|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W.F.& John Barnes was founded in 1872 and became especially well-known for their range of foot and hand-powered wood and metal-working machinery. Their metal-turning lathes were invariably, but not exclusively, of the lighter, treadle-powered type in the 9" to 13" range and were often derided in their home country as being of the "farmers' type". However, this was an unfair put-down, for those Barnes seen by the writer were all well constructed of good quality materials and performed, having regard to their specification, in a most satisfactory way.

Today, the idea of using a treadle to drive a lathe seems very strange but, before the advent of widespread electrical connections and inexpensive generating plant, it was a convenient (and healthy) way of powering small - and not so small - machine tools in remote locations. Naturally, the "treadler" was often a long-suffering apprentice or other assistant - and one cannot pretend that it could have been much fun. Professional machine shops in such areas, where they existed, usually employed a stationary "gas" engine to turn line shafting, this being used to drive several machine tools at once. Of course, once you had your Barnes treadle lathe, you could contemplate buying the necessary castings and building a small engine to drive it, such sets of parts to do just that being very popular during the latter part of the 19th and early part of the 20th century.

Judging by the numbers surviving, the most popular Barnes was the lightweight No. 41/2 (with a 4.5" centre height). Unsuited to employment in a general engineering shop, this little lathe nevertheless contrived to bring versatility and usefulness to many farm and home workshops where its excellent built quality enabled it to absorb endless misuse and neglect. The No. 5 was also popular and, having a 5.5" centre height, a T-slotted boring table and a proper compound slide rest, was more useful for general work. Any foot-powered Barnes larger than the No. 5 is comparatively rare - machines of that size would have been expected to perform on a professional level - though the company did offer a proper "engine" lathe, the No. 18, that appears to have been heavily built with a deep bed and wide, flat-belt pulleys on the headstock spindle.

Having sampled the craft of "treadle turning", the writer can report that it quickly becomes a salutary lesson in the need to keep cutting tools sharp and correctly set. Any attempt to rush a job, or increase the rate of feed beyond what is reasonable, is met with instant, fatiguing feed back - and one quickly learns to reduce the amount of turning required to the very minimum. A surprising amount of energy can be absorbed by the drive to the leadscrew and the leadscrew bearings themselves; careful assembly and checking for free rotation of each component on the drive pays dividends on any small, low-powered lathe, treadle-powered or not. In common with many other makers of lighter lathes, many of the Barnes models were available with raiser blocks to lift the centre height an extra 6" or so.

The examples illustrated below represent the more common types produced by the company over the years - the range was large, and constantly evolving with many unrecorded detail changes made during production runs (the unusual twin-leadscrew version is shown here)

Can a Barnes lathe still make an effective work tool today? A reader writes:

I acquired a WF & John Barnes #13 lathe. I did not buy it to restore it as the antique that it is, but to make it usable for my projects as a viable piece of equipment to my workshop. At the time I really didn't know how old it was, but knew that with a little help it would fill my need for a medium-sized lathe. After some close examination I was also able to discern that, even though old, it was in pretty good shape! It had been sitting idle in a heated garage for more than 25 years and appeared to be fairly "low mileage" - or at least it was never used for production work. The spindle bushings were still tight and the ways were still tight and straight.. It is dirty, OILY, and cruddy looking, but it runs very sweetly!

It was retrofitted with an electric motor many years before I got it and still has the ancient motor fitted. I have retrofitted the headstock with brass drip-oilers for the spindle bushings, a large and beefy new 3-jaw scroll chuck with face-reversible jaws, and an Alouris quick-change tool post. The lathe is greasy and oily, but definitely a workhorse.

I have run it for hours and hours on end and it doesn't complain. I actually find it to be a descent piece of equipment and quite usable for a machine as old as it is - my guess being around 110 years plus..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9" x 25" Barnes Model 41/2

This was the smallest in the range, the most popular and widely sold and, in its basic form, supplied with just a single, swivelling tool slide--a proper compound arrangement of cross and swivelling top slide being missing.. Although the drive to the leadscrew was devoid of tumble reverse, or even a dog clutch, there - as on most of the lighter Barnes lathes - twin leadscrews to give an instant reverse to the carriage feed. In later years, Barnes realised that if the two leadscrews were properly "synchronised" it was possible for the operator to flick from the engagement of one leadscrew to the other--and so run a tool forwards and backwards while generating thread - or using the power sliding feed. Apparently some lathes can be found with marks on their changewheels to indicate that the leadscrew will be in synch.

The mandrel was bored through 3/8" and fitted with a standard No. 1 Morse taper. Backgear was also fitted, an essential feature on any human-powered lathe. The saddle was unusual in not being allowed to contact the front top way of the bed, instead it rested against the front angled way and on top of the screw-on rack. The lathe was available with a choice of either a conventional treadle, or a rather wonderful "bicycle" system. In the late 1870s, when the lathe was introduced, the term bicycle was not used so the mechanism was known by the contemporary French term Velocipede - the name originally given to the modified "Hobby Horse" with front-wheel pedals produced by Pierre Michaux in his Paris workshops during the 1860s. The introduction of the lathe also coincided with the development of the first successful light-weight chain - and it was the incorporation of one of these that enabled the Barnes' engineers to design a neat, compact, low-energy loss drive system which turned an overhung flywheel on the outside of the left-hand leg.

The operator's seat, which could be slid along the bed and locked into a convenient position, resembled those fitted to early farm machinery - and indeed the lathe was often advertised through the medium of general and mail-order catalogs sent to farming and other remote communities. The lathe was, in both its general aspects and detailed design, typical of the lighter sort of machine produced during late Victorian times.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Barnes Screwcutting "Lathe No. 41/2" with what the makers described as a Stand-up

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Barnes 11" No. 5 lathe with velocipede drive.

This 11" lathe was more substantially constructed than the 9" with an increased weight of over 150 lbs. The 15/32" bore spindle ran in what were known at the time as bronze "boxes", which were adjustable for alignment and wear. As standard, the toolslide was a single, swivelling unit - although a compound slide rest was available for an additional $3.50. Like the Model No. 41/2, the No. 5 was offered with a choice of a $20 power-type countershaft, an ordinary treadle or a velocipede pedal drive - in the latter case with three rather than two pedals so that the adjustable seat could be moved down the longer bed to undertake turning jobs near the tailstock.

The Model 5 was also available with a 15-inch capacity gap bed and an improved specification. The cross slide was enlarged to become a useful, T-slotted boring table which carried a swivelling top slide as part of the regular equipment. The set-over tailstock was completely redesigned along more conventional lines with a thick base plate and a greatly extended nose to reach over the wide cross slide.

In the picture above, the slotted cruciform-style backplate on the floor by the pedals was used as a "driver" or "catch" plate to turn work between centres - this particular design must be the most dangerous ever invented - perfect for grabbing the sleeve of an unsuspecting operator and winding him into the mechanism. If you have one with your antique lathe - bin it, or frame it, but don't use it; ever. They have been proved, however, to have their uses: Doug Elliot, a Barnes owner in California reports that the previous keeper of his lathe had attempted to force onto the Barnes' spindle a 3-jaw chuck intended for a 6-inch Atlas - and so violently had this been done that the chuck had split into two parts. Undeterred, the enterprising and presumably impecunious "machinist" recessed the cruciform backplate a 1/4" or so, to the exact diameter of the chuck, bolted it in place through slots and went on using it …

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Barnes 11" No. 5 lathe with standard treadle drive and single swivelling tool slide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Barnes 11" No. 5 lathe with gap bed and large, T-slotted boring table and compound slide rest. Note the extended tailstock casting designed to carry the barrel over the wider slide - and the three-pedal arrangement to permit the operator to work nearer the tailstock.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Barnes' No. 13 was specified with an even longer bed that necessitated a four-pedal drive

Barnes No. 13 lathe

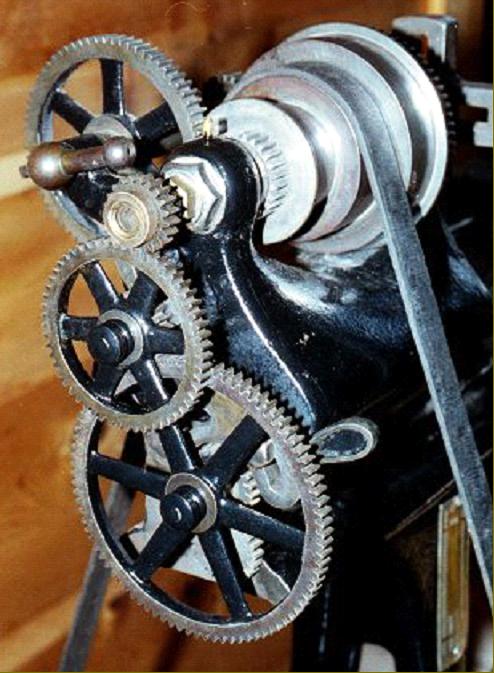

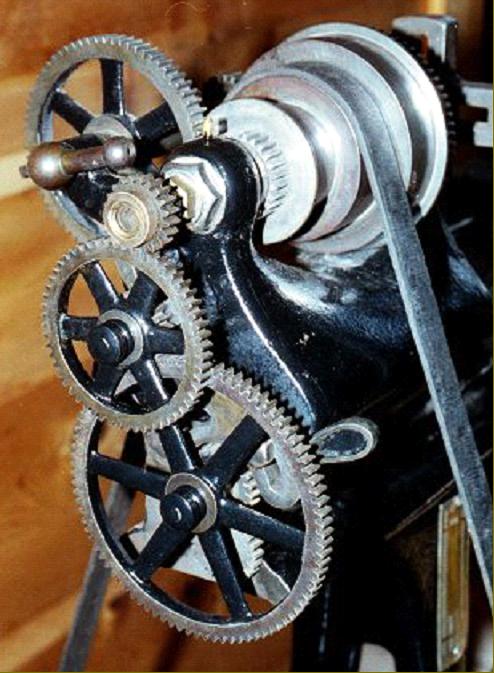

The No. 13 was, naturally enough, of 13-inch swing and the smallest Barnes to incorporate power sliding from other than the leadscrew thread. The mechanism (illustrated below) was subject to a 1902 patent and of unusual design; it provided both various rates of feed from fine to coarse and, by swinging the operating lever down and sliding the drive gear along the leadscrew, instant reverse. The drive could also be made to engaged with the cross-feed screw and so provide variable-speed power surfacing.

The lathe was available with between-centres capacities of 33", 45", 57" 69" and, rather ambitiously for so slender a bed casting, a massive 93".

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Barnes Variable-speed Power-Feed Mechanism employed a slotted leadscrew to drive, through a key, a gear which could be slid into engagement with any one of four ring gears cut on an apron-mounted wheel. The operating lever slid in a long slot milled in the lower part of the apron. To reverse the fed the lever, which was hinged just below its connection with the sliding gear, was swung in the opposite direction and the drive gear moved right across and meshed with the other side of the ring gears.

Power surfacing was also driven by the device, the large gear being pivoted so that it could be raised slightly to mesh with a gear formed on the end of the cross-feed screw

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Barnes' No. 13 with the optional power-driven countershaft unit.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Barnes 18-inch Engine lathe

Besides the rather frail-looking treadle lathes, Barnes also made this much more substantial and serious 18-inch "Engine" lathe - or, in British terminology, "BGSC" for Back-Geared and Screw-Cutting. The sliding control to vary the power sliding and surfacing feeds can be clearly seen at the bottom of the apron and the bed is obviously of much deeper section and was cast with box braces between the walls. The bed ways extended to almost the centre of the headstock assembly, which allowed the compound slide rest to be well supported in the middle of the saddle.

Made from forged crucible-steel, the spindle was bored through 15/8", carried a No. 3 Morse taper and ran in phosphor bronze boxes which were adjustable for wear.

Like most competing models, the saddle wings carried long T-slots so that they could act as a boring table - whilst offering alternative locations for the toolpost when unusually difficult or complex jobs had to be tackled.

Screwcutting was exclusively by steel changewheels - no gearbox being on the options' list - with threads from 1 to 56 t.p.i available from the standard set of 18 gears.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|