|

Based, originally, in Sowerby Bridge, Yorkshire, Henry Broadbent Ltd. was, for decades, one of the UK's leading maker of lathes. In later years they became part of the Kerry Group and amalgamated with another Kerry-owned Company, Oldfield & Schofield to become Broadbent-Schofield Ltd. - the group having factories in Halifax, Sowerby Bridge, Mytholmroyd and Barnsley (the latter town the home of Qualters & Smith, makers of metal saws, drilling machines and lathes re-branded from the makers Kerry and Harrison)

Only larger and specialised lathes were offered by Broadbent and Broadfield-Schofield including the Types C BSB BSC BSD BSH BSN BSV BSX, several types without model designation but just described as, for example, "Oil Country Heavy and Medium", "Dual Spindle", Drum Turning and Grooving". By the 1970s, the heavy K Series was in production along with a wide range of other lathes including centre lathes types 2534, 3748 and 4860; surfacing and boring lathes were listed as the BSX 1820S, BSN 2225S, 2534S, 3748S and 6084S; Oil Country and Crane Drum lathes were catalogued as the 1215HS and 6072S with vertical boring and turning mills manufactured in the Series 60, 72, 96 and 108, Shaping machines were divided into the Series 20 and 36 and, as ever, the makers offered to make one-off machines - typically for railway wheel and special purpose jobs - to a customer's specification.

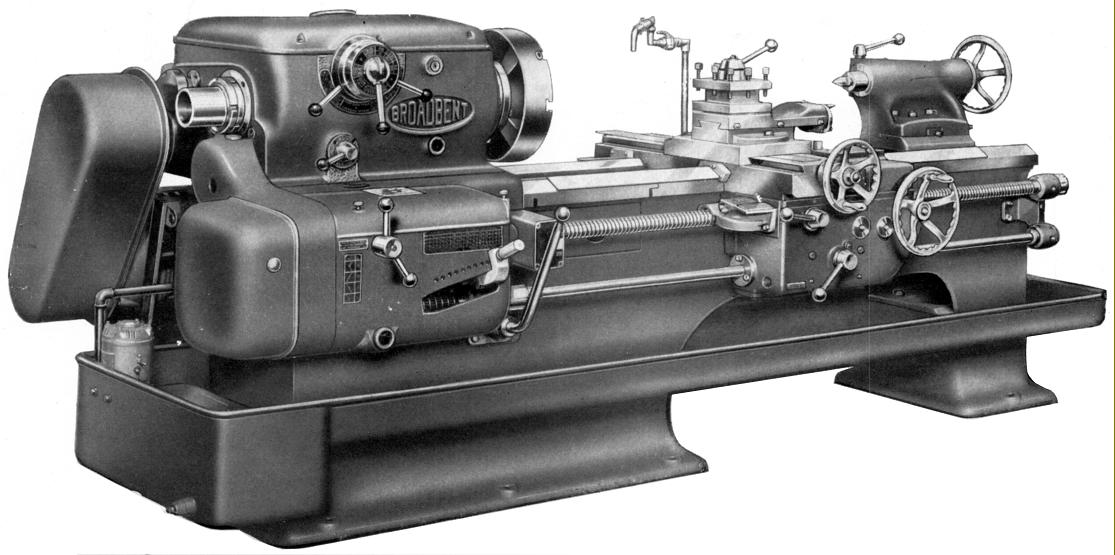

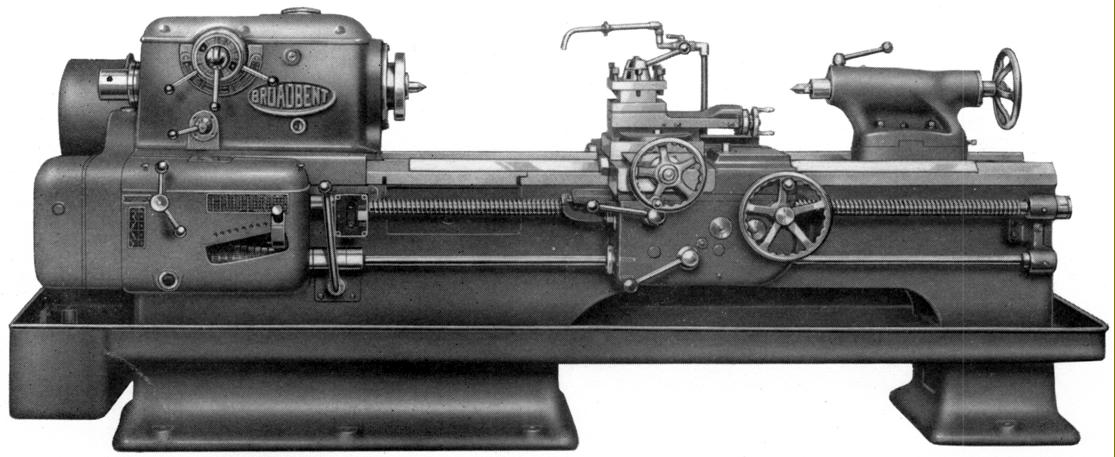

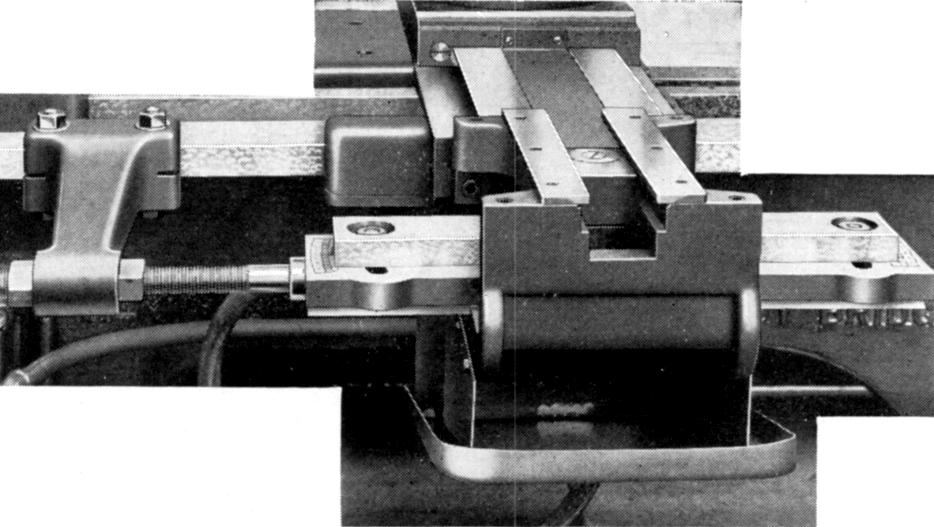

The smallest types made by the factory were the early and also un-named 12" and 14", and the two models covered on this page, the L8V and L10V - which, apart from their centre height (the former 8.5" and the latter 10") were identical. Between-centres capacities were 48 and 72 inches respectively - though longer beds could be provided to special order. With deep walls, the unhardened bed was cast as a box section 17.75" wide and strongly braced by diagonal ribs; a detachable gap section, able to accept work 17.75 inches in diameter and up to 11-inches thick when mounted on a faceplate, was provided as standard, The section beneath the gap, normally a point of weakness on such lathes, was strengthened by an extended headstock-end foot that reached to the half-way point of the bed's full length. V and flat ways were used, the former of the symmetrical type.

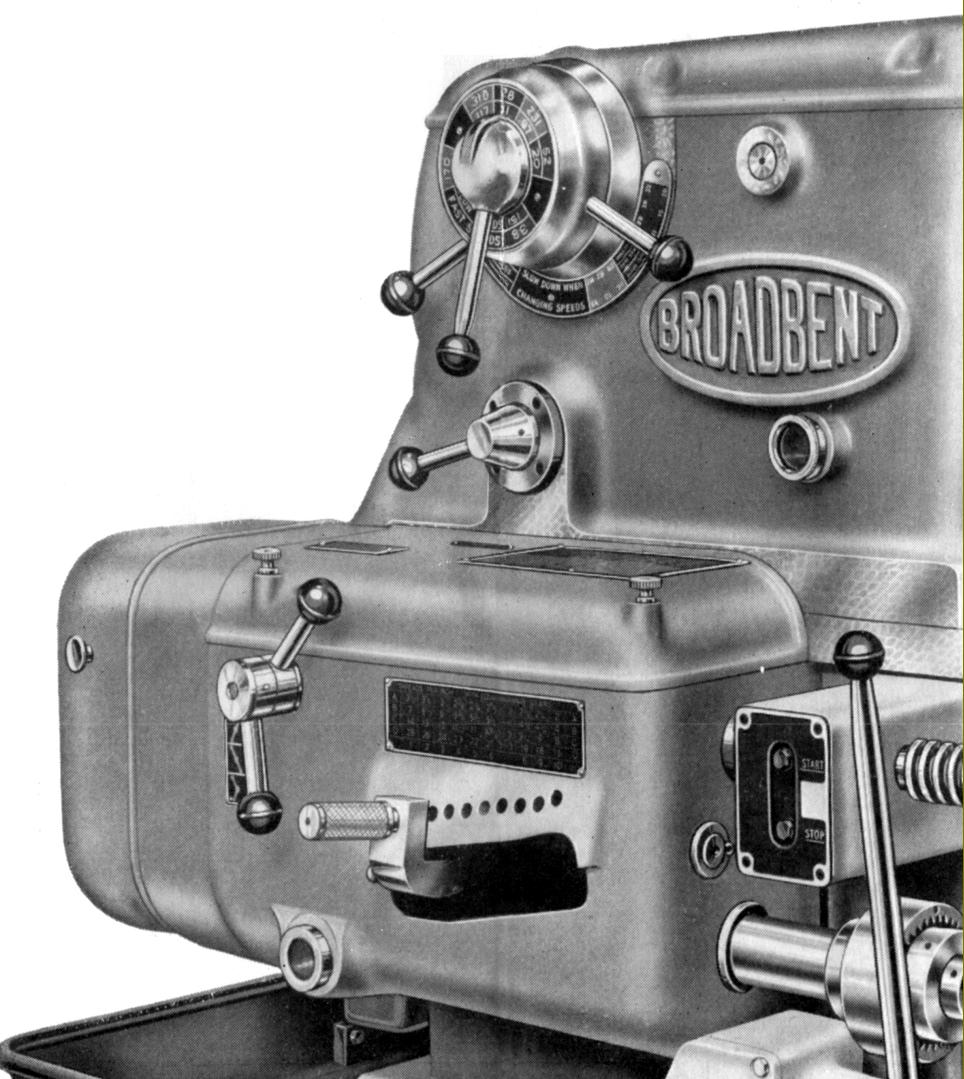

Holding gears of heat-treated, nickel-chrome steel sliding on splined shafts supported in ball bearings, the headstock was equipped with a gear-type oil pump that supplied lubricant under pressure. Bored though 3.125" the spindle, forged from high-carbon steel, ran in anti-friction bearings, the pair at the front being Timken taper rollers 4.75" in diameter and at the rear a 4" ball-journal type. The spindle nose was normally supplied as a flange to which fittings could be bolted, but as an option the makers offered an American A1-8 short-taper nose - and presumably any other fitting the customer desired. Drive came from a single-speed mounted on an easily adjusted swing plate at the rear of the bed with power transmitted to the 10-inch diameter headstock pulley through multiple V-belts; the makers also offering the option of a 4.25-inch wide flat belt. For the 8.5-inch lathe a 5 h.p. motor was supplied and for the 10-inch a 10 h.p., both running at 960 r.p.m. To control the spindle's rotation - start, brake to a stop and instant reverse - a double-sided, multi-plate oil-immersed clutch-cum-brake unit was fitted outboard of the headstock pulley with control by a single lever just to the right of the screwcutting gearbox - though on those machines where the bed length exceeded 10 feet, a second lever was provided, pivoting from, and hence moving with, the apron. Twelve spindle speeds were provided that ranged from 17 to 500 r.p.m. on the smaller model and from 14 to 410 r.p.m. on the larger - both sets being considered rather slow even by the standards of the 1940s.

Continued below:

|

|