|

Home Machine Tool Archive Machine-tools Sale & Wanted Arundel Page 2 Arundel Page 3 - J4 Junior J4 Senior Arundel M300 |

||

|

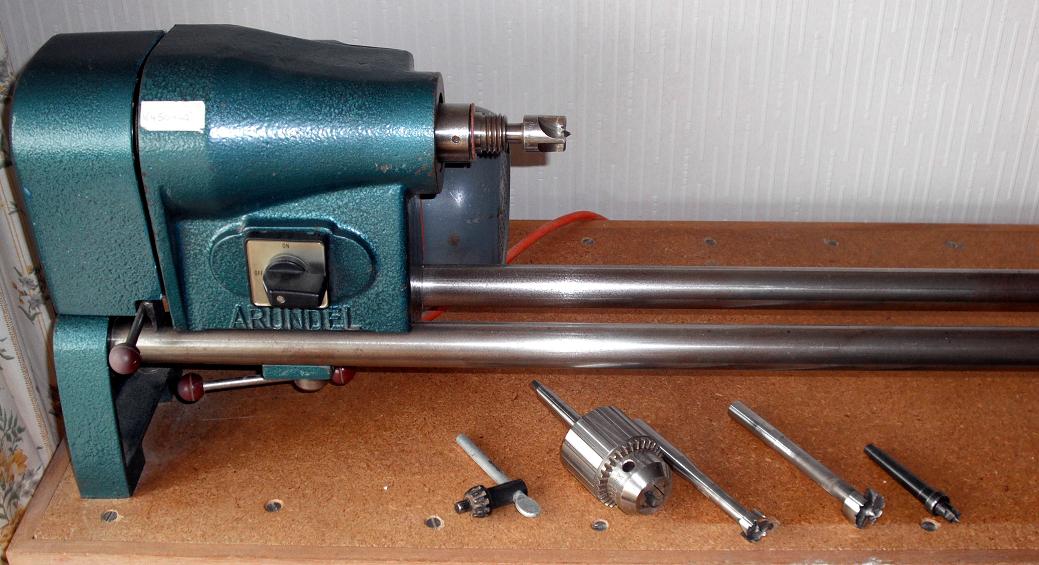

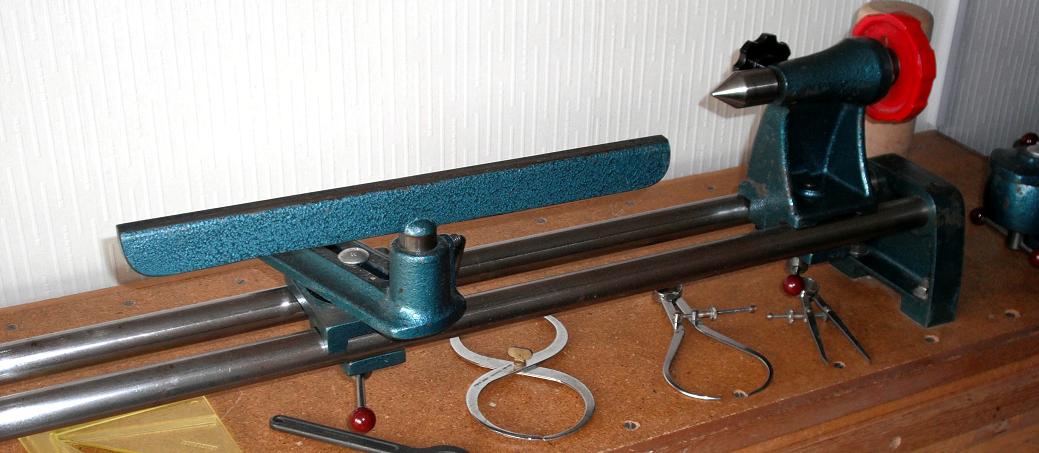

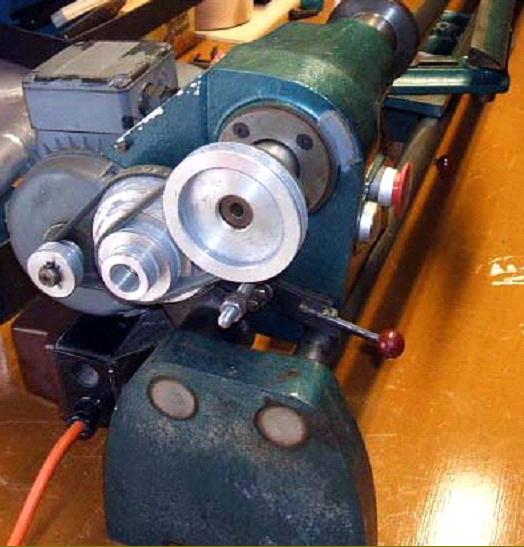

Made in Mills Drive, Newark, England, by D. Arundel & Co. (founded 1947) Arundel lathes were noted for their fine finish and smooth, vibration free running. Run personally by Mr. Doug Arundel and his brother, for a small company a surprisingly wide range of models was offered - not for them the Myford scheme of only ever offering two types. While some Arundel lathes were of very simple but rugged construction, like the E5 with its split-bearing headstock assembly, others, like the J4 and M300, were even more robust with enclosed cast-iron headstocks and a choice of plain or roller-bearing spindle assemblies (the M300 being upgraded late in its life from ball to roller bearings). The very best machine was probably their last, the twin-bar K series (elements of this design being incorporated in the very successful Record twin-bar bed lathes introduced by the Sheffield-based company to whom Dough Arundel had, on his retirement from business, became a consultant). The largest in the K range, the 600, featured solid-steel bed bars and drive by either V or Poly-V belts. The drive pulley was overhung on the end of the spindle with the 7-speed drive coming from a built-on countershaft and motor assembly (the 7th speed arranged by driving directly from the motor) - an unusually generous number for any type of wood lathe. Of neat appearance, the headstock end of the lathe had fully enclosed belts and the switchgear built into the lower section of the headstock's front face. The standard bowl turning assembly was a separate unit that, as on other lathes in the Company's range, bolted to the bench. However, in this case, because the overhung pulley prevented the mounting of a thread on the left-hand end of the spindle, bowl turning was achieved by sliding the complete headstock-cum-motor assembly to the tailstock end of the bed where the bowl turning rest could be mounted. All K lathes were built to order and it was possible to specify one of five metallic colours, the bed length as well as the type and size of thread on the headstock spindle. Elements of this design are recognisable in today's popular and very successful range of "Coronet" wood lathes machines manufactured in Sheffield, England by the Record Tool Company. |

|

|

||

|

On the Arundel K lathe, because the overhung pulley prevented the mounting of a thread on the left-hand end of the spindle, bowl turning was achieved by sliding the complete headstock-cum-motor assembly to the tailstock end of the bed where the bowl turning rest could be mounted. |

|

|

|

|

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||