|

Machine Tool Manuals Machine Tool Catalogues Accessories Belts Factory Tour Home Page Factory Tour Page 2 Factory Tour Page 4 |

||

|

|

|

|

|

|

|

|

|

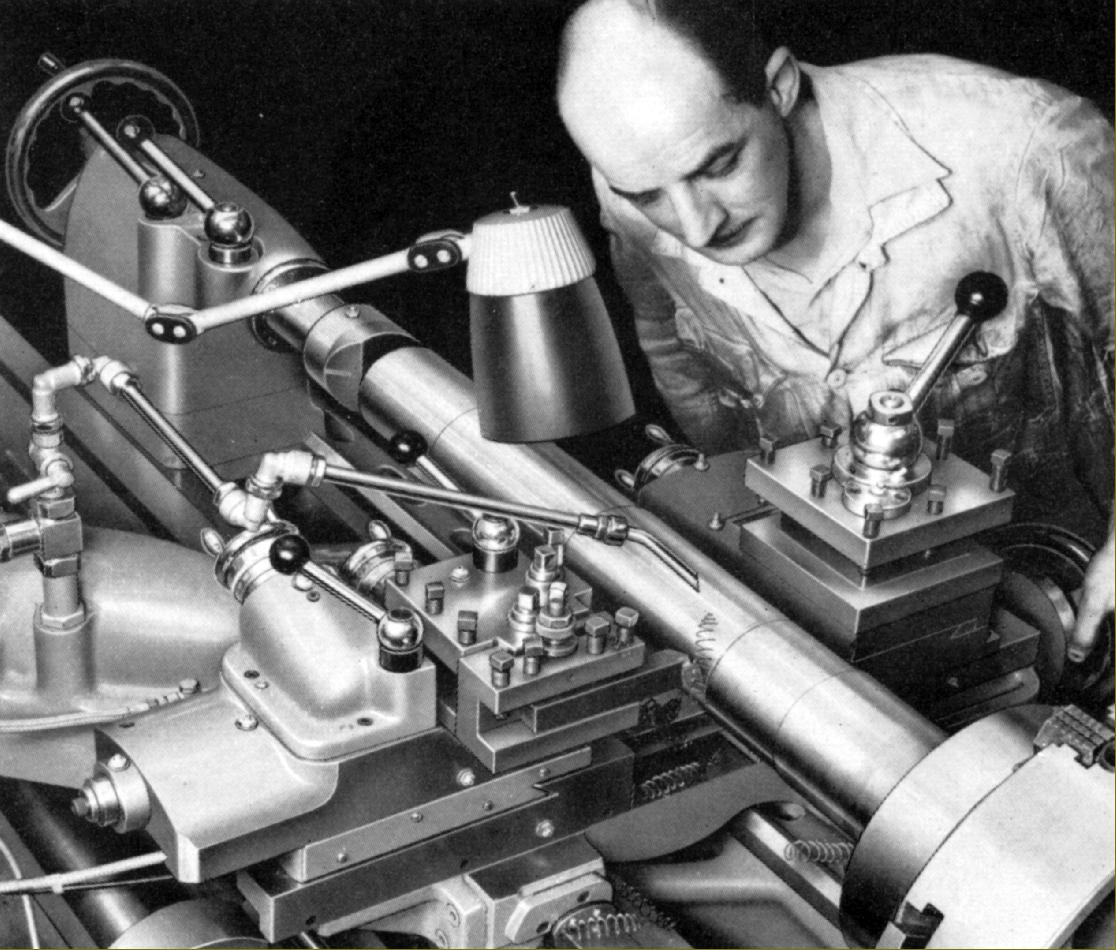

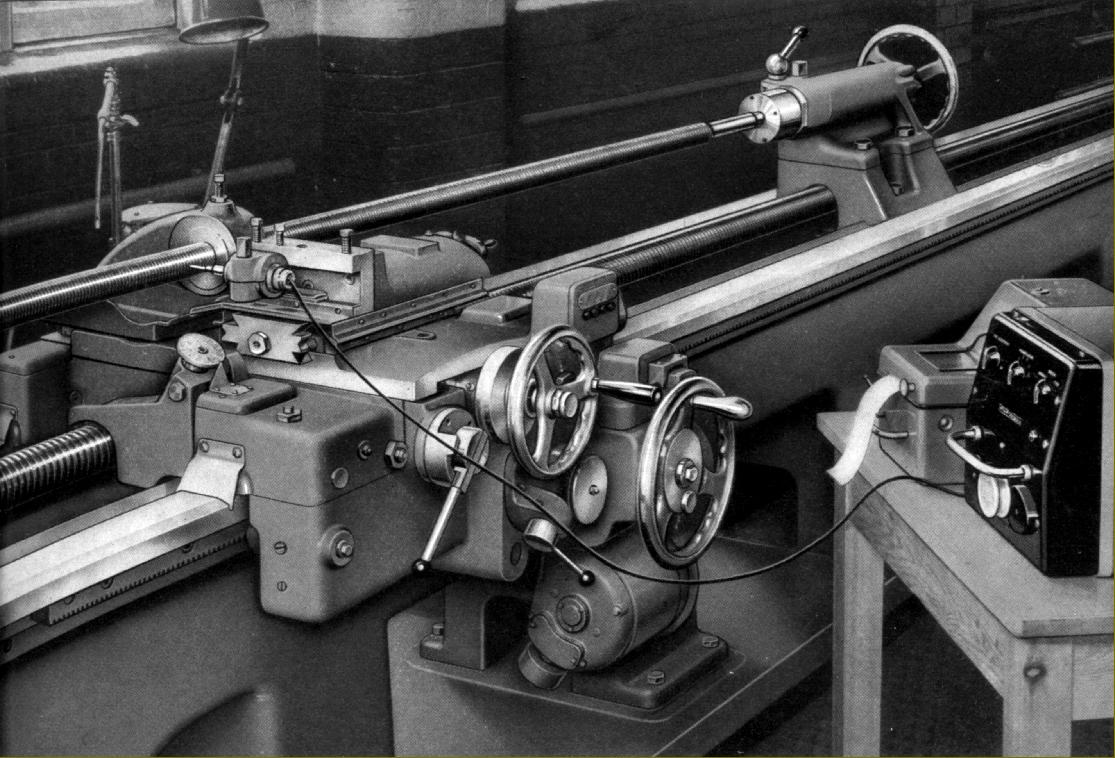

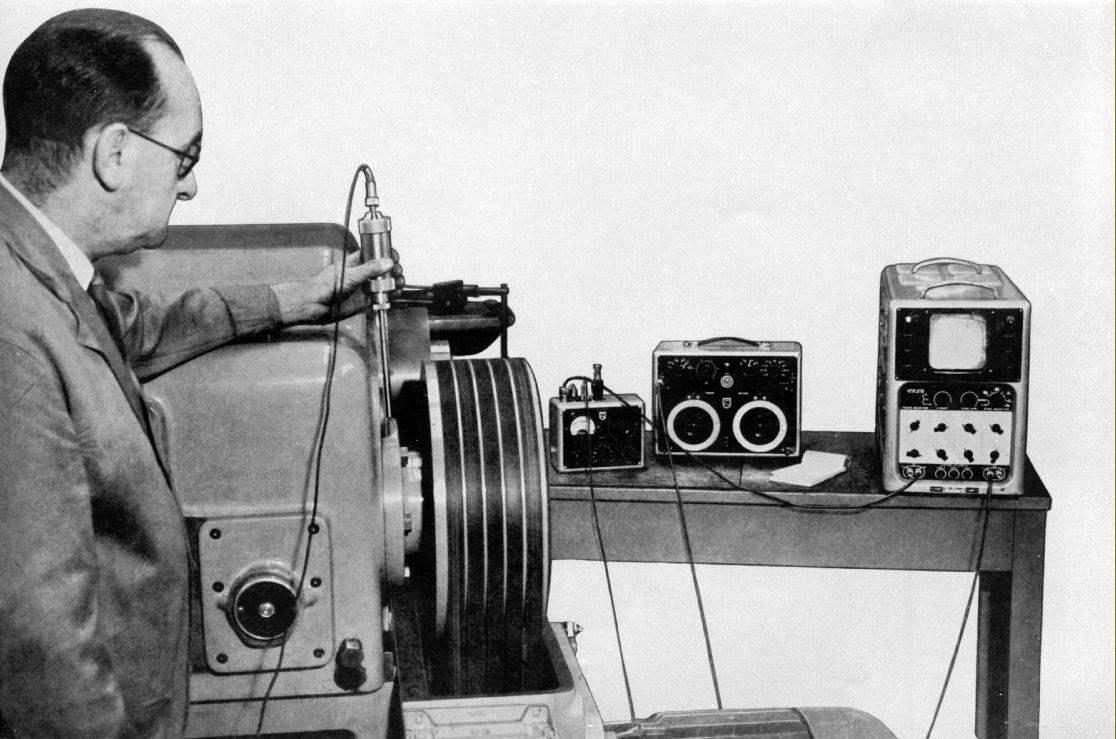

Leadscrew correcting lathe. This was built by Dean, Smith & Grace and hosed in its own temperature-controlled room. The lathe is shown being checked with a national Physical lavatory certified master screw--a probe on the tool slide being connected to the Taylor Hobson recording equipment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E-Mail Tony@lathes.co.uk Machine Tool Manuals Machine Tool Catalogues Accessories Belts |

||