|

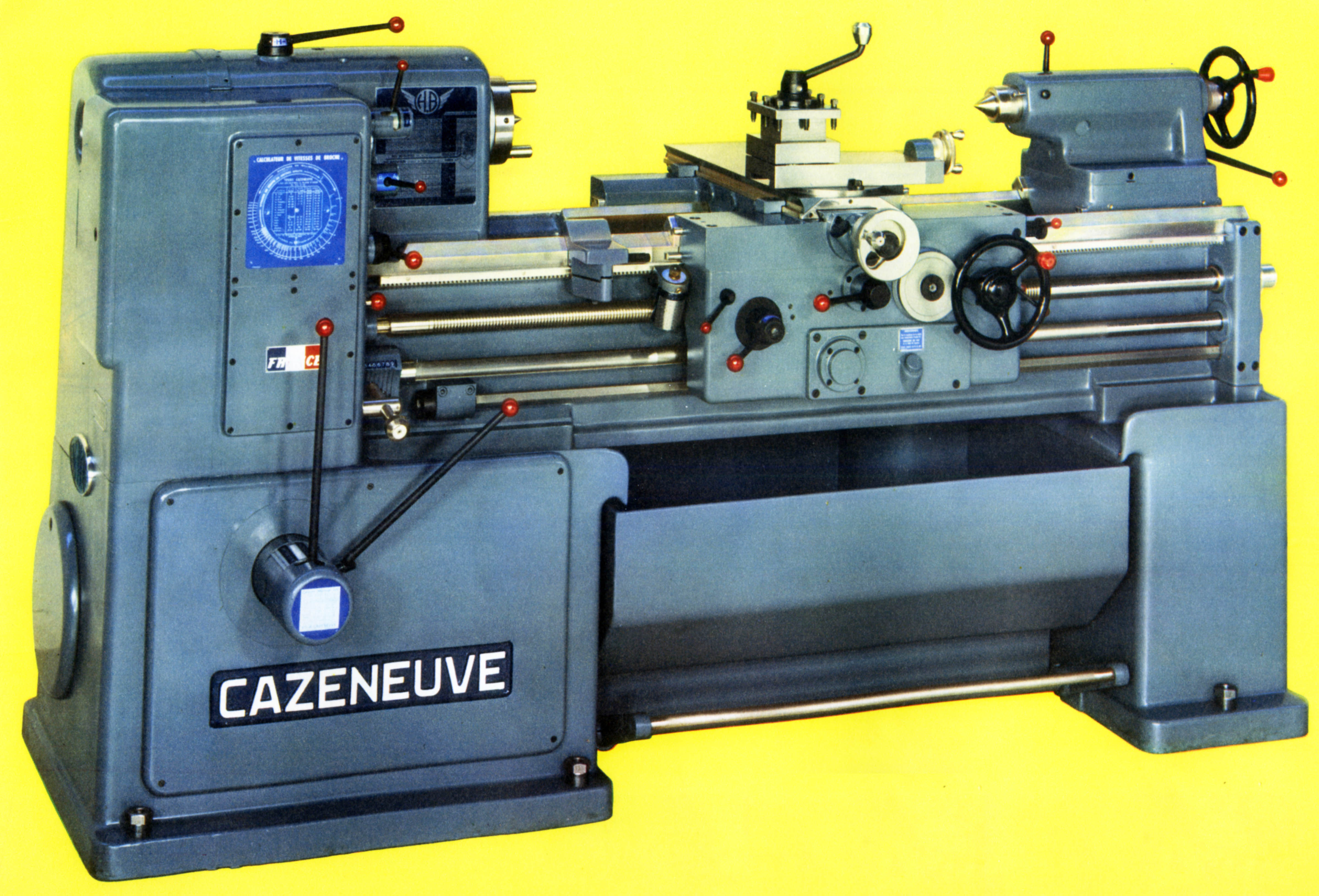

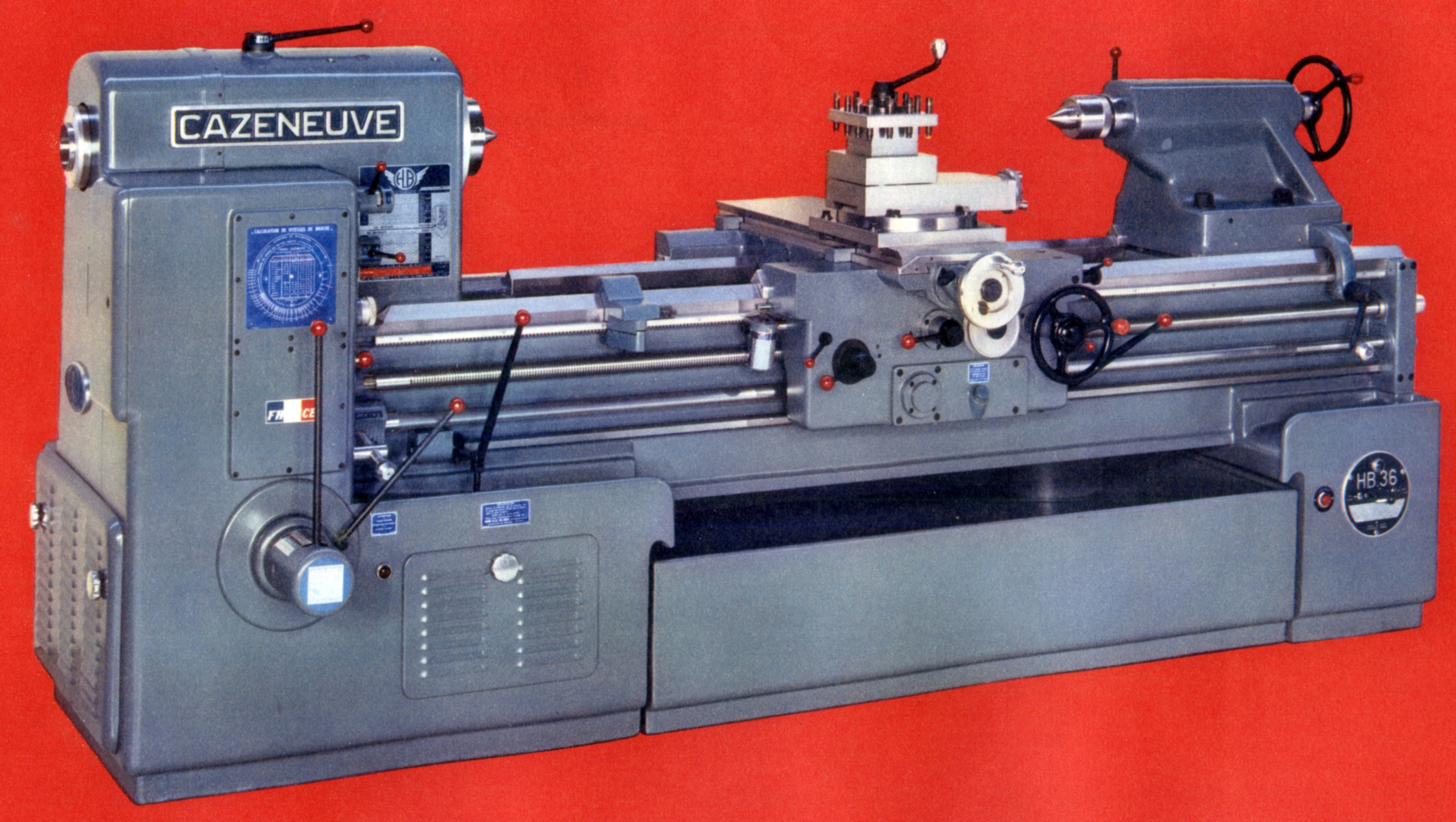

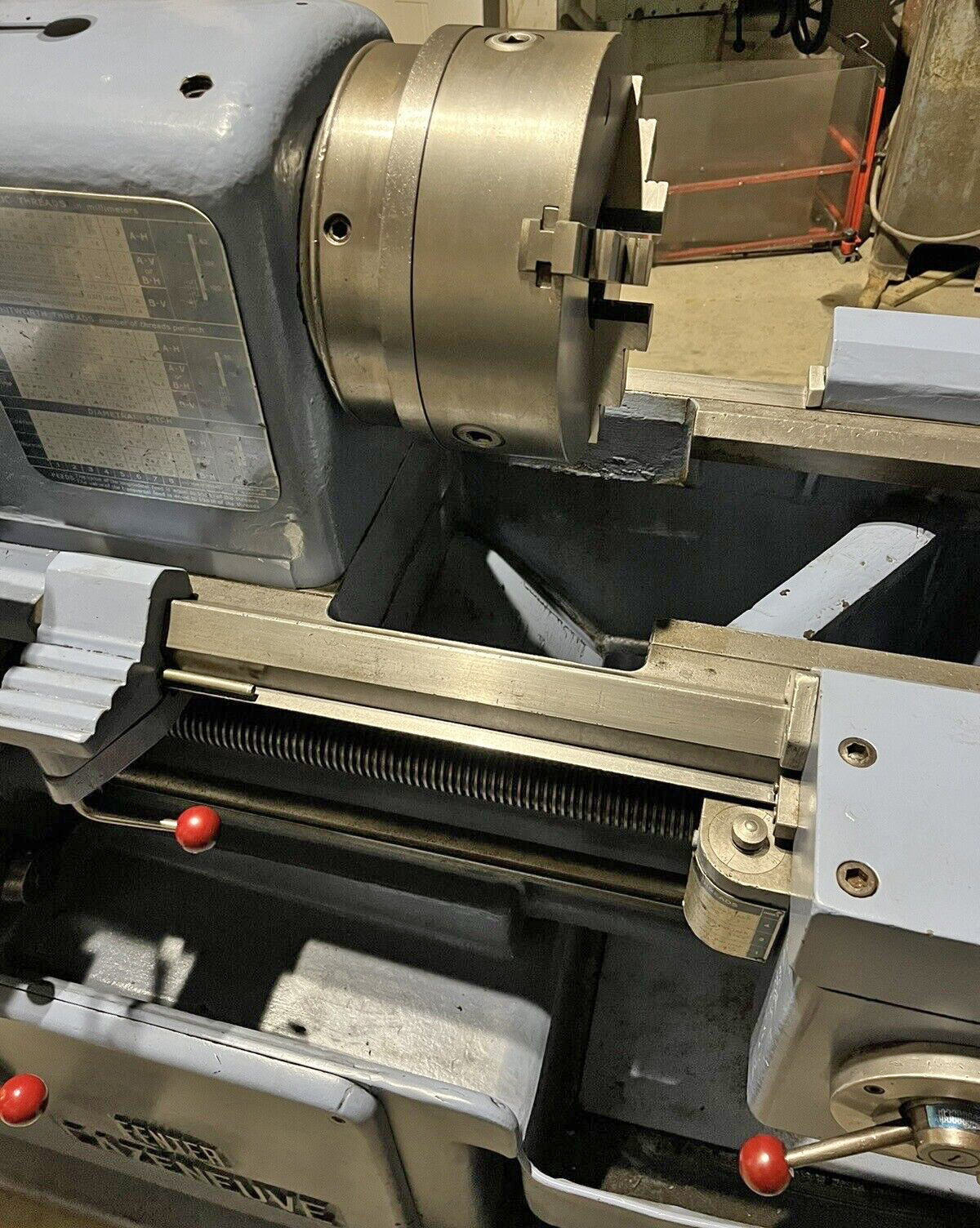

Cazeneuve HB 500 and HB575 - additional pictures on this page

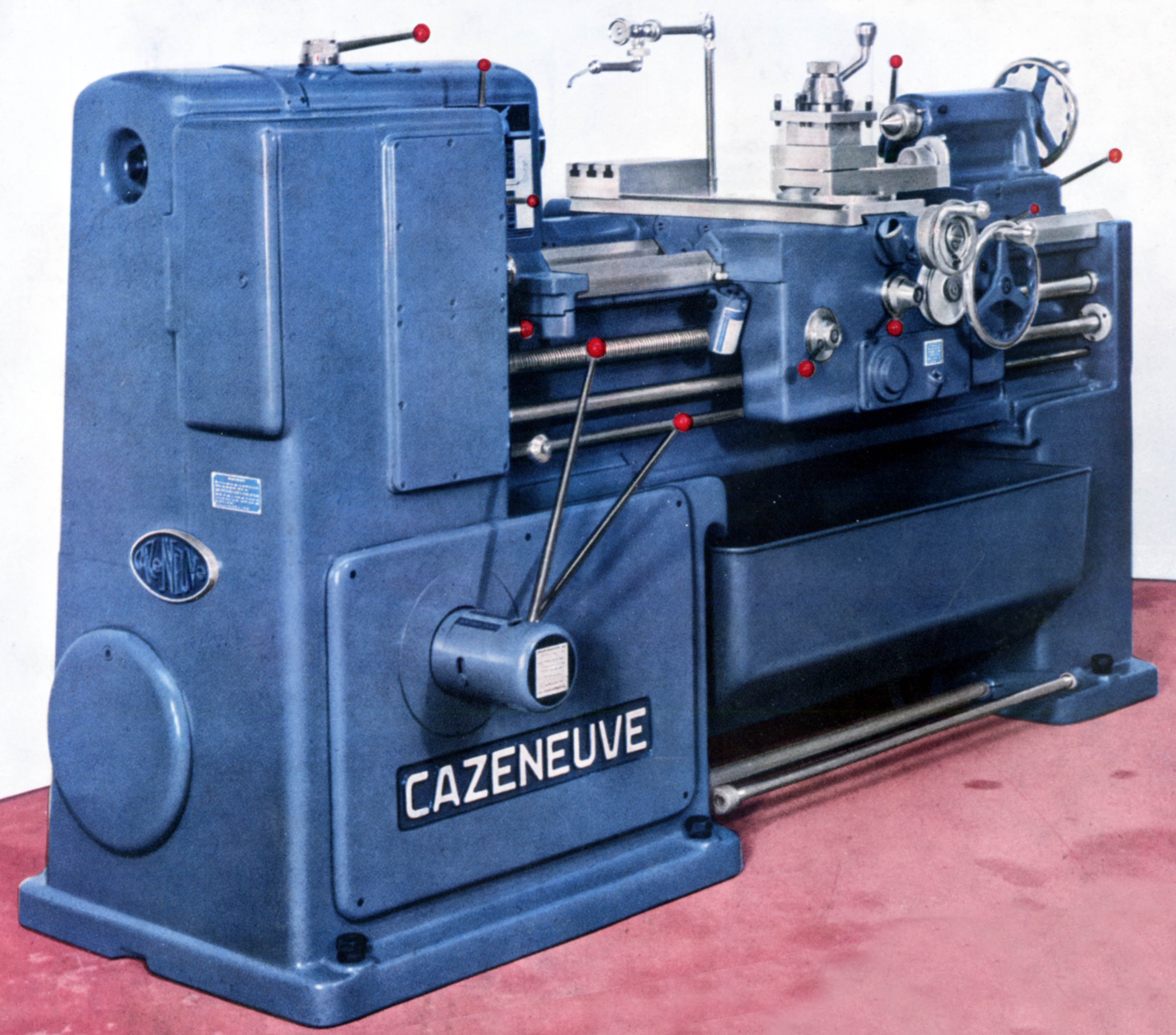

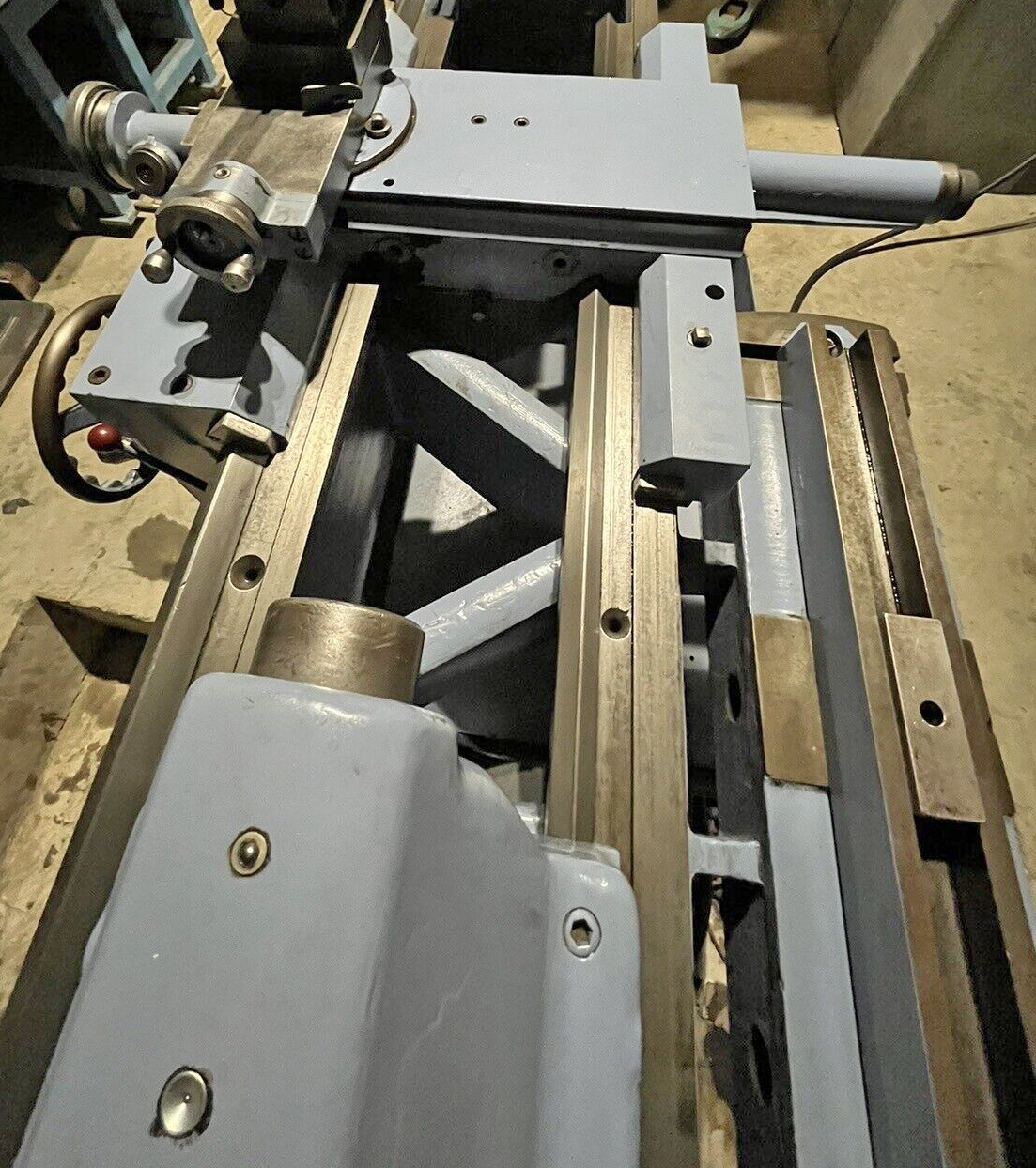

Cazeneuve HB Series lathes were truly impressive machines - the 500/700 lathes for example, with centre heights of approximately 8 and 10 inches respectively, had beds that were 15.75 inches wide. Interestingly, although they just failed to meet that old rule-of-thumb for a toolroom-class lathe which states that the width of the bed must be at least equal to the "swing" (i.e. twice the centre height) these were still lathes of very high accuracy. Made in three different centre heights the models numbers - HB 500, HB 575 and HB 725 - represented the maximum diameter in mm that could be swung over the bed. They could also be ordered in a variety of specifications, to suit particular purposes: with and without full screwcutting, with a straight, gap or semi-gap bed, in a variety of bed lengths, with different spindle nose fittings and with various speed ranges - for example, the 500/700 model shown above could be fitted with either a 7 or 12 HP motor; with the former, a choice of four ranges was offered, each having 18 speeds: 12.5 to 1000 r.p.m. 16 to 1250 rpm 20 to 1600 r.p.m. 25 to 2000 r.p.m. With the 12 h.p. motor installed, the ranges became: 20 to 1600 r.p.m., 25 to 2000, 32 to 2500 and 40 to 3200 r.p.m.

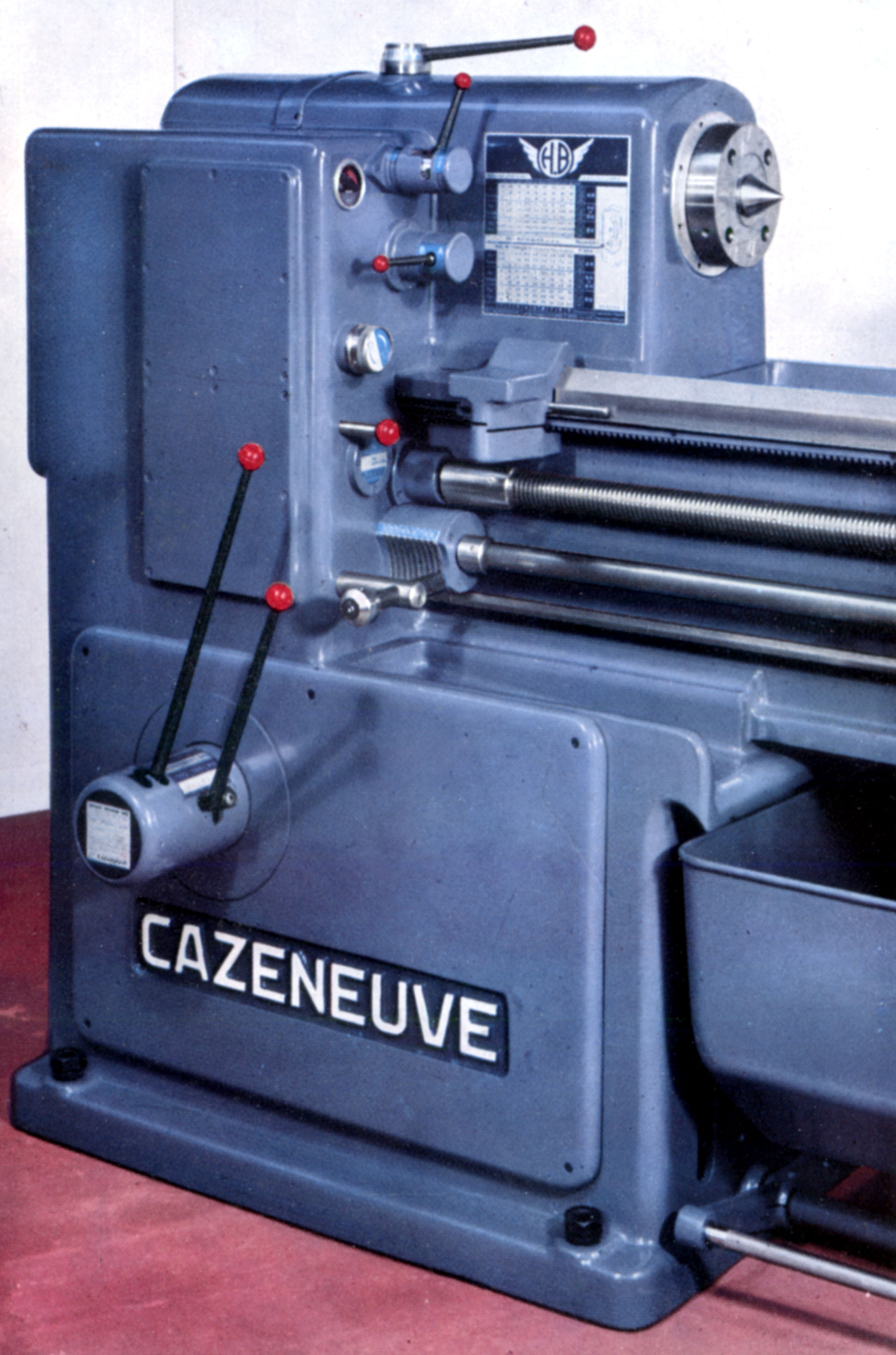

Lubrication was well thought out: the headstock spindle and its gearing system had a pressure-fed a supply of filtered oil while a built-in hand pump allowed the operator to force oil in and dirt out from under the cross and top slides and saddle. Certain restrictions were imposed on the choice of specification: lathes with beds that exceeded 5 feet in length were restricted to a maximum speed of 1600 rpm - while those longer than 6 feet and 8 inches were, wisely, limited to 1600 rpm.

A No. 5 Morse-taper headstock spindle was common to both 500 and 575 models but whilst the former had a bore of 119/32" (40.5 mm) that on the larger lathe was increased to just over 50 mm.

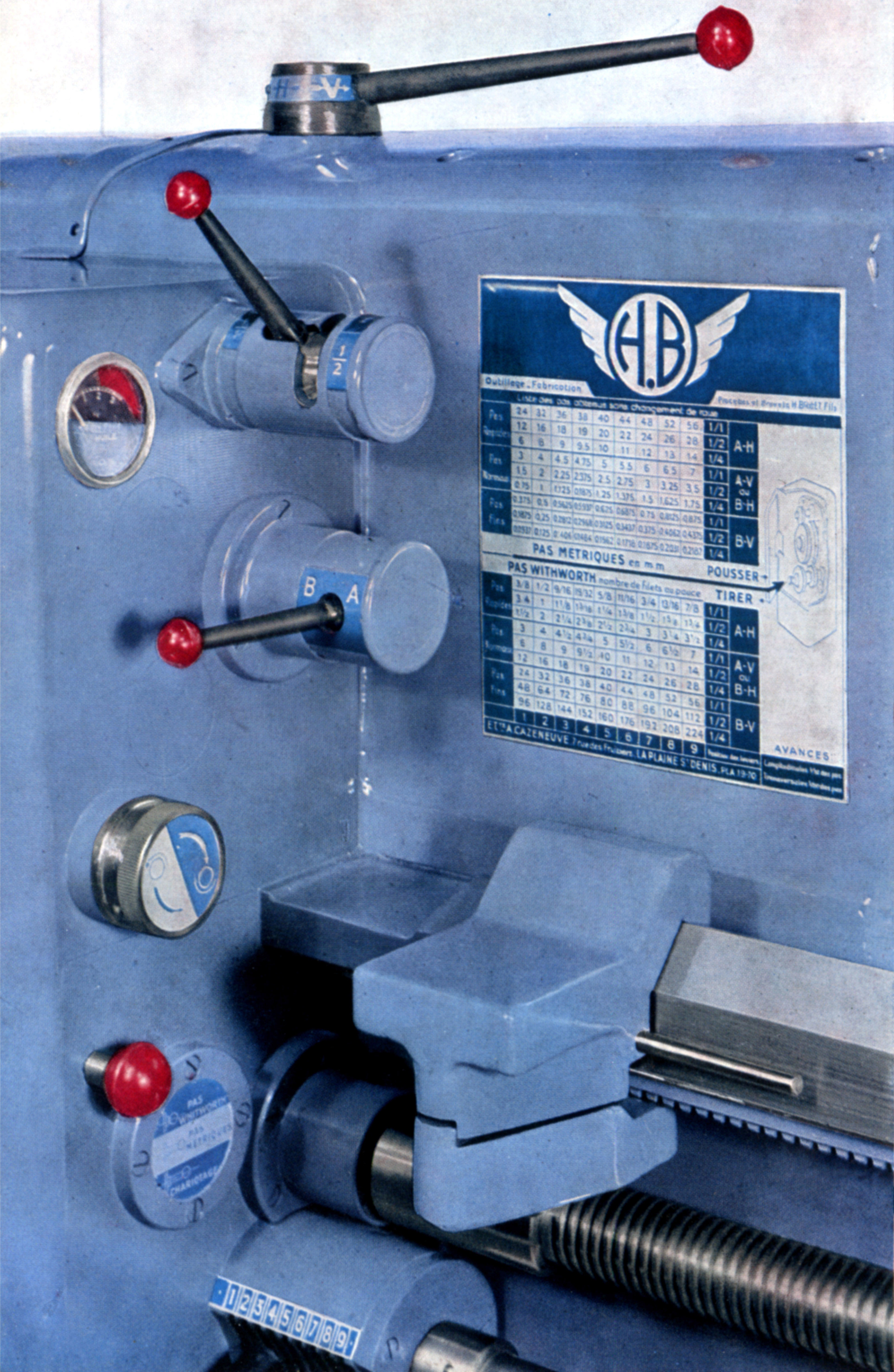

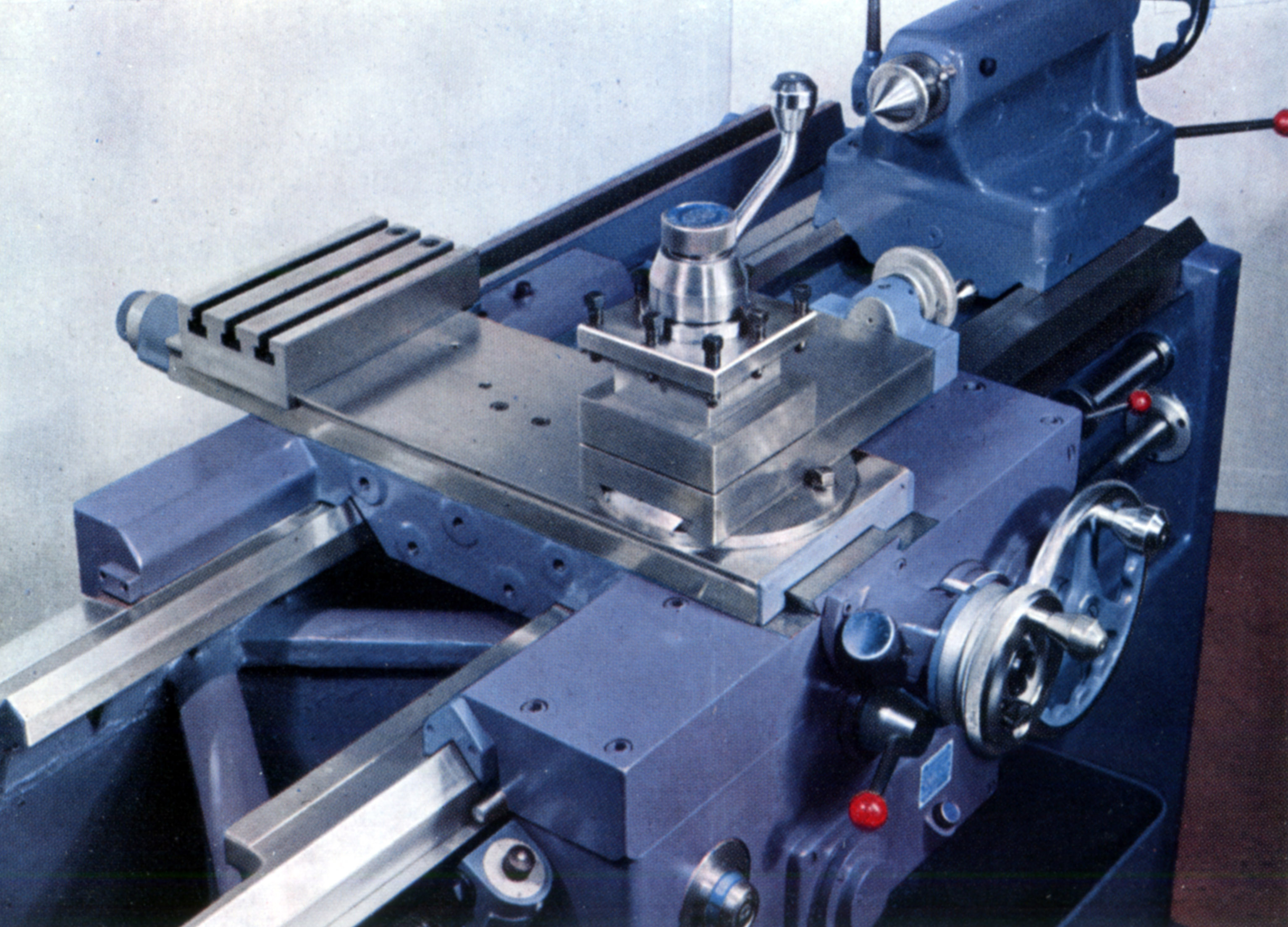

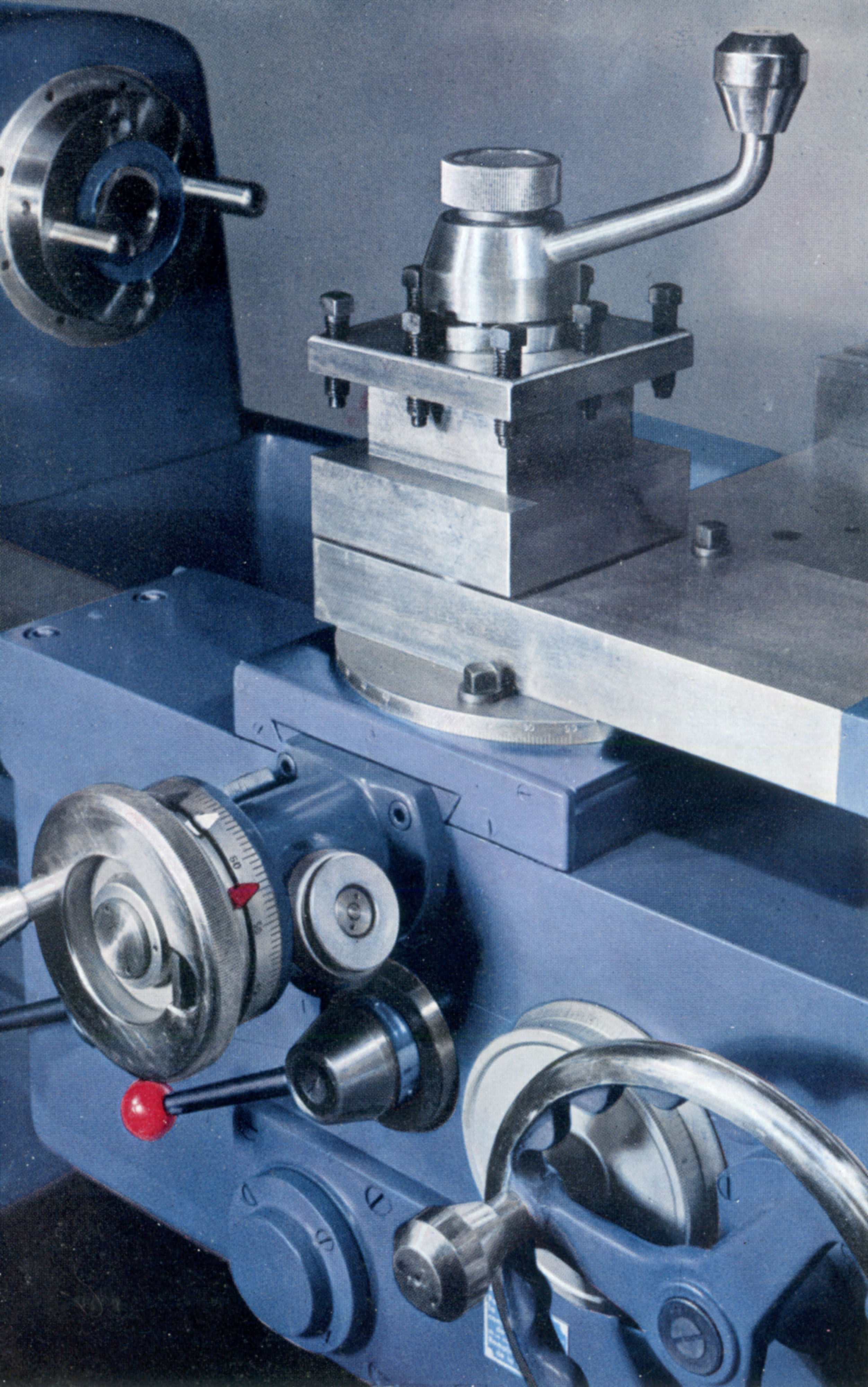

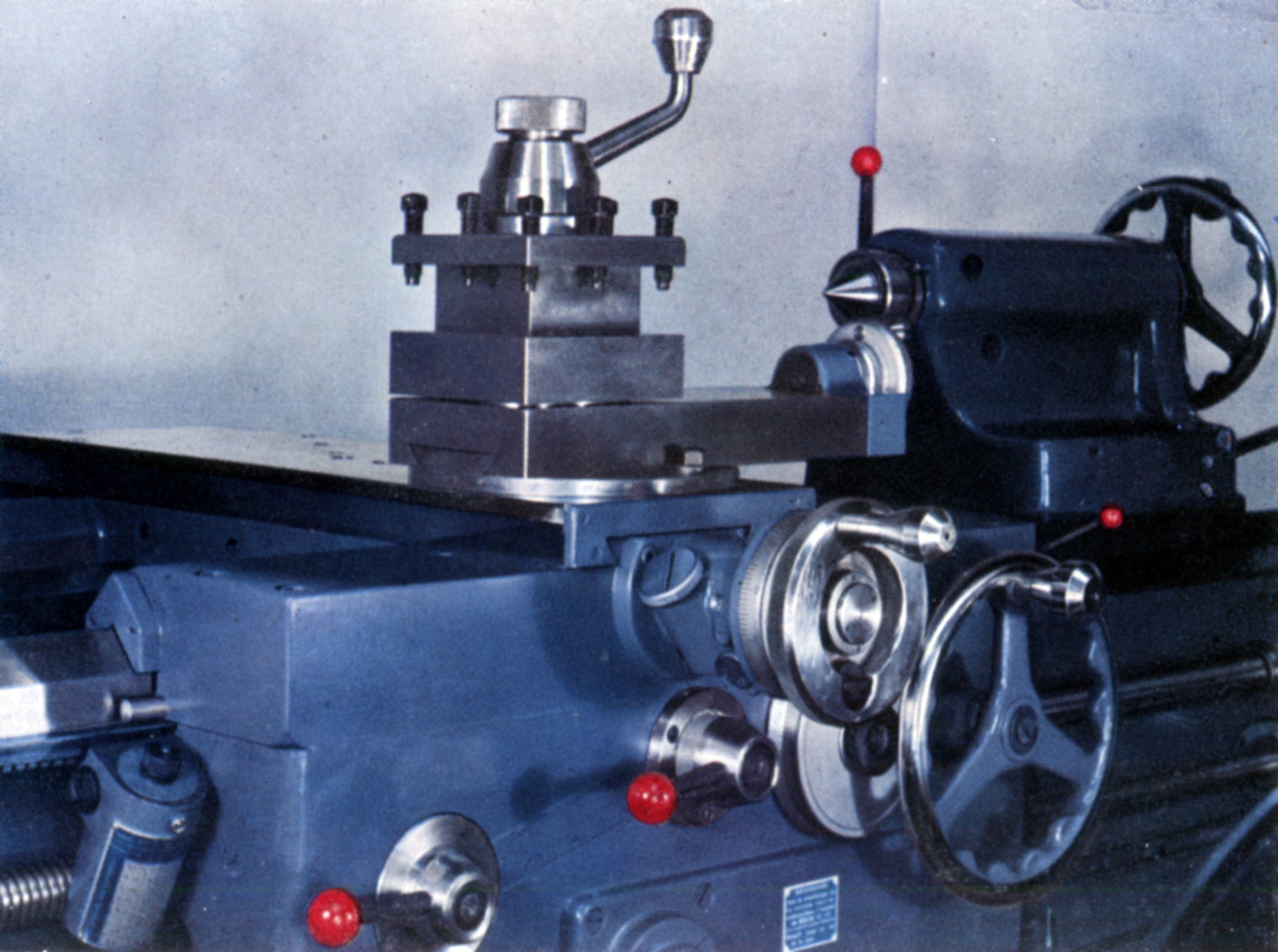

Especially large and very clearly calibrated, the micrometer dials allowed readings down to 0.0001" (0.0025 mm). A graduated dial was also fitted to the carriage handwheel - which itself was fitted with a "counterweight" to help the operator move the mass of the heavy carriage more easily. Both power sliding and surfacing feeds were fitted, with stops to disengage the drive and, in addition (and a useful safety feature) an adjustment was provided to vary the effort required to disengage the feed.

Made of steel, in a deliberate effort to provide extra rigidity when it was locked and heavy cuts taken, the cross slide was particularly strong with its feed screw running submerged in an oil bath. The 4-way toolpost was a Cazeneuve patent, capable of repeating its location to within a claimed 0.0001".

Screwcutting - where fitted - was by an enclosed gearbox able to generate 73 metric pitches and, by changing one gear on the quadrant to a 127 tooth wheel, 73 English.

Lathes with gap beds were able to swing a maximum diameter of 2.625" (HB 500) or 29.5" (HB 575). The total width of the gap on both models was 9.25" and metal up to 6.6875 thick could be run inside the gap on a faceplate.

On certain Cazeneuve models (HB-18 amongst them) an unusual mechanism was included (operated by a lever on top of the headstock) that disengaged the spindle from the drive train yet left the feed and screwcutting system engaged. In short, with the spindle disengaged all the power feeds to the carriage and cross slide were still available and could be used to cut splines and keyways using the carriage feed - the only drawback being that no provision was included to index the spindle..

|

|