Part 22 - and an overhead-drive belt tensioning device Part 23 (not shown)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

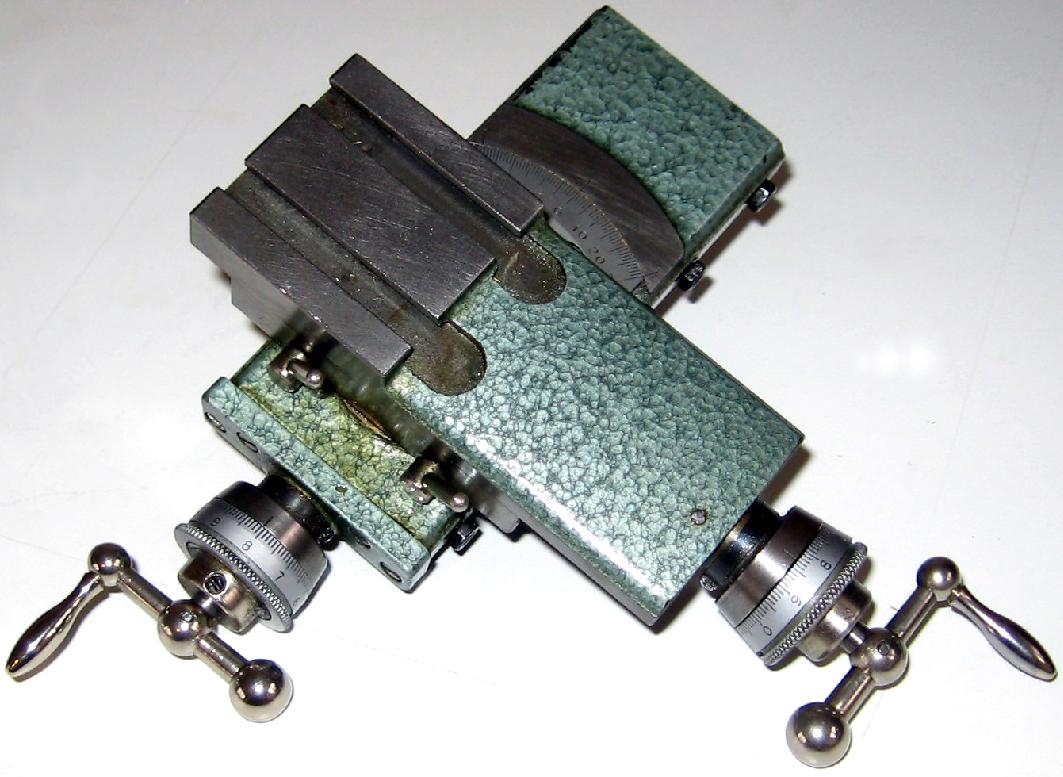

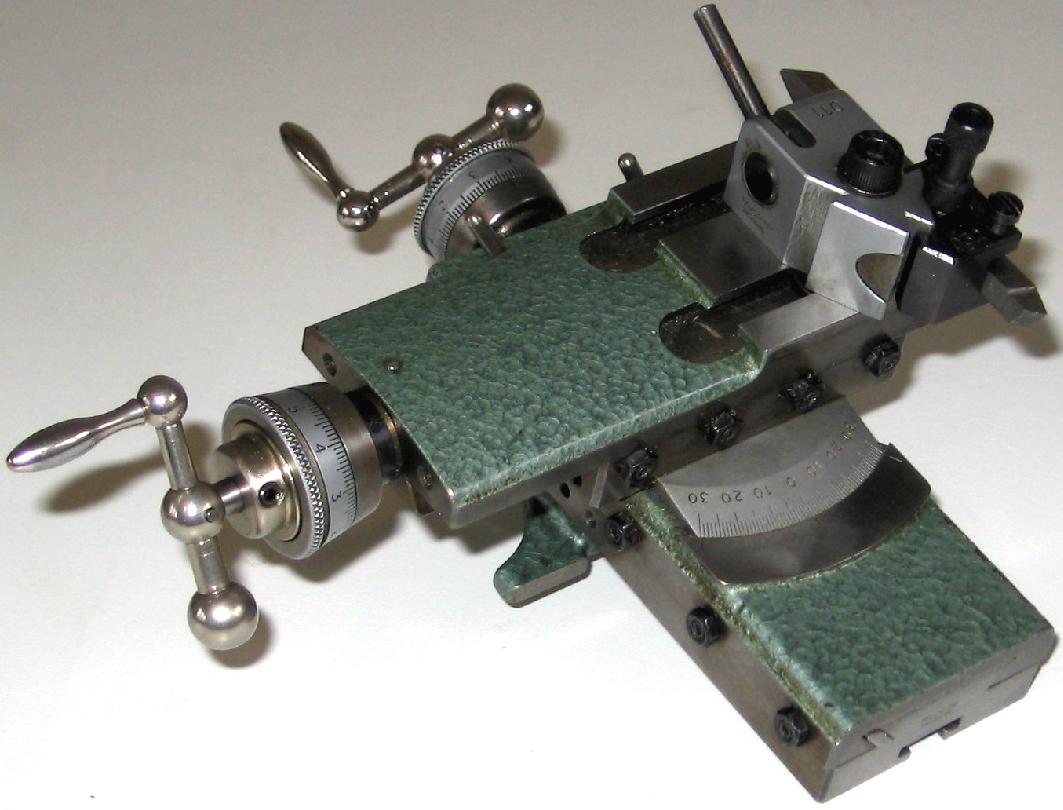

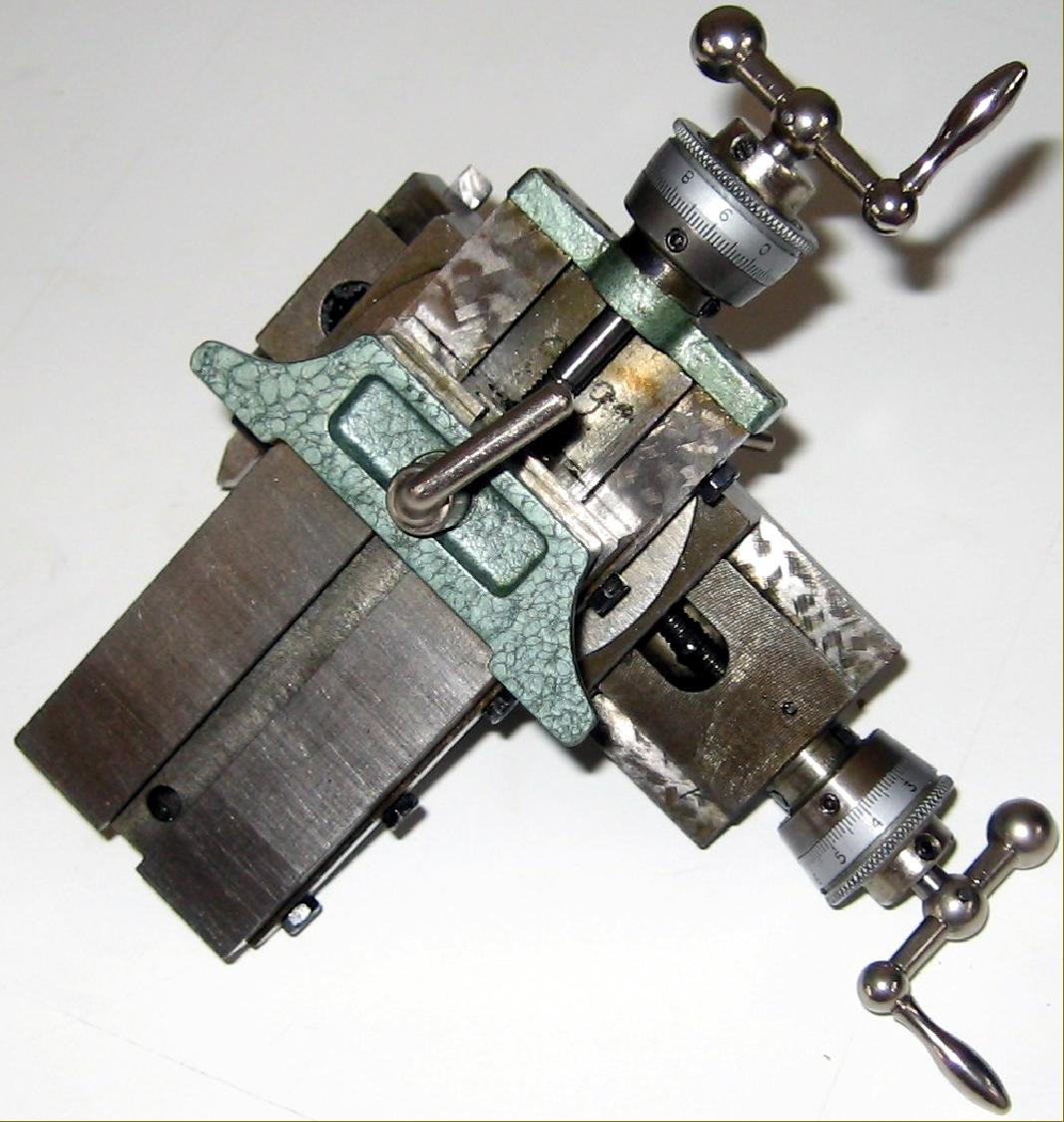

Favorite 3 screw-feed compound slide rest Part F6

|

|

|

|

|

|

|

|

|

|

|

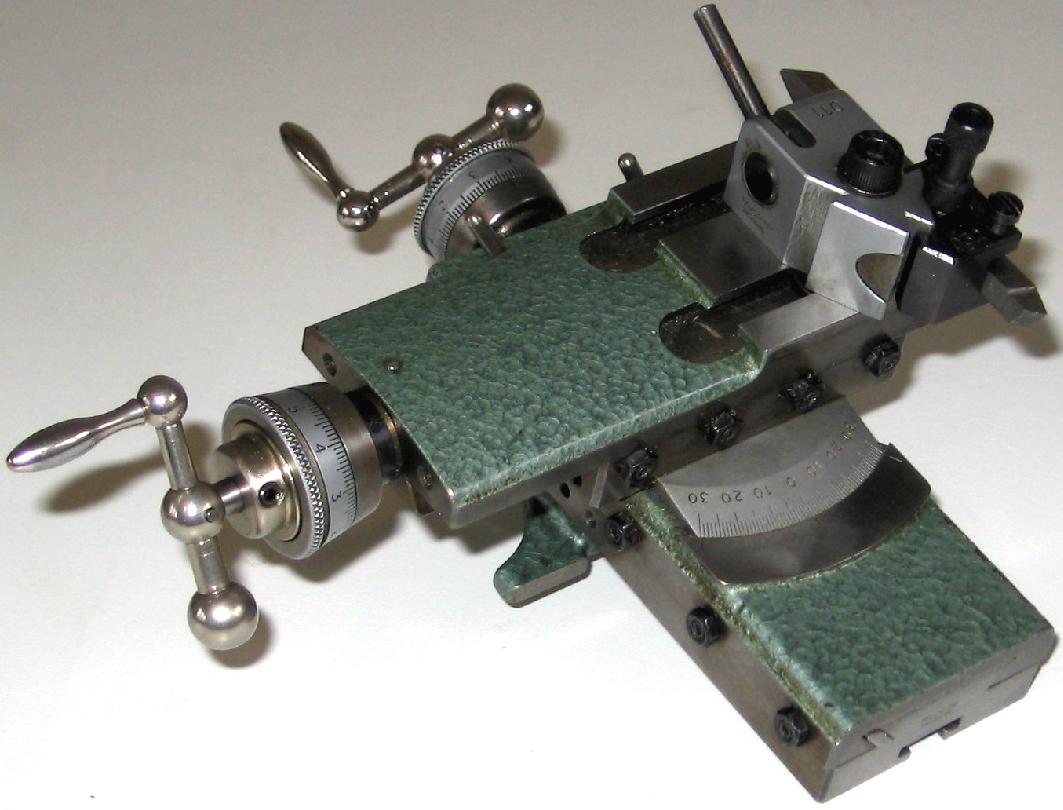

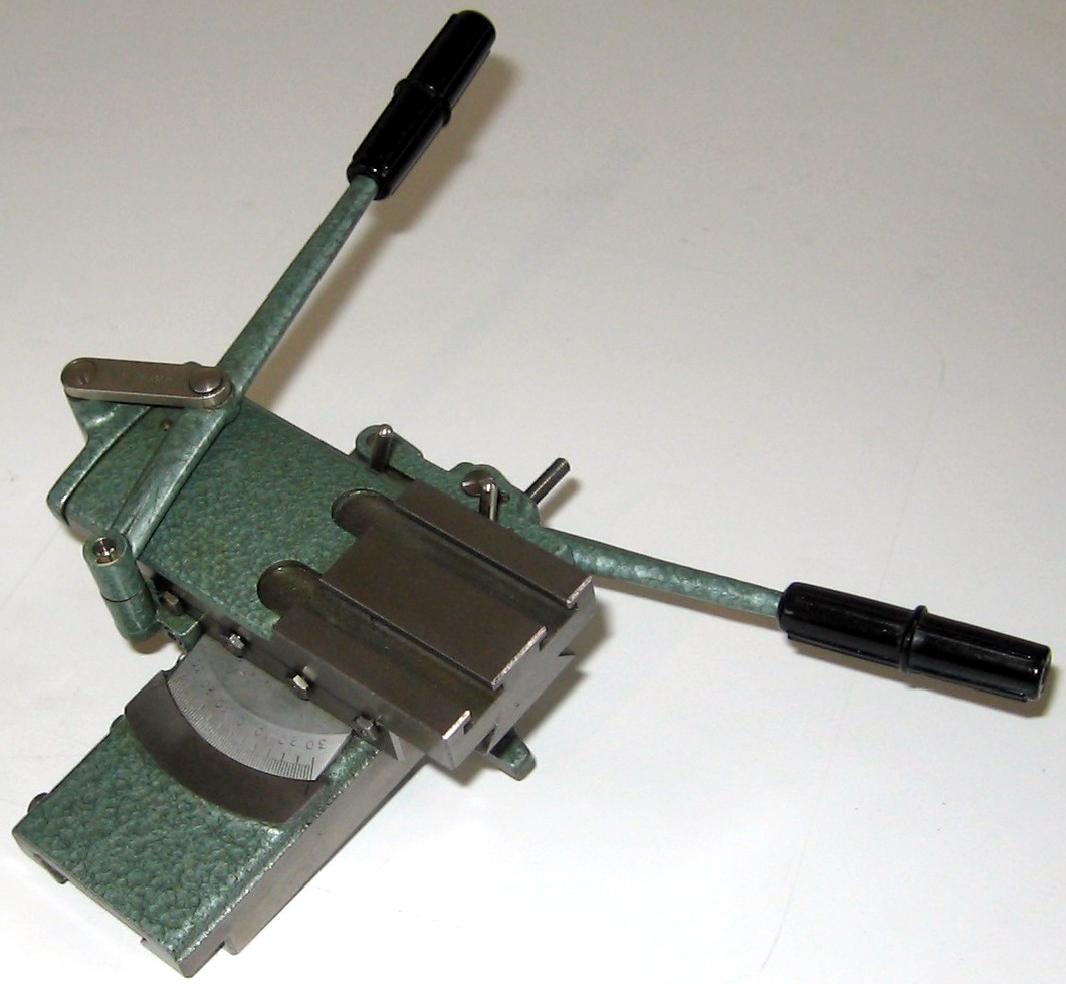

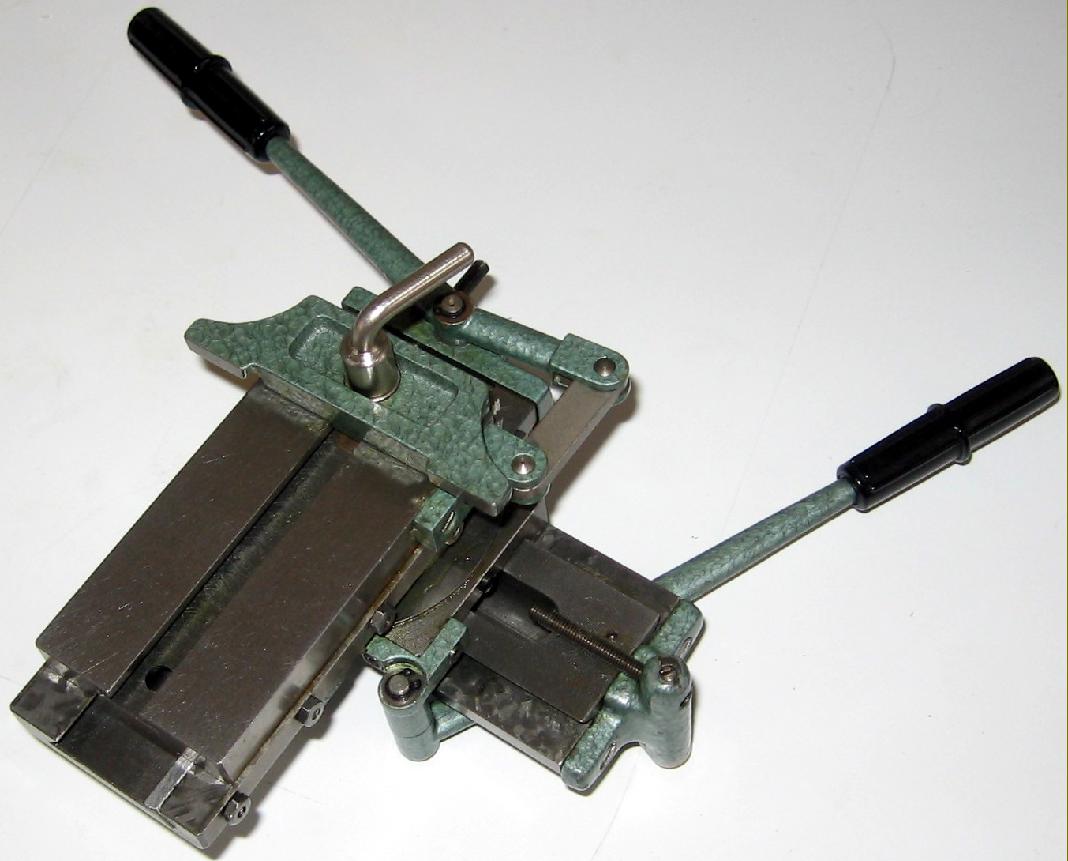

Favorite 3 lever-feed compound slide rest Part 6R

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

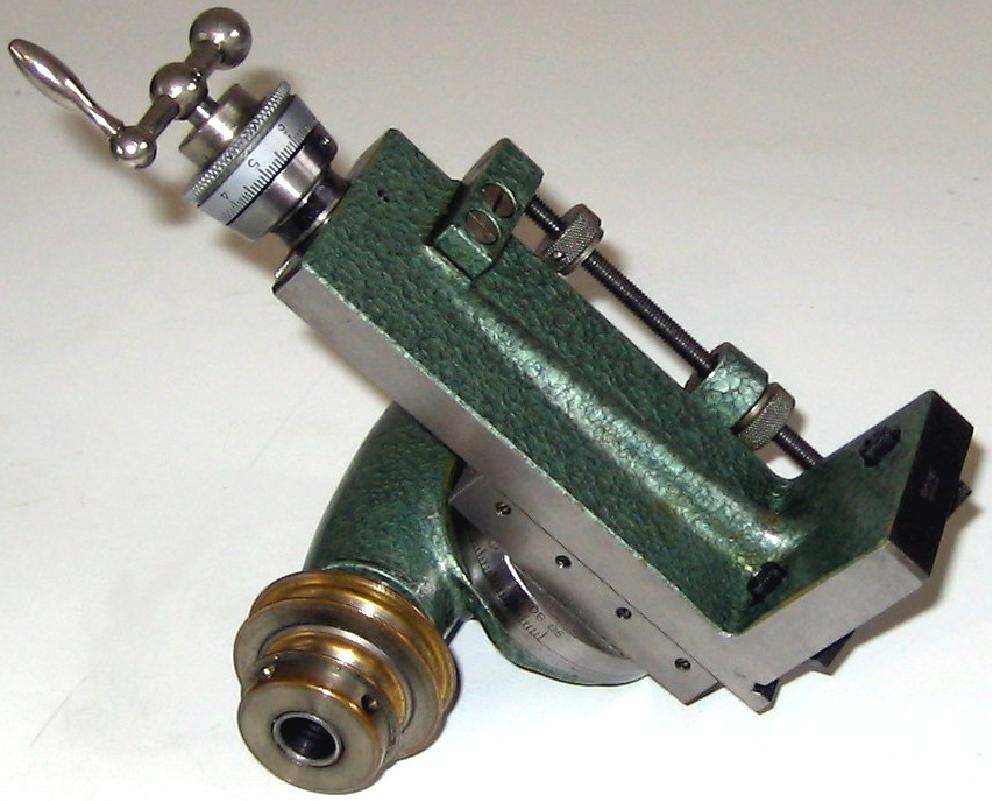

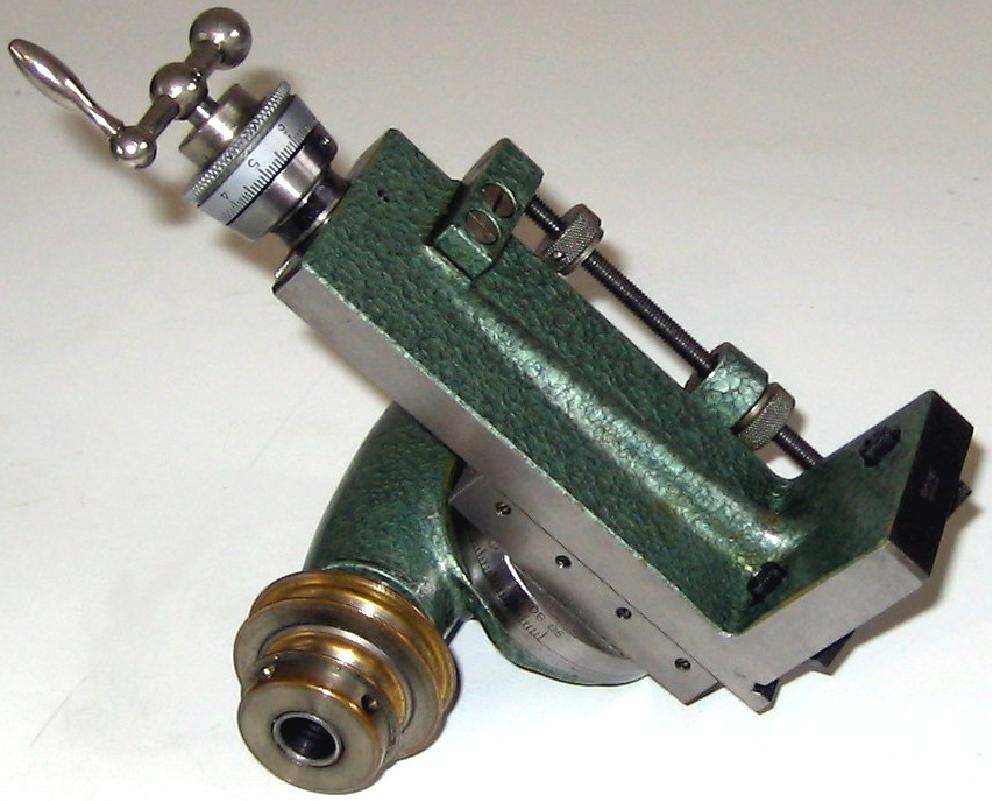

Favorite 3 Vertical milling and grinding attachment Part 20 with dead-length stop - shown without the quill and draw bar in place.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quill with 2-step pulley and Draw Bar Part 21 to take 8mm collets. Designed to be used with both milling cutters and grinding wheels.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Grinding Attachment Part 19 - to accept the quill and draw bar unit - and mounted on the screw or lever-feed compound slide units

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6-jaw chuck or ring chuck

2.75" diameter Part 10648

|

|

|

|

|

|

|

|

|

|

|

|

6-jaw chuck Part 10649

2.75" diameter for external gripping only

|

|

|

|

|

|

|

|

|

|

|

|

Slim 3-jaw chuck Part 10645

2.75" diameter

|

|

|

|

|

|

|

|

|

|

6-jaw bezel chuck part 10647

2.75" diameter for internal and external gripping

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

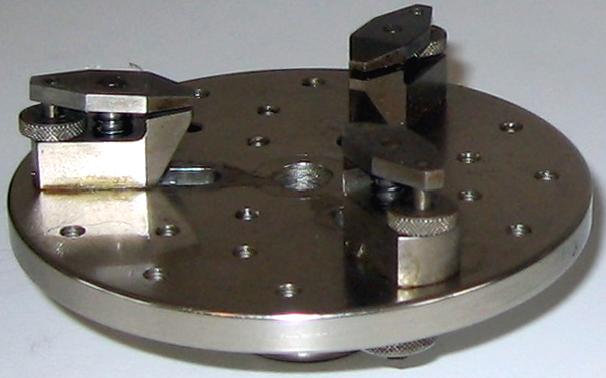

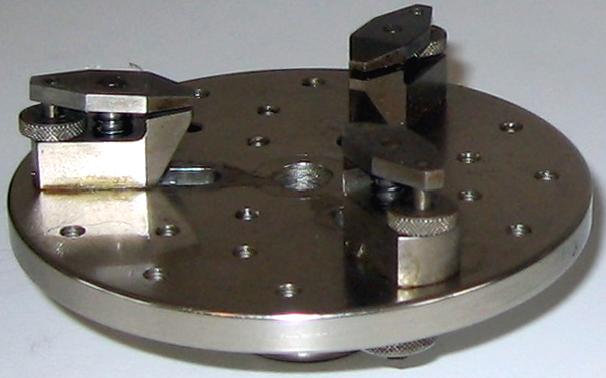

Horological style faceplate Part 26 with removable clamps and tapped holes in the face

|

|

|

|

|

|

|

|

|

|

|

|

Universal Runner Part 36 - designed to assist in the re-pivoting of the finest wrist-watch to the largest wall-clock pivots. The set included the accessories shown below.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centring Plate Part 37R for small clocks. 10 taper holes 1.10 mm to 6 mm

|

|

|

|

|

Centring Plate part 37P for larger wall and alarm clocks. 7 taper holes

|

|

|

|

|

Part F38 Jacot drum pivot polishing (burnishing) device with 18 grooves from 0.35 mm to 1.4 mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Favorite 3 pivoting accessory Part 8A used in conjunction with a standard tailstock

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Combined Runner Part 39 with pulley. The pulley could be removed and set up either as an eccentric (as shown) or, if inserted directly into the spindle, concentric.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Set of Small Centres F41 for use with the Combined Runner Part 39

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spindle with Extractor Part 5B with tapered hole to mount various centres.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pivoting and Tailstock centres Part 42. The three on the left fit into the Spindle with Extractor unit No. F5B. The others were used with a centre holding collet.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|