|

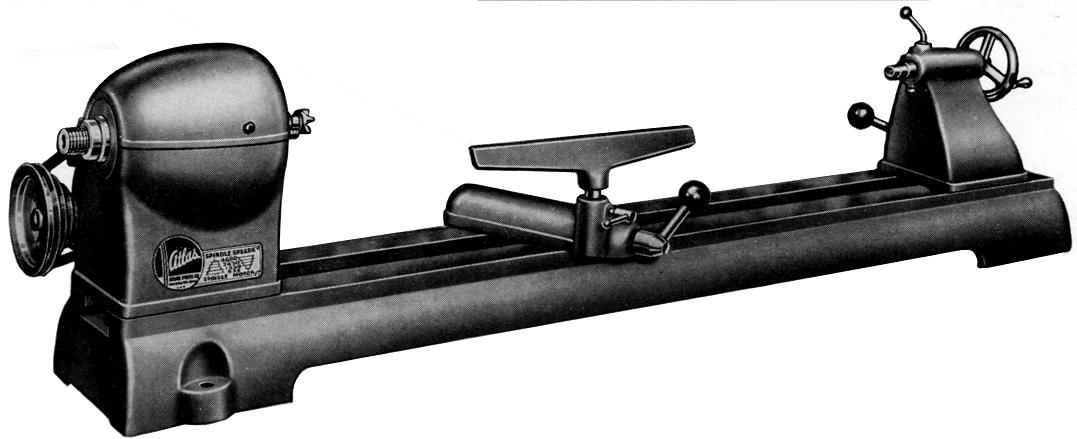

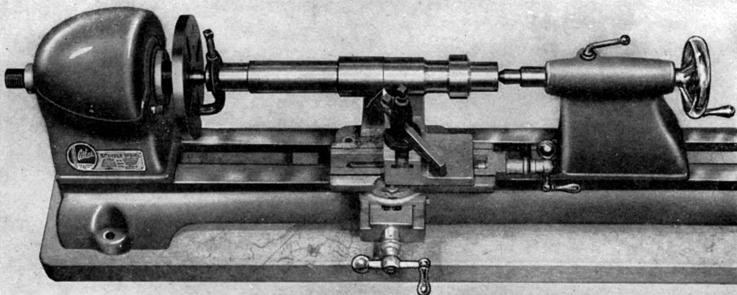

Although Atlas (and other makers) constructed various sizes of wood-turning lathes for marketing by Sear, Roebuck as "Craftsman" products, their own range of such machines, from the early 1930s to the late 1950s, was much more limited. By 1941, and the advent of WW2, wood lathes had even been displaced entirely from the Company's main catalog - and did not reappear again until 1948 when, in a dedicated Wood Lathe Sales Brochure, the new 12" x 36" Model "7121" (later the "7122") was introduced.

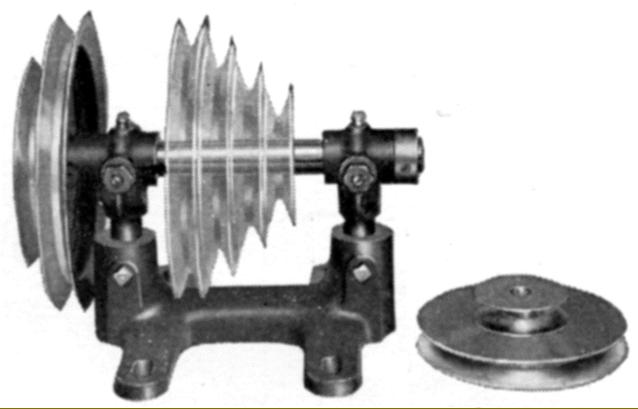

The first Atlas wood lathes of any real usefulness were the 12-inch swing Model "1250" and the 10-inch Model "1050". Both were of identical construction with the bed in a semi-steel iron and 50 inches long that allowed 36 inches to be admitted between centers. The Model "1250" weighed (less motor) 115 lbs and the Model "1050" 100 lbs. Both could be had for bench mounting with the drive coming from behind, or fitted to cast-iron legs joined with a heavy wooden tray beneath the bed and a second one, acting as a handy shelf, near the floor. The bare stand - weighing 160 lbs - was listed as part No.W17 and could be fitted with a choice of two underdrive systems, a 4-speed with direct drive to the headstock by V-belt - Type W18 - or, with the addition of an intermediated countershaft - Type L2-675 - that both doubled the number of speeds to eight with four of these being set slower to help with large-diameter bowl turning. The standard range of speeds on these earlier lathes was very similar to the later "7121" and "7122" models and ran from 750 to 4000 r.p.m. on the "1050" and 650 to 4300 on the "1250". It's likely that the slow-speed range on the 8-speed model ran from around 200 to 1350 r.p.m. On these first models, sales catalogs show the motor and countershaft hanging beneath the underside of the headstock - while on the 7121 and 7122 the motor was carried on the lower wooden shelf.

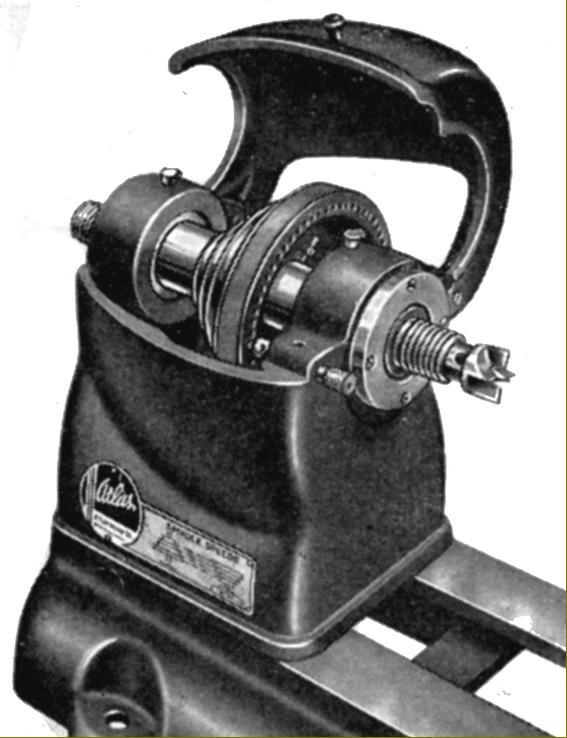

The headstock, in a grey iron, was located to the bed by a tongue and grove, was a separate casting and carried a spindle running in deep-groove SKF ball races (able to be adjusted by shims) that were designed to take both radial and end-thrust loads. Sized to take an "A" section V-belt, the pulley have four steps and a ring of 260 indexing On the "1250" the spindle thread was 1" x 8 t.p.i. and the bore 9/16"; on the "1050" the thread was 3/8" x 16 t.p.i. and the bore 3/8". A simple lift-off cover in cast-iron was provided for speed changes.

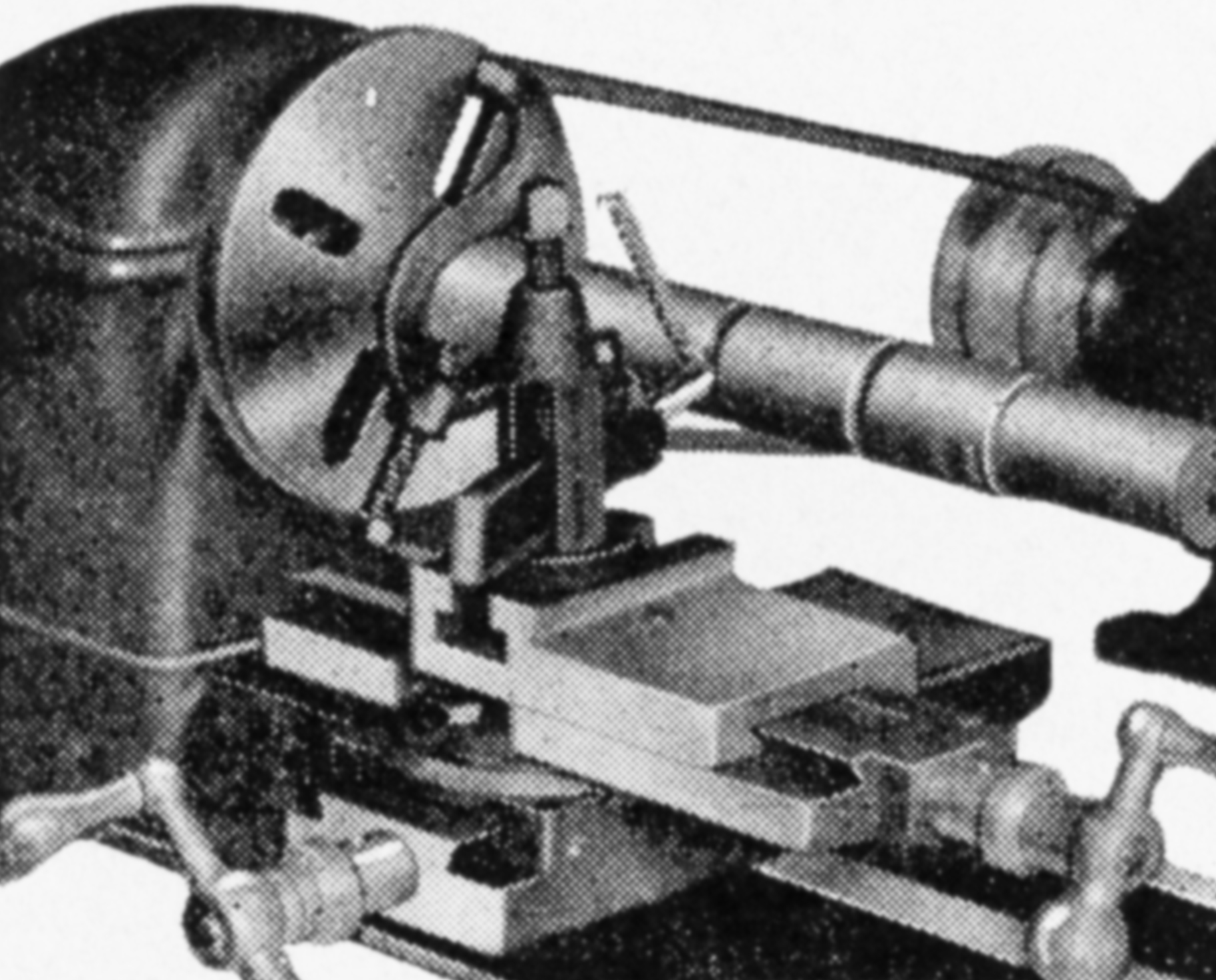

Accessories, identical to the later models, included a conversion kit to metal turning (the main component being a screw-feed compound slide rest assembly; a floor-standing bowl-turning unit; a larger faceplate; woodturning tools; 3 and 4-jaw chucks; Jacobs drill chucks, tailstock rotating centres and electric motors.

In 1948 production of wood lathes resumed, the first model being the Model "7121", a simple machine, but heavily built (115 lb.). The lathe was also sold, mounted on an under-drive stand with variable-speed drive, as the Brodhead-Garret J-Line Model J-112. Like all good-quality wood lathes, to gain the mass that is so helpful in successful wood turning, all the main castings were in iron. Ground-finished, the No. 2 Morse taper, 9/16"-bore headstock spindle ran in sealed, factory-preloaded and shimmed deep-grooved SKF ball bearings with, at first on the Model "7121", was threaded 1" x 8 t.p.i at both its ends (left-handed, of course, on the outboard, "bowl-turning" side) and later (on the Model "7122") 1" x 10 t.p.i. The spindle carried a 4-step V pulley which, like the 10" Atlas metal lathe, had a ring of 60 indexing holes on the face of its largest pulley. The belt run over the pulley was guarded by a neat, swing-open cast-iron cover hinged from lugs cast into the rear section of the headstock. Faceplates were charged extra with several available including 9-inch and 5.25-inch combination types with radial slots (to hold and drive metal) and drilled holes for wood threaded to fit either inboard or outboard spindle; a plain 3.5-inch unit with just drilled holes for the inboard spindle and a 6-inch combination type for just the 1" x 8 t.p.i. Spindle.

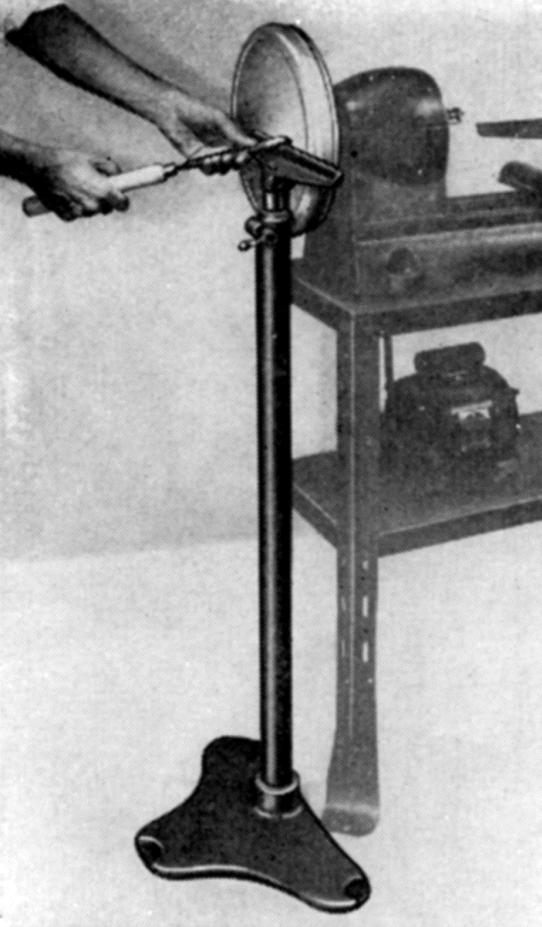

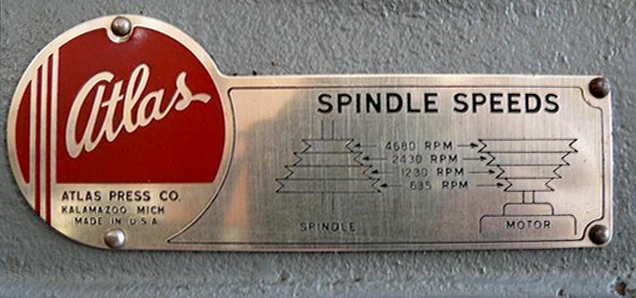

Normally, for wood turning, a standard American-style 60 Hz, 1725 r.p.m. 1/2 hp (or optionally 1/3 hp) 1-phase (or 3-phase) electric motor was mounted behind the lathe and fastened directly to the bench. Considering how well specified Atlas metal lathes were (and how complete and well-integrated their drive systems), it is odd that the wood lathe was not even offered with a simple, adjustable motor-mounting plate - which would at least have allowed the belt to be slackened before changing speeds. A fixed-position "jackshaft" (countershaft) was, however, on the options' list and this retained the original direct-drive speeds of 635, 1230, 2430 and 4680 rpm while providing an additional, slower range, more suited to the turning of large-diameter bowls (and light-duty metal and plastic machining) of 197, 372, 710 and 1343 rpm. For assistance with bowl turning, Atlas offered a rather unusual (for a small lathe) floor-standing rest and it is difficult to say why the flat end of the bed, was not used instead to carry a simple and rugged bolt-on bowl-turning attachment. Such an attachment, as used on many other makes of lathe, would have had a greater range of adjustments - and been a great deal safer.

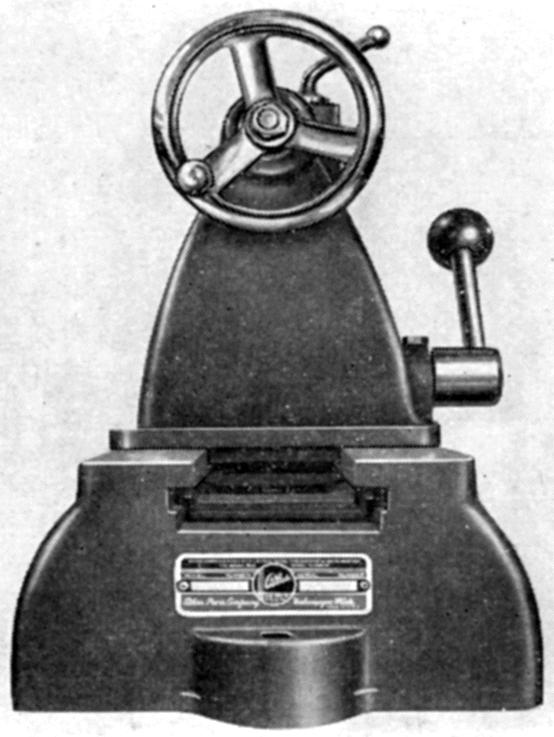

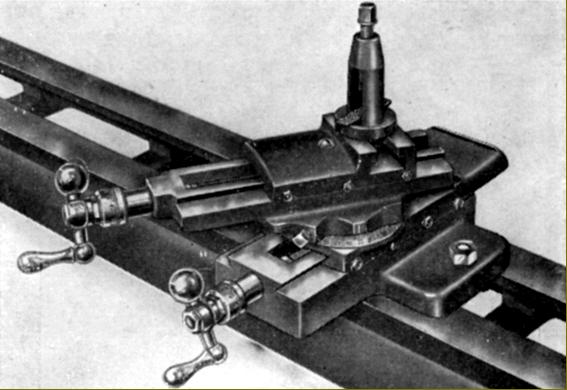

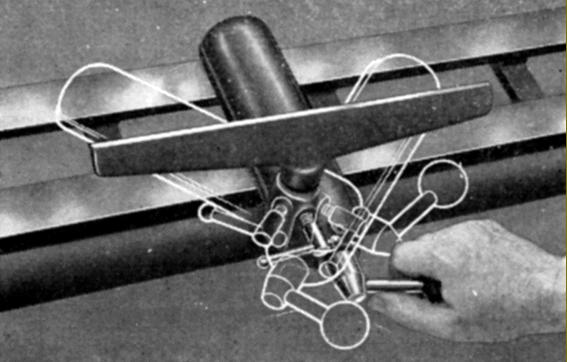

Mounted on a swivelling base and fitted with convenient, permanently-mounted handles, the standard tool holder had a T-piece a usefully long 12-inch T-rest with the option of three others: No. 5618 a right-angle for turning and facing at one setting and two shorter straight rests: No. 0-334 at 4-inches and No. 9-33 at 8-inches. While the tailstock was locked to the bed by a fixed, cam-action lever, the ruler-graduated, 21/8"-travel No. 2 Morse taper tailstock spindle was locked by a crude, direct-acting bolt. Although the spindle was provided with self-eject for its centre, this meant that it could not be hollow and hence not used as a handy guide for long-hole boring.

|

|