|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||

|

|

||

|

|

||

|

|

|

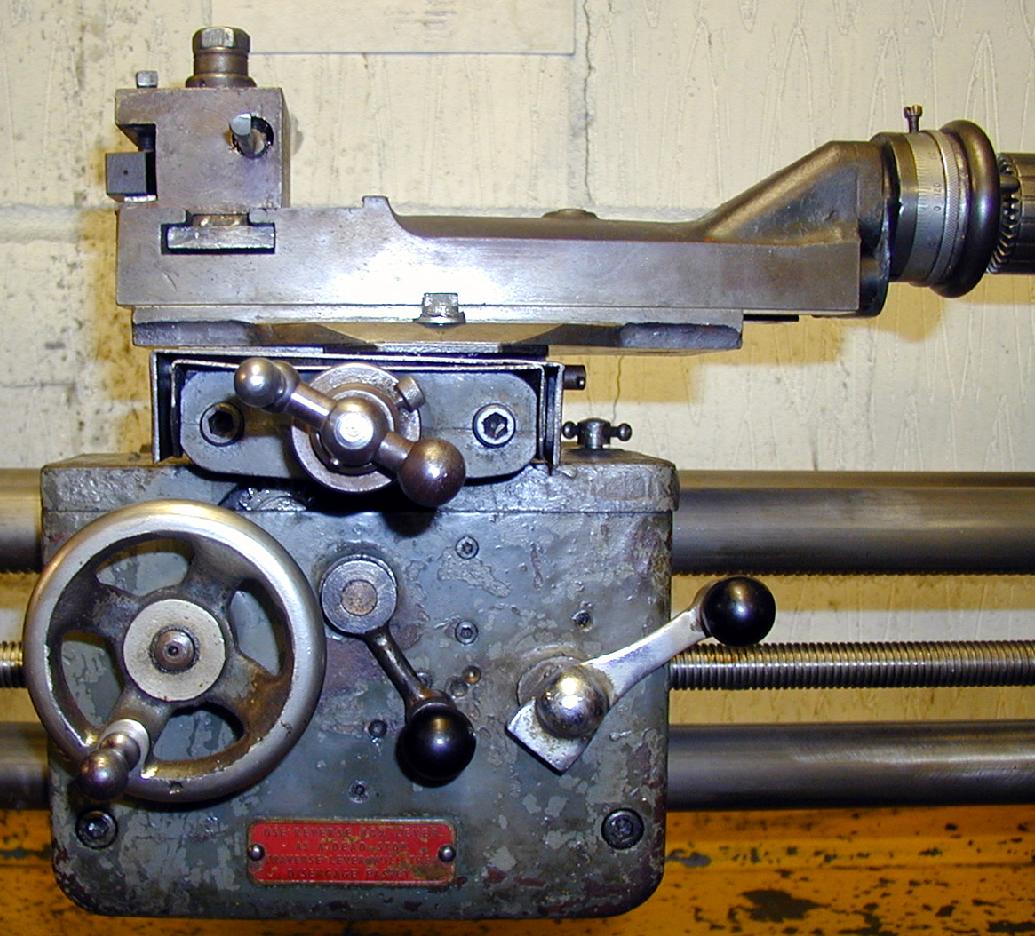

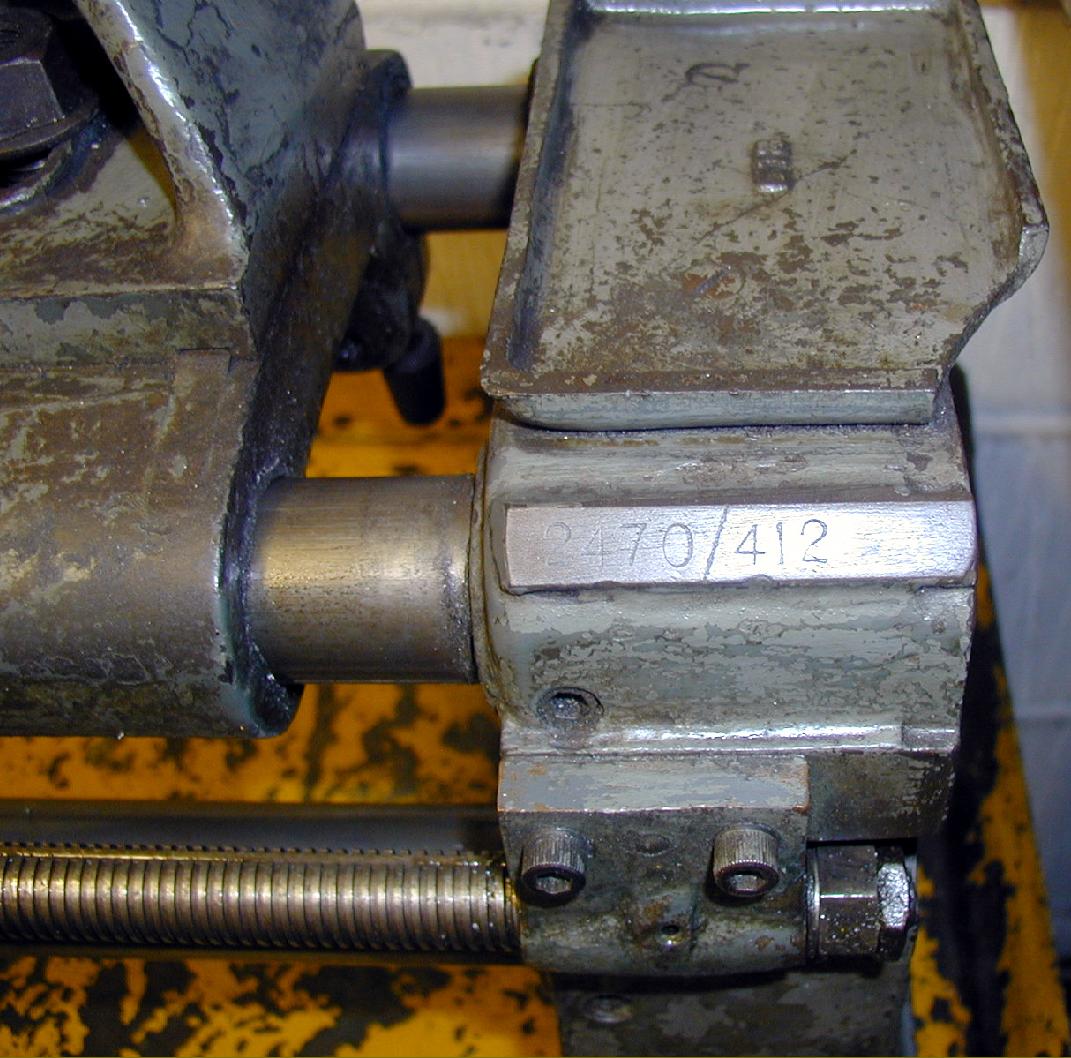

Both sliding and surfacing feeds were selected and engaged by a single 3-position lever on the front face of the apron. A small plate riveted to the lathe instructed the operator how to use the automatic release for the sliding feed: "Use reverse box lever as a dead stop . Traverse lever will then disengage easily". |

||

|

|

|

|

||

|

|

||

|

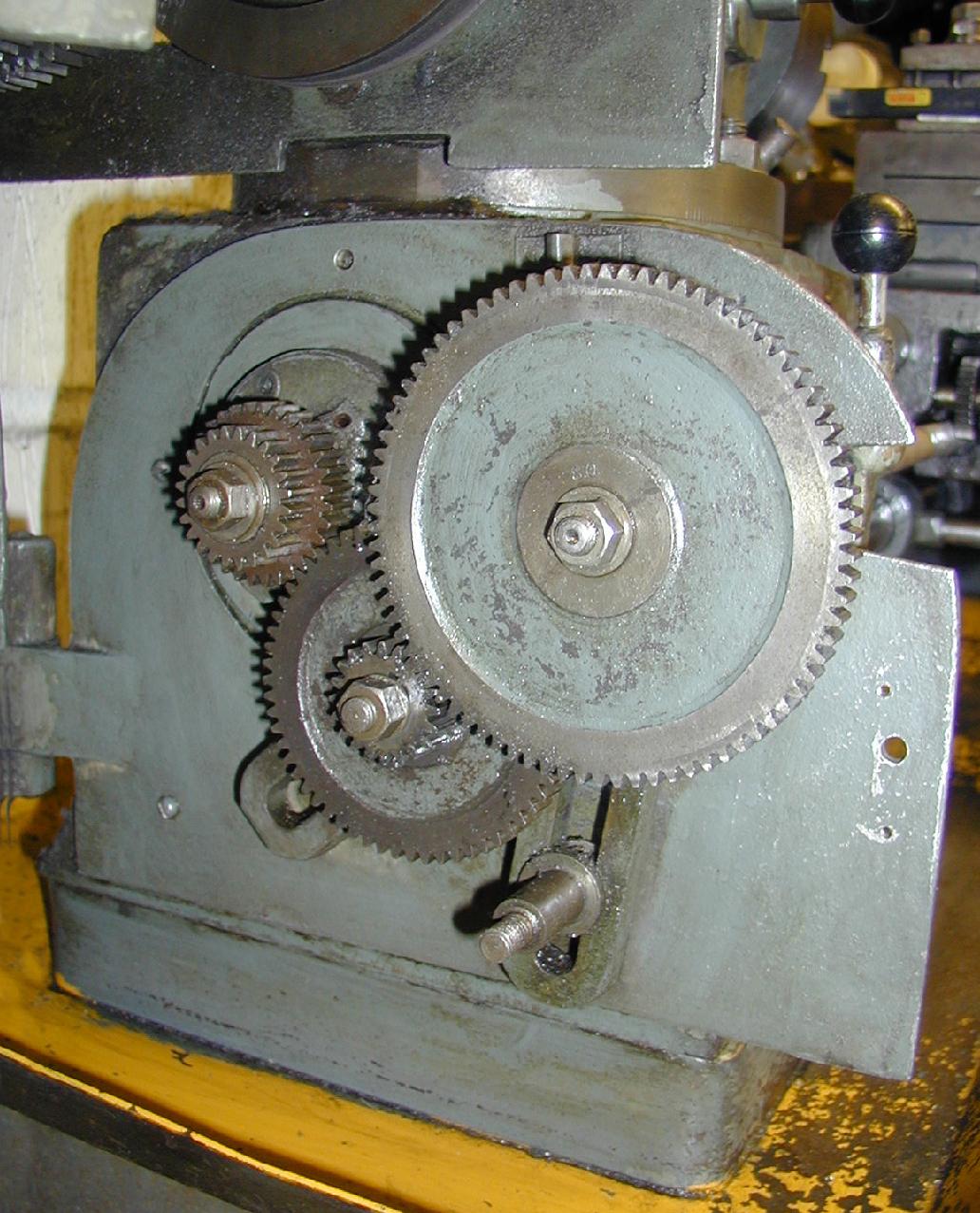

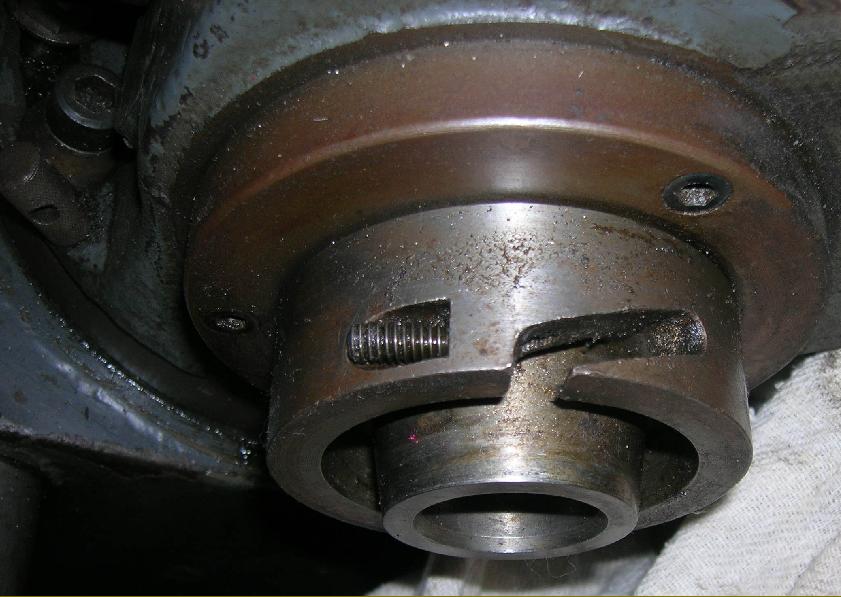

A pair of bevel gears under the headstock transmitted a drive out to a conventional arrangement of changewheels carried on a slotted bracket. |

|

|

|

|

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||