|

A company quite separate from the better known and still current Cowells Small Machine Tools Ltd., E.W. Cowell of 7A Sydney Road, Watford in Hertfordshire were once well known in model-engineering circles for their range of built-it-yourself workshop equipment and offered, during the 1950s and 1960s, kits to construct such useful items as power hacksaws, drilling machines, hand-operated shapers, compound milling tables and machine vices. However, as the country's standard of living improved, there was a decline in demand for this type of low-cost, do-it-yourself product, leaving only keener enthusiasts to attempt what was often a considerable task for completion in a home workshop. A similar situation existed in the United States, with the Pootatuck Corporation (later the David Jones Machine Company) offering sets of castings and drawings to build lathes, shapers and milling machines.

Although, so far as is known, the plain-turning precision 2.5" x 12" Cowell lathe was never offered as a finished machine it was, for a short time during 1953, available as a collection of casting with the larger or more awkward machining operations already completed.

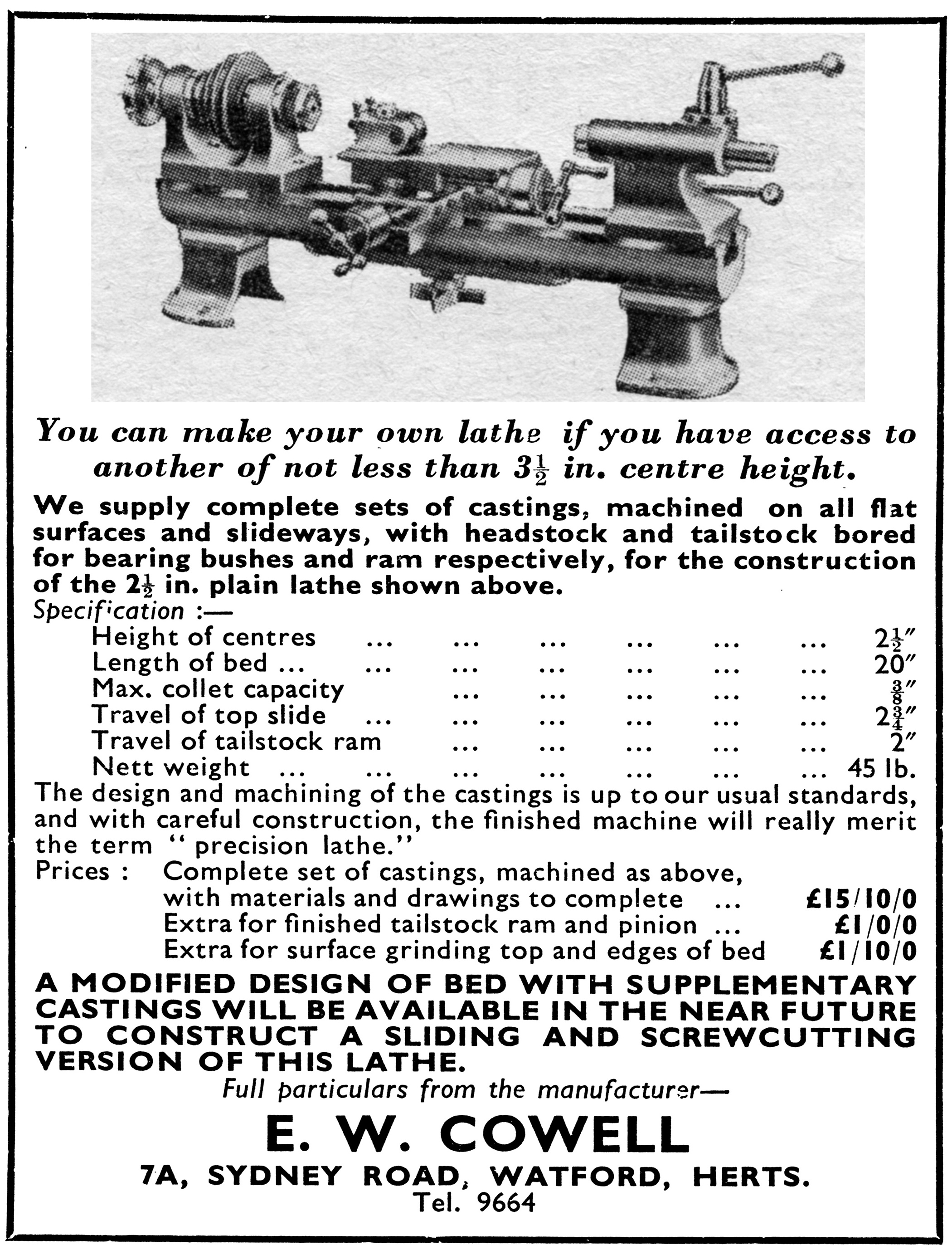

Of distinctive appearance, the E.W. Cowell lathe appears to have been very well engineered with a bed formed in the traditional "bench precision" manner with a semi-circular section and a flat top. However, the edges were vertical, rather than bevelled, and the tailstock located between the ways with the compound aligned by bearing against the front vertical way. Heavily built, the headstock had a spindle running in large-diameter plain bearings and carrying a 3-step drive pulley which looked to have been sized to accept either a "Z" section V-belt or a 7 or 8 mm diameter round type. The tailstock featured a quick-action, rack-driven 2-inch travel spindle, this assembly also being offered an accessory (with a 4-spoke capstan) for a range of small English lathes.

With suitably large (and unusually deep) micrometer dials, the compound slide rest carried what looked to have been an extended-travel copy of the Drummond M-Type top slide with the front half thinned down to mount a Norman Patent quick-set toolholder.

Was the lathe an affordable proposition? In 1953 the generally earned minimum wage for an unskilled man was around £6 for a 44-hour week, making it necessary to labour for three weeks to afford the basic castings with the bed and difficult-to-machine-accurately tailstock bore and spindle factory finished. A skilled man might have managed to earn as much in half that time - and the cost was certainly a considerable saving on the £48 : 5s : 0d asked for a new Myford ML7 (less a motor) and with delivery stretching to almost 4 months. However, once the E.W.Cowell had been built there was also the small matter of constructing a suitable countershaft or different drive system - possibly a variable-speed DC motor.

According to the Company's (very limited) advertising sheets, a screwcutting version of the lathe was planned, though whether it was ever offered is unknown.

If any reader has a Cowell lathe of this type the writer would be very interested to hear from you..

|

|