|

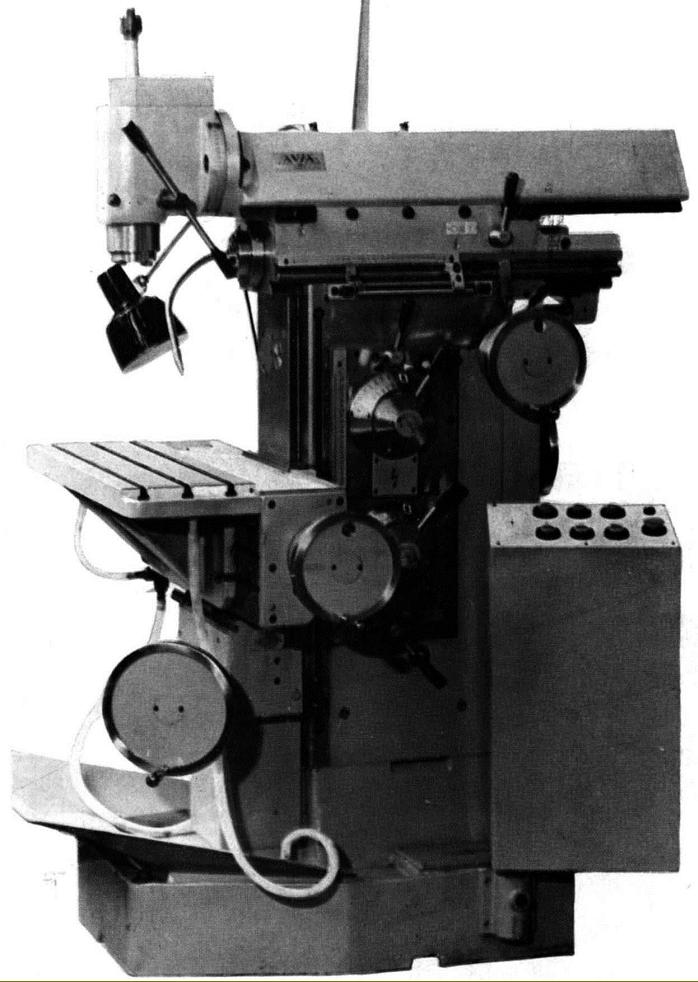

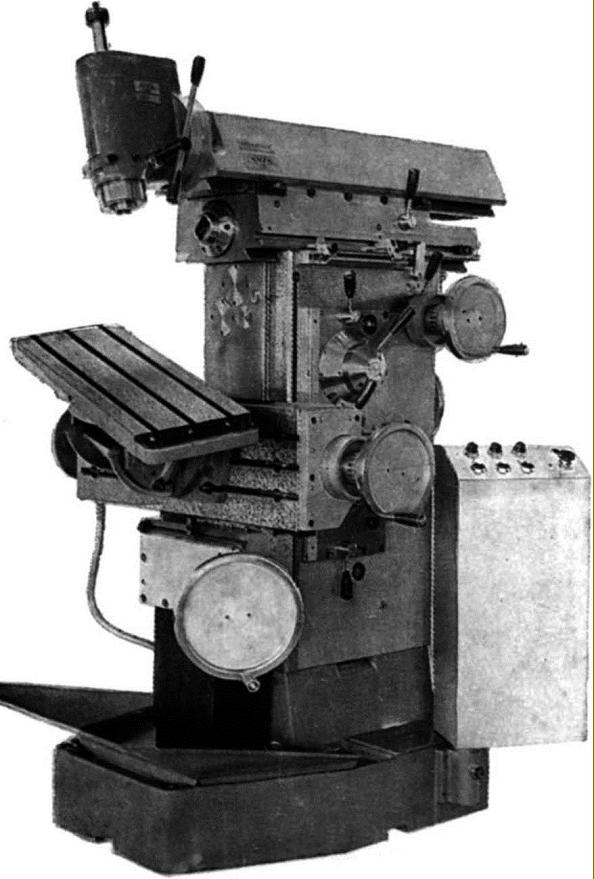

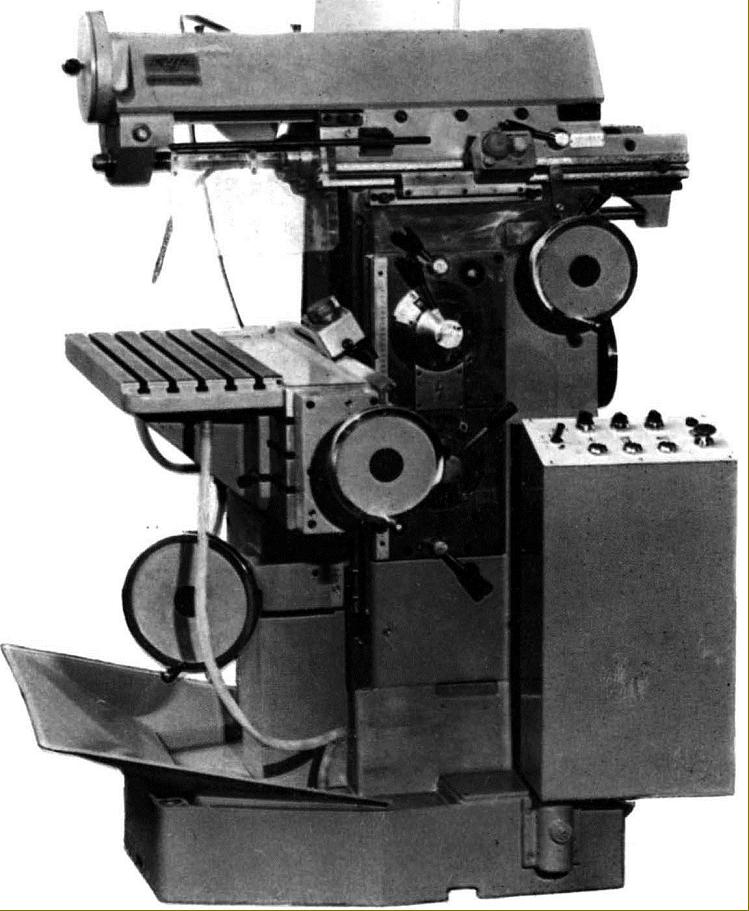

FNC-25 with the Type FNCz Universal Table

Continued:

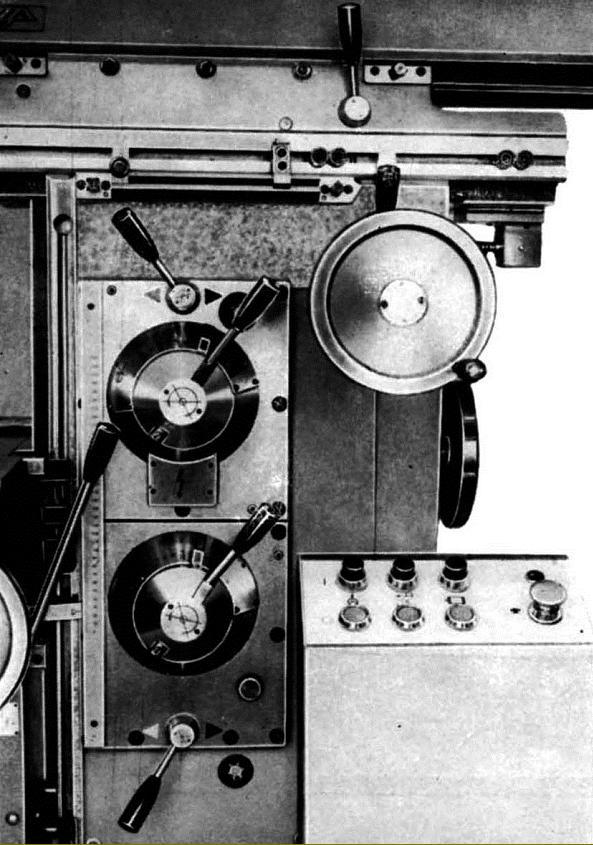

Safety limit and intermediate adjustable knock-off stops were fitted to both axes of travel, as were finely-engraved rulers in mm divisions and holders able to take D.T.I.s reading down to 0.01 mm, precision, micrometer-drum-equipped length rods and Johanson slip gauges. Handwheels were the full-circle type (with sufficient weight to impart a flywheel effect) and equipped with satin-chrome micrometer dials of a good diameter. Indicative of the quality built into each machine was the fact that all slideways were hardened (to "50 HRC") with knee and head feed-screws of large diameter, hardened and ground and running though bronze nuts adjustable to eliminate backlash. However, offered as an option for the table's longitudinal feed (and the head) were screws running through what is sometimes called a "worm and sector" arrangement where the nuts, instead of being bronze, were equipped with recirculating balls - a system that guaranteed no backlash, long freedom from wear and a somewhat finer feel to the controls.

Supplied as part of the standard equipment, and able to be bolted to the vertical, was a 280 x 750 mm Horizontal Rectangular Table with five 12 mm T-slots set on 50 mm centres. However, in order to get the most from the miller, a required accessory was the 250 x 600 mm Type FNCz Universal Angular Table. This could be tilted around the longitudinal axis by 30° each side of horizontal, by 30° in the same manner on the lateral axis and tilted by 45° each side of an axis perpendicular to the table's surface.

Machined as a hardened slideway, the top of the main column carried a separate housing, able to be moved my hand or under power, that housed a horizontal spindle with an ISO 40 nose running in high-precision roller races. To solve the problem of how to drive the spindle when its housing was moved in and out (and so provide lateral travel to the cutter), the final gear in the speed-change box was enormously long and engaged by a narrow gear fitted to the horizontal spindle. The top of the sliding housing was machined to take a dovetail overarm to which could be clamped the usual type of drop bracket to support the outer end of a horizontal milling arbor. In addition, the overarm carried the Type FNCk-3 Vertical Swivel Head, also driven by gearing (from the horizontal spindle below) and with the same 16 speeds from 56 to 1800 r.p.m. By mounting the vertical head in this way - at not on the end of the lower sliding housing, as on the Russian version - valuable extra clearance was gained between spindle nose and table. Mounted in high-precision bearings, the vertical spindle was hardened on its ISO40 nose, had a quill travel of 80 mm and could be swivelled 45° each side of vertical. Unfortunately, control of the quill was by a quick-feed lever - the addition of a fine-feed handwheel, working through worm-and-wheel gearing, would have been a considerable improvement.

Accessories:

Available at extra cost was the 56 kg Type FNCI-3 High-speed Vertical Head. Driven by a 0.75 kW motor and using a V-belt, this had 6 speeds from 2000 to 6300 r.p.m. it was designed for the use of smaller cutters and (with precautions taken to protect the machine's slideways) grinding wheels. Carried in high-precision anti-friction bearings, the spindle was arranged with spring loading to automatically compensate for expansion as it worked and carried a hardened and ground ISO40 nose. The quill had 60 mm of travel, with control by a lever (again, like the standard head, no fine-feed was possible) and could be swivelled 45° each side of vertical. The maximum clearance between spindle nose and table was a useful 410 mm.

Slotting was catered for by the Type FNCj Slotting Head, a unit able to be inclined 45° each side of vertical and with a maximum tool travel of 80 mm in 12 rates of stroke that varied from 18 to 224 per minute.

Of unusually rigid design, with a dovetail overarm, the Type FNCh-3 Dividing Head was designed to hold a workpiece directly in the spindle with the aid of a drawbar, between centres, in a 3-jaw chuck - or on the 195 mm diameter Type FNCn-3 Die Mounting Plate that had four 10 mm radial T-slots and was supplied complete with four finger clamps. The unit was fitted with a simple, plunger-index wheel with 12 holes for direct dividing, a ring notched every 1° and provided with a pointer and a set of three dividing plates (used in conjunction with the usual worm-and-wheel gearing) for indirect indexing. Oddly, for this class of machine, it lacked the provision to mount a set of driven changewheels for the development of spirals. With its head able to be swivelled through 360° on the mounting plate, the unit could be fitted on any of the tables - vertical, horizontal or swivelling.

Supplied with each FNC25 was a complete set of electrical equipment on 3-phase, ready-to-run and with a machine light; coolant equipment and splash guard; a horizontal milling table; one 22 mm milling arbor complete with a set of spacing rings; plain and bent-shank hexagon and "C" spanners for ordinary maintenance and the adjustment of bearings; an oil gun, foundation bolts and an operator's handbook.

*Proof of the type's success - the genus Precision Universal Milling Machine - is evident from the number of similar machines made in various countries including:

Austria: Emco Model F3

Belgium: S.A.B.C.A. Model JRC-2

Czechoslovakia: TOS Model FN22, 32 & FN40 Optic

Spain: Metba Models MB-0, MB-1, MB-2, MB-3 and MB-4)

England: Alexander "Master Toolmaker" and the Ajax "00", an import of uncertain origin.

France (?): Perron Montier

Germany: by several companies including: Macmon Models M-100 & M-200 (though these were actually manufactured by Prvomajska); Maho (many models over several decades); Thiel Models 58, 158 and 159; Hermle Models UWF-700 and UWF-700-PH; Rumag Models RW-416 and RW-416-VG; SHW (Schwabische Huttenwerke) Models UF1, UF2 and UF3; Hahn & Kolb with their pre-WW2 Variomat model and Wemas with their Type WMS.

Italy: C.B.Ferrari Models M1R & M2R; Bandini Model FA-1/CB and badged as Fragola (agents, with a version of the Spanish Meteba).

Japan: Riken Models RTM2 and RTM3

Poland: Fabryka Obrabiarek Precyzyinych as the "Avia" and "Polamco" Models FNC25, FND-25 and FND-32

Russia: as the "Stankoimport" 676

Spain: Metba Models MB-0, MB-1, MB-2, MB-3 and MB-4

Switzerland: Aciera Models F1, F2, F3, F4 and F5; Schaublin Model 13; Mikron Models WF2/3S, WF3S, WF-3-DCM & WF-2/3-DCM; Christen Types U-O and U-1 (and Perrin frères SA, Moutier) and Hispano-Suiza S.A. Model HSS-143.

The former Yugoslavia: Prvomajska (in Zagreb with Models ALG-100 and ALG200); Sinn Models MS2D & MS4D; Ruhla and "Comet" Model X8130, imported to the UK in the 1970s by TI Comet.

At least five Chinese versions have been made, including one from the Beijing Instrument Machine Tool Works. A number of the "clones" merely followed the general Thiel/Maho/Deckel concept whilst others, like Bandini and Christen, borrowed heavily from Deckel and even had parts that were interchangeable. Should you come across any of these makes and models all will provide "The Deckel Experience" - though you must bear in mind that spares are unlikely to be available and, being complex, finely-made mechanisms, they can be rather difficult and expensive to repair..

|

|