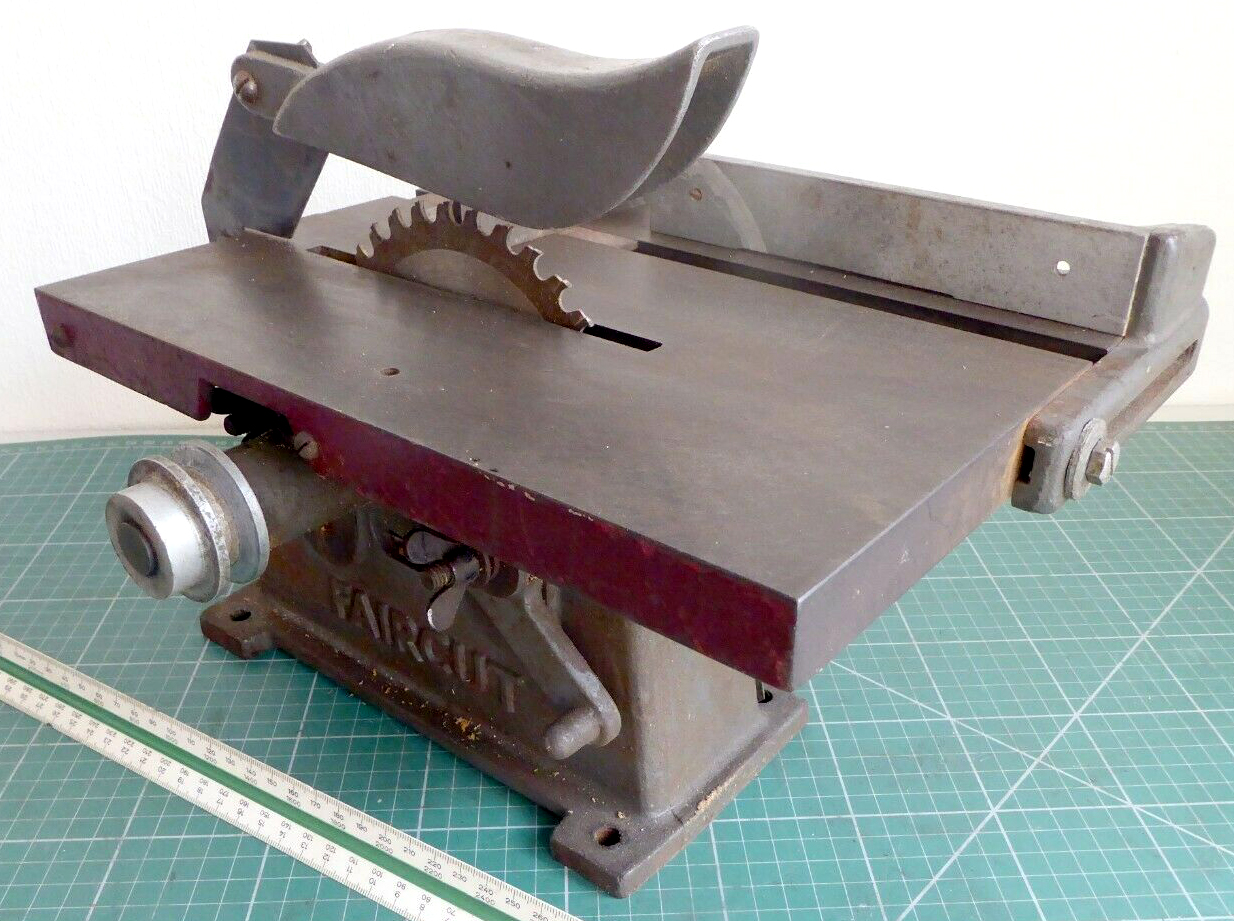

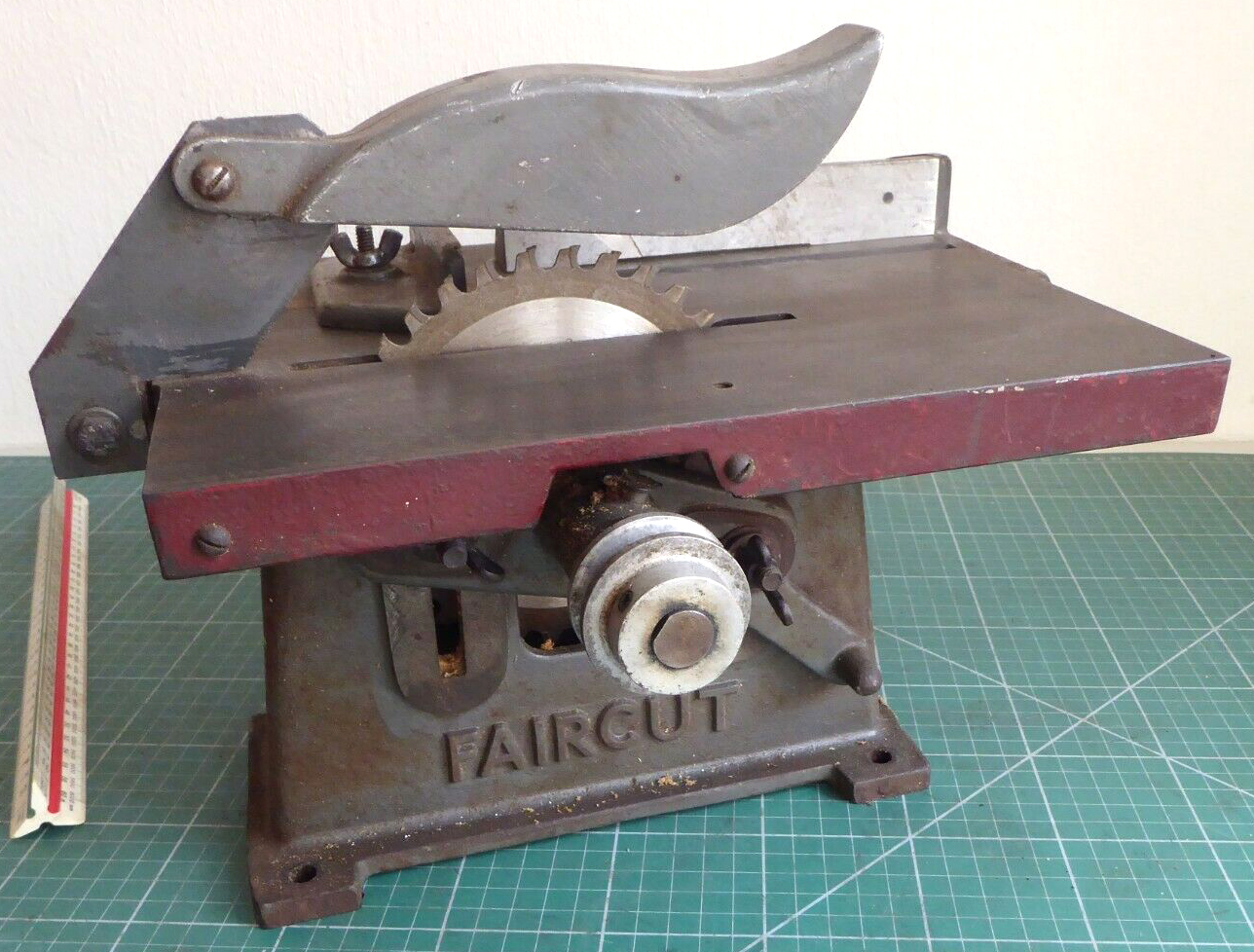

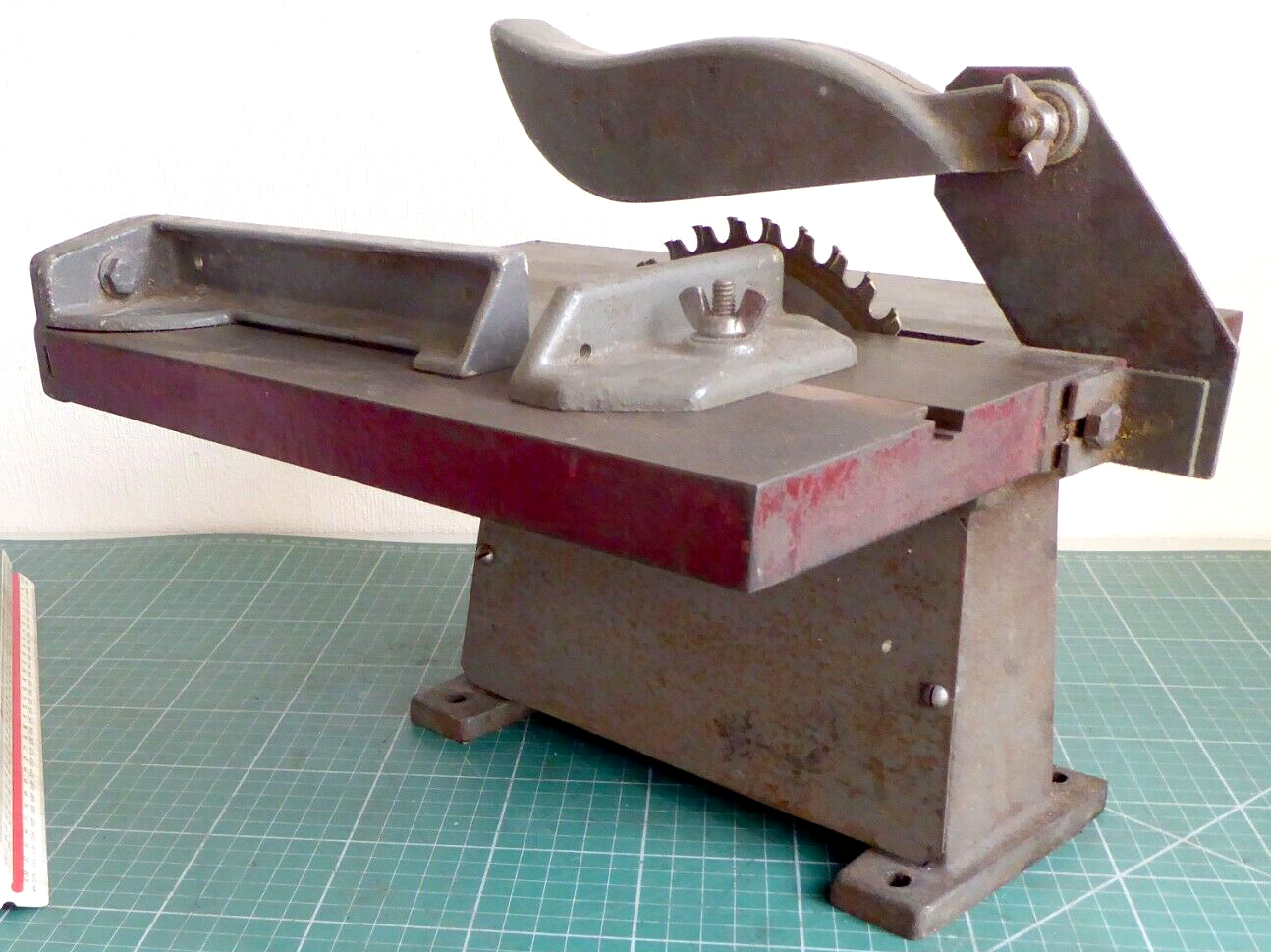

Faircut Home Page Faircut Page 2 Faircut Page 3 Faircut Saw Bench

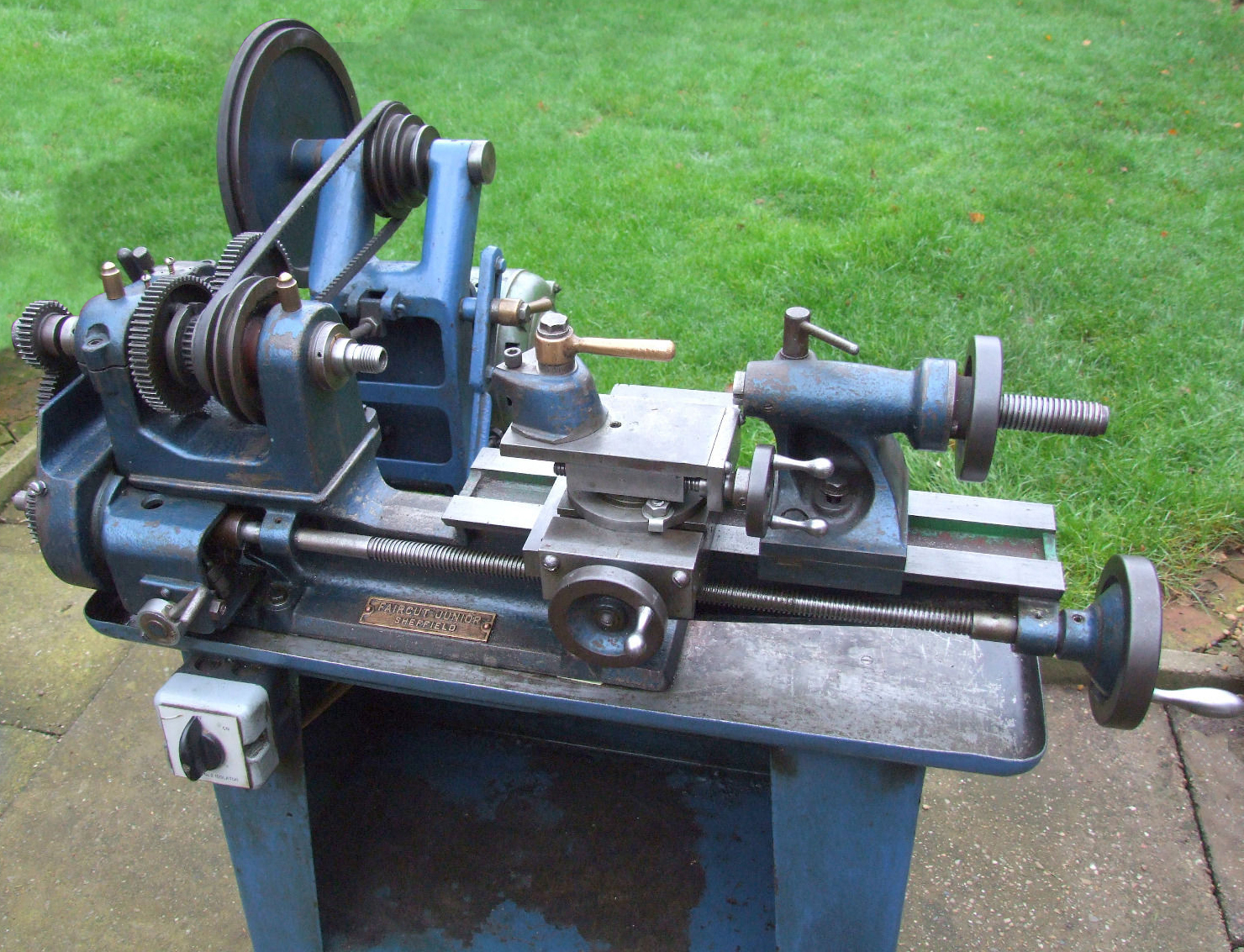

More common in its plain-turning form, the 3.5" x 13" gap-bed, backgeared and screwcutting Faircut Junior had an actual centre height of 319/32" (some sales literature quoted 39/16") a capacity in the gap of 91/2" and accepting 121/2" between its No. 1 Morse taper centres. Although of simple design the lathe was very well made, heavy (110 lbs) and finished to a standard that was not only vastly superior to that of the other Sheffield maker of small model-engineering lathes, Portass, but one that would bear comparison with machines costing several times as much (most Portass lathes had an appallingly poor finish and scrappy detailing). For example, on screwcutting versions of the Faircut the 14 D.P. changewheels (as on small Drummond lathes) were mounted on a proper 2-slot arm shielded by in a sheet-metal cover; the backgear guard and toolpost clamp lever were gun-metal castings, the finish of turned parts on every model was exceptional and castings properly fettled and smoothed.

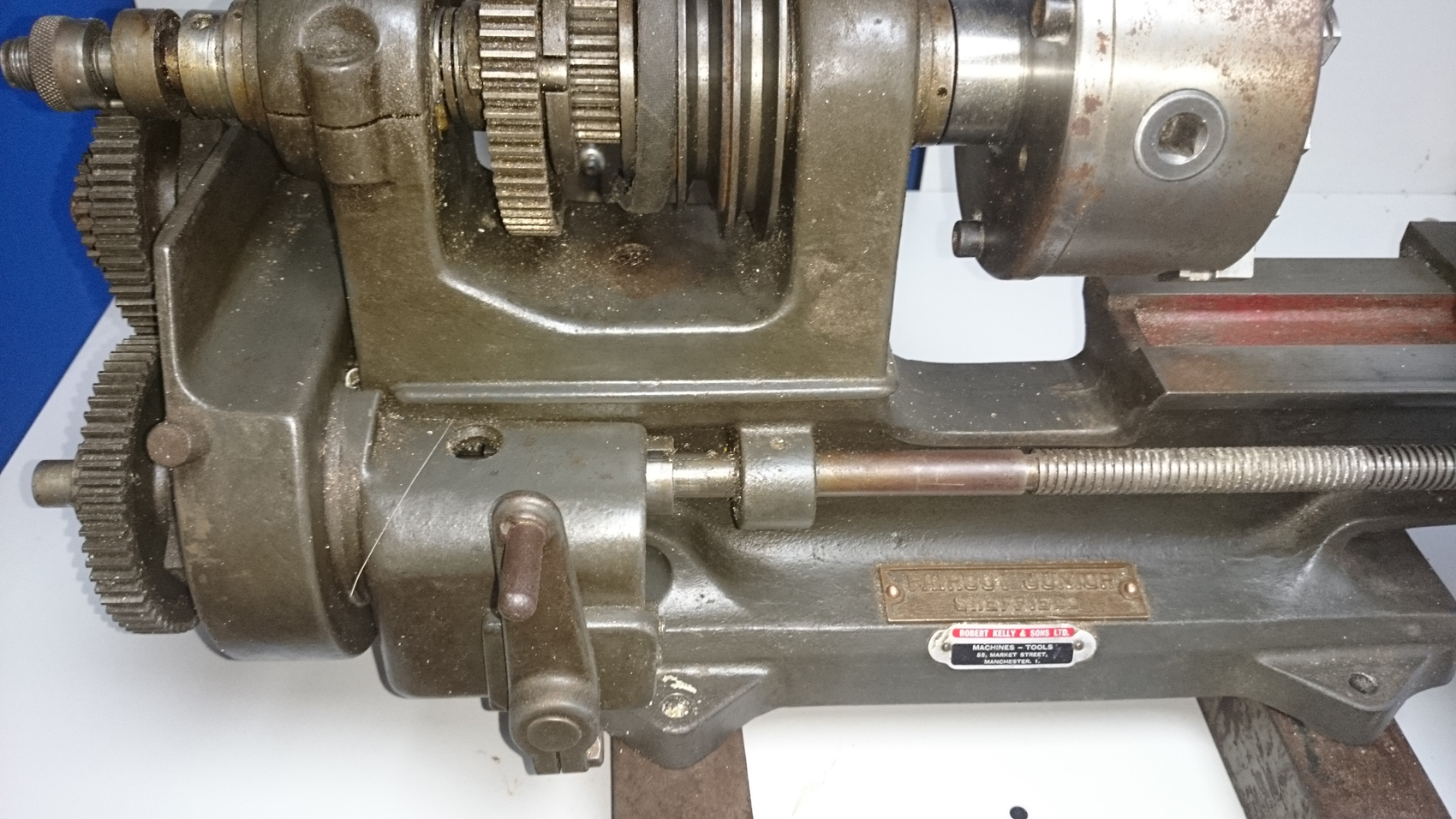

Relatively wide (at 31/2") and weighing 40 lbs, the flat-topped, the 60-degree V-edged bed was cantilevered from a single, long foot that was (unlike many rivals) designed to minimise deflections caused by the gap in the bed and the left-hand overhang of the headstock. There was no tumble reverse on the changewheel drive (or apron clasp nuts) instead, a simple dog clutch was fitted to the 5/8" diameter by 8 t.p.i. leadscrew to engage and disengage the carriage drive. On some models the clutch was adapted to provide a very useful automatic knock-off for the carriage feed, while others had the same mechanism enclosed, rather unnecessarily, in a housing formed as part of the bed casting. All models had a leadscrew of identical specification, but with that on the plain turning models being properly supported in a bearing housing, cast as part of the bed at the headstock-end, instead of being overhung as so many cheaper rivals.

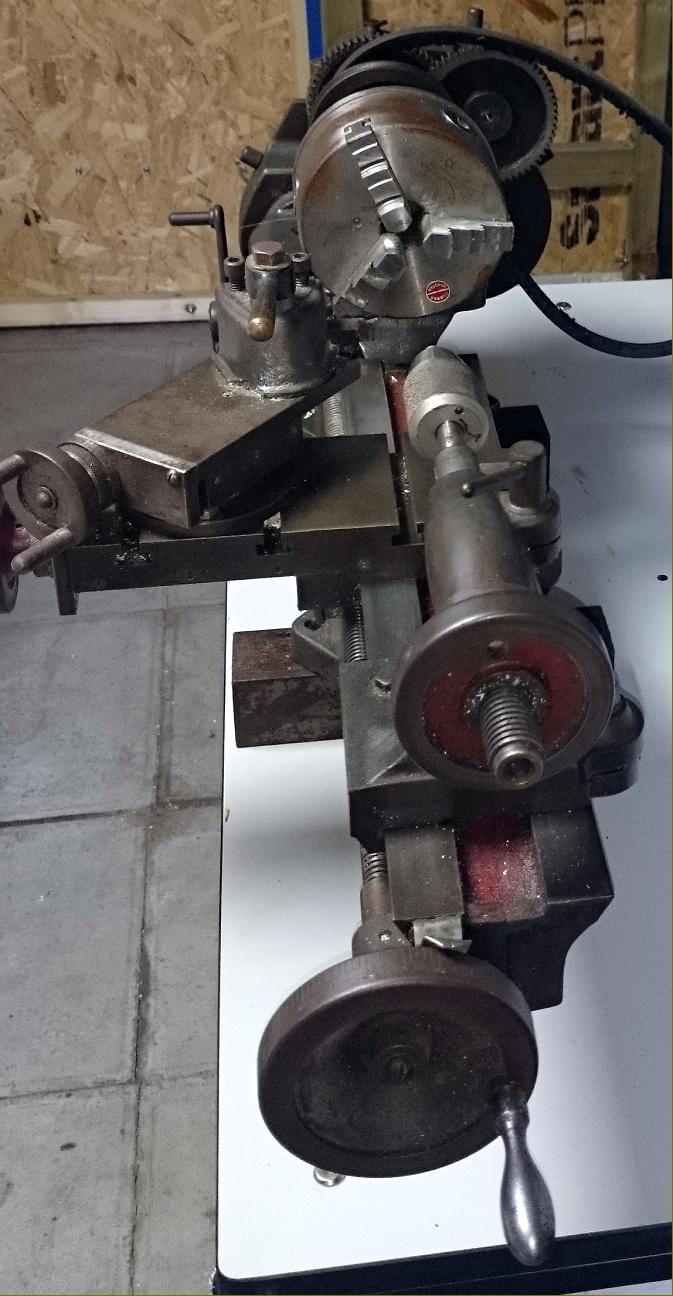

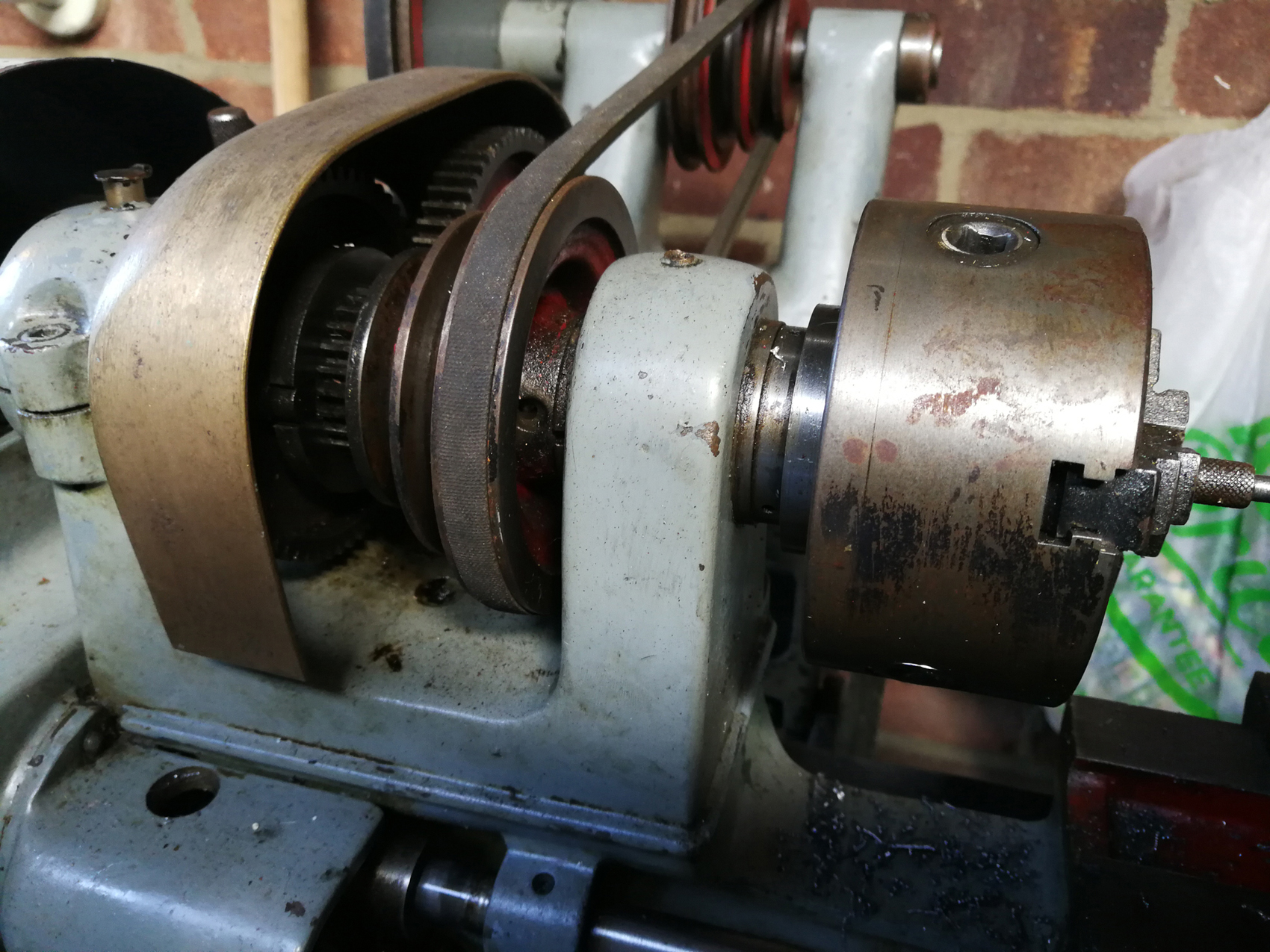

Detail design of Faircut headstocks varied considerably: some had bearings adjusted by being drawn into tapered holes in the casting, others had their right-hand bearing clamp screw at the rear and the left-hand at the back - while others had both clamps to the front. When fitted, the backgear assembly on the Junior was unusual in being clustered inboard of the left-hand headstock bearing, and - like the 2-inch long, adjustable split-tapered bronze headstock spindle bearings - were of substantial proportions for so small a lathe. Although some contemporary British lathes of the 1950s still used a flat-belt final drive all Faircut Junior lathes seen by the writer have had a (cast-iron) V-belt drive headstock pulley with cones of 4", 31/4" and 21/2" diameters - and one can only assume that this was a standard feature from the start to finish of production. The headstock spindle was bored through to clear 3/8" bar stock, had a No. 1 Morse taper centre and a 3/4" x 12 t.p.i. nose thread.

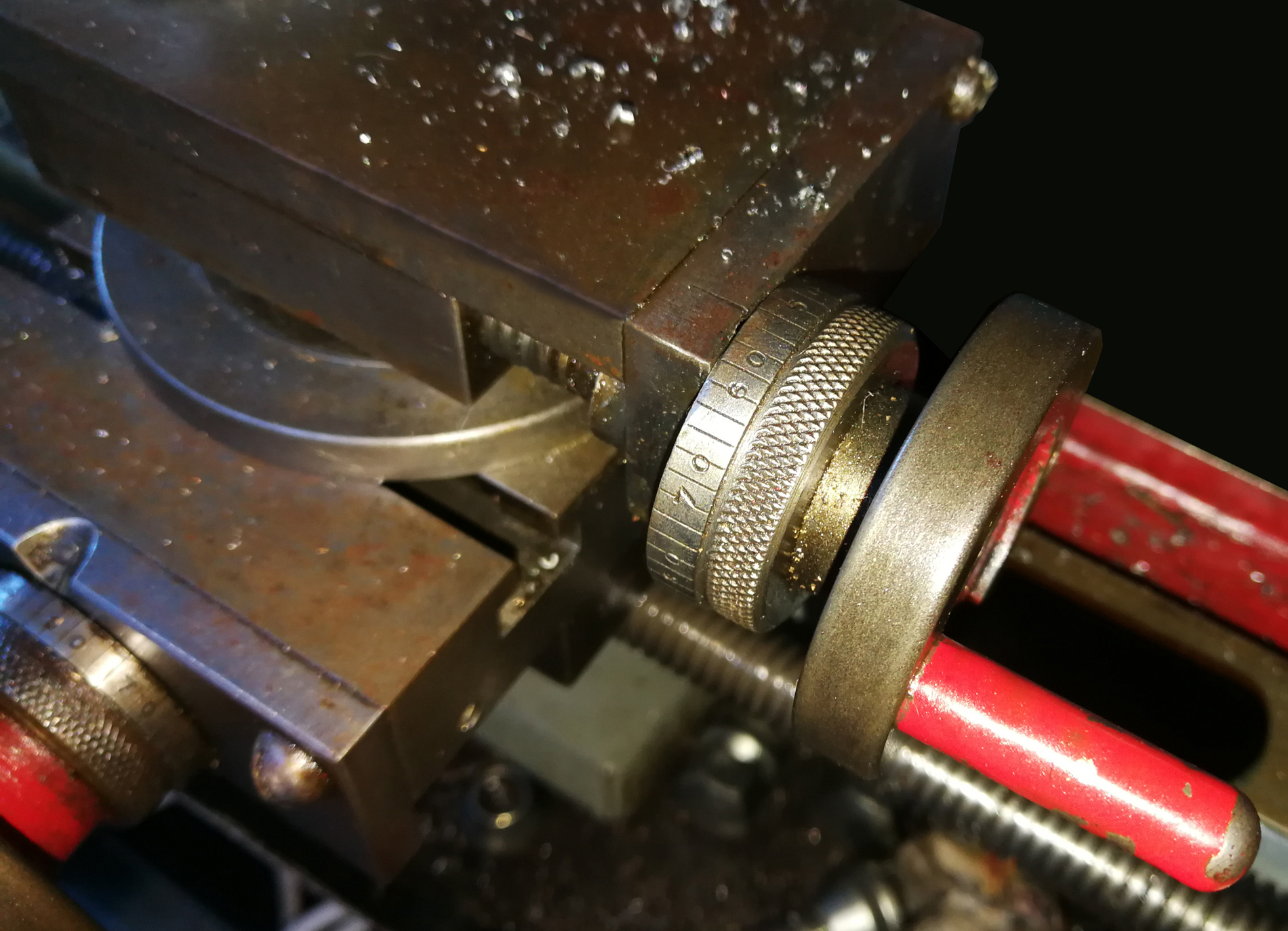

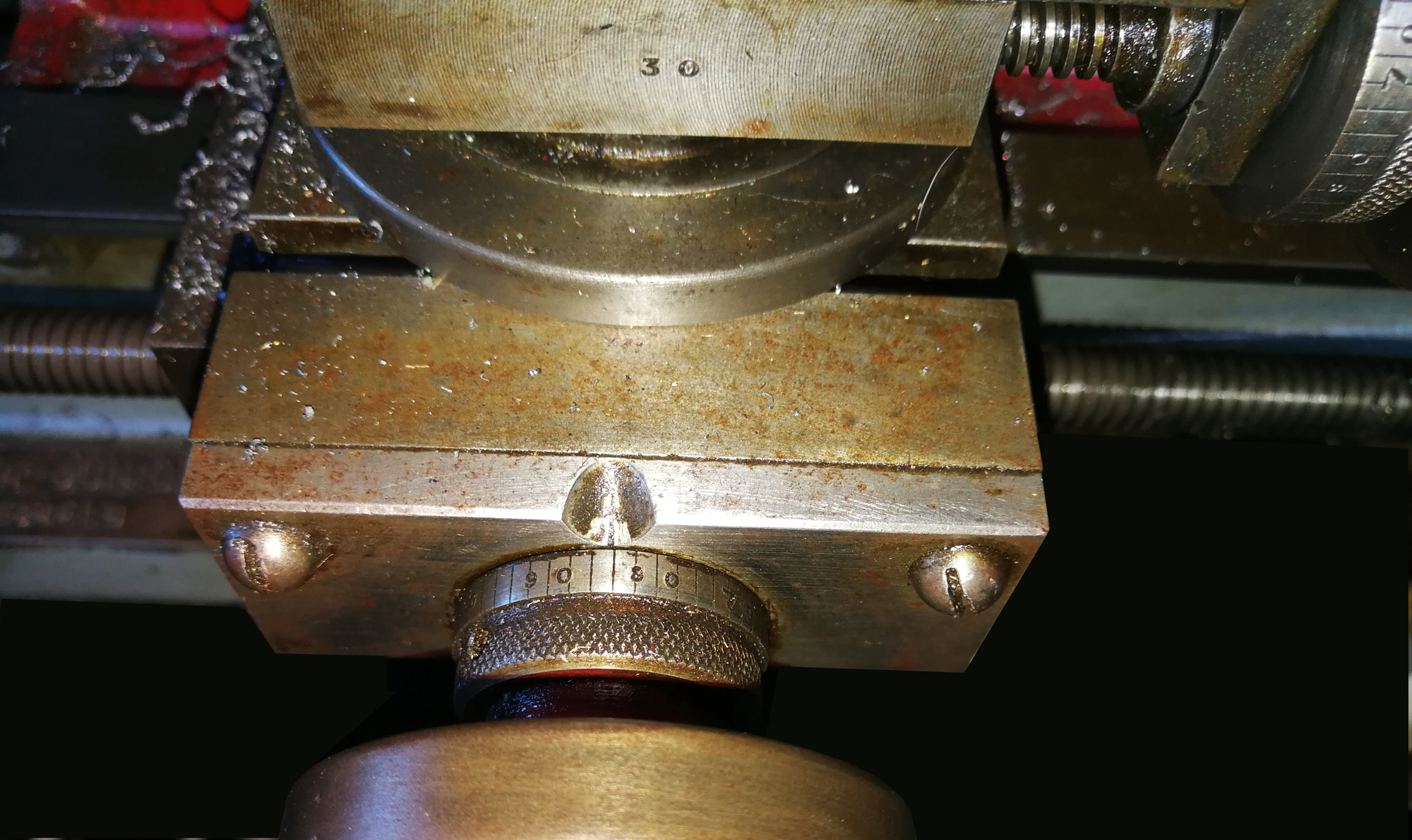

Most Junior lathes, unlike the company's larger models, were not fitted with a T-slotted cross slide as standard - something of a drawback in a lathe intended for amateur use - but of the full-length type, some 73/8" long and 55/8" wide, it was of good proportions for its task. However, in the late 1940s a 4-inch by 6-inch slide with 3 T-slots was on the accessories list for £3 : 10s : 0d and occasionally lathes so fitted are found. Drummond-like in appearance, the top slide was fitted with a small, 2-handle wheel on the end of a feed screw off-set to the front side - the aim of both design points being to give clearance between handwheel and tailstock when the latter was drawn right up to the headstock.

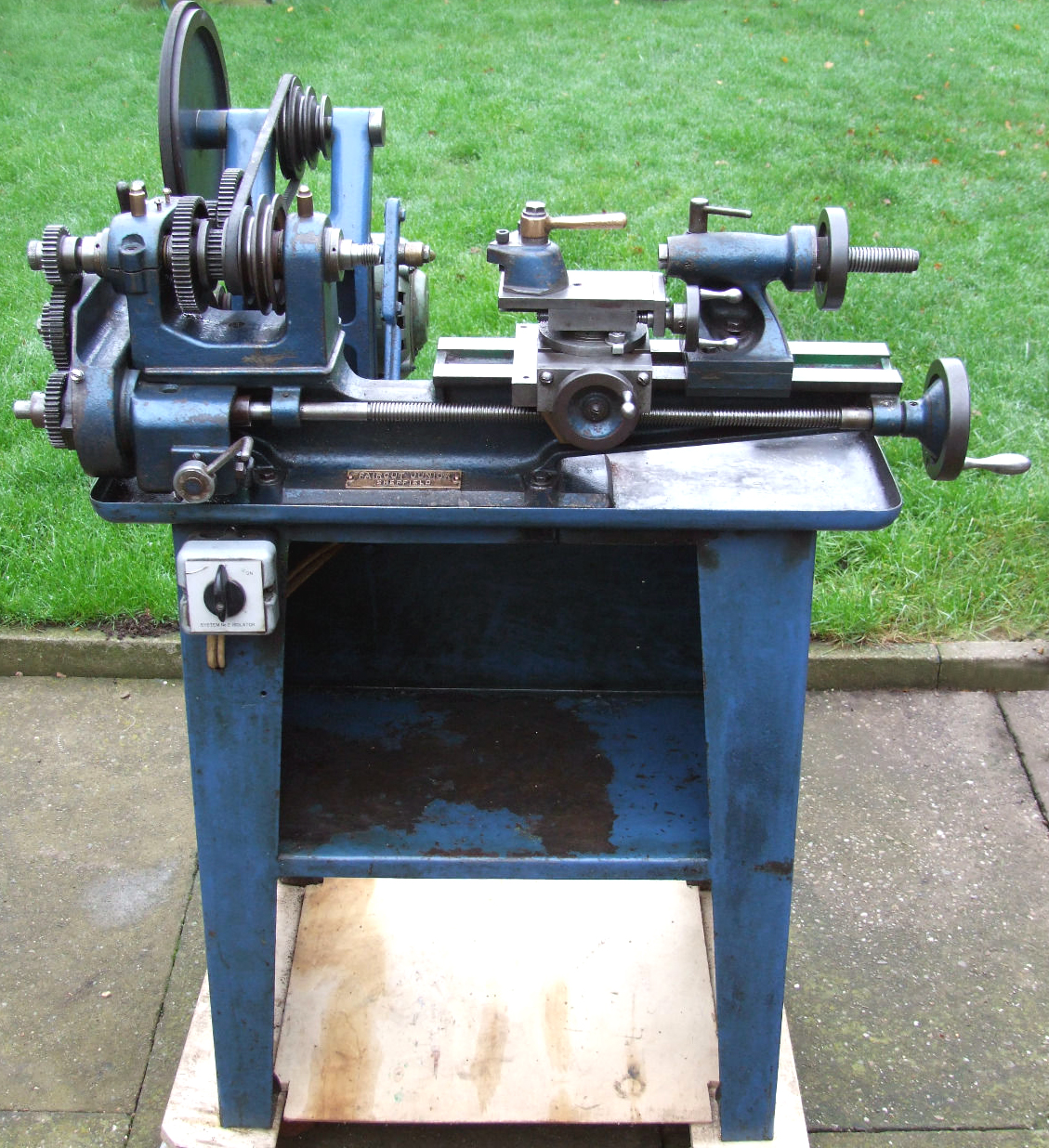

Appearing only to have been offered as an option on the Junior, the maker's stand was constructed from braced, welded sheet steel - other models having their in cast iron. The standard countershaft had an unusual feature (though used on other Faircut models and also on South Bend 9-inch "Workshop" lathes) the V-belt from motor pulley ran over a large-diameter flat pulley on the countershaft - though so the writer has yet to see a Junior with the arrangement converted to a fast-and-loose system as used on the Senior" and other Faircut models. The writer's first decent lathe, a Myford M-Type, was fitted to a Faircut stand with an identical drive system, the whole assembly working with efficiency and in almost complete silence..