|

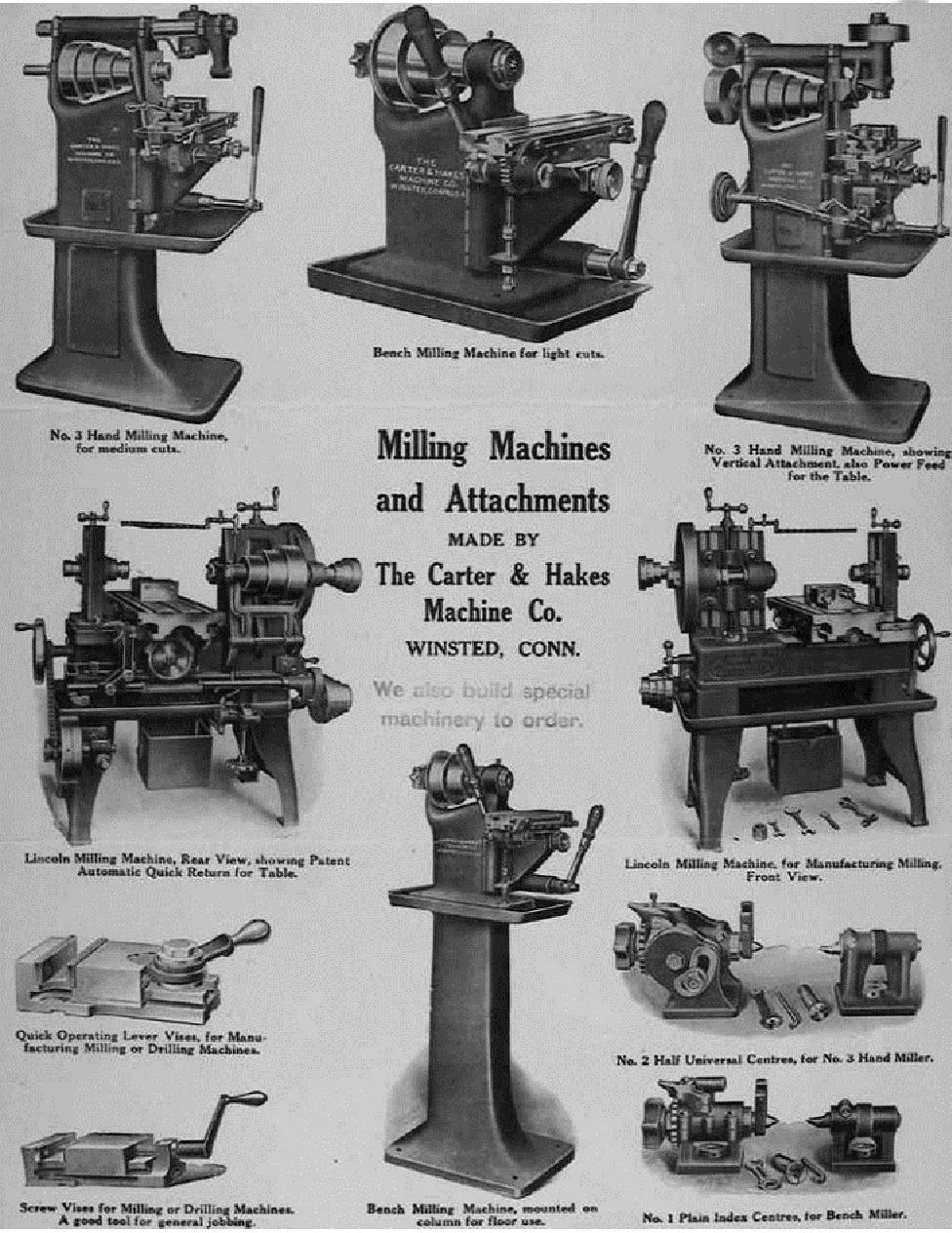

Carter & Hakes of Winstead, Conn (founded in 1899), produced a range of milling machines including conventional horizontal and vertical models and a number of the "Lincoln" type - these having a fixed-height table and elevating cutter head. The tiny horizontal precision "stub" milling machine shown below bore a close resemblance to similar models offered by the better-known makers of high-class lathes such as Ames, Cataract and Hardinge, Pratt & Whitney, Rivett, Stark and Waltham, etc.

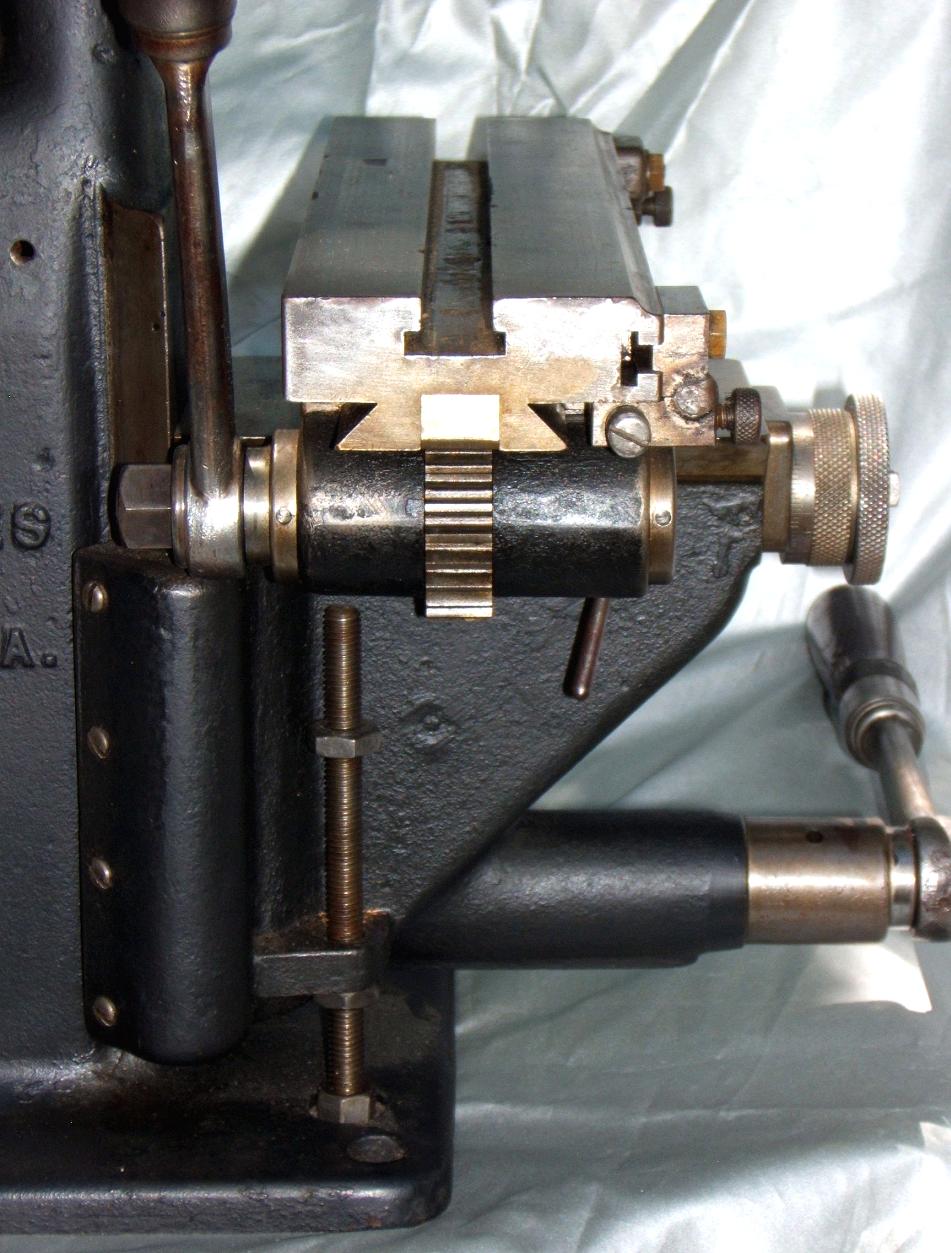

Manufactured from 1904 until 1920 (or possibly later) the miller stood on a 7" x 10" cast-iron base with the single T-slot table being 12" long and having very restricted travel movements of 3" both longitudinally and in traverse and 2" vertically. On this model only the traverse feed was by screw (with a micrometer dial) with substantial, wooden-tipped levers controlling the longitudinal and vertical motions - for the latter action the knee had to be lifted, an abutment stop on a stud screwed up or down and the table set back down against it.

Following the pattern of contemporary precision bench lathes, the spindle ran in bronze bearings, the front 2" in diameter, tapered on the inside but parallel on the outside and pinned to prevent rotation. With this bearing assembled, the spindle could be moved forwards and backwards to set the running clearance with a ring, mounted inboard of the end bearing and bearing against the end face of the pulley, being provided for this propose. The split rear bearing, 15/8" in diameter, had a parallel bore and a tapered outside, being drawn into a tapered seat formed as a sleeve pinned into the head casting. In order to provide a positive location or "stop" as the bearing was compressed, a long, thin, tapered wedge was fitted into the split and trapped between the adjuster rings - the ends of the wedge being stepped so that they sat below the root diameter of the thread. To ensure that the minimum amount of distortion as the bearing was compressed, two longitudinal slots were cut in the outside to provide some extra flexibility. On the machine shown below all the parts are assembly stamped, the spindle being marked "2" and both the front and rear bearings stamped "2" and "19" - the threaded retainer collars numbered "2" and "19."

With reasonably large spindle bearings, just three very wide pulleys (where there was room for four narrower but still adequate ones) and no overarm to support a cutter-holding arbor, the miller would have been intended for continuous running on very simple but high-accuracy production jobs. However, the makers would, no doubt, have offered a range of optional extras - perhaps a screw-feed conversion for each axis for one-off precision jobs, dividing heads, angle plates and swivel-base machine vises - to extend its capabilities.

Should any reader have a Carter and Hakes machine tool, or any literature about the Company, the writer would be interested to hear from you.

|

|