|

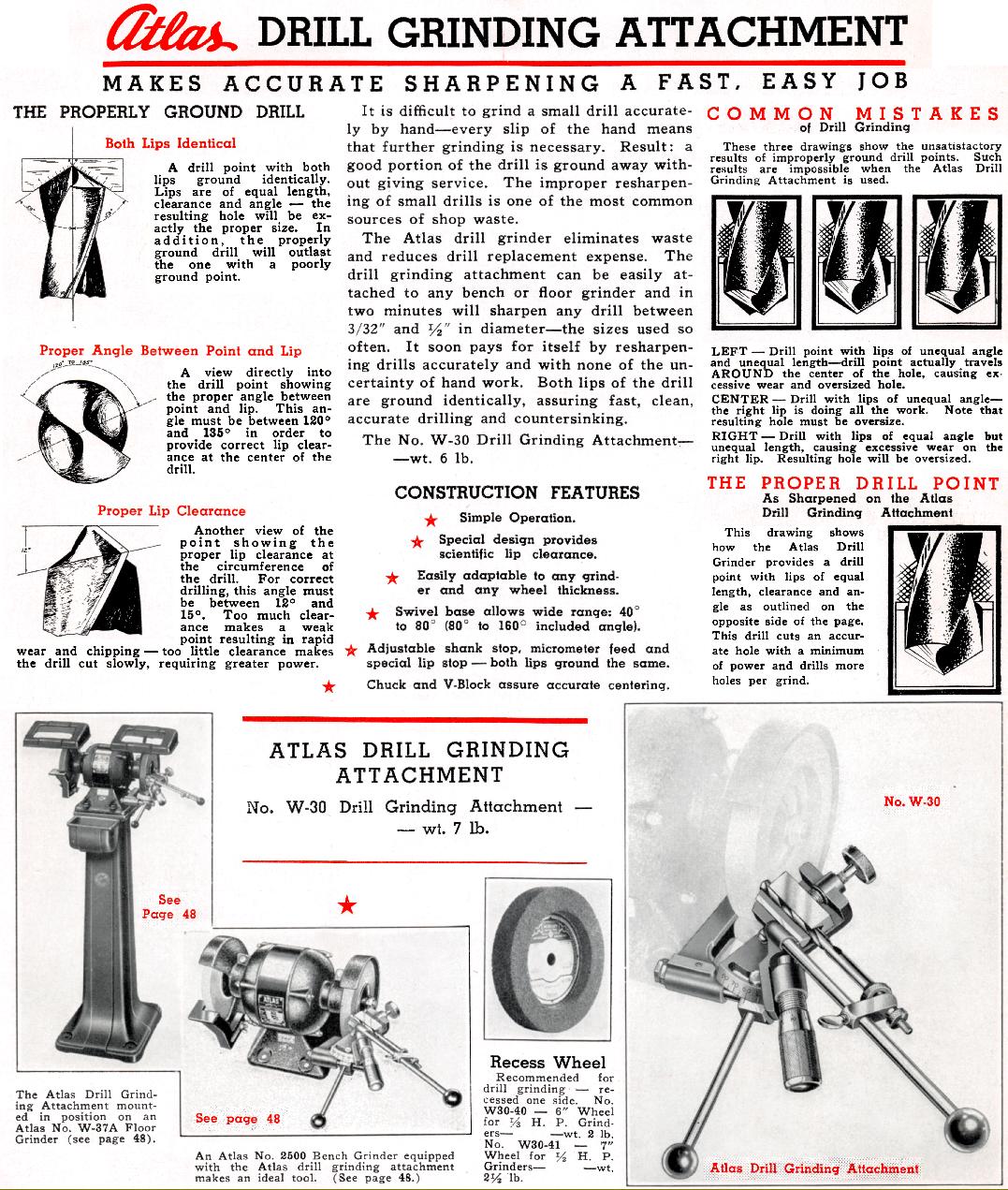

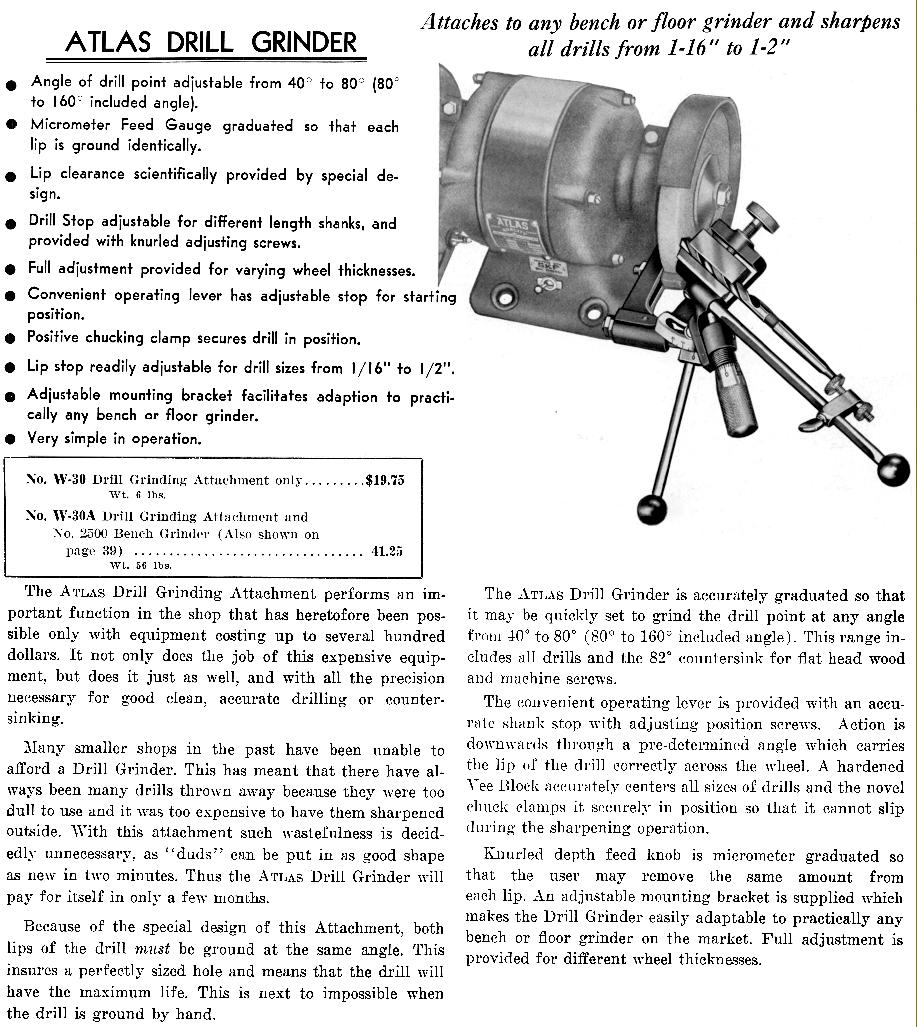

Listed for the first time in the Atlas "All-models Catalog" for circa 1935 (the second edition of such), the Atlas drill grinding attachment followed an established design as produced by a number of other makers and was offered in a single size designed to sharpen drills from 3/32 to 1/2" in diameter. Also branded for the Atlas-manufactured "Craftsman" range, although limited in its capacity, the Atlas had one rather superior feature: "micrometer" adjustment of the feed gauge that ensured each lip of a drill was ground accurately. The matching unit offered in the UK was originally by a Company called Reliance - and constructed in a similar fashion using all steel and iron parts.

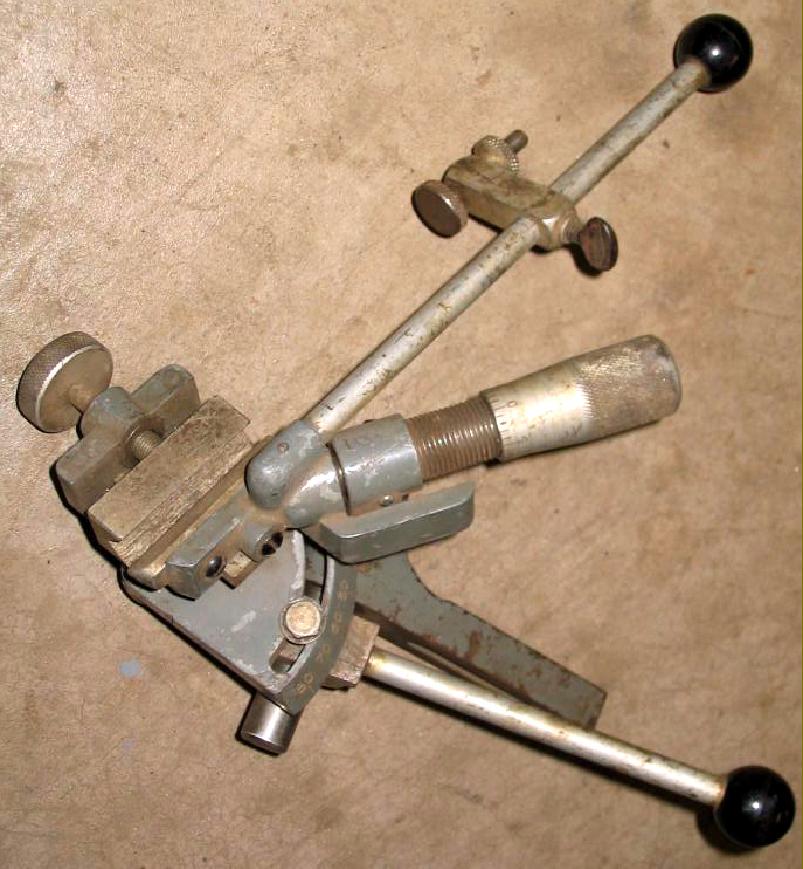

Long a popular - if frequently misunderstood and badly used tool - the drill grinding jig was introduced during the early 1920s and built, as a Reliance form, in three sizes: the No. 1 to take drills from 1/16" to 1/2", the No. 2 for drills from 1/4" to 1" and the No. 3, this being able to handle drills from 1/4" to 2". Of all the types, the most likely to be encountered is the No. 1, with the No. 3 rarely found. The unit was intended to be clamped to, or bolted alongside, a suitably powered grinding wheel - though the writer remembers, when a boy, his next door neighbour (a skilled die sinker) having one attached to a little hand-cranked wheel. Reliance also offered, during the 1950s, a completely self-contained unit mounted on a double-ended grinder, this assembly also including a point thinning attachment.

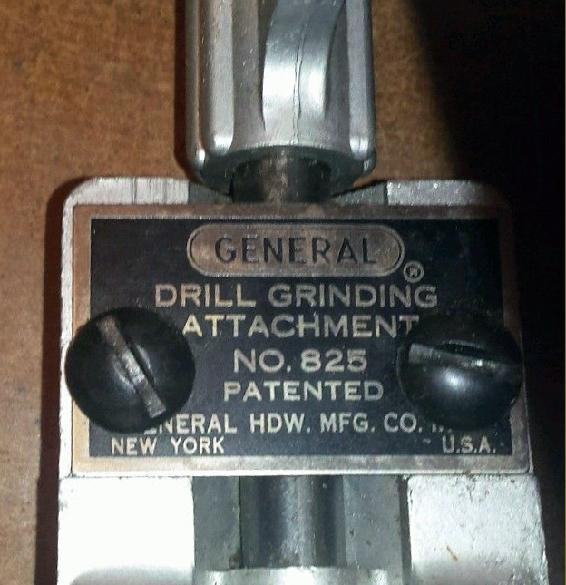

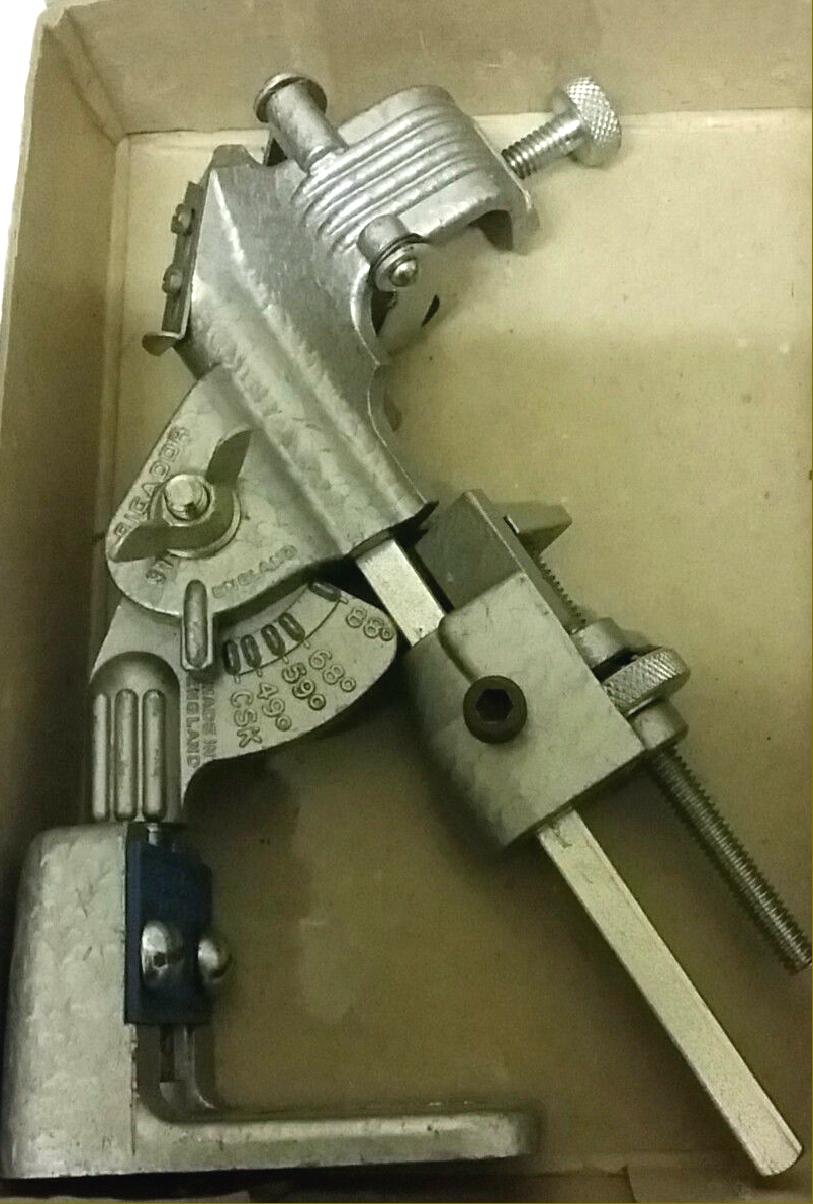

More recent models, from the late 1950s onwards, include the English-made Picador and two another almost identical die-cast examples, these currently sold in the UK as the "Draper" and "Spiralux" - the latter marketed for many years in the United States as the "General" and "Blue-Point" (the latter a lower-cost branding of Snap-On). It is almost certain that the unit has also been sold, and continues to be available, in various unbranded or oddly-named forms. All the American types appear, apart from their price, to have been identical and are often discovered (as are other brands, in other countries) complete with their original box and in almost unused condition….

Although the "General", "Blue-Point", "Picador", "Draper" and "Spiralux" all work (or fail to work) in exactly the same way as the older types, they look almost toy-like in their construction and compare badly to the all-steel and well-engineered original. However, when employed skilfully - and with a full understanding of the principles involved - excellent results can be obtained, though it is all too easy to make a complete hash of the job and give up in despair.

A very experienced American user points out that:- the angle of the pivot pin differed from make to make - some being aligned vertically while others were at an angle, the latter probably introduced as being un-adjustable and hence more suitable for the amateur market. With a vertical pin, the cutting edges of the drill require aligning at the "5 to 5 o'clock" position to produce the correct back-off angle, though by twisting the drill slightly this setting can be altered. With the pin at an angle the cutting edges need to be set vertically and so the back-off angle is, essentially, fixed; if the drill is subsequently twisted in its holder, unpredictable effects result, believed to do with the diameter of the drill being ground. In general, these devices seem to work better when used with a narrow cup wheel dressed flat. When employed as shown in the instructions (on the side of a normal grinding wheel) a hollow wear pattern is eventually formed that destroys accuracy.

An important tip is to set the angle and projection first, adjust the registration pointer and end-stop and then remove and replace the drill. If it goes in easily, sharpening can commence - if not, adjust as needed, take out - and try again. The "in-and-out" method guarantees a symmetrical point because the drill insertion method is the same for both. However, adjusting, grinding and then turning over will tend to produce asymmetrical results.

If any reader has another make of drill grinder of the same pattern, the writer would be interested to hear from you.

|

|