|

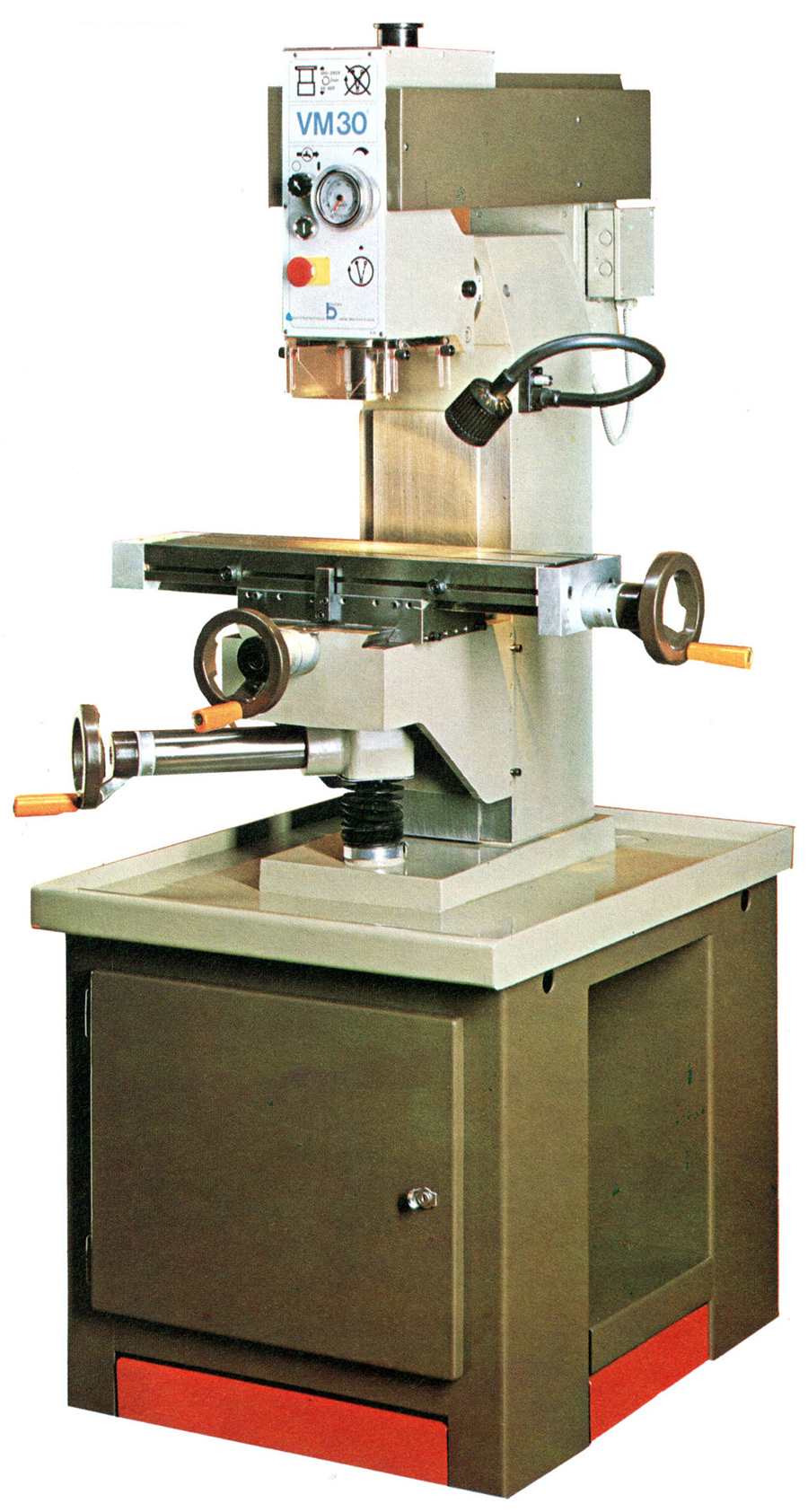

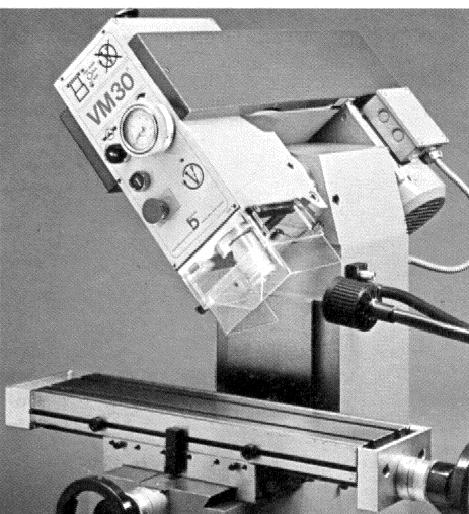

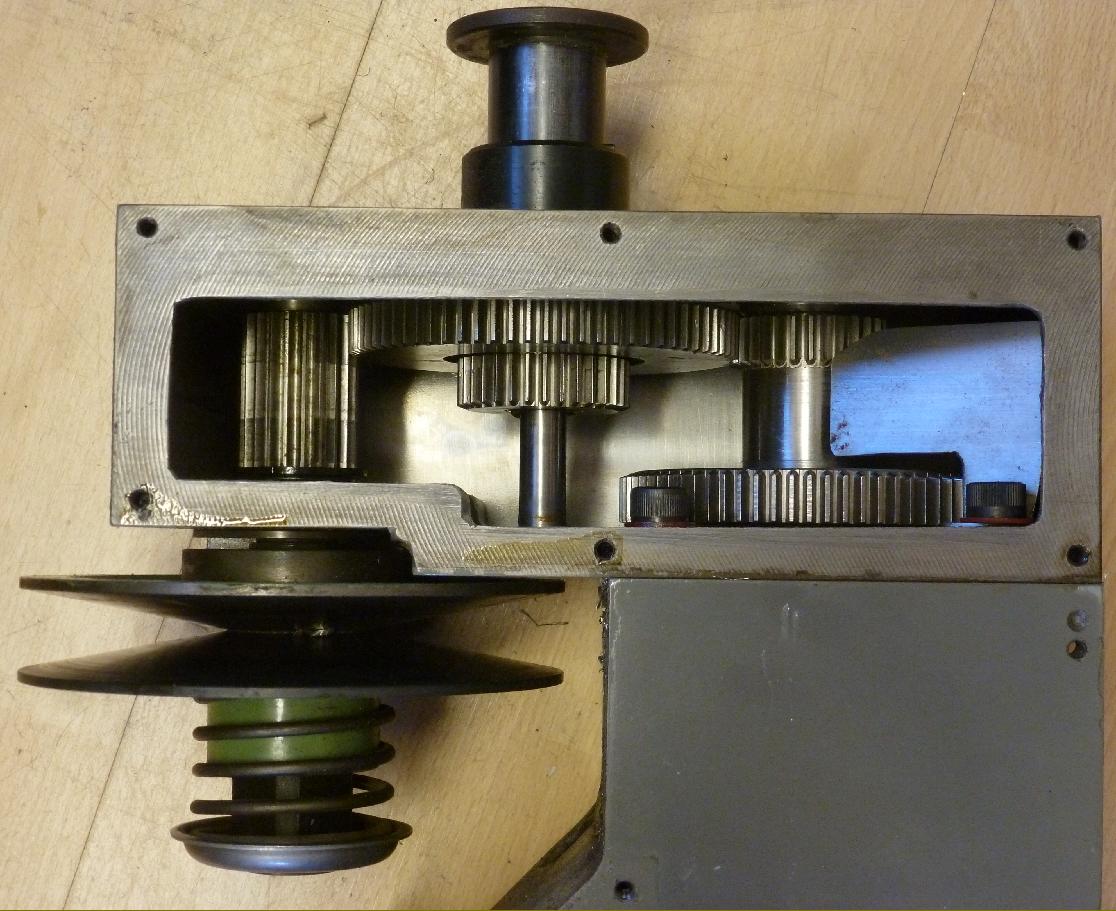

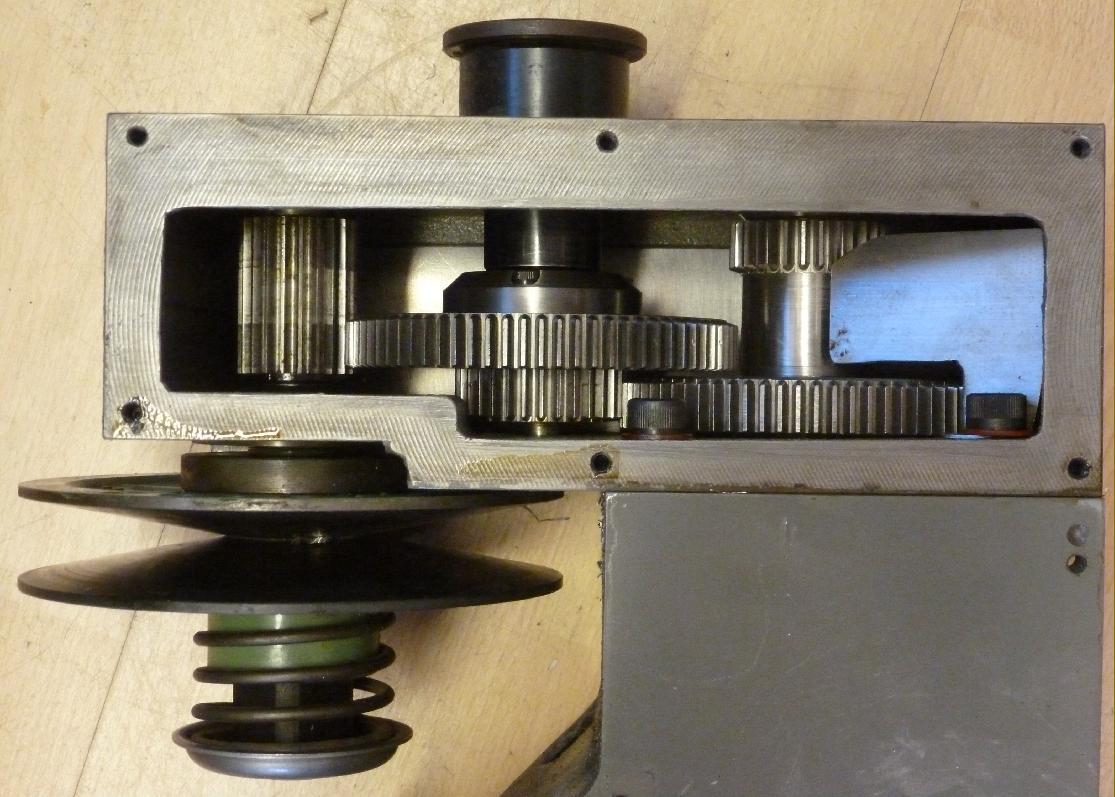

Unusually compact and of a clean, modern design, the Boxford VM30 was fitted with an infinitely-variable speed spindle-drive mechanism that operated through expanding and contracting cone pulleys in conjunction with a speed-reducing, 2-speed gearbox. The head, fitted with a 30 International taper spindle, was capable of being tilted over through 45 degrees either way of central. The spindle ran in "sealed-for-life", pre-loaded Timken taper roller bearings with a 12 mm thread drawbar to retain collet chucks and other fittings.. Sadly, the straight-cut spur gear in the box, though robust, were the cause of some noise and the miller does not run as quietly as it might, so posing a possible drawback to its use in domestic situations. When tilting the head the operator was helped by a friction device, this being fitted to help obtain, more easily, the desired angular setting. Without the device the head is heavy enough to overcome the strength of other than a strong man - a dowel pin used to located the head back in its true vertical position. Early versions employed a coil spring to assist with the opening and closing of the driven pulley, later models used a neater diaphragm-spring arrangement.

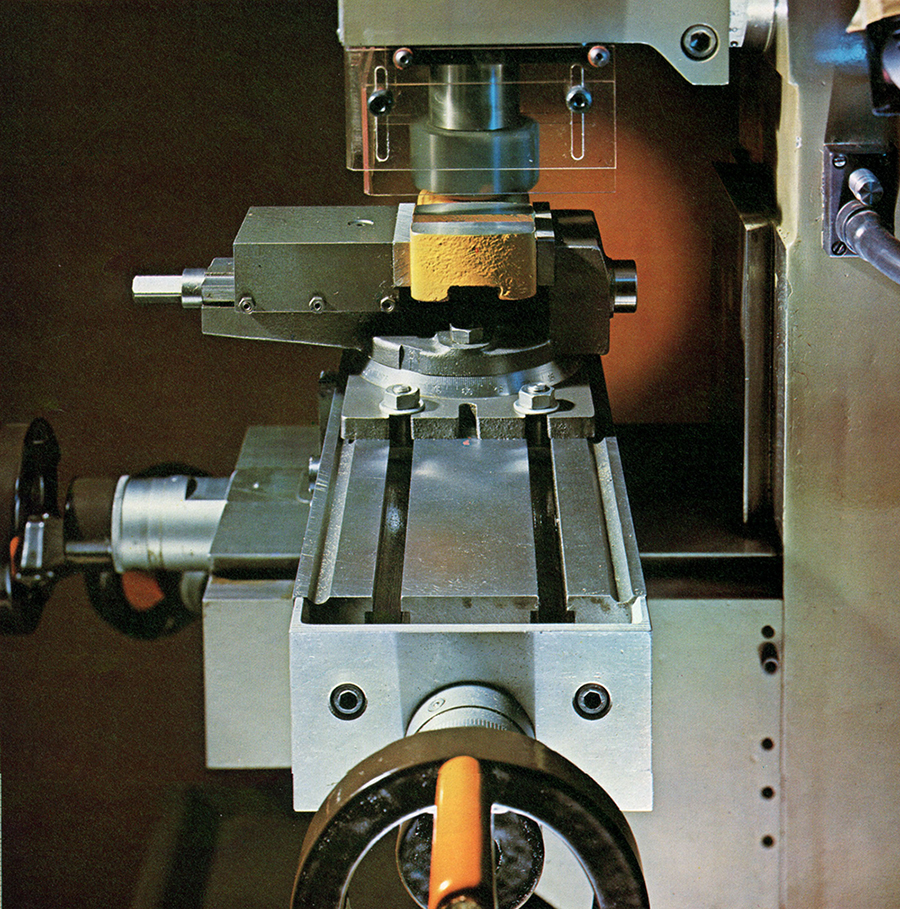

Spindle speeds from 55 to 2000 r.p.m. were available, being divided into high and low ranges, the former from 50 to 500 r.p.m. and high from 500 to 2000 r.p.m. Each range was infinitely variable between its higher and lower limits, the selection of one or the other being by a large black knob on the head's top face. The knob (it lacked knurling around edge to aid grip by oil fingers) was lifted and then rotated through 180° by which means a central "idler gear" was brought into play - a photograph of the box in its high and low-speed positions is reproduced below. The advantages of being able to infinitely vary a spindle speed are considerable; it is nearly always possible to obtain a setting which is just right for the job in hand, and the changes can be made both instantly and in very small increments). Unfortunately - as an obstacle to fine work, though perfectly adequate for general use- there was no quill feed on the head - either drilling or fine - all vertical movements had to be generated by elevating or depressing the knee.

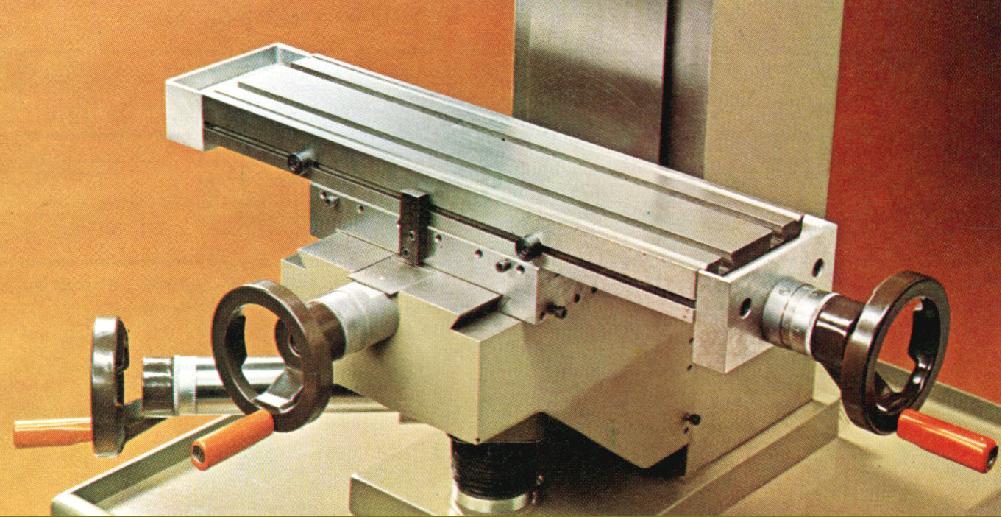

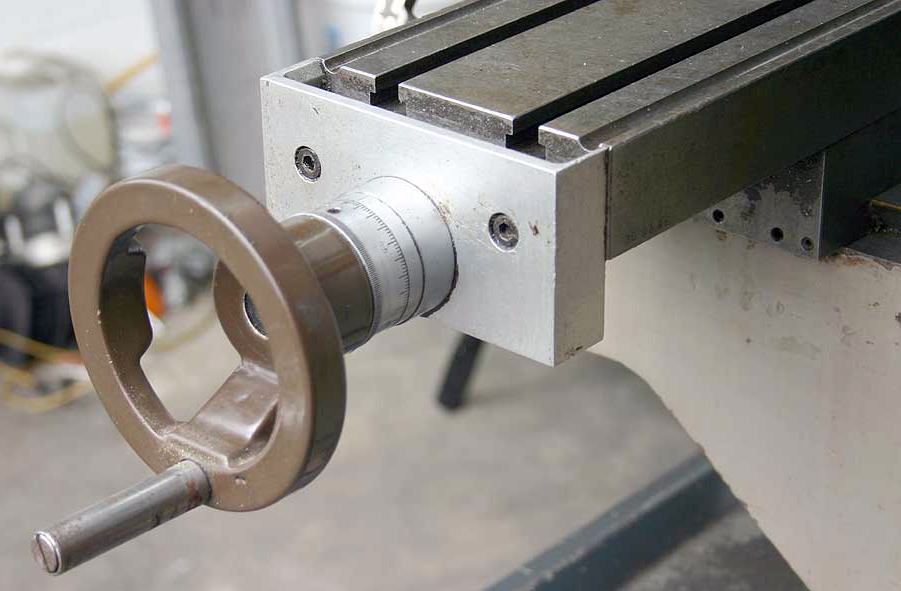

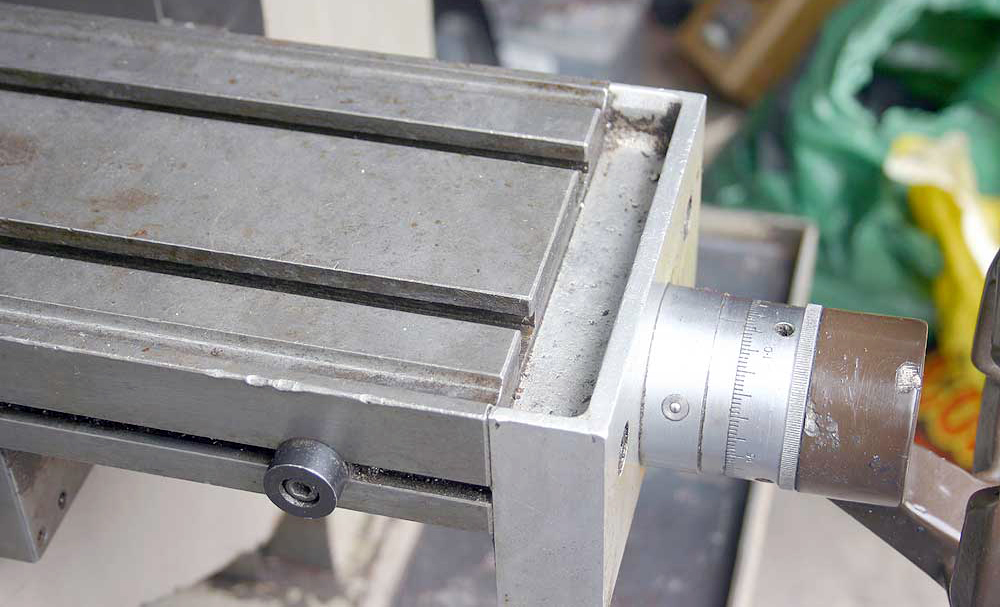

With two T-slots, the 21.65" x 5.9" table had 11" of longitudinal travel and 5.5" of cross; unfortunately the table handles were in powder-coated aluminium and, while very smart when new, the coating has a tendency to peel off and look very untidy. Power table feeds were never offered - though the writer has seen third-party and home-made units attached, the latter type driven by a 24-volt truck windscreen wiper motor and gearbox. The miller's throat was 11" - as was the maximum vertical clearance between the table and the spindle nose.

Nearly all VM30s were fitted with a 3-phase motor and changing it for a correctly-size single-phase unit (unless you can find one with the same diameter shaft as the original to mount the variable-speed pulley) is difficult; it's far easier (and more efficient) to employ an electronic variable-speed "Inverter" that, in conjunction with the mechanical speed change, gives both a wider speed range and finer control of the speed setting.

Complete on the maker's stand the Boxford milling machine weighed approximately 339 kg (748 lbs)..

|

|