|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

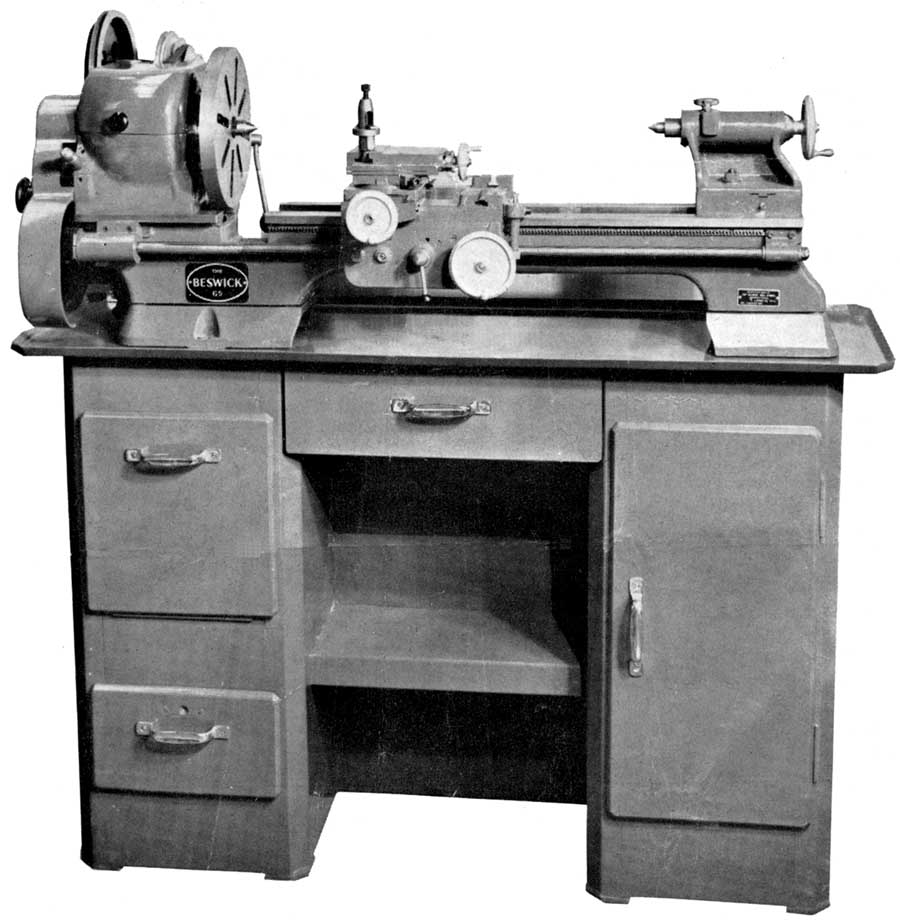

Beswick and C.H.Joyce Lathes

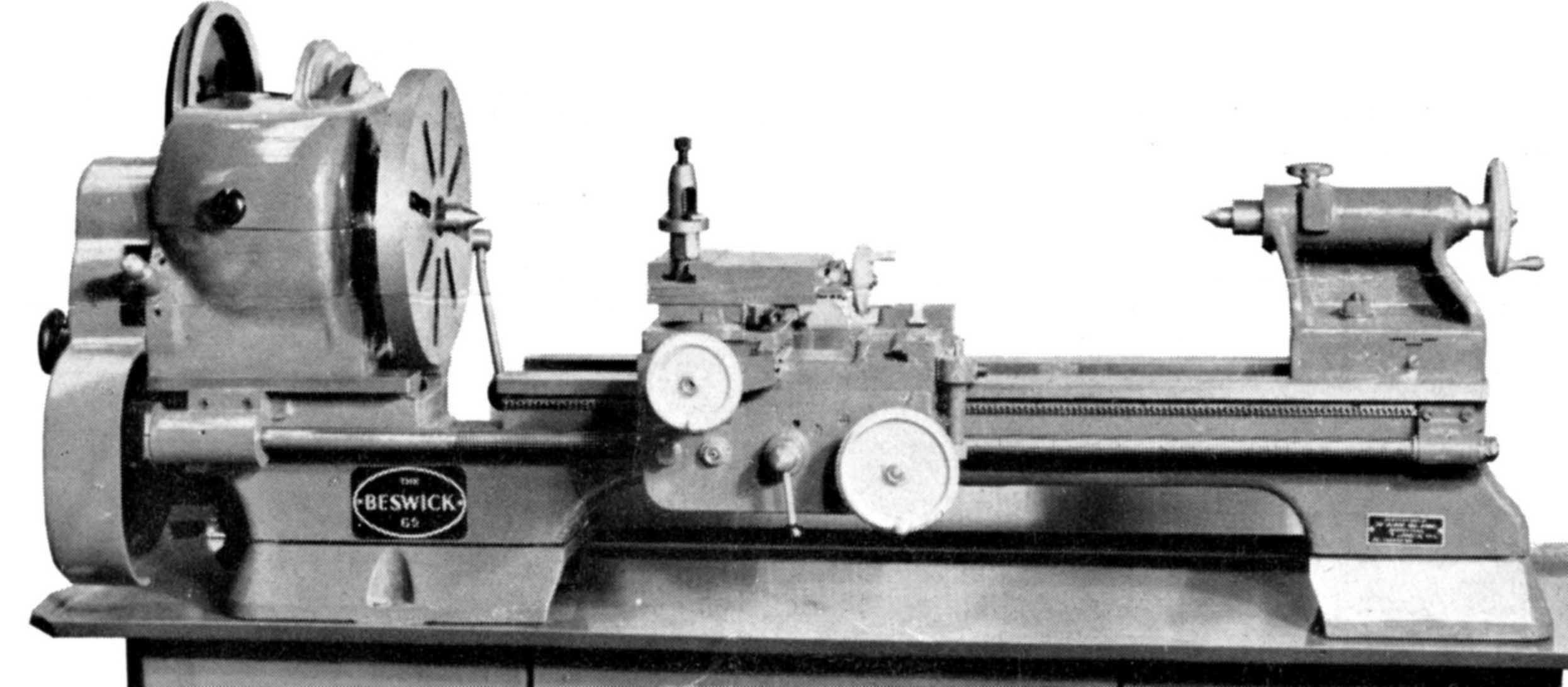

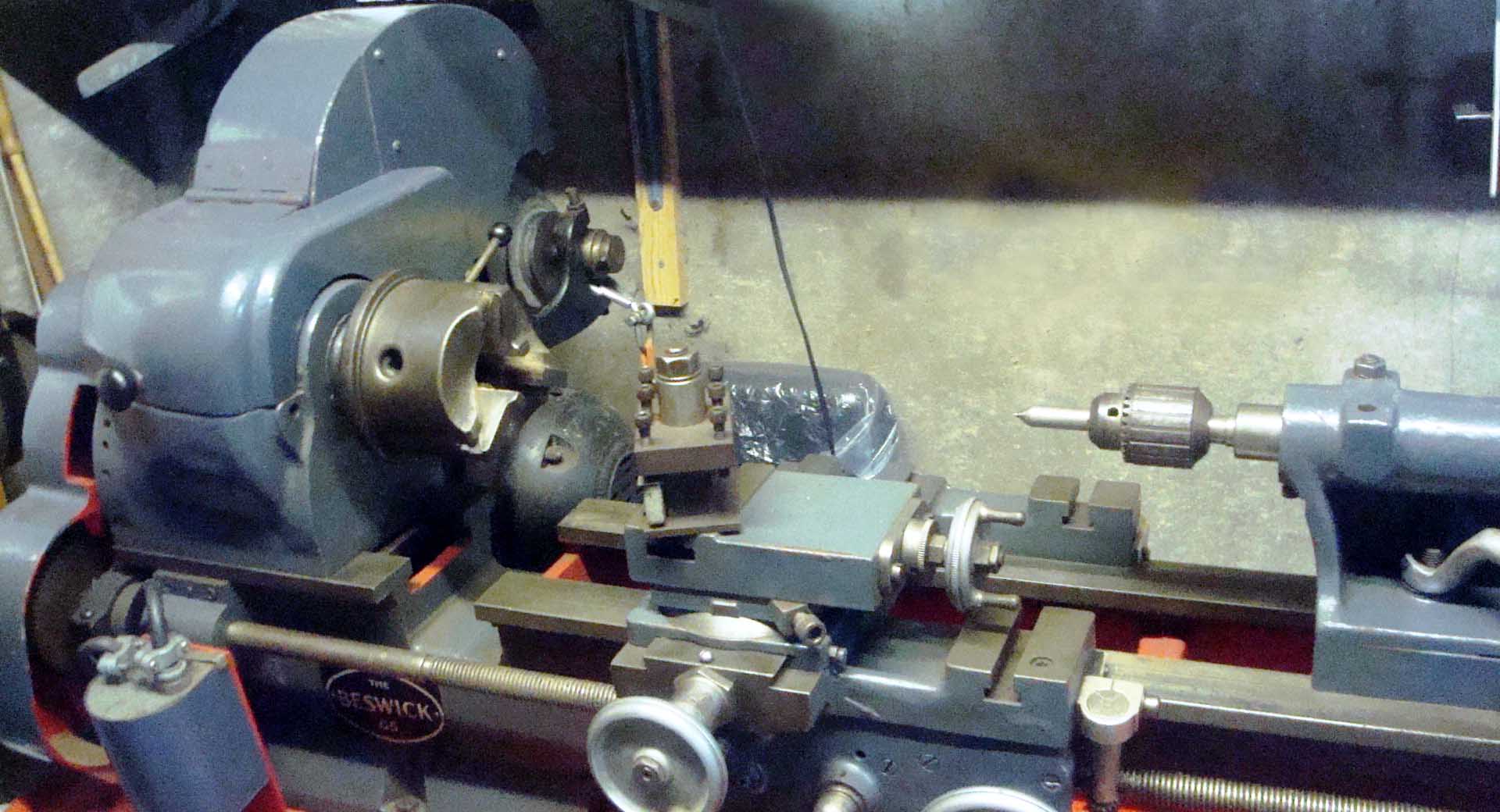

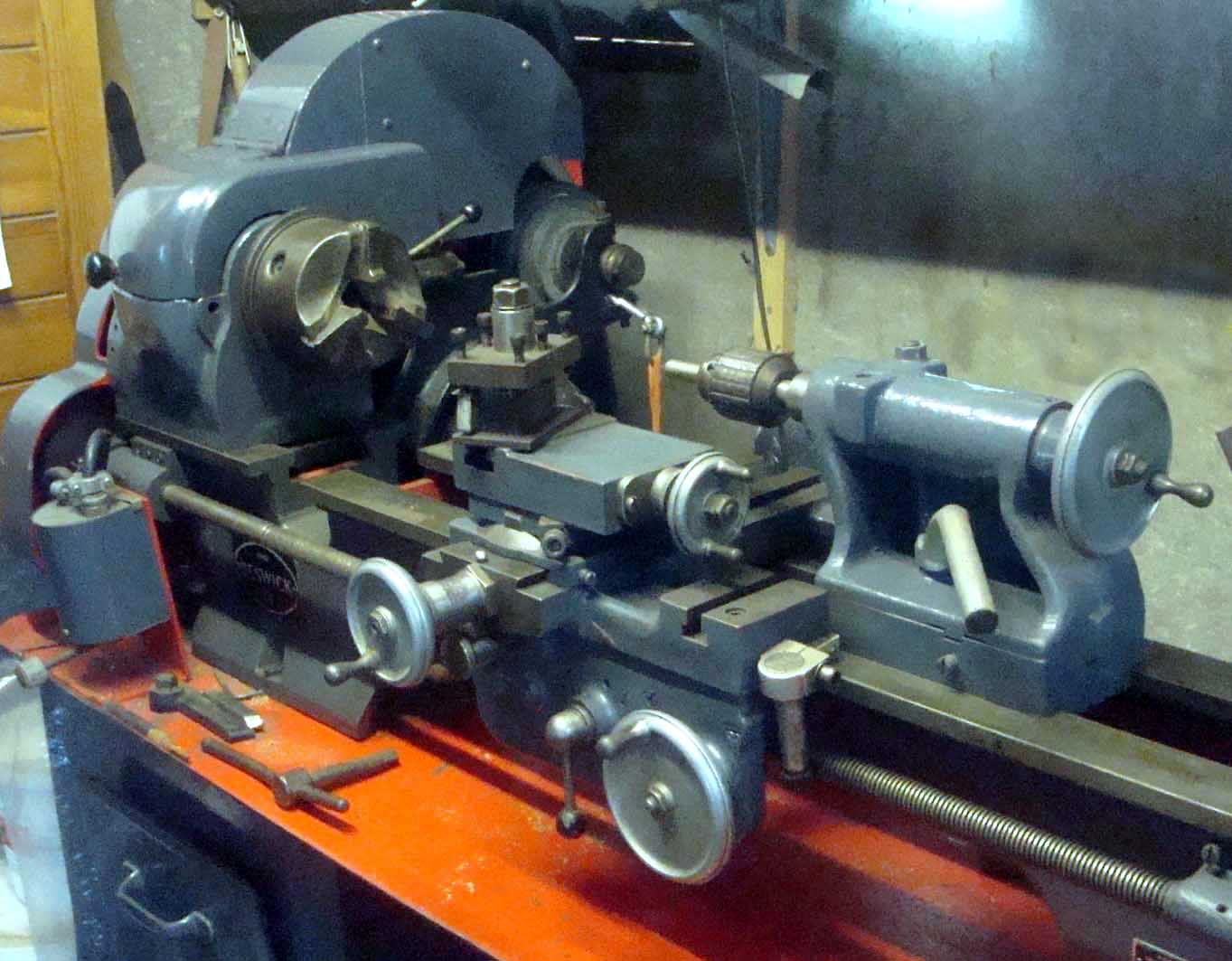

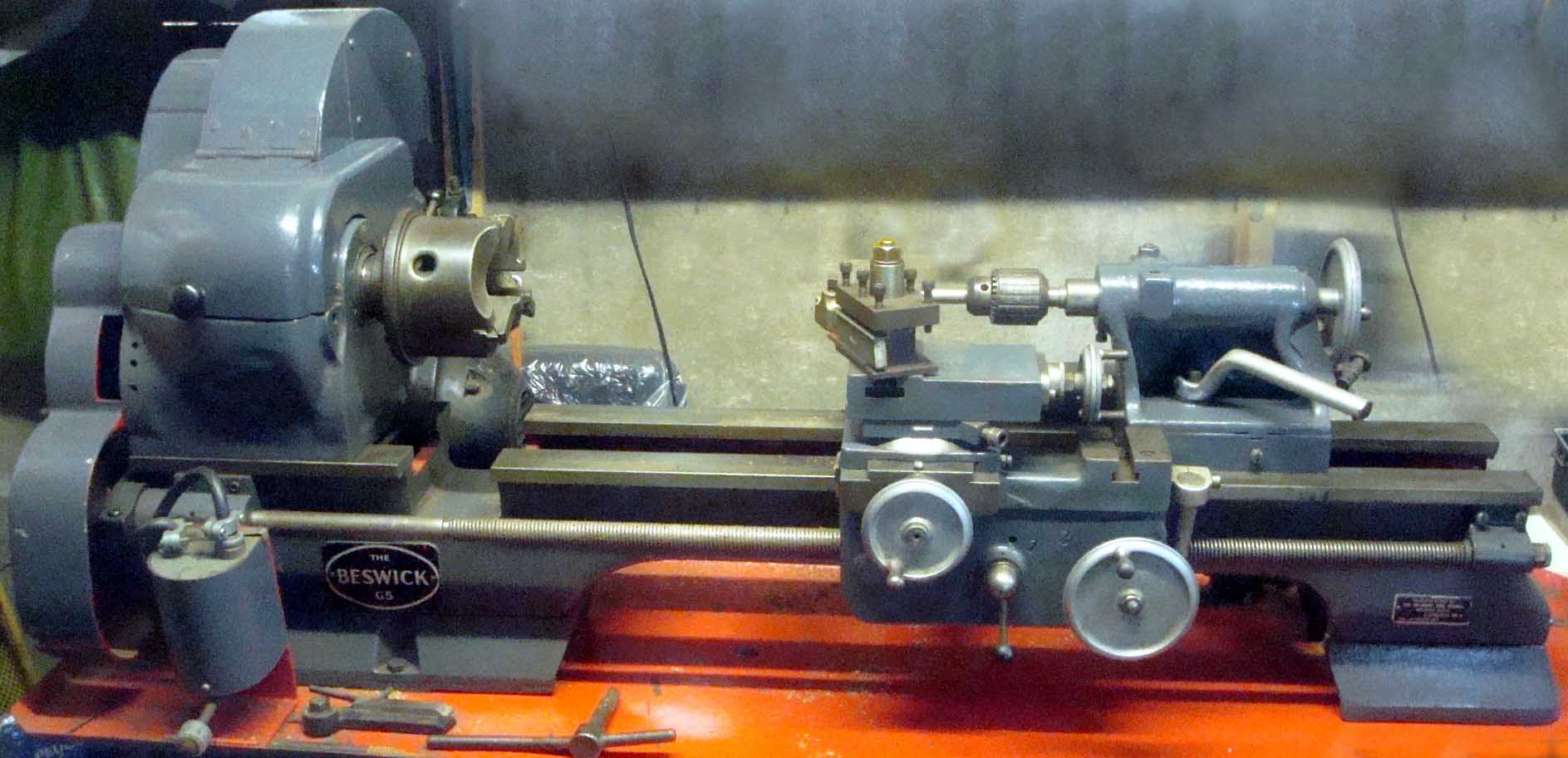

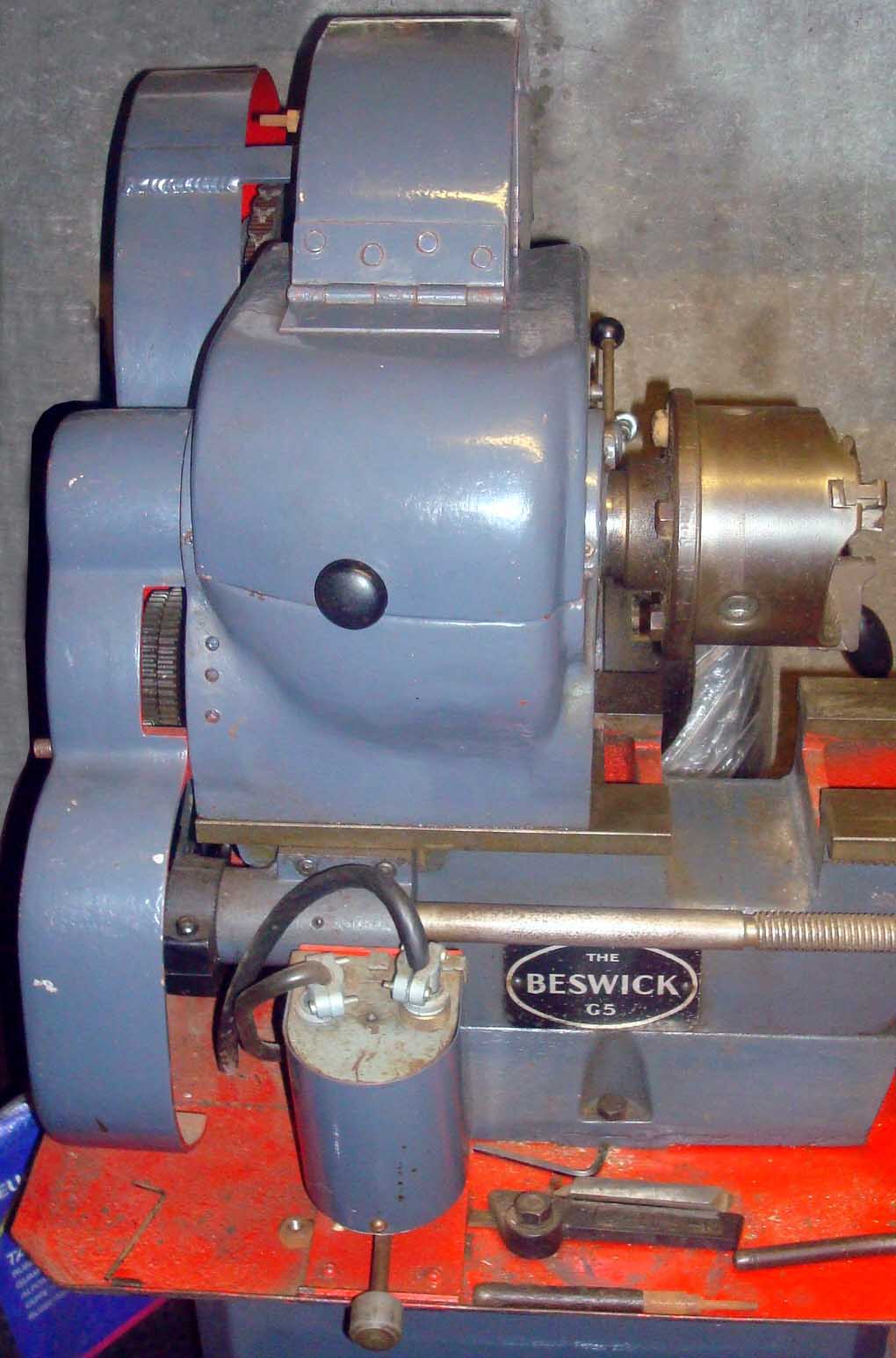

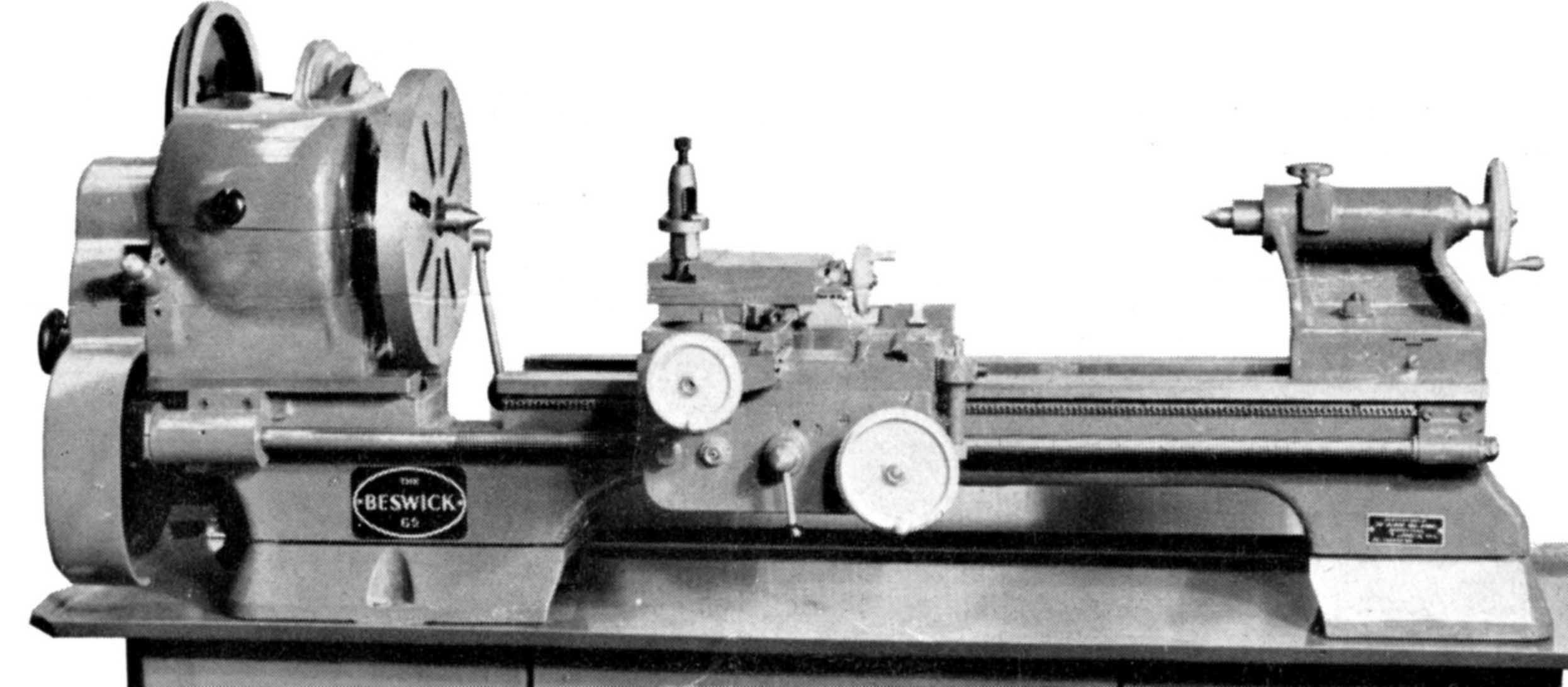

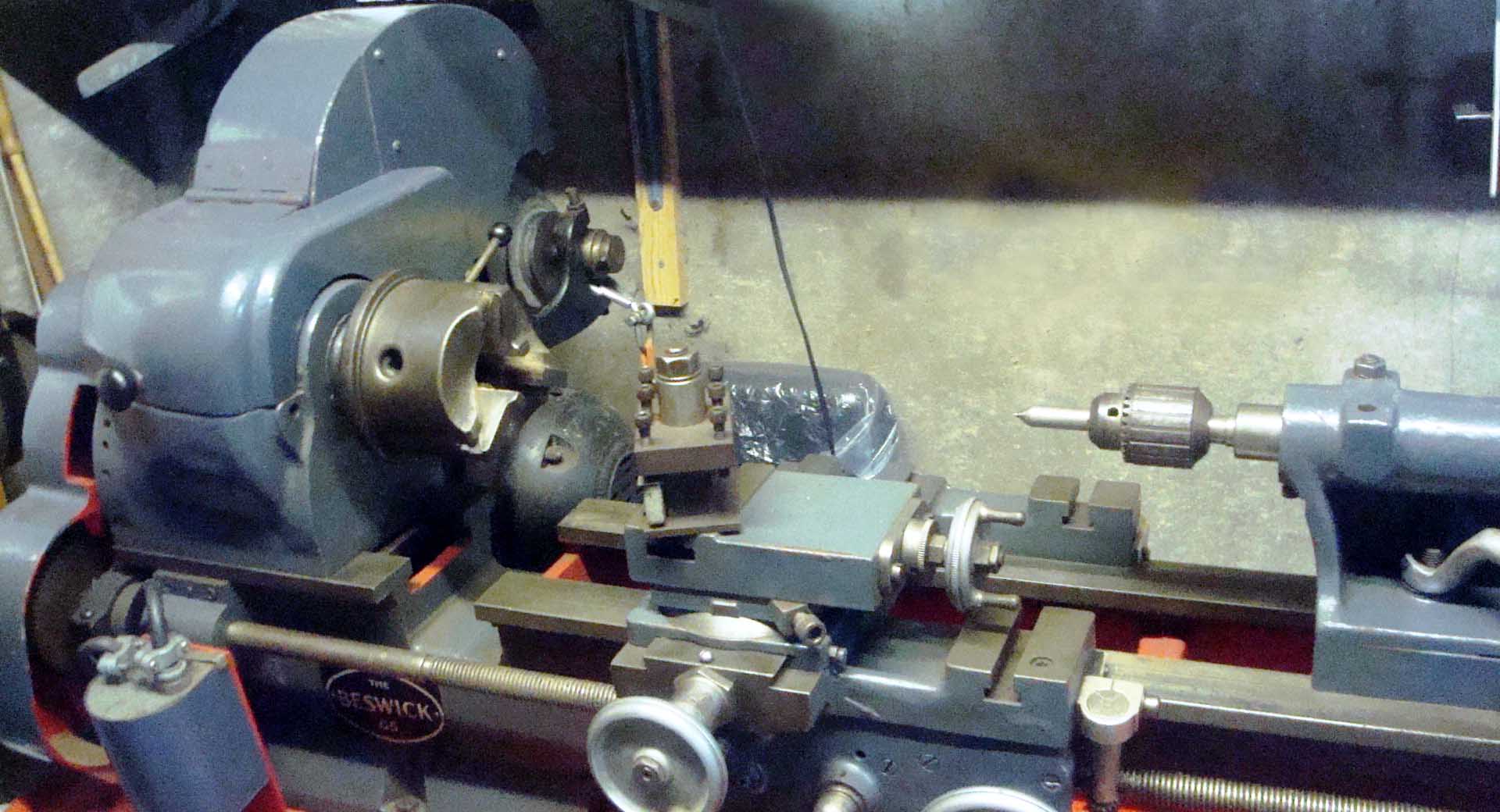

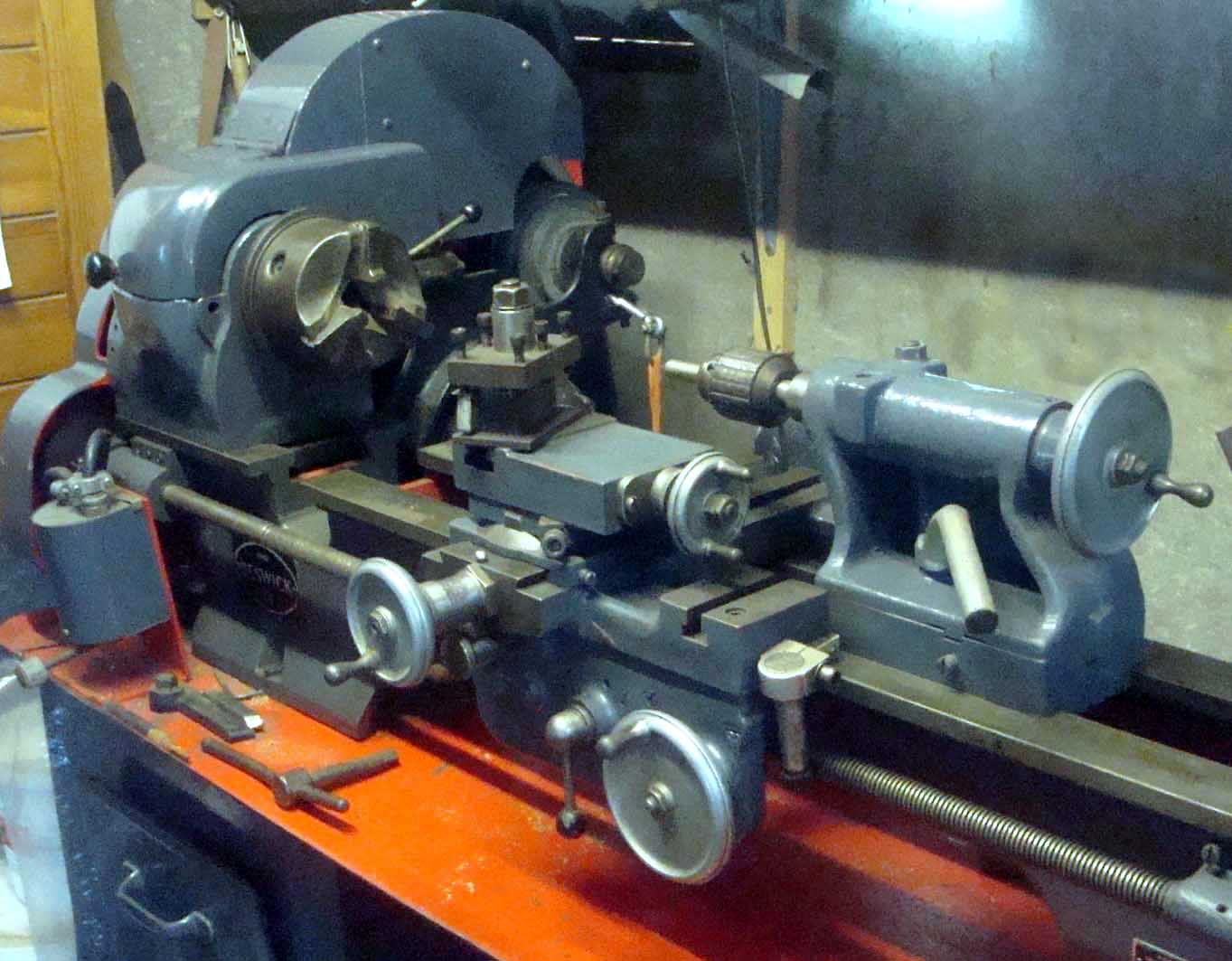

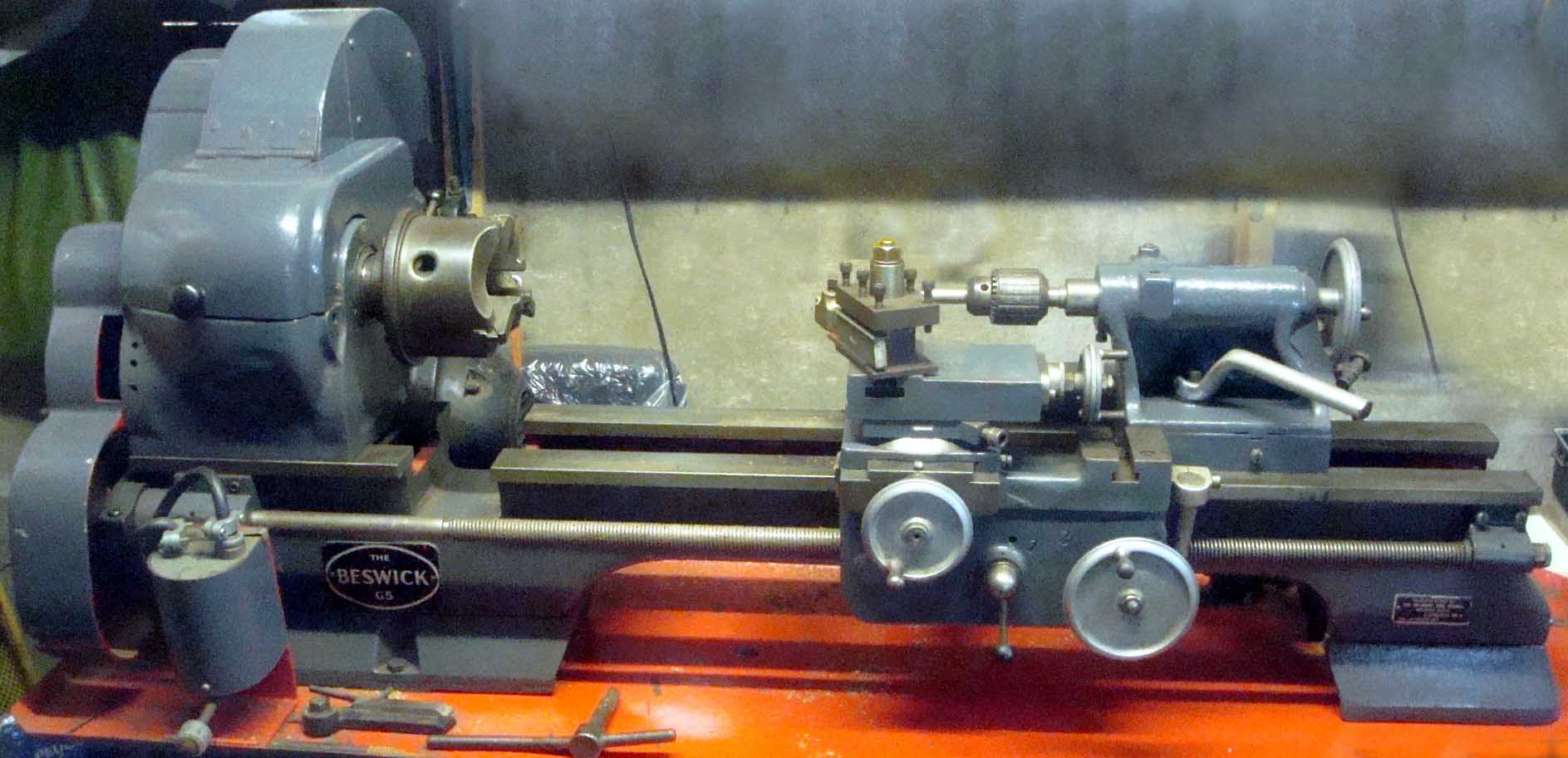

Not a company to advertise widely, C.H. Joyce (of 40 Monkton Street, Kennington, London SE11), were responsible for a number of small lathes including some high-precision, plain-turning types that were manufactured during the first two decades of the 20th century - an example is shown below. Much better known than their now almost-impossible-to-find early lathes is the (still rare) "Beswick", this having a centre height of 5" and taking 24" between centres. Known as the Model G5, the lathe was, from its general appearance, almost certainly produced during the late 1940s and early 1950s and intended to compete with the likes of the Boxford and British built versions of the Atlas 10-inch, the Sphere and Halifax.

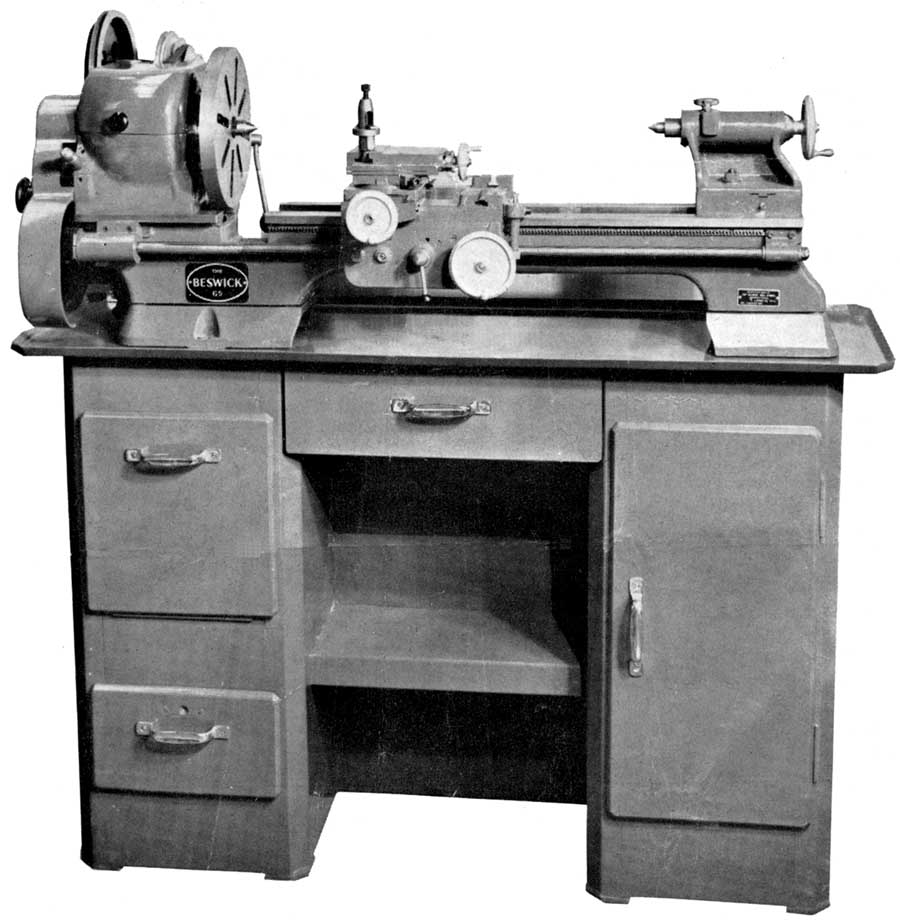

As the company claimed, 'Years of practical experience in the manufacture and operation of small precision lathes' - the specification of the G5 certainly reflected a knowledge of what would make a 5-inch centre height machine an effective tool for general workshop use. The bed, of traditional English pattern with flat-topped ways, had it front and back faces "cut away" rather savagely and unnecessarily between its mounting feet, leaving little vertical depth to resist twisting forces. The capacity between centres was 24-inches and in the gap material up to 14-inches in diameter could be swung. As on Raglan lathes, two bolts secured the bed foot at the headstock-end and a single bolt at the other - the 3-point mounting allowing a degree of self-alignment to take place and doing something to prevent the owner stressing the bed by bolting it down tightly to an uneven bench .

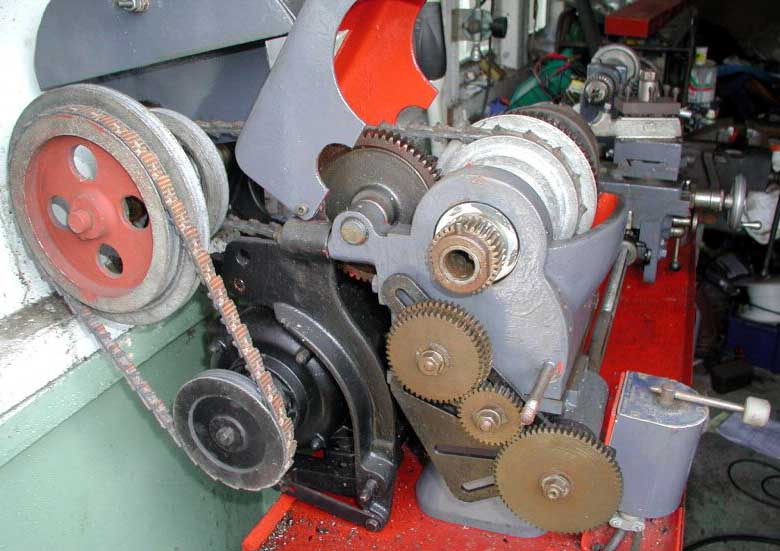

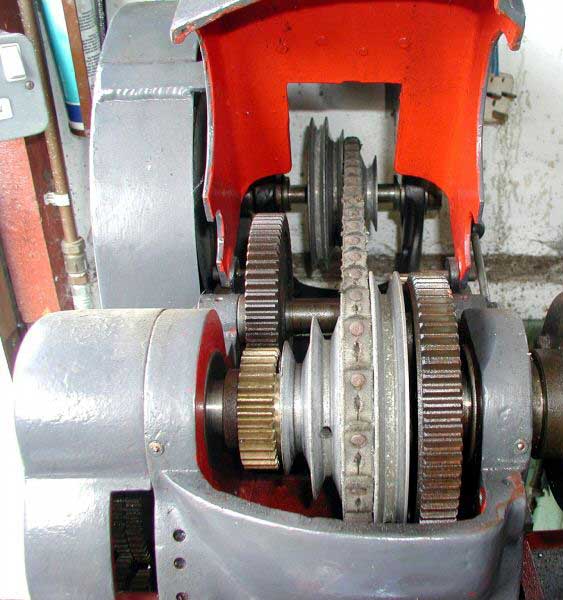

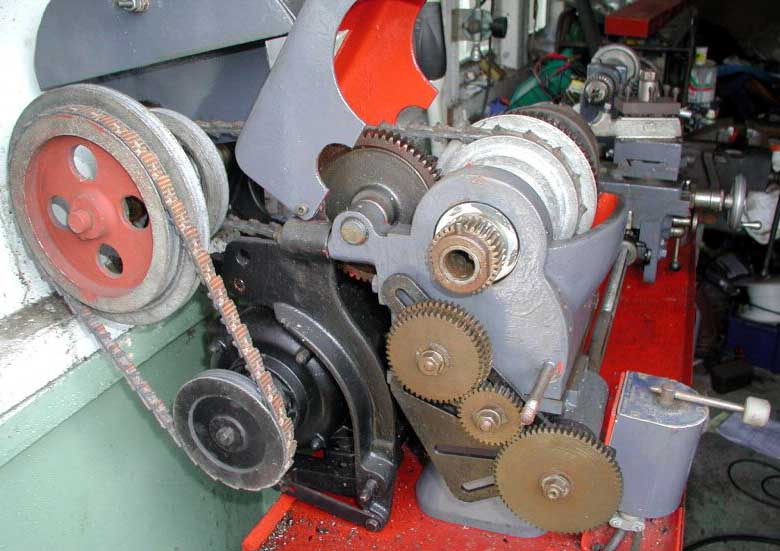

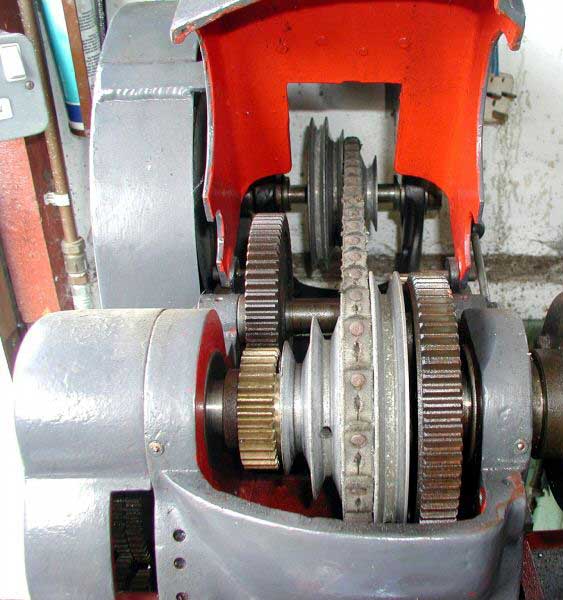

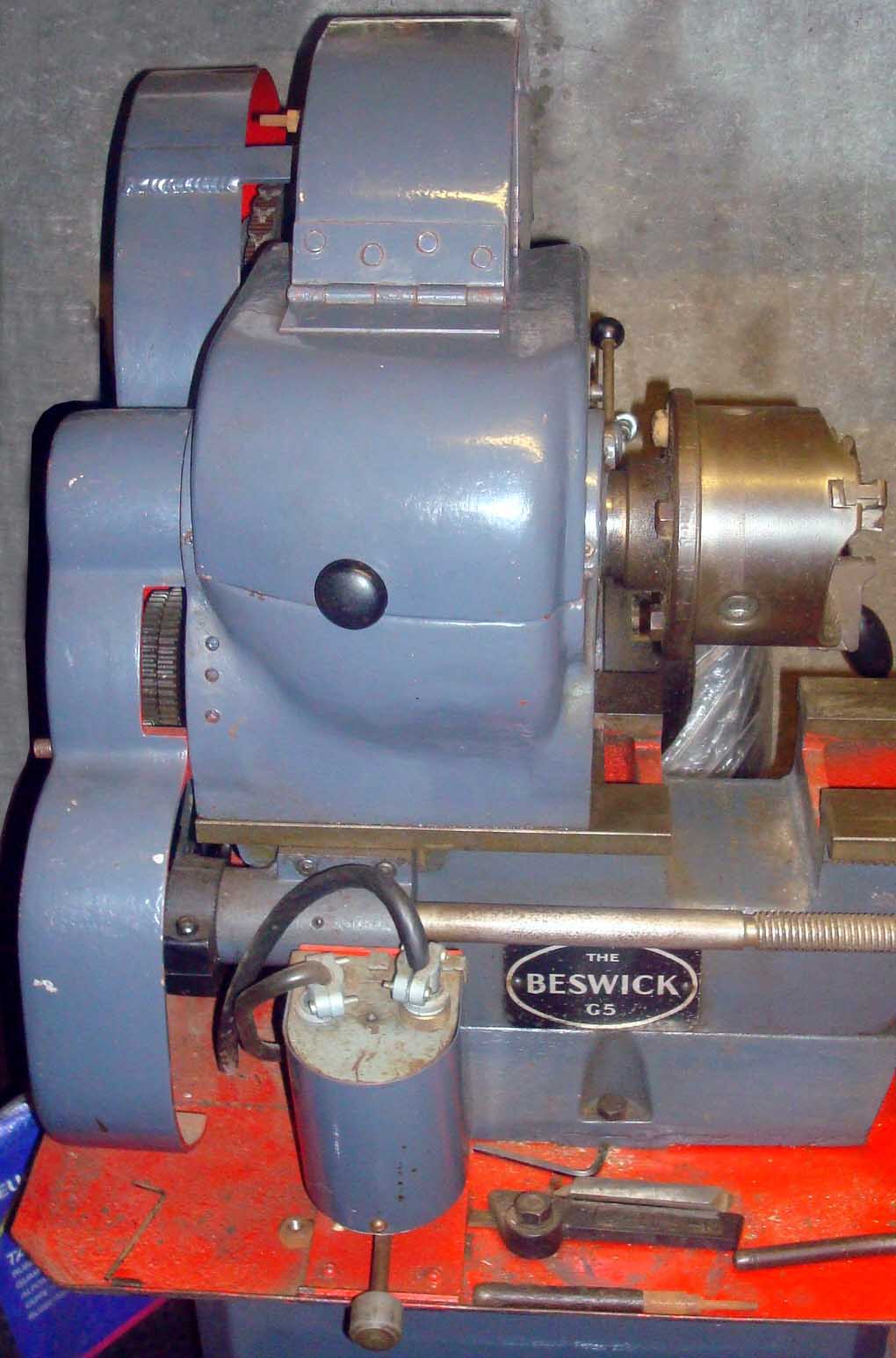

With a No. 3 Morse taper in its nose and bored through 3/4-inch, the headstock spindle carried a robust 11/2 '' x 8-t.p.i. nose (identical to that used on the 9-inch South Bend and Boxford) and ran in Timken taper roller bearings - all other headstock bearings being in the ubiquitous OILITE material. The backgear assembly was carried in brackets bolted to the back of the headstock so allowing, by their omission, the possibility of marketing the lathe in a cheaper form. To the back of these brackets was bolted the upper section of a built-on countershaft unit fitted with a double-diameter motor pulley and a 4-step Vee-belt drive to the headstock that gave an excellent spread of 16 speeds: 28, 44, 69, 82, 110, 128, 182 and 290 rpm in backgear and 170, 260, 410, 480, 650, 730, 1200 and 1820 in direct drive. Like those on the well-known Atlas 10-inch lathe, the countershaft bearings were supported by an ingenious yet very inexpensive arrangement consisting of opposed alignment screws that could be quickly and easily adjusted. While the motor-to-countershaft pulleys were left exposed, the front headstock drive belt was covered by a neat, rear-hinged if rather short cast-aluminum guard of the type deemed acceptable at the time.

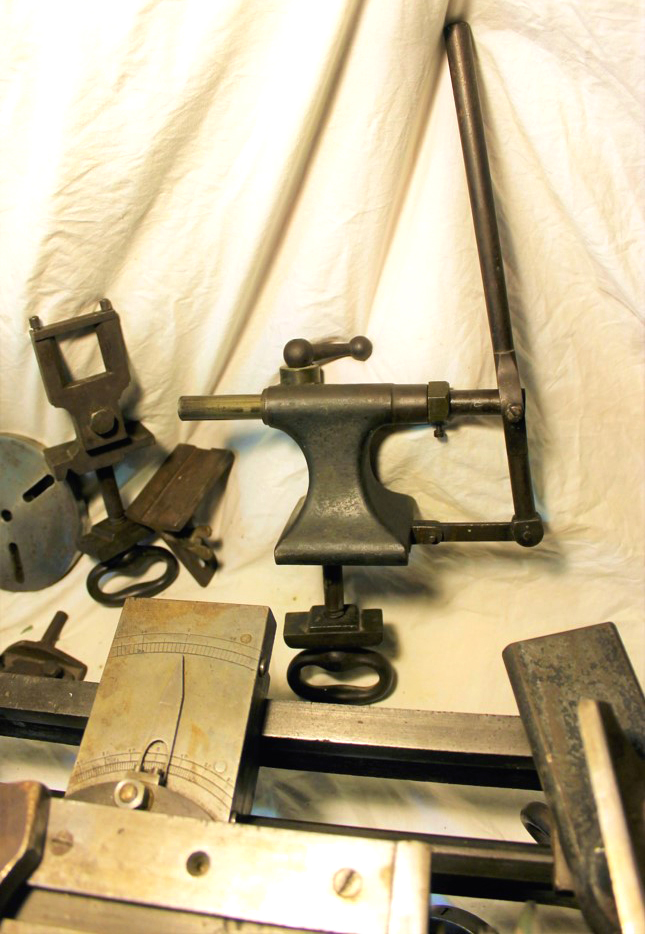

Screwcutting was by changewheels, with the drive from headstock to 3/4-inch diameter Acme-form 8 t.p.i. leadscrew through tumble-reverse gears fitted to a bracket with a spring-loaded location plunger. The changewheels were carried on a very unusual and highly adaptable bracket with four radially disposed slots that would have allowed almost any combination of gears to be mounted. The threading range with the supplied gears was a respectable 4 to 96 t.p.i.

With an "open" gap bed fitted as standard, and to stop the saddle running over fresh air when working close to the faceplate, the cross-slide was fitted in a very unbalanced position along the left-hand edge of the saddle. The front and back saddle wings to the right-hand side of the saddle were provided with a T-slot to mount the travelling steady and the cross-slide travel, driven by a 1/2" x 8 t.p.i. Acme-form screw, was a generous 7 inches. However, the top slide (fitted with an "American-style" toolpost) failed the critical test - with a movement restricted to just 2 inches it could not cut the full length of a standard No. 2 Morse taper centre.

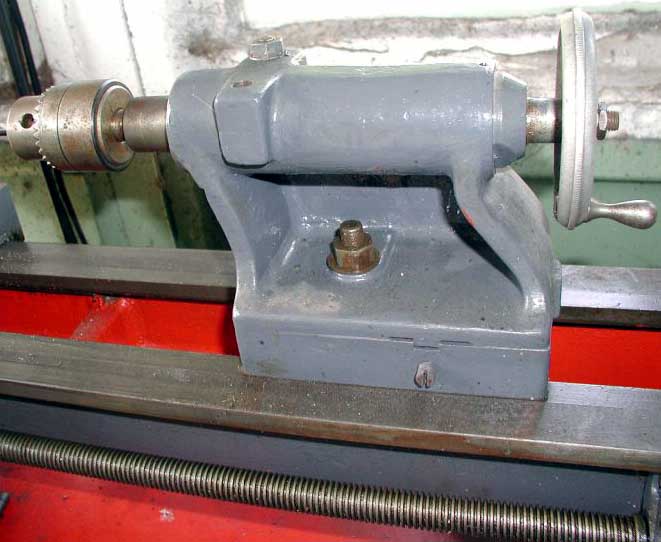

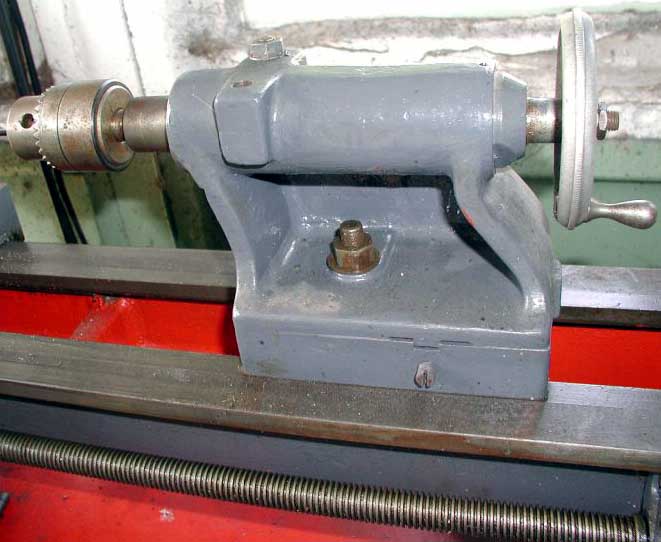

1.187-inches in diameter, the tailstock ram had a travel of 23/4", carried a No. 2 Morse taper in its nose and was engraved in 1/16" divisions for a length of 3-inches. While the upper section of the tailstock casting could be set over up to 5/8" on the sole plate to allow slight tapers to be turned, the unit required the services of a loose, self-hiding spanner to lock it down to the bed.

With its beveled-edged corners the pressed-steel stand, was not dissimilar to that offered for the Raglan "Little John" (though with a too-shallow chip tray) and offered generous storage space in its two cupboards and two drawers.

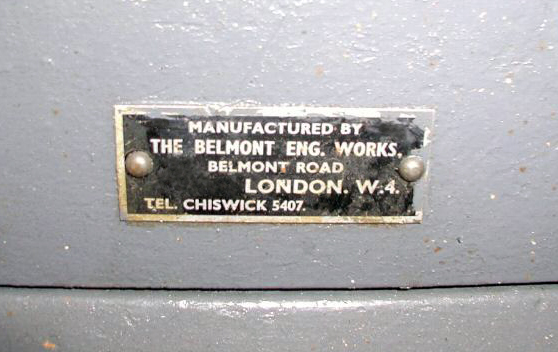

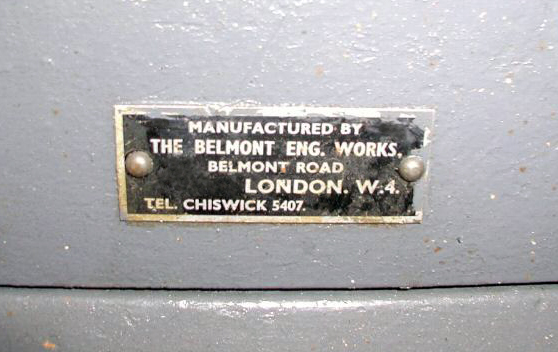

And the final piece of the jigsaw? Some Beswick G5 lathes have been found with a plate proclaiming "Made by the Belmont Engineering Works, Belmont Street, London W4"

If you have a Beswick lathe; or other Beswick machine tool, or any information about C.H. Joyce, Ltd. and the Belmont Engineering Works, the writer would be pleased to hear from you..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

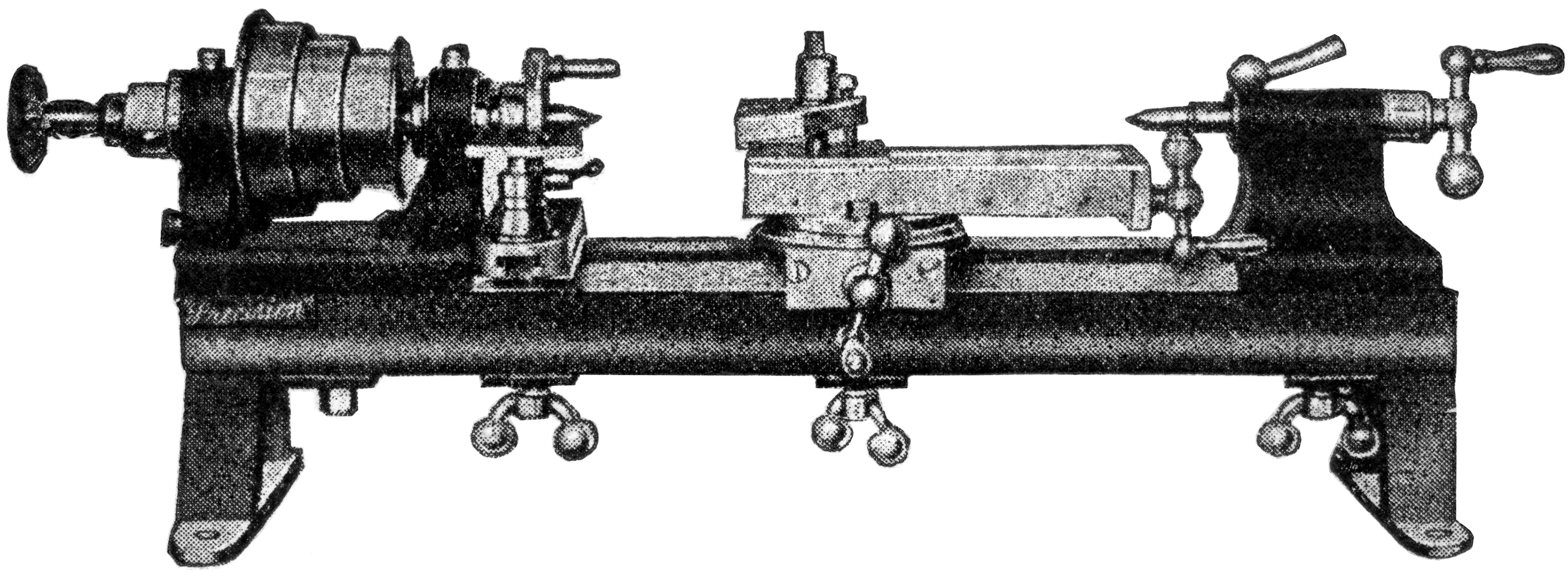

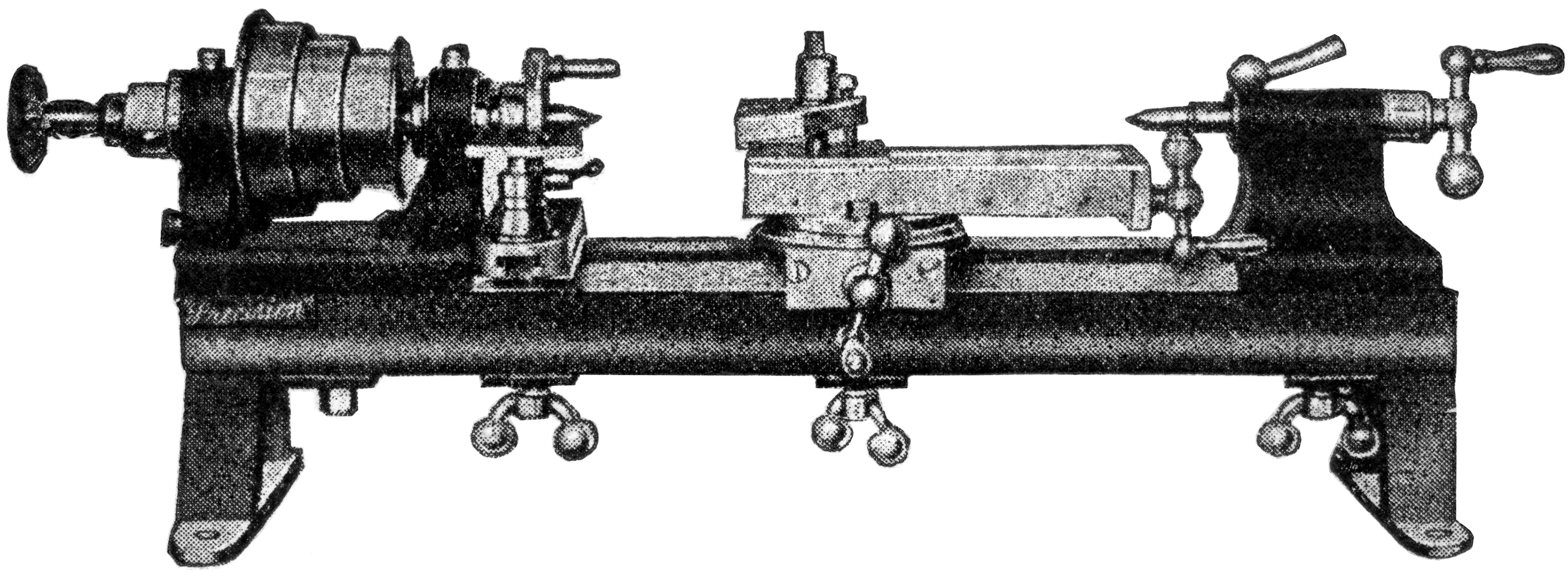

A late-model C.H. Joyce precision bench lathe with flat-belt drive as advertised during 1920/21.

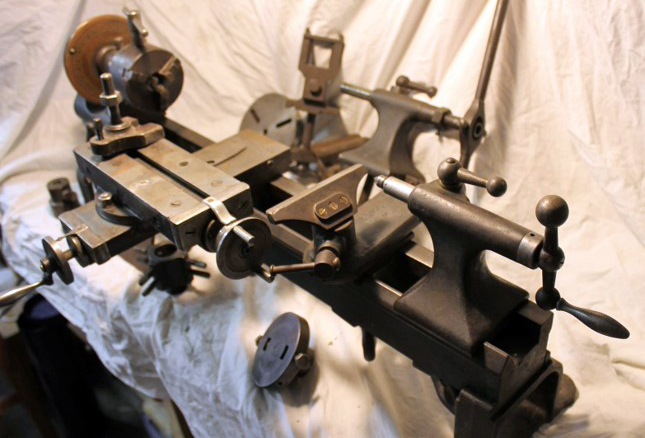

Although precise details cannot be confirmed, the centre height appears to have been around 3.5" and the capacity between centres 16". Instead of the bed having the usual flat top and two bevelled edges common to this class of lathe, the Joyce used a single V-way at the front and a flat to the rear - rather like that other exception to the rule, Sloan & Chase in the USA who used two conventional V-ways. Another unusual feature was the long-travel top slide with its single, full-length, central T slot; while the length of travel was not unusual (all such lathes had slides with a similar travel) full enclosure of its ways was - these normally being of the open type that left the finely finished surfaces (and sometimes the feed screw as well) exposed to the wearing effects of dirt and swarf. The only other bench precision lathes known to have used such a design during the early part of the 20th century were made by Schaublin, in Switzerland, their Types 65, 70 and 102 all enjoying this feature. However, while the Schaublin lathes all had large zeroing micrometer dials the Joyce had none, though they might, just possibly, have been on the options' list. The only known C.H.Joyce precision plain lathe known to exist does have micrometer dials, but this is an early example and the dials have almost certainly a retro-fit by a previous owner. One unusual - possibly unique feature - was a top slide provided with two swivel degree scales, engraved into the top surface of the cross slide and set well apart - the outer scale being, of course, the more accurate but of limited range.

The picture above - the only known illustration from an advertisement - shows the lathe marked below the headstock with the word "Precision" - though if this really was in place, or just an addition at the advertising art-work stage, is not known.

Could the lathe have been of continental, possibly German manufacture? While the two-ball hand-nuts used to secure the hand T-rest, compound slide and tailstock look to be copies of those used on some older Lorch lathes, the "open-frame" bed feet are unique to this type of lathe and nothing else resembles other German precision plain lathes of the period so writer believes that this notion can be firmly put to rest.

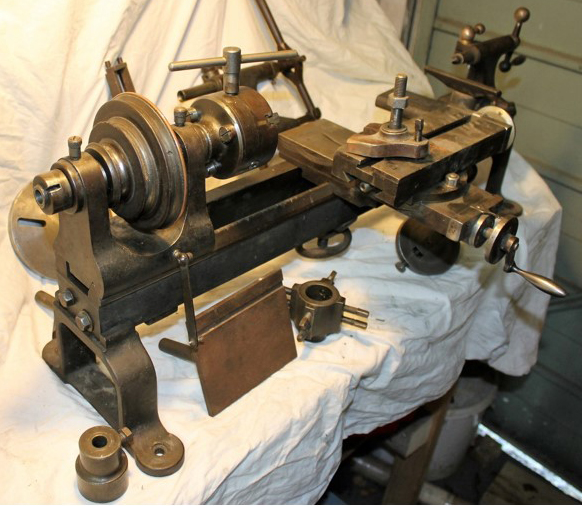

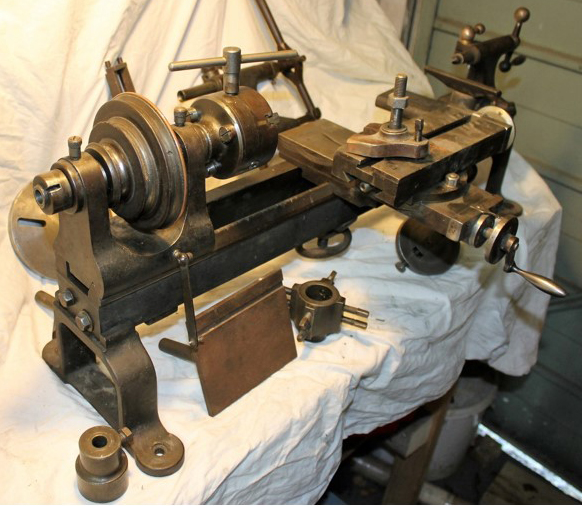

Earlier C.H.Joyce lathes were more typical of their period, and might have been made as early as the late 1800s, this conclusion being reinforced by the use of a narrow, 3-step headstock pulley to take a round-rope leather "gut drive", a multi-circle division plate on the front face of the headstock pulley, an elegantly styled tailstock (so common of the period) and a fixed steady of the very early rectangular pattern that used replaceable wooden inserts..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

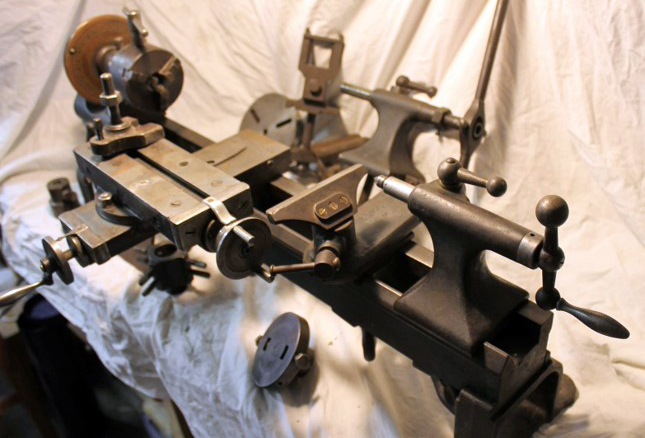

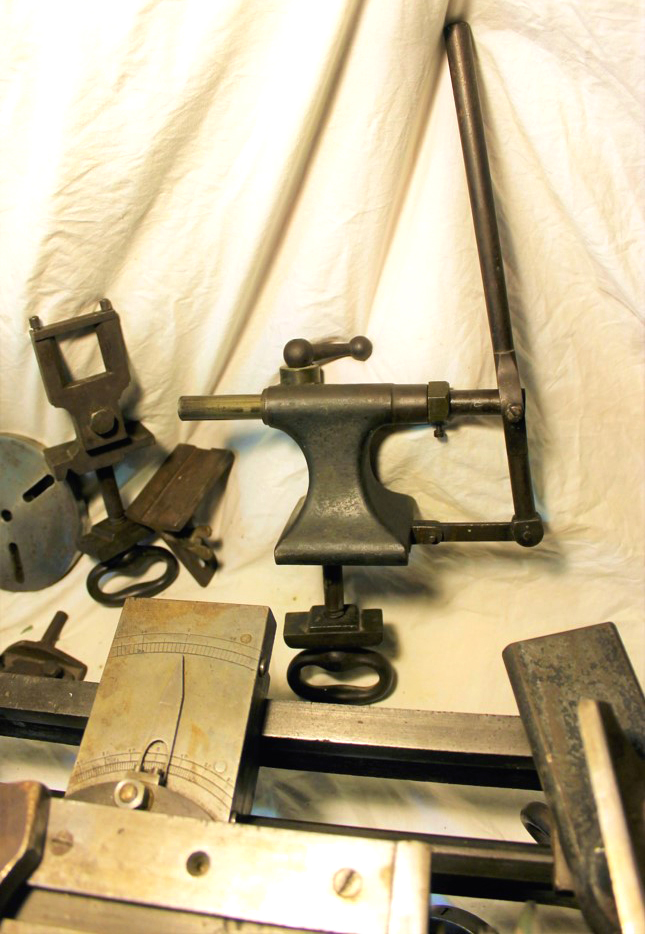

An early C.H.Joyce lathe, probably circa 1890 to 1910. The lathe has survived complete with a number of original fittings including headstock bearing oilers, both screw-feed and lever-action tailstocks, a rather fine 2-jaw chuck, a box chuck with 6 radial screws, a fixed steady of typical 19th century design, a saw table and a hand T-rest. The micrometer dials are a later fitting.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

One unusual - possibly unique feature - was a top slide provided with two swivel degree scales, engraved into the top surface of the cross slide and set well apart - the outer scale being, of course, the more accurate but of limited range.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The original fixed steady - a design from Victorian times that used interchangeable wooden inserts that could be bored to the size required. An example of the type, as used on the Hamann ornamental turning lathe, looked like this

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Beswick 5" x 24" "Model G5"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

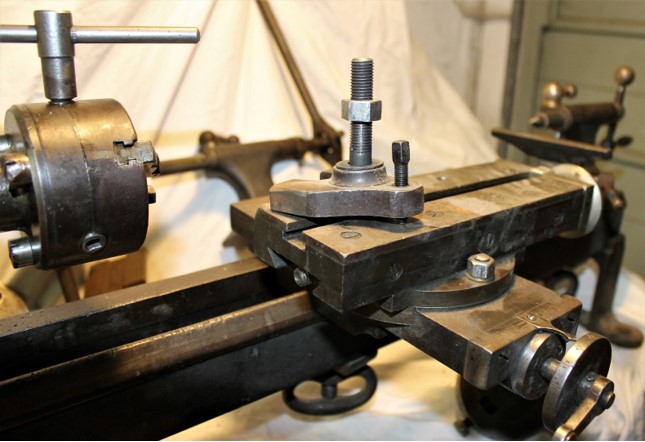

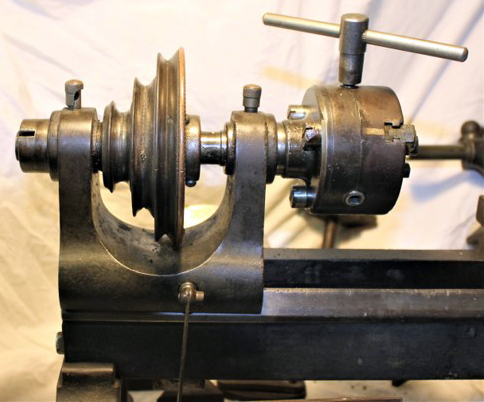

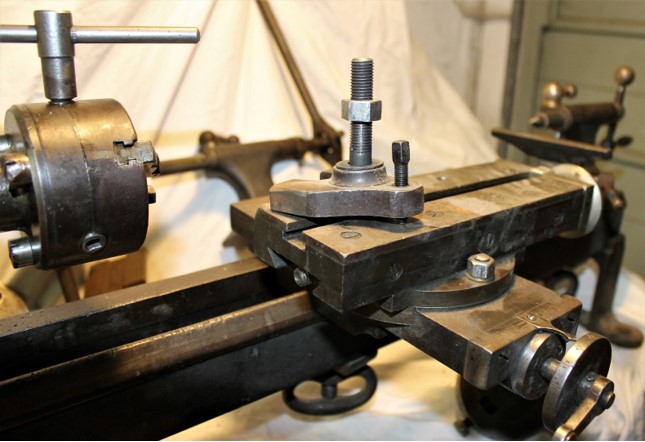

The backgear assembly was carried in brackets bolted to the back of the headstock so allowing, by their omission, the possibility of marketing the lathe in a cheaper form. To the back of these brackets was fastened the upper section of a built-on countershaft unit fitted with a double-diameter motor pulley and 4-step Vee-belt drive to the headstock. Note the unusual changewheel bracket with its 4 radial slots.

|

|

|

|

|

|

|

|

|

|

|

|

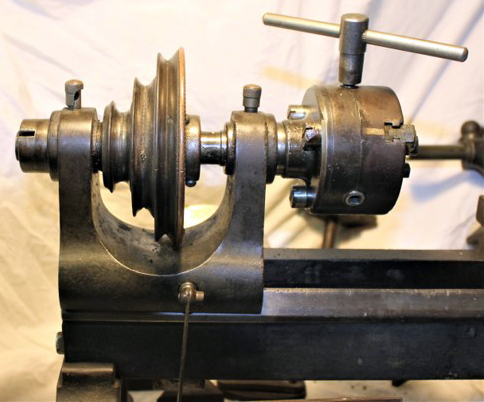

The No. 3 Morse taper 3/4-inch bore headstock spindle carried a robust 11/2 '' x 8-t.p.i nose (identical to the 9-inch South Bend/Boxford) and ran in Timken taper roller bearings--all other headstock bearings being in the ubiquitous OILITE material.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.187-inches in diameter, the tailstock ram had a travel of 23/4", carried a No. 2 Morse taper in its nose and was engraved in 1/16" divisions for a length of 3-inches. While the upper section of the tailstock casting could be set over up to 5/8" on the sole plate to allow slight tapers to be turned, the unit required the services of a loose, self-hiding spanner to lock it to the bed.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Like those on the well-known Atlas 10-inch lathe the countershaft bearings were supported against pairs of opposed alignment screws that could be quickly and easily adjusted.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|