|

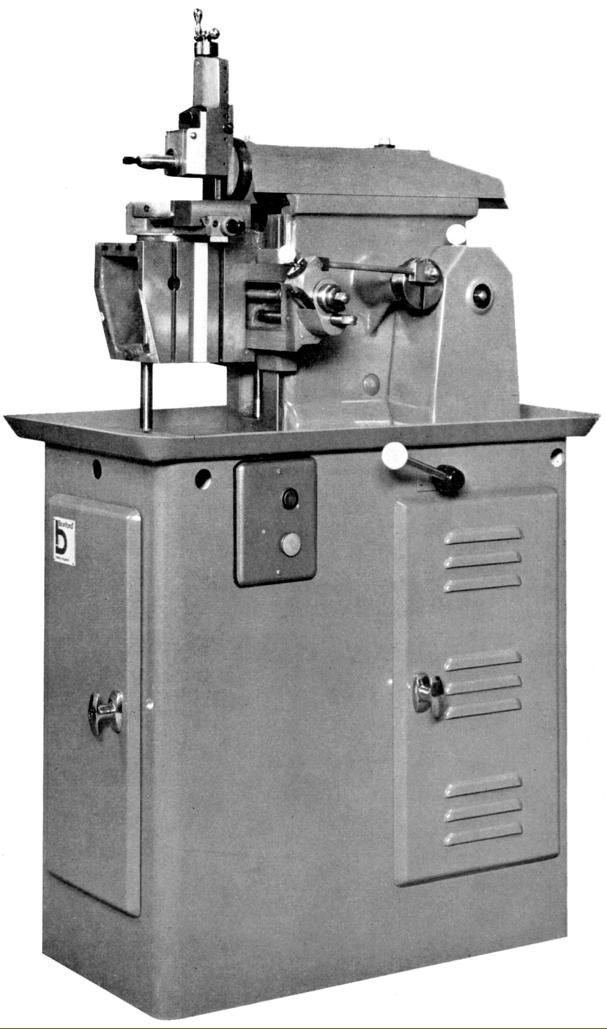

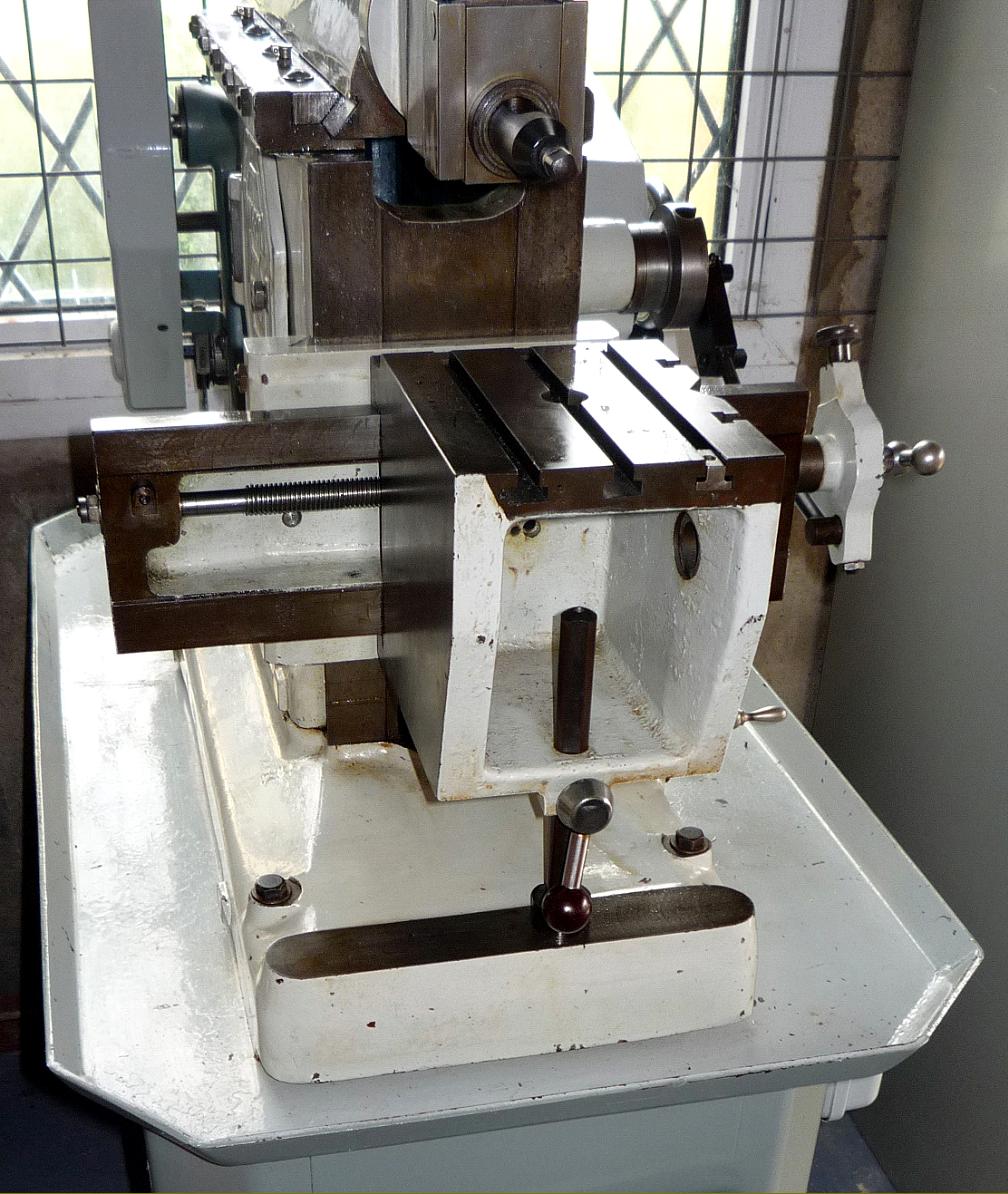

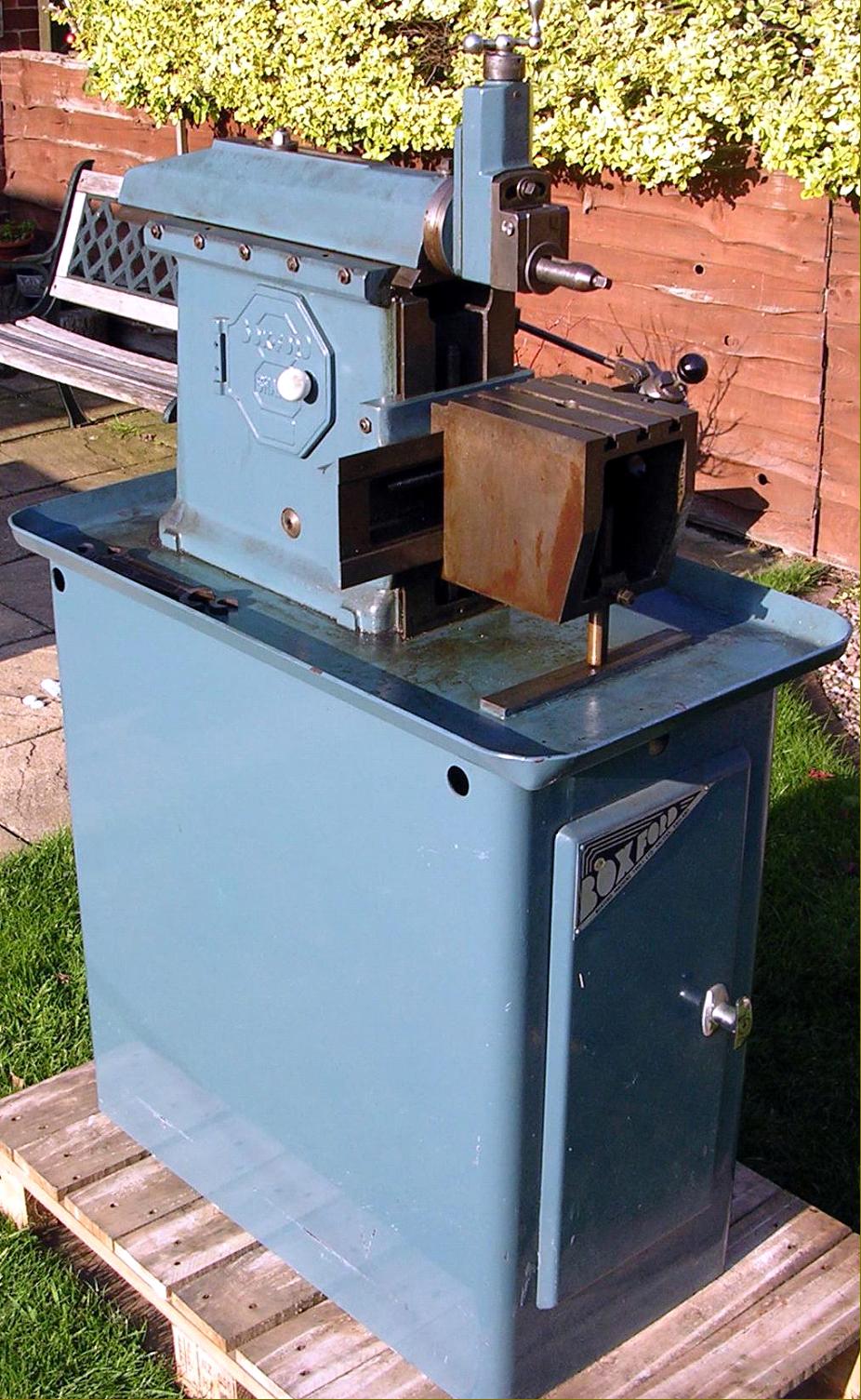

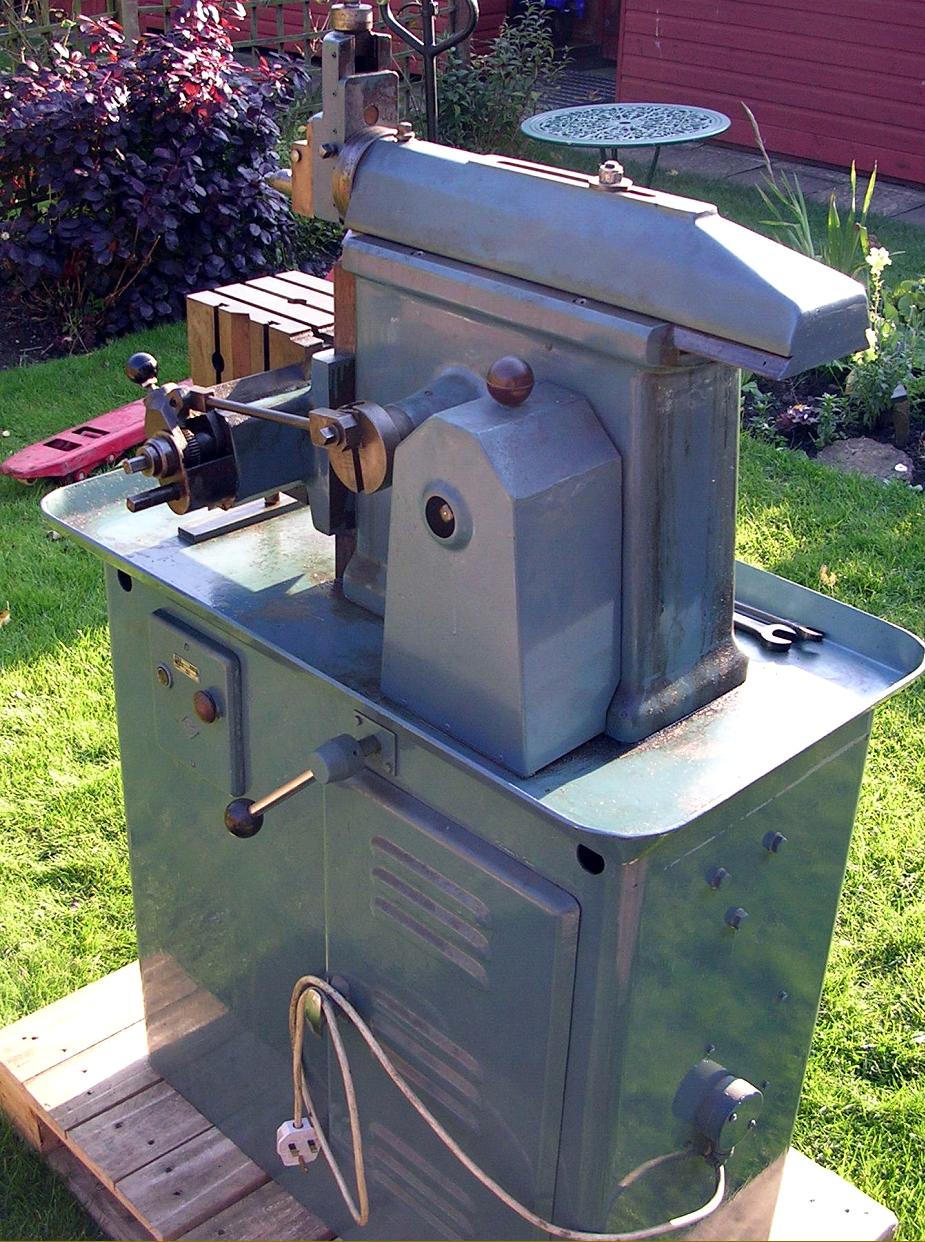

Introduced during the 1950s, the handy little Boxford 8-inch (200 mm) shaper was made in two distinct forms: an early and now rare Mk. 1 version, with an external, rear-mounted countershaft (that was a slightly modified copy of the long-established South Bend type) and a later Mk. 2 model mounted on an enclosed underdrive stand designed to help improve safety in educational and training establishments. Inside the stand was a complete countershaft drive system (with either a 0.5 h.p. or 0.75 h.p. motor) using V-belts to transmit the drive to an external (but guarded) 4-step pulley. Eventually to be called the Model S200, the Boxford sold well into educational establishments though, as a result of timid instructors, many of them emerged onto the second-hand market in pristine condition - the great majority of them appearing to have never been used (the ones in the writer's school being in the latter category - indeed, we even had to gain entry to the metalwork shop in a "suppositious way" at lunchtime in order to make parts for our motorcycles…) |

|

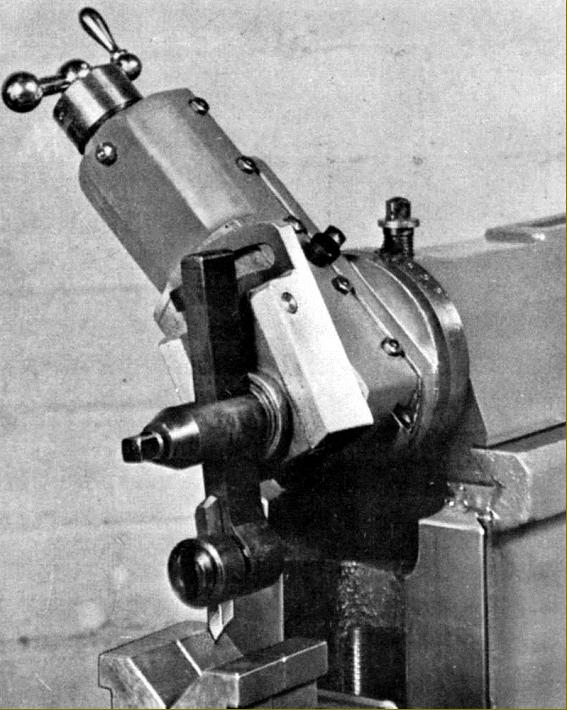

Mk.2 Boxford shaper on its neat underdrive cabinet stand |

||

|

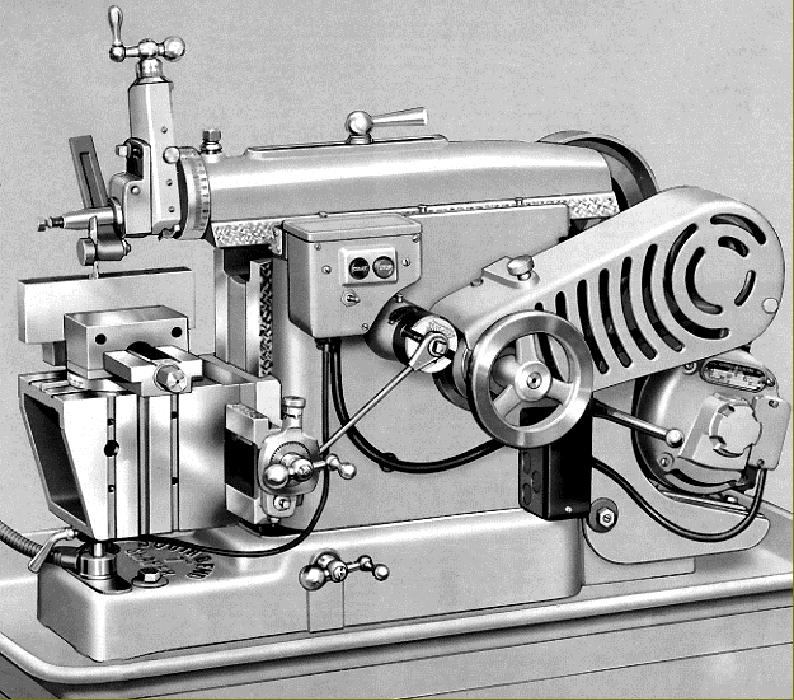

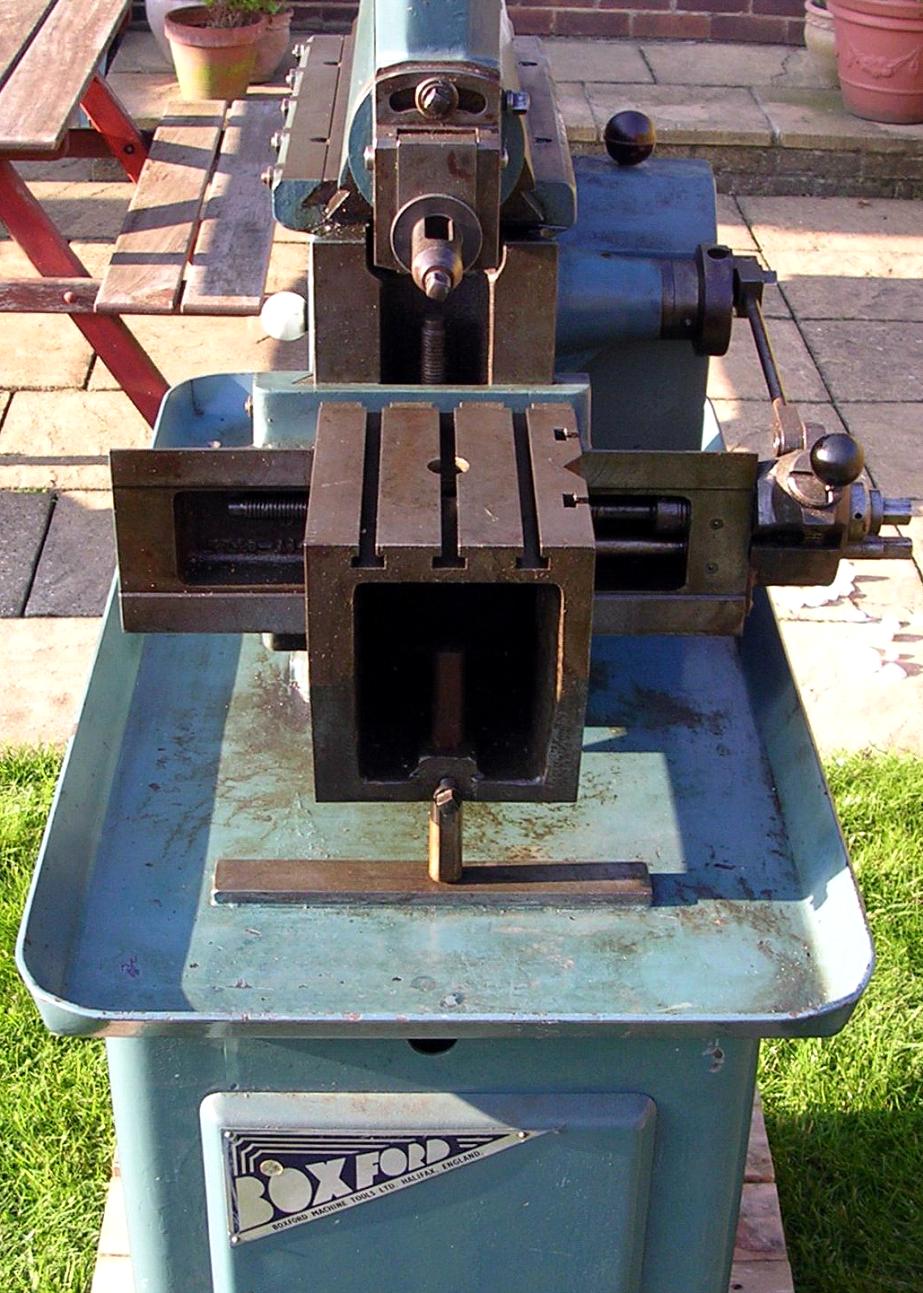

The very rare early Boxford shaper on the maker's stand and equipped with a rear mounted countershaft. This model was a modified copy of the South Bend shaper, a machine that had been introduced during 1950. Although some parts may have been interchangeable between the early and late Boxford types, all the main castings appear to have been different. In addition to the rear-mounted drive system, the first Boxfords to be produced retained the South Bend method of elevating the table, with a handwheel set low down on the right-hand face of the main casting. Underdrive models had the table lift altered, with a second cross shaft, square-ended to take a crank handle and positioned below and parallel to the table-feed screw. |

|

|

|

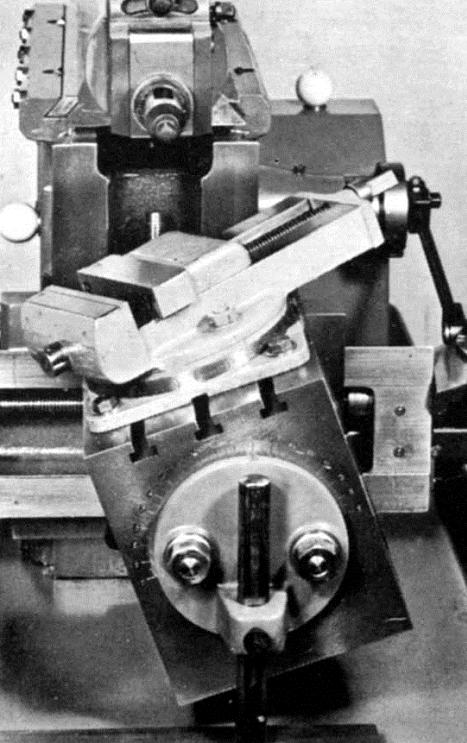

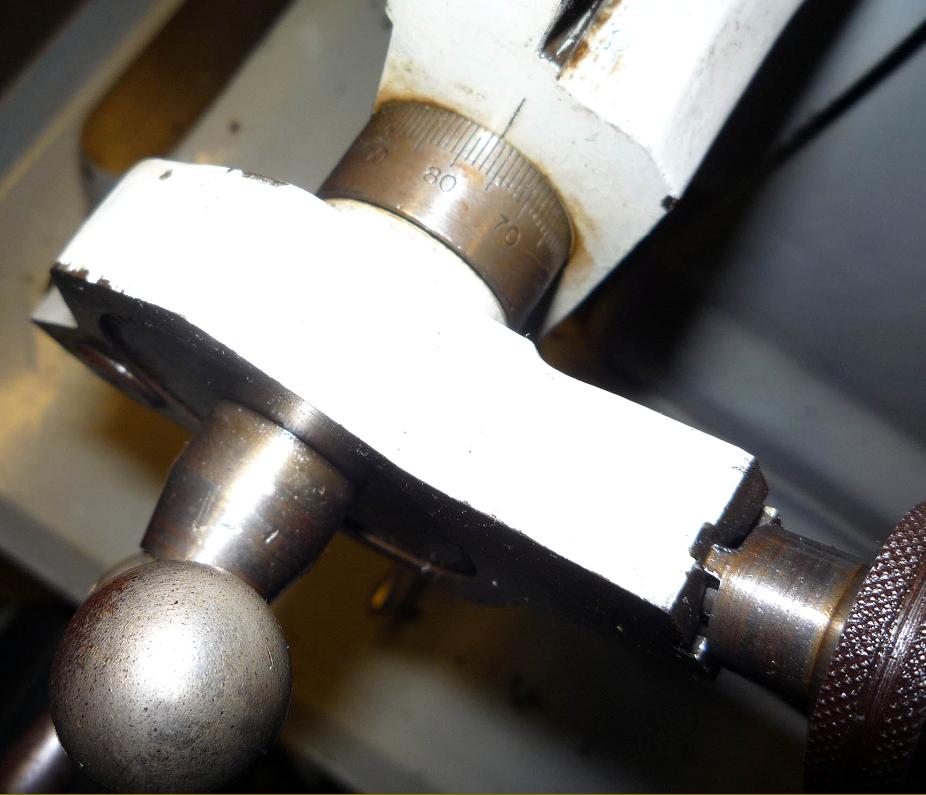

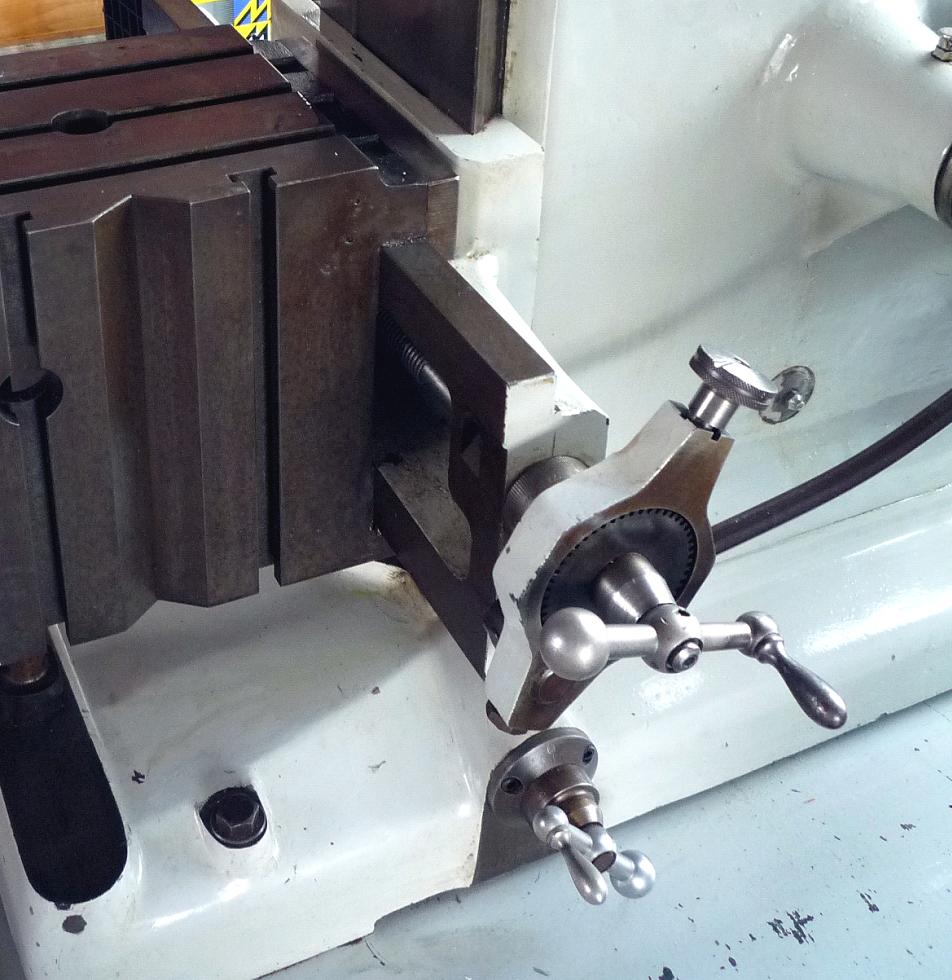

The rarely-found swivelling table |

||

|

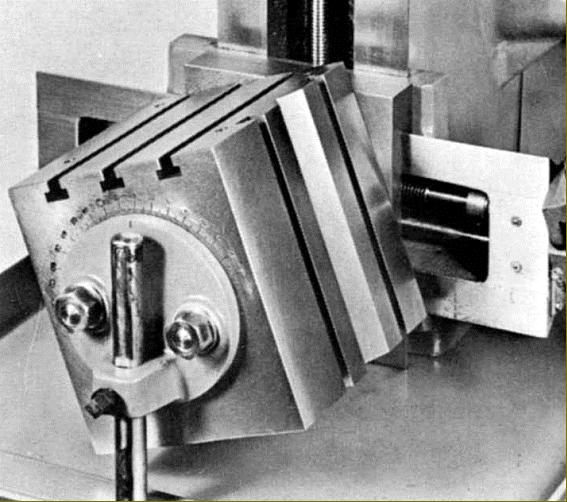

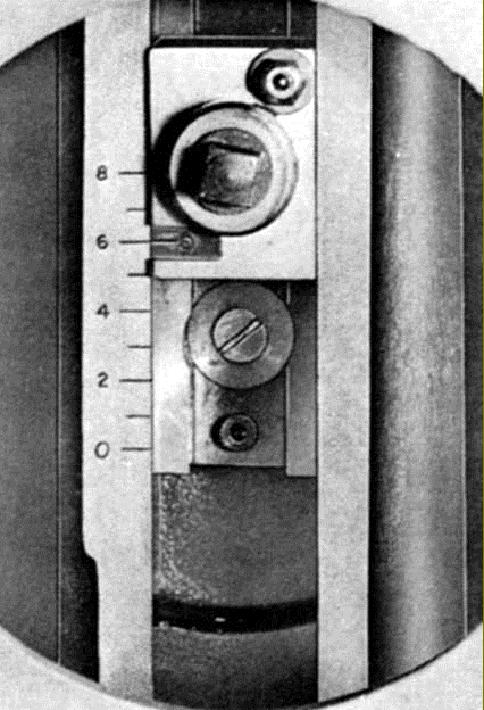

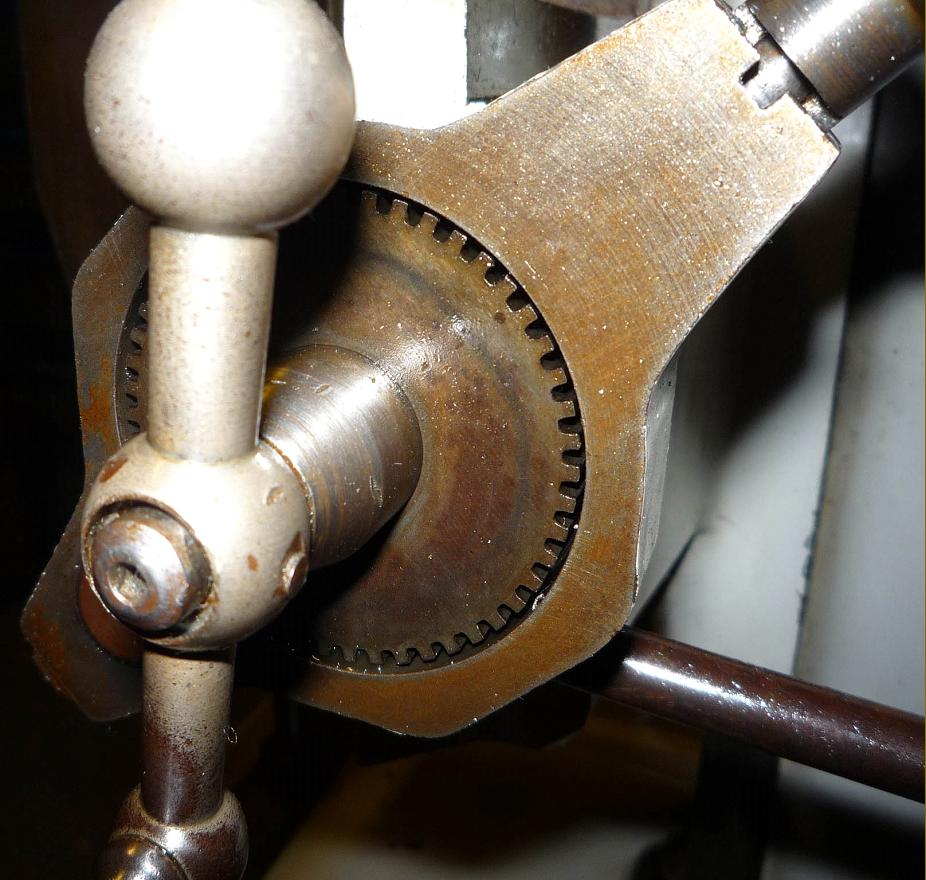

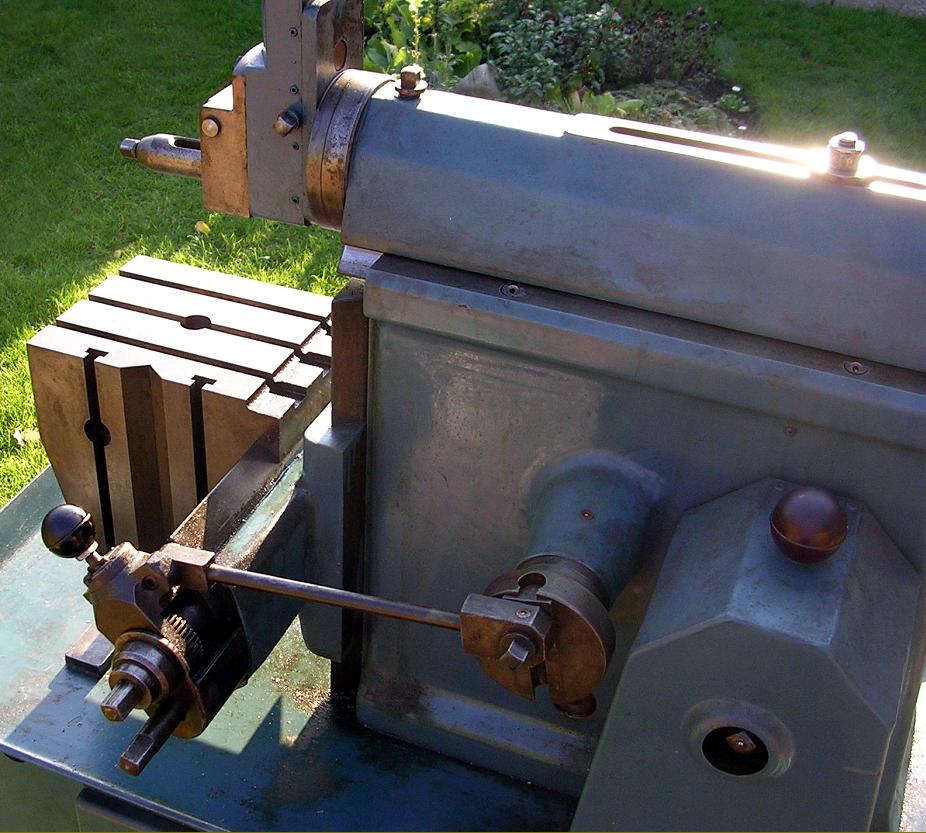

Face of the crank gear and the marks used to set the stroke length |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

An Operation and Parts Manual is available for the Boxford shaper Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories |