An Operation Manual is available for the Cowells Lathe

Cowells Small Machine Tools Ltd. is based near Colchester in England - and not be confused with the now-closed E.W. Cowell of 7A Sydney Road, Watford in Hertfordshire, a company once well known in model-engineering circles for their range of built-it-yourself workshop equipment offered, during the 1950s and 1960s, as kits of castings to construct such useful items as lathes, power hacksaws, drilling machines, hand-operated shapers, compound milling tables and machine vices.

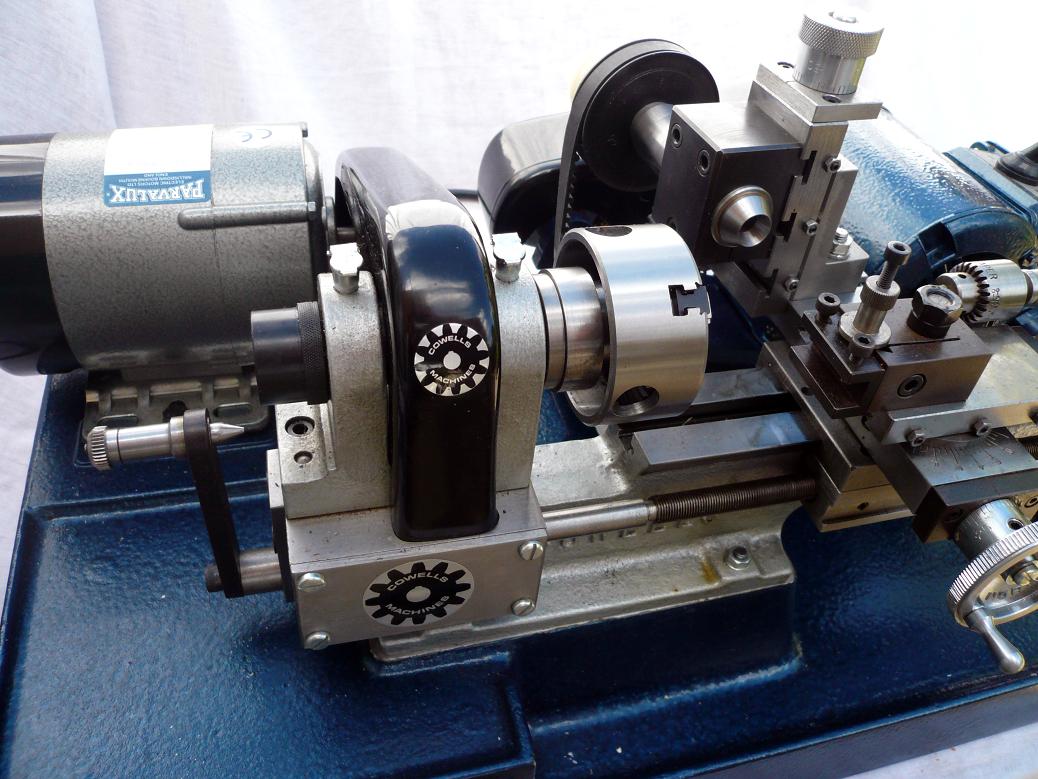

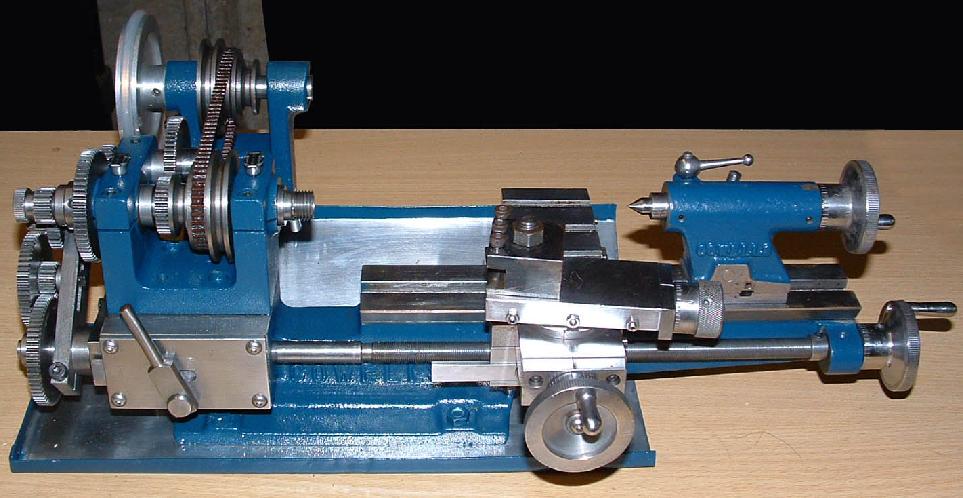

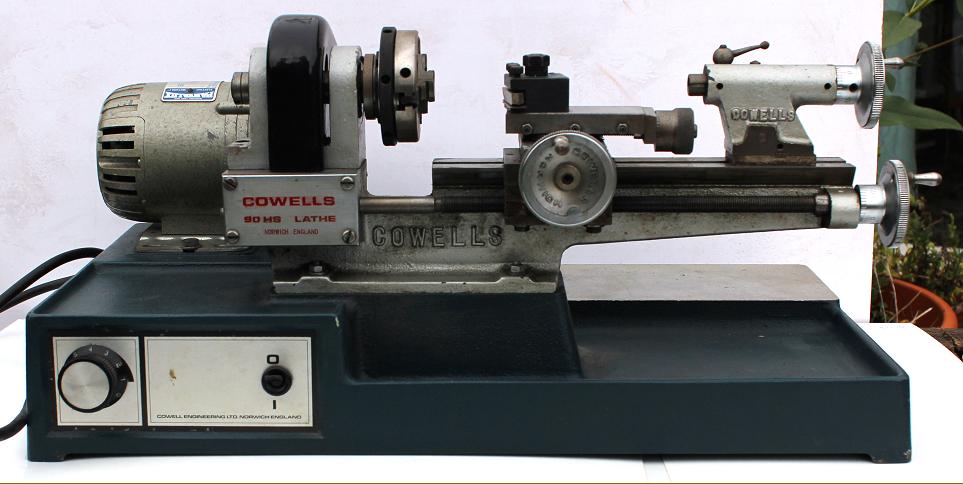

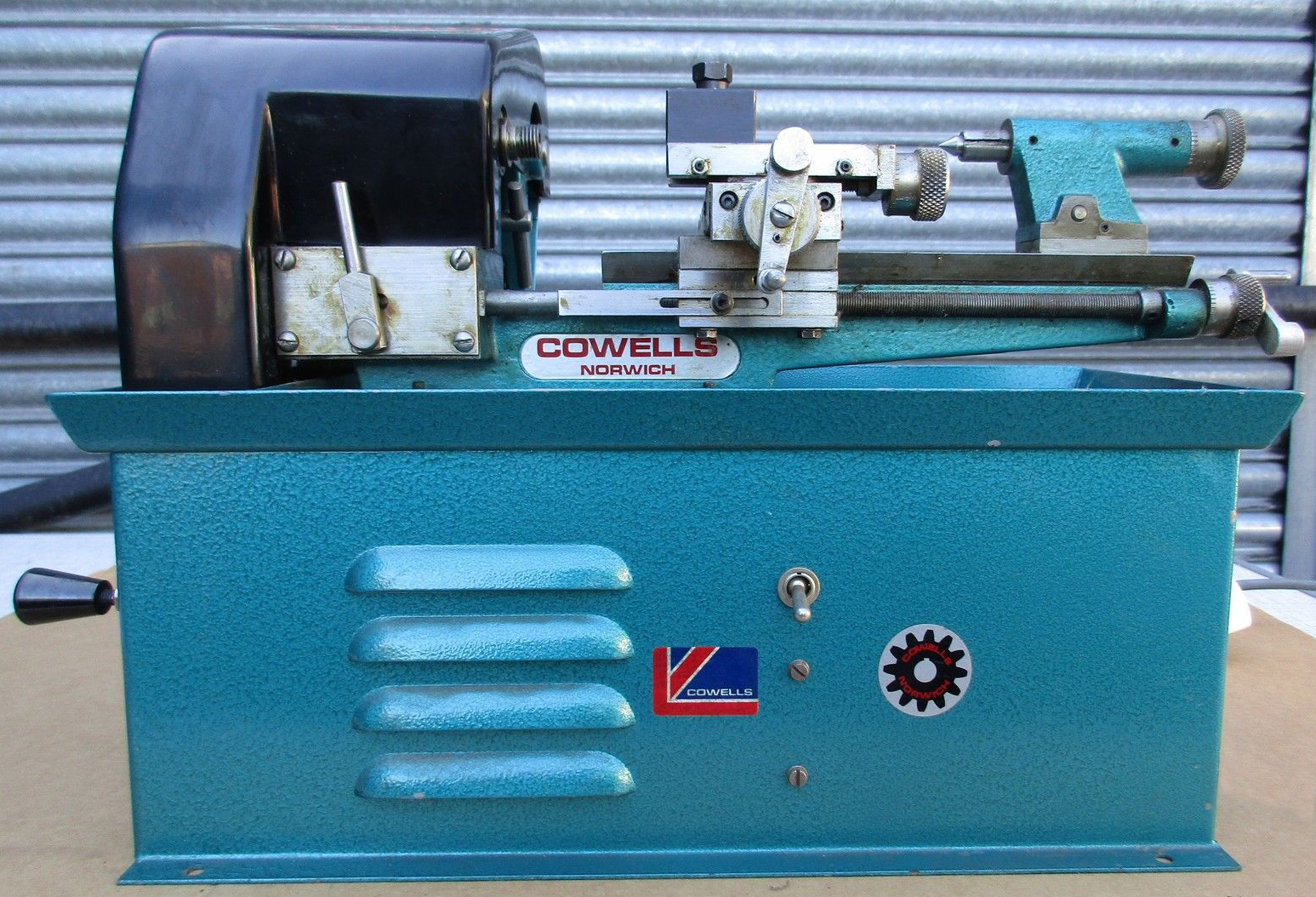

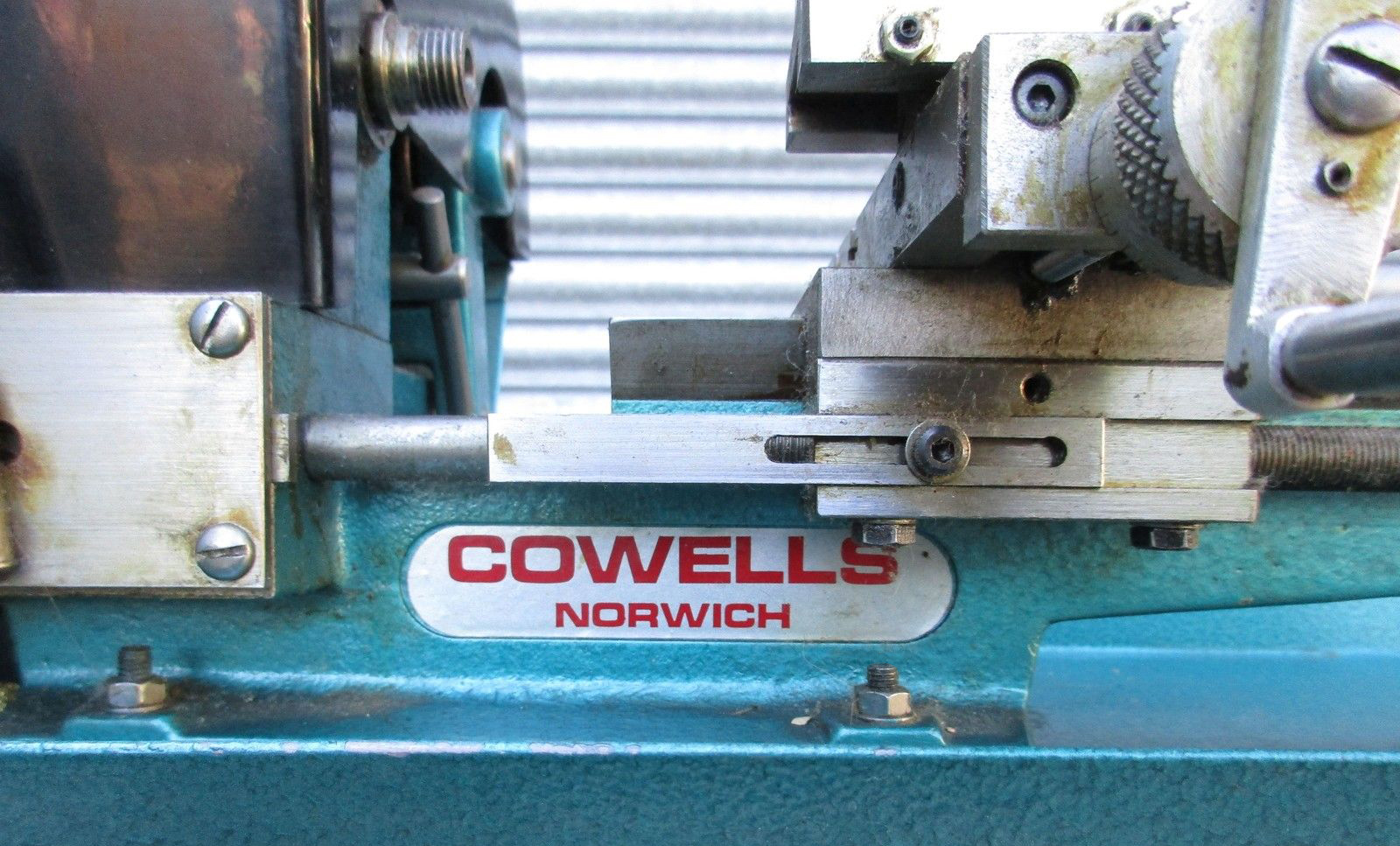

Today, Cowells offer a range of well-built, miniature machine tools and accessories popular with knowledgeable watch, clock and instrument makers throughout the world. Items made in the past and some still manufactured today, include small lathes, vertical millers and dividing and high-speed milling heads. Construction has always been from top-grade materials with close attention paid to the detail of their design and specification - for example, all the handles (apart from those on the miller) dials, levers and gib strips are in metal, not the cheap plastic of similar-sized lathes from European and Far Eastern manufacturers. The first Cowells lathe can trace its origins back to the Sheffield-made Flexispeed of the 1940s - a popular small machine that continued in production, in various forms, for nearly fifty years. Over many years, and several changes of ownership, the Flexispeed became, variously, the Simat 101, Meteor, Hector and Norfolk and finally the Perris PL90, in which form it was adopted, almost unaltered, as the first Cowells model and is still offered today as the basic Model 90E. The first Cowells to be offered as a complete, stand-alone and ready-to-plug-in-and-use unit used a badge with the words Cowells, Norfolk and this model, although the badge was also used on early bench-mounted models, is now commonly referred to as the "Norfolk"

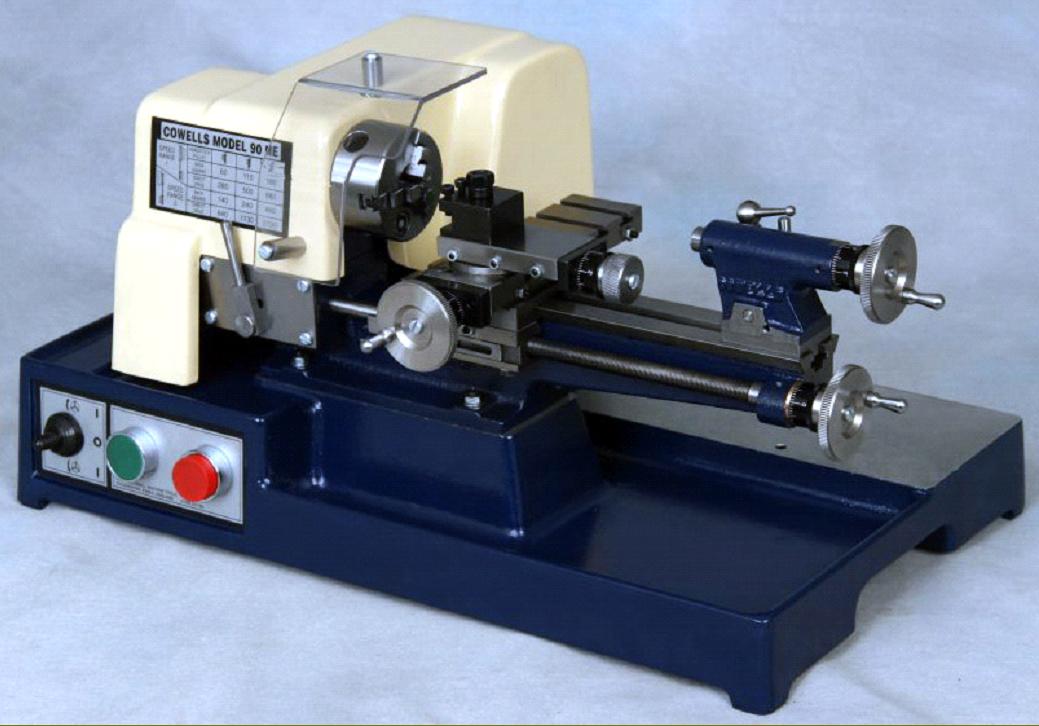

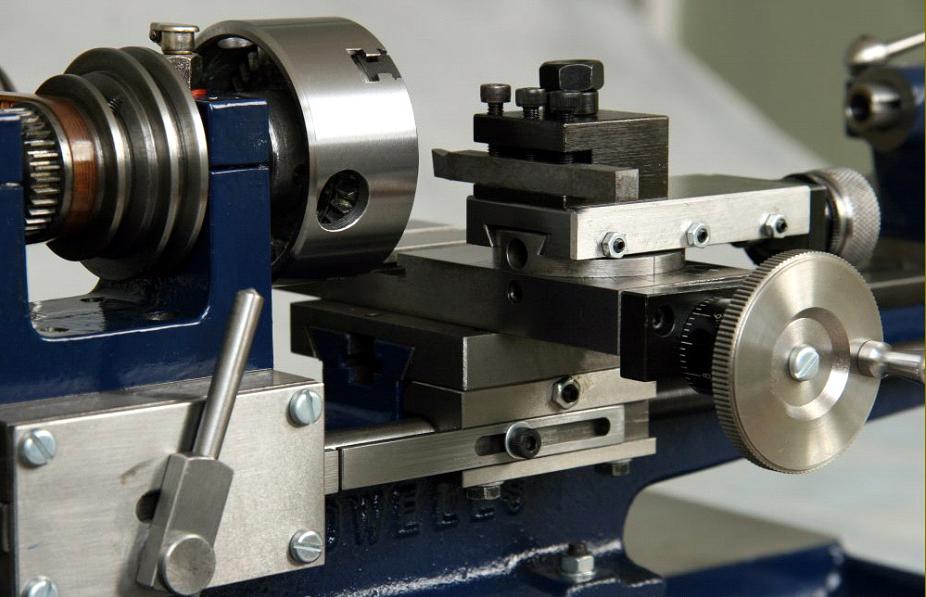

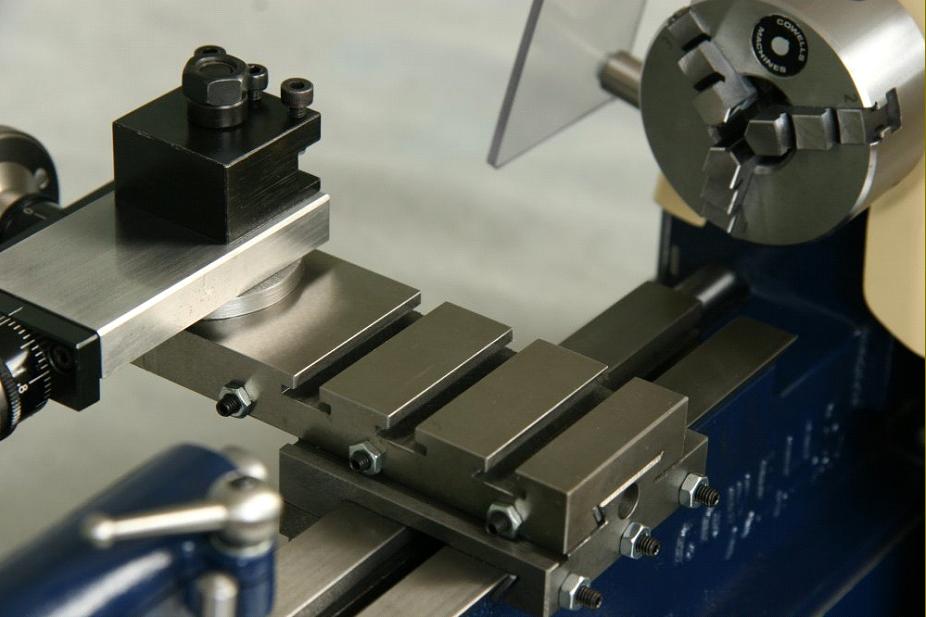

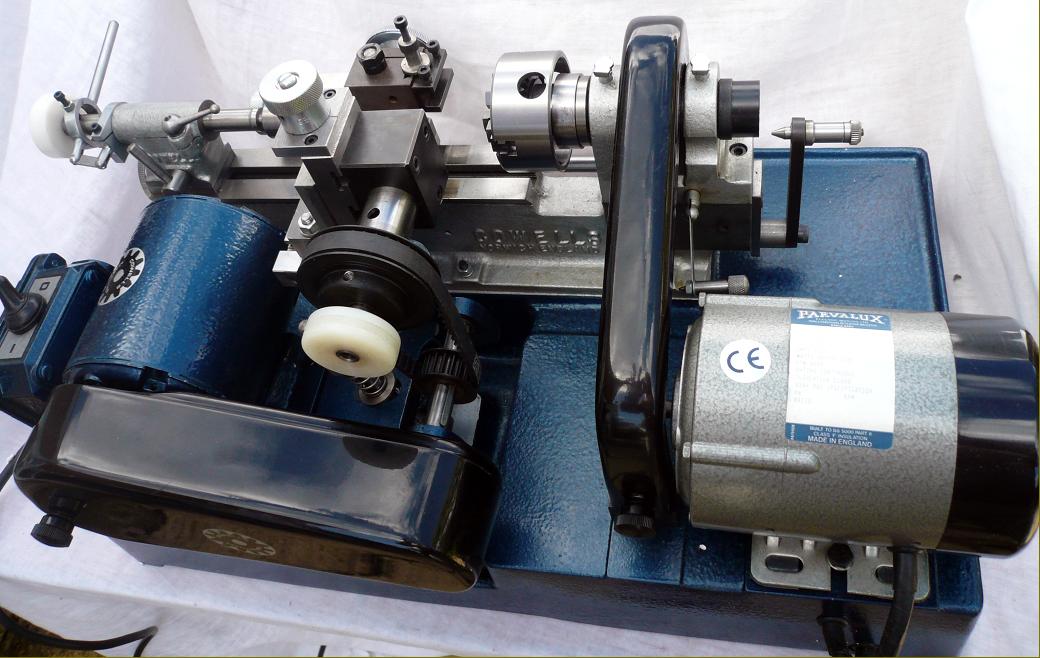

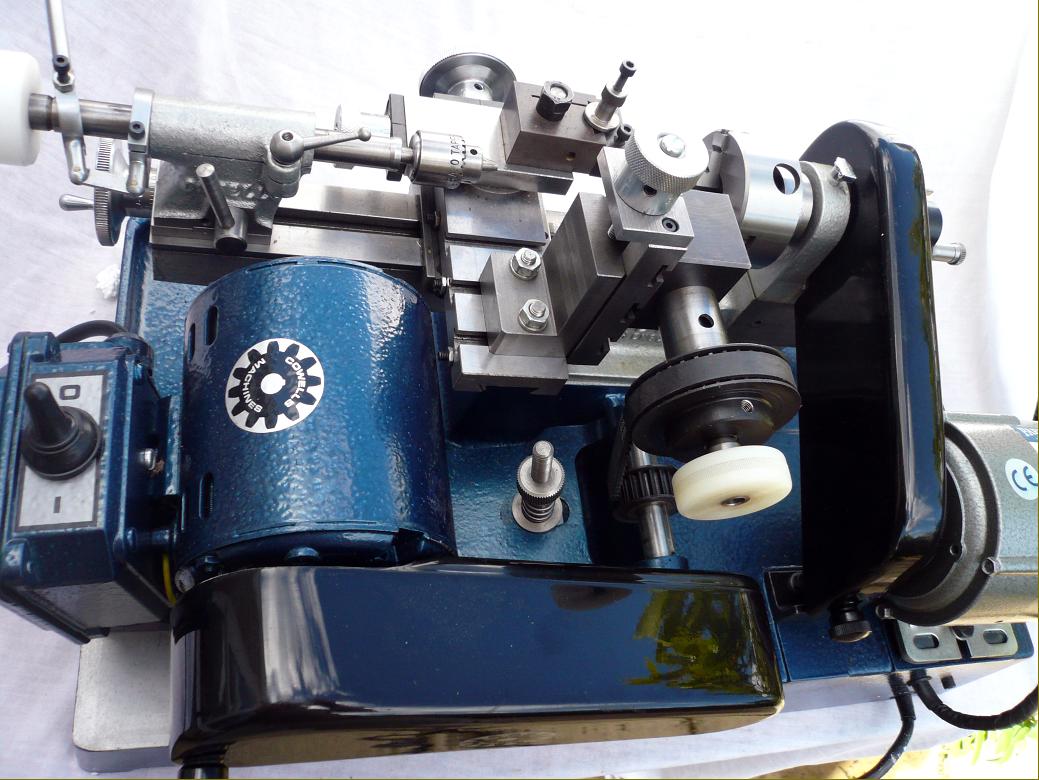

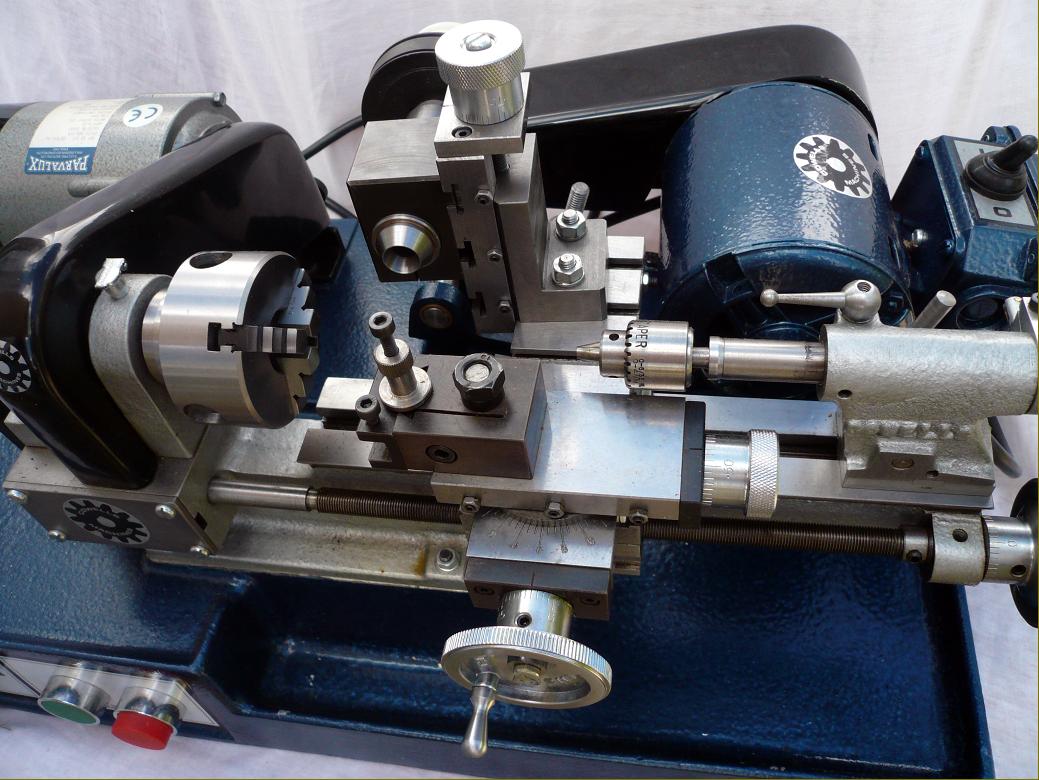

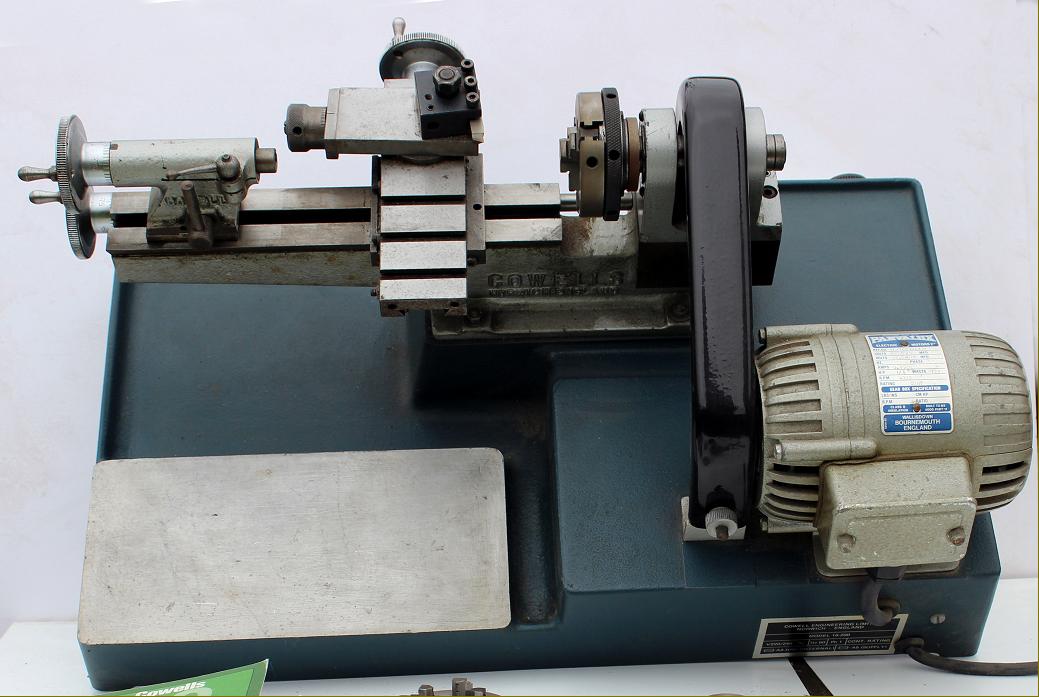

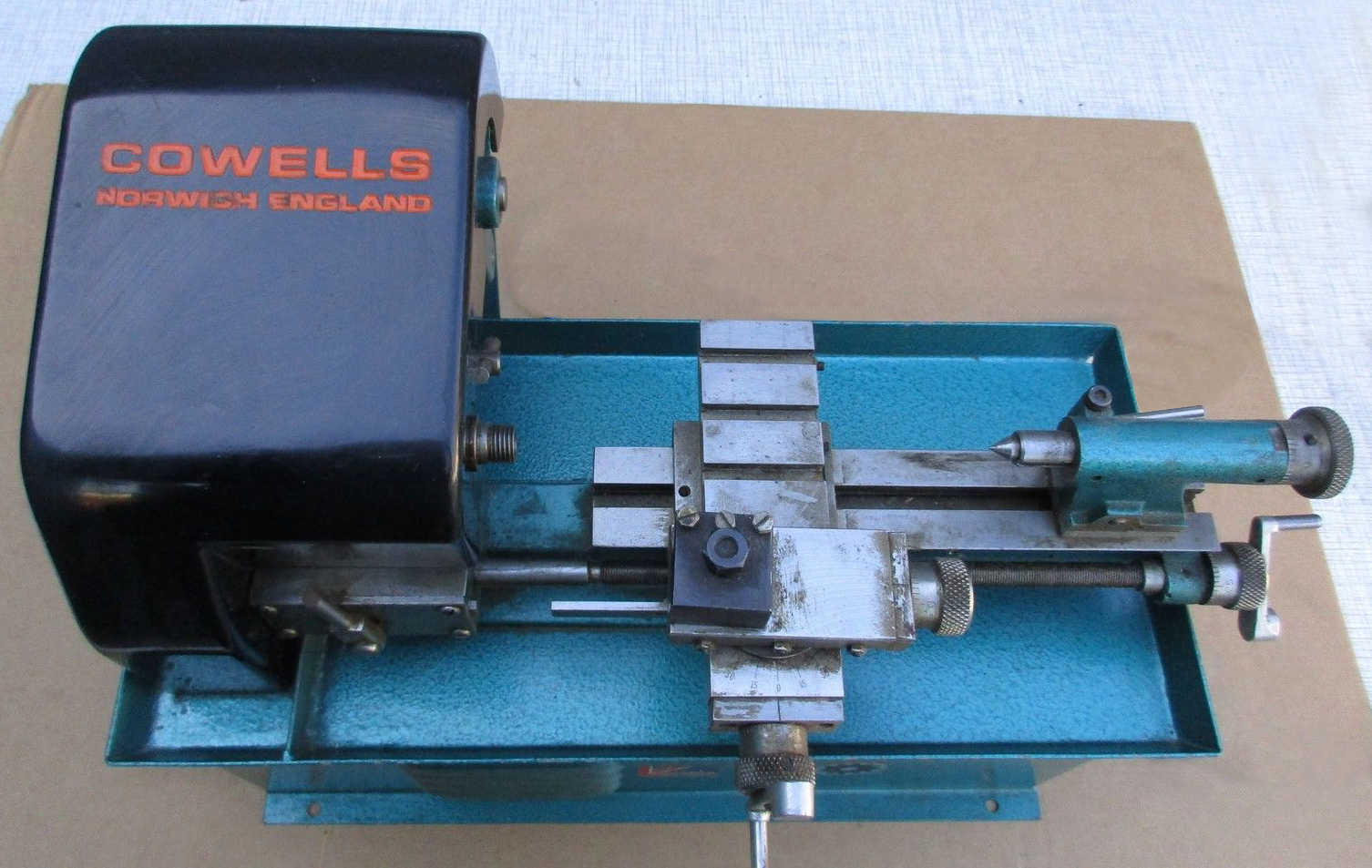

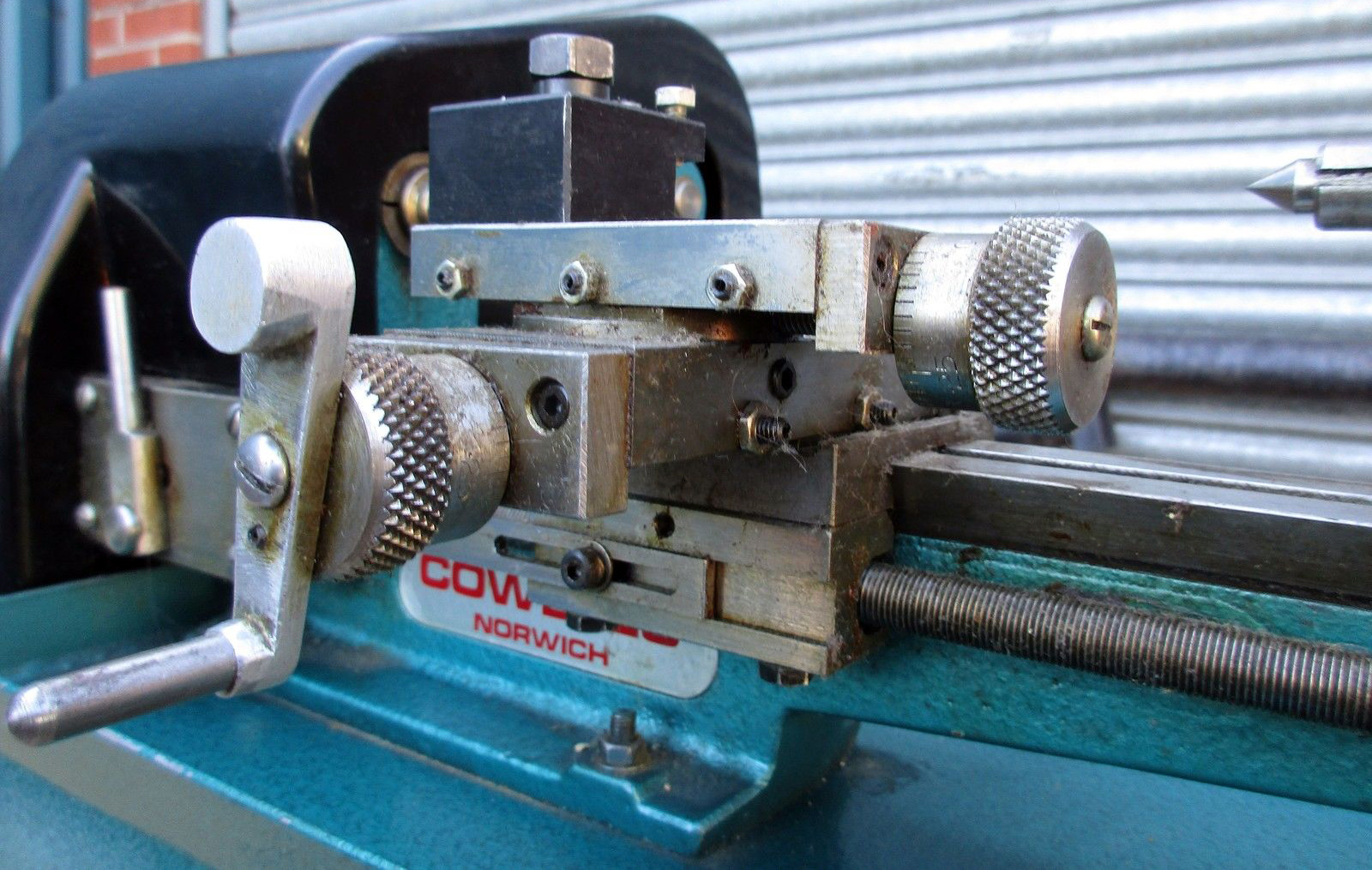

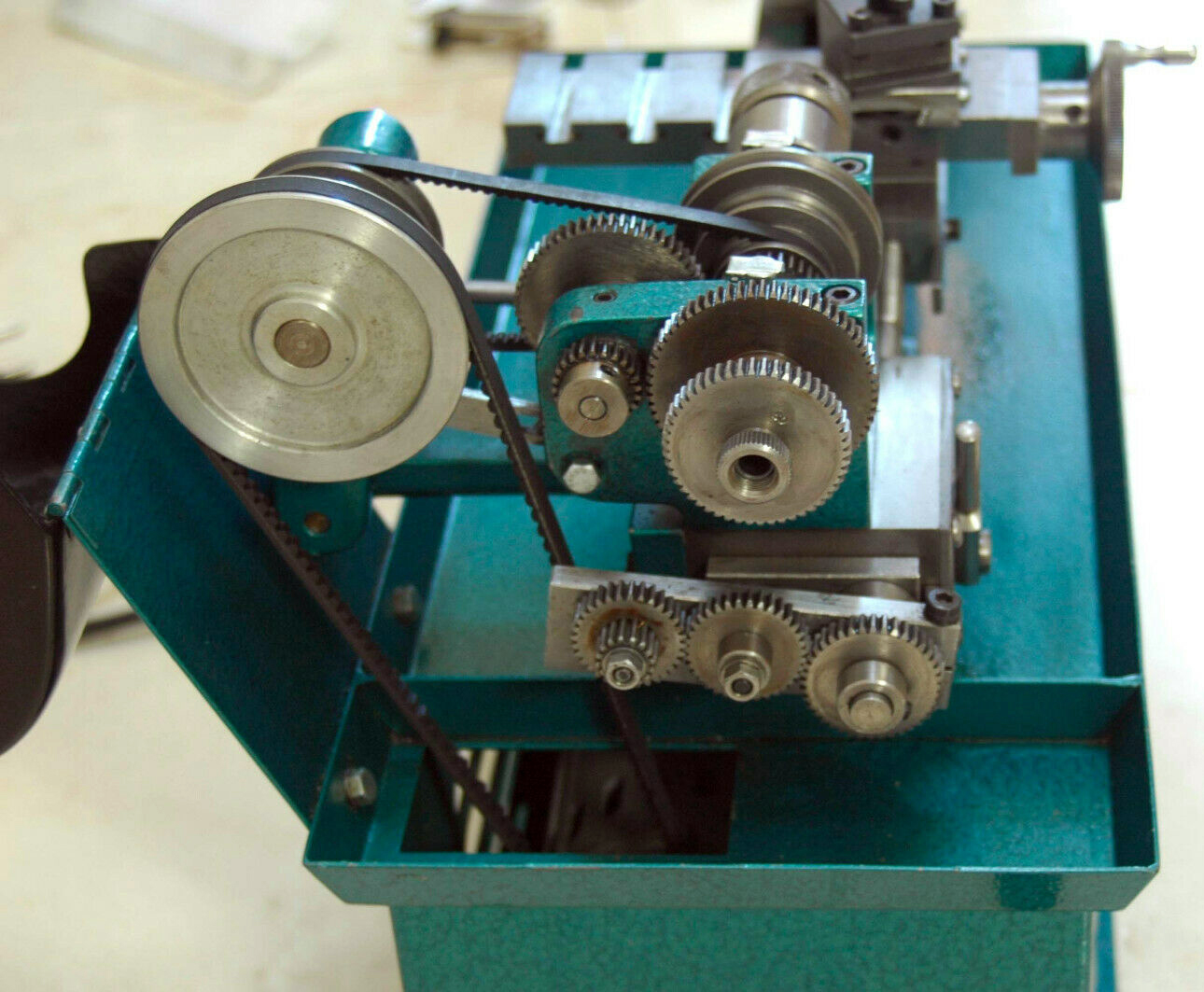

For such small lathes (all are 1.75" centre height by 8" between centres) Cowell's are unusual in incorporating many of the features, and hence the usefulness and adaptability, of larger machines; consequently, the Model 90ME (also with its origins in the Perris PL90) is designed for smaller model engineering use, has a proper backgear assembly (clustered at each side the left-hand headstock bearing) with the 12 speeds spanning 60 to 2100 rpm; the bed has a gap, the cross slide is extra-long and T-slotted, a swivelling top slide is fitted as standard and - most usefully - the saddle traverse incorporates an adjustable, automatic disengage mechanism. On recent models, beautifully finished, chemically blacked zeroing micrometer dials (with the crisp, computer laser etched lines and numbers coloured white) are fitted to all screw-driven movements: compound slide assembly, tailstock barrel and the leadscrew handwheels

Fitted with a double-step pulley on the motor, the rear-mounted countershaft uses miniature V-belts and gives six speeds - the whole drive system being neatly and safely enclosed under a hinged plastic cover. The machine is also mounted on a rigid cast-aluminium base with recesses at each end to facilitate lifting, neatly built-in switchgear and a machined flat at the back that can be used as a mounting for a dial-test indicator or scribing block. A wide range of accessories is available including steadies, collets (including horological types) 4-way and rear toolposts, a vertical milling slide, dividing and indexing units, a roller-filing rest, etc. - and all at surprisingly reasonable prices.

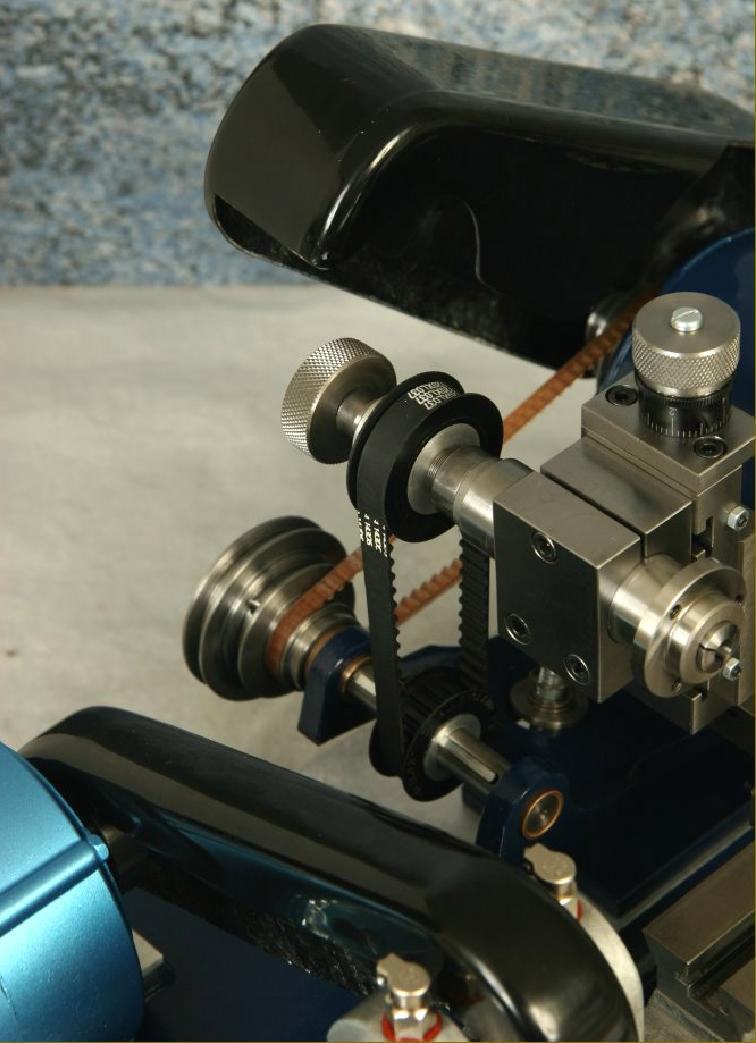

Hand-built on a modular system, it is possible for the makers to combine features from different models in the range - hence the plain-turning clock and watchmakers' version, the Model CW, with its hardened spindle and opposed bronze-bearing headstock can be supplied with the screwcutting mechanism from the ME model to give a power feed along the bed. An earlier version of the CW was the Model HS (presumably standing for High-speed) a model that, like the CW, was powered by a thyristor-controlled motor to give infinitely-variable speeds of up to 4000 r.p.m.

Cowells also make a range of other useful machines including a tiny vertical miller, miniature jigsaws, a wheel and pinion cutter, a small dividing head and, in the past, several small machine tool accessories..