|

Home Machine Tool Archive Machine-tools Sale & Wanted Roll-turning Lathes Deutschland Home Page Roll Lathes Wheel lathes Facing Lathes |

|

Deutschland Dortmund built a wide variety of specialised roll-turning lathes - rolling being used in industry for a huge variety of tasks including (amongst many others) crushing sugar cane and rocks, producing paper and sheet steel, printing, textile work and forming, by the shape of a groove cut into the surface of a pair of rollers, the required profile on a strip of red-hot steel passed between them. |

|

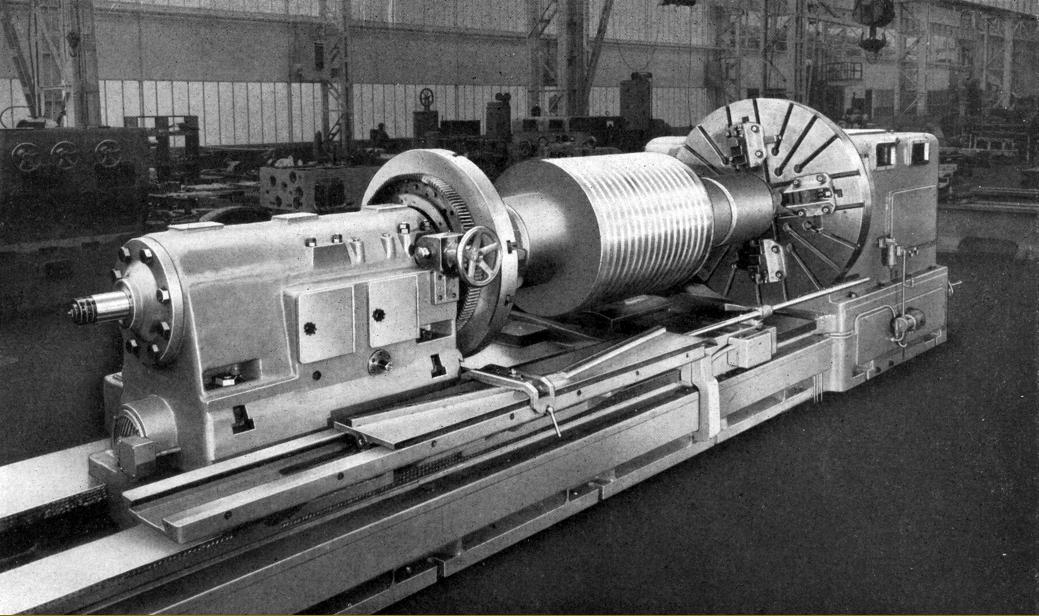

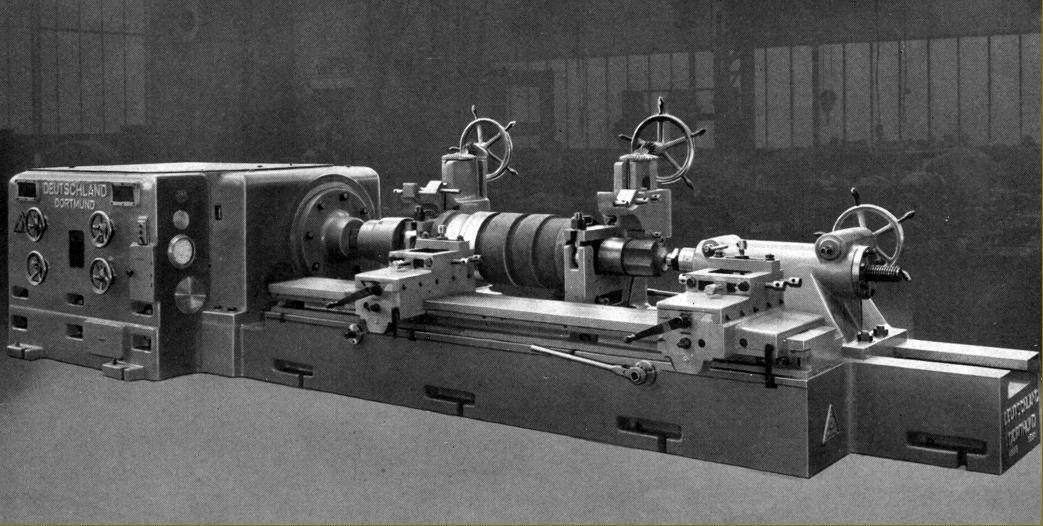

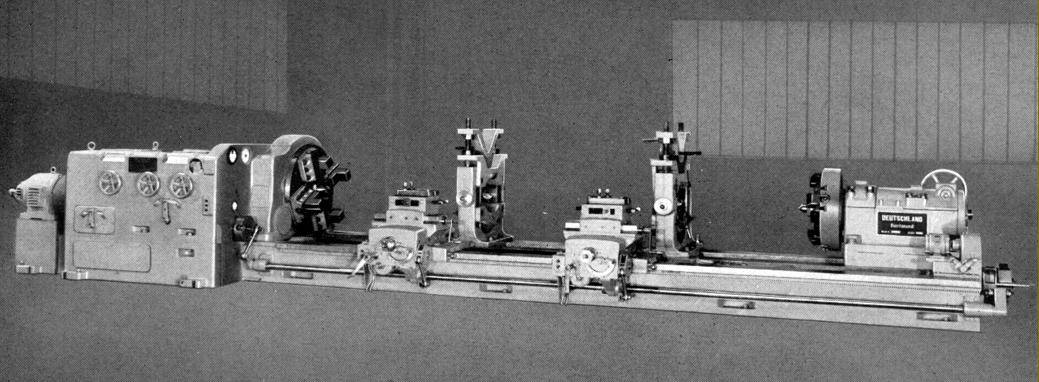

Type D-11-80L with a swing of 1600 mm and 5,500 mm between centres. This is a roll-turning lathe - built specially for a sugar cane crushing plant. This example has a tailstock fitted with a faceplate with an inner, gear-equipped rim for use as a dividing apparatus |

|

|

|

|

|

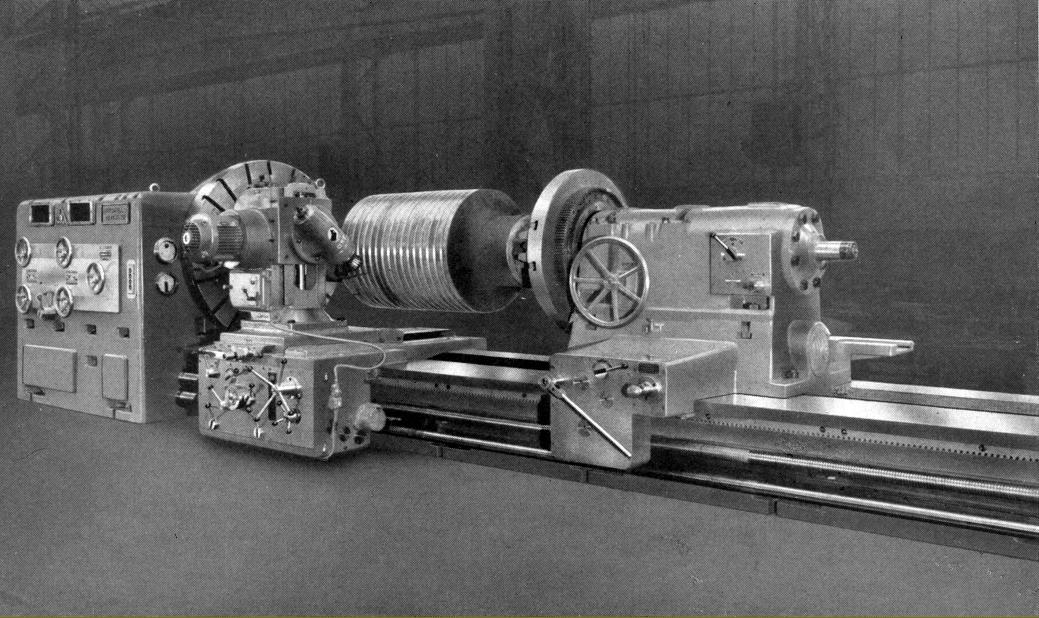

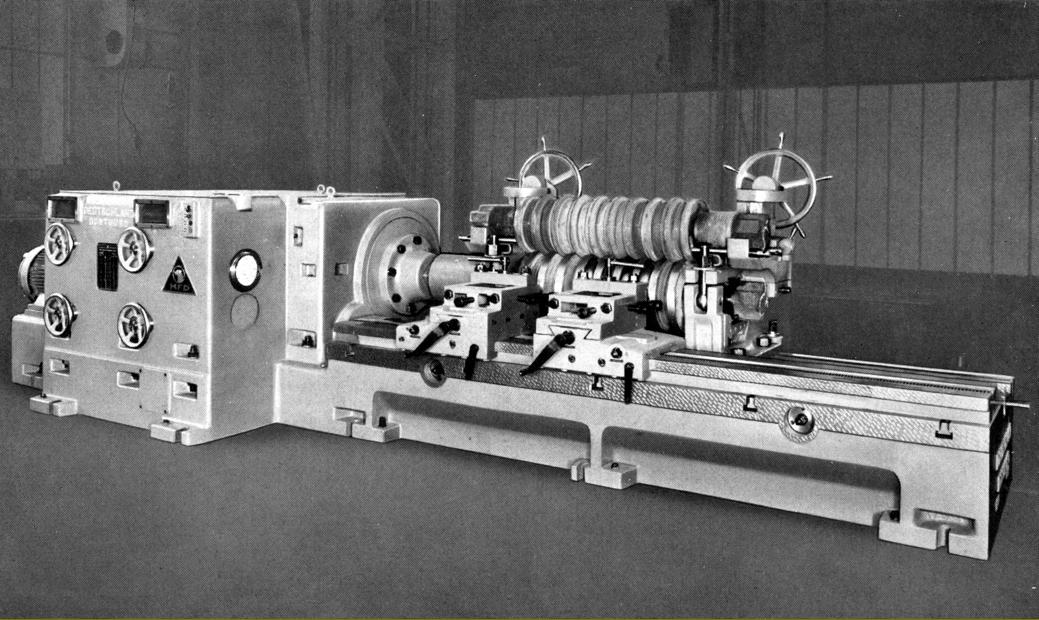

Two roll-turning lathes of the Type DWv-31 with a separate front sliding bed - the upper section able to be moved along the supporting casting by a hand-operated ratchet (the holes to accept the long ratchet handle being visible to the left of the left-hand carriage and immediately below the right hand carriage). The carriages had no power longitudinal or other feeds and were operated entirely by hand. |

|

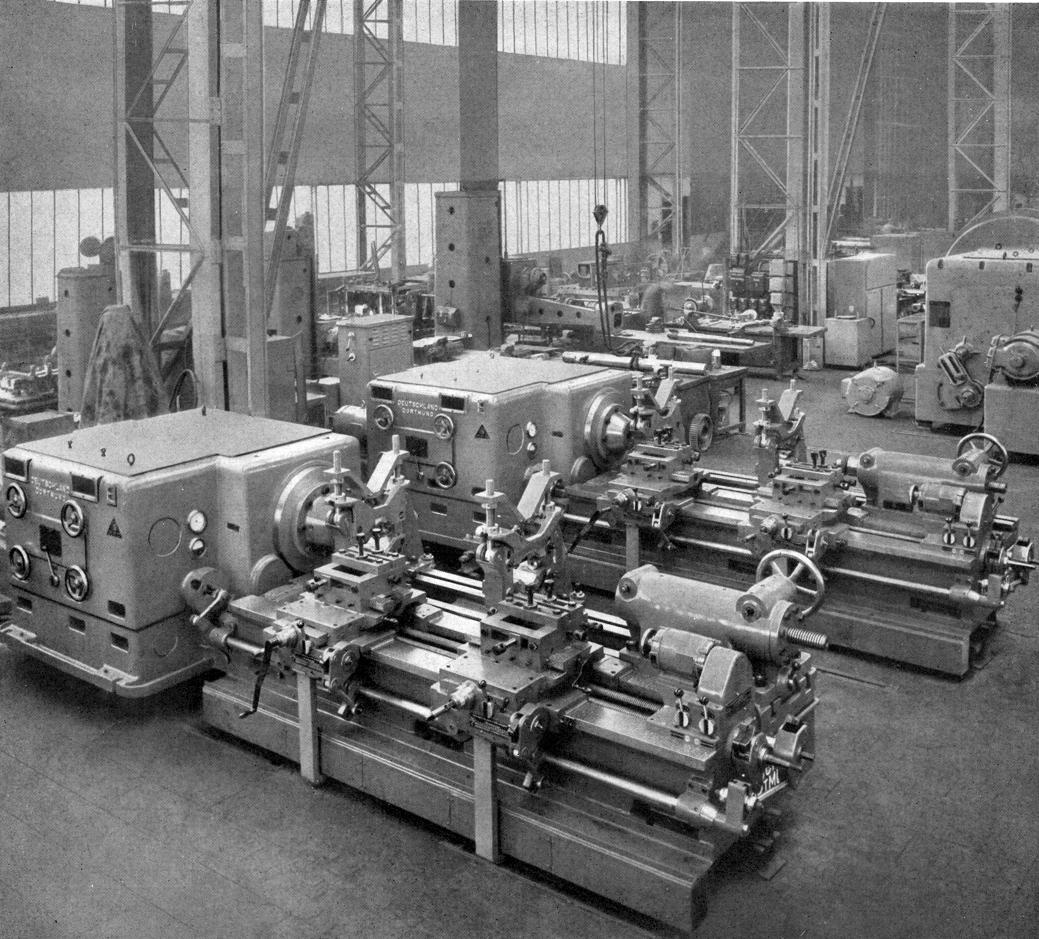

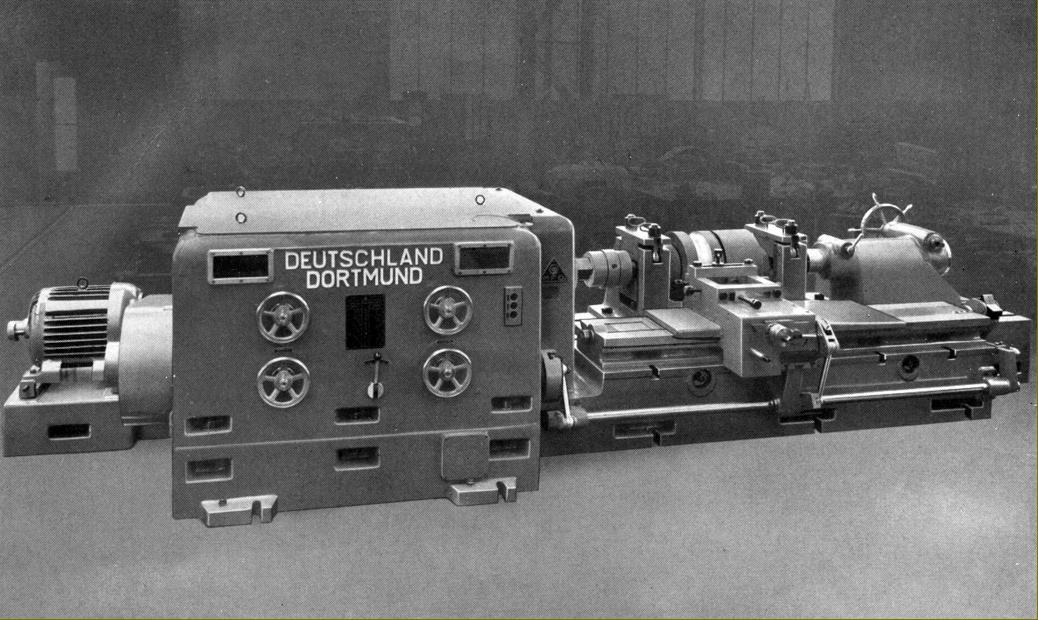

Sliding-bed lathe of the Type DWv-40 with a 600 mm swing and taking 3200 mm between centres (23" x 10' 6") and equipped with hinged brackets to take the second counter roll. |

|

|

|

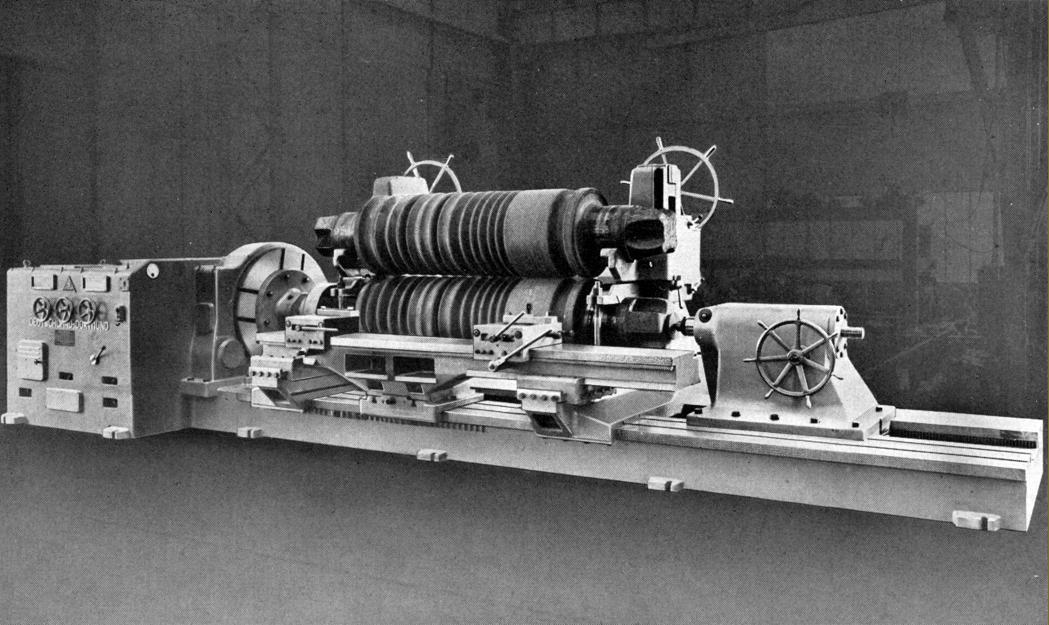

Types DWv45 and DWv 40. The former with a swing of 700 mm and taking 3700 mm between centres (27" x 12') and the latter a swing of 600 mm and a capacity between centres of 3300 mm (23" x 11'). These lathes carried special steadies capable of carrying rolls complete with their roller bearings or, with some adjustment, plain bearings |

|

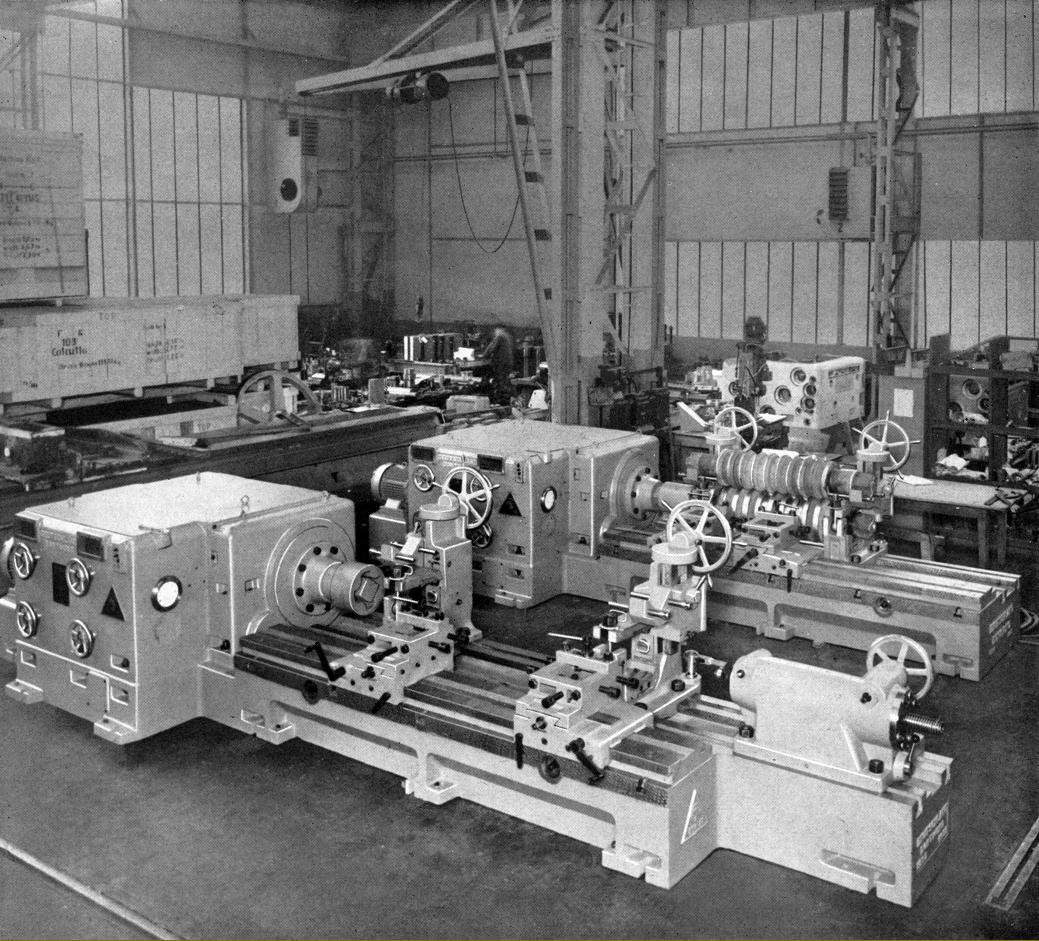

Roll-turning lathe Type DWv with a 600 mm swing and taking 2000 mm between centres (23" x 6' 6"). A sliding-bed model, this version was fitted with a crank-driven front shaft (just like the drive to a shaper's table) to provide power longitudinal and traverse feeds |

|

Type DWS-75, a specially arranged lathe for re-turning deep-grooved rolls. Note the short front bed carried on saddles able to be slid on the main bed (all DWS models had this feature) . This lathe had a 1225 mm swing and took 5500 mm between centres (48" x 18') |

|

Type DW-111-71 with a 1150 mm swing and taking 4500 mm between centres (45" z 15'). A 3-way bed model this had a conventional form of front-mounted power shaft to give longitudinal and traverse feeds and rapids |

|

Roll-turning Lathes Home Machine Tool Archive Machine-tools Sale & Wanted |

||