|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

An Arundel K4 installed a professional wood-turner's workshop where it's robust built has allowed it to absorb thousands of hours of hard use

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The less-expensive but well-made Arundel Type E5 circa 1975

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arundel J4 Mk. 2 9" Swing Junior Lathe circa 1975. An unusual feature of the J4 was the arrangement of the bed rails - standard drawn square-section steel bar with the front rail arranged with an edge (rather than a face) upwards to give what Arundel called a "prismatic-guiding edge". The rail to the rear was set so that a flat surface was uppermost. A three-speed V belt or four Poly-V belt drive was available and the standard bed length was 31" - but any length could, in fact, be ordered. Bowl turning was an option, using the separate bench-mounted unit also specified for the K and E Series machines

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For a small company Arundel made an astonishing variety of models: this J4 Senior is unusual in having a long bed, raised bed and headstock supports, a built-on bowl-turning attachment of increased capacity and what appears to be a maker's supplied cabinet stand with well-arranged switchgear. More on the J4 Senior on this page

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The J4's robust, built-on bowl-turning attachment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The headstock from the Arundel E5 was also offered as a stand-alone bench unit for large diameter faceplate work. The special E5 headstock (picture below) with outboard bowl-turning, was an option on the E5R lathe and featured a modified thrust bearing allowing a clear bore through the spindle and the fitment of a left-hand faceplate with a 19" diameter turning capacity.

The standard lathe cross slide could be fitted to the bench-mounted swivelling bracket. This combination of a sliding and swivelling slide action on a swivelling base provided the tool rest with a very useful range of movements.

A floor-mounted tripod support was also listed for the tool rest and, given a suitably slow speed, allowed very large diameters indeed to be turned.

An Arundel E5R user writes:

...the "R" means equipped with an outside faceplate and external tool rest, for large jobs. I did a couple of wine table tops, long time ago. But mostly I just use the inside faceplate for shallow bowls, breadboards etc. However, the "R" - which cost an extra fiver, I believe! - is one of the best features of this lathe. I have the outside faceplate constantly mounted, and always use it to start and stop the lathe. Most of my turning is between-centres. Using my left hand on the faceplate, I first check that wood spins freely, without fouling the toolrest. Then I give it another manual spin, and quickly before it stops I press the ON switch. This saves the motor a wee bit of stress ! When stopping, I switch off and then immediately put my hand on the faceplate and brake it. Saves lots of seconds ! The headstock spindle is not bored through on my lathe (I think Arundel offered this at extra cost). To remove live centres and drill chuck from the Morse taper, I keep a big hex nut screwed on the 1" nose. I just unscrew this nut and it effortlessly pushes out the centre/chuck/drill . . .

I do a lot of long boring, so the generous traverse of the tailstock is a big help. All in all, I made a great purchase 50 years ago!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arundel Type E5 (5.25" x 29.5") was a very well made but essentially simple machine. The bed was constructed from plain steel rails of rectangular section and the cast iron headstock featured plain bronze bearings (with wick-feed oil cups) and a single ball bearing-type thrust arrangement of type last seen in late Victorian times. Drive was by an A section belt and offered 4 speeds of 470, 920, 1640 and 3000 r.p.m. when driven by the recommended 0.75 h.p. 1420 r.p.m motor. Centres were No. 1 Morse taper and all locking movements were provided with self-contained handles, no spanners being needed to operate the lathe.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A superb example of an Arundel E5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The seldom-found Arundel E5 sanding table

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The E5 was supplied with a generously large faceplate

|

|

|

|

|

|

|

|

|

|

|

|

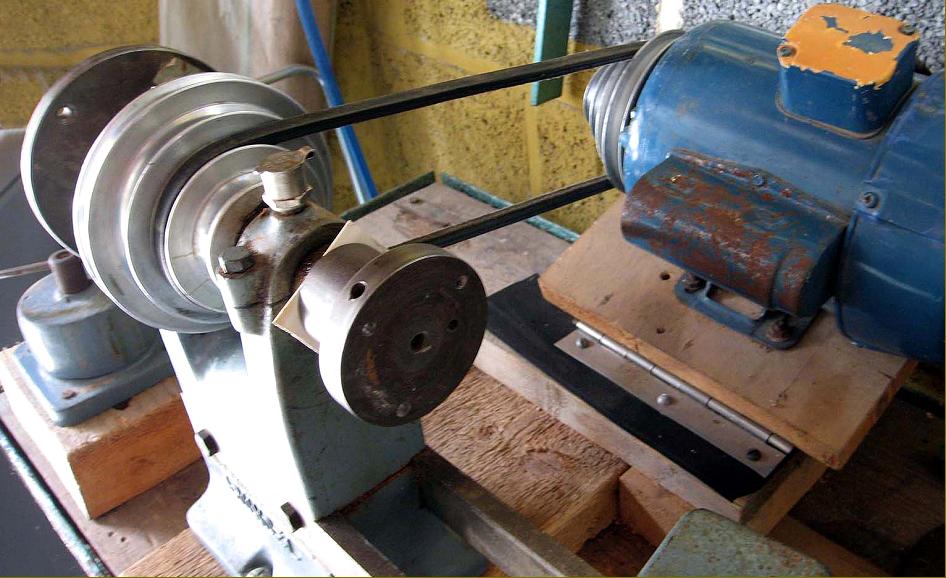

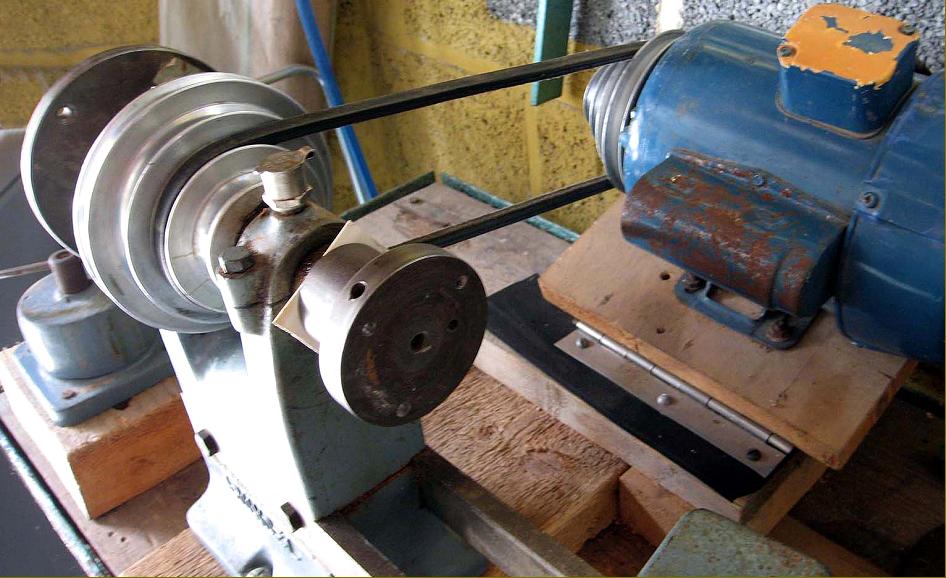

A motorised Arundel E5 with separate bowl-turning attachment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plain bronze bearing headstock of the Arundel E5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Independent bowl-turning attachment as used on an E5. The advantage of this arrangement was it versatility, it

being possible to position so that the operator could maximise his or her chances of producing exactly what was required.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arundel J4 Mk. 2 9-inch Swing Junior Lathe on the maker's stand

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|