|

Now resident in Europe, this interesting and very high-quality miniature milling machine would have been constructed, it is believed, by the American Watch Tool Company in either the last years of the 19th century or first few of the 20th..

Similar to the fine restoration project shown here, this model also resembles, in a general way, other small horizontal milling, grinding and gear-cutting machines made by various American manufacturers* of high-class machines tools. As with all machinery made by the American Watch Tool Company since 1872, the miller used exclusively metric dimensions - through in this case one exception has been found: the screw that holds the spindle for the vertical movement. However, could it be a German or Swiss-built copy? For example, the Waltham Company sold a number of lathes into Switzerland (which were then reproduced as the Brequet and Juvenia) and American makers are known to have advertised in German machine-tool and horological publications. In addition, there was bound to have been an exchange (or stealing) of ideas and technology between the American industry and Swiss and European makers.

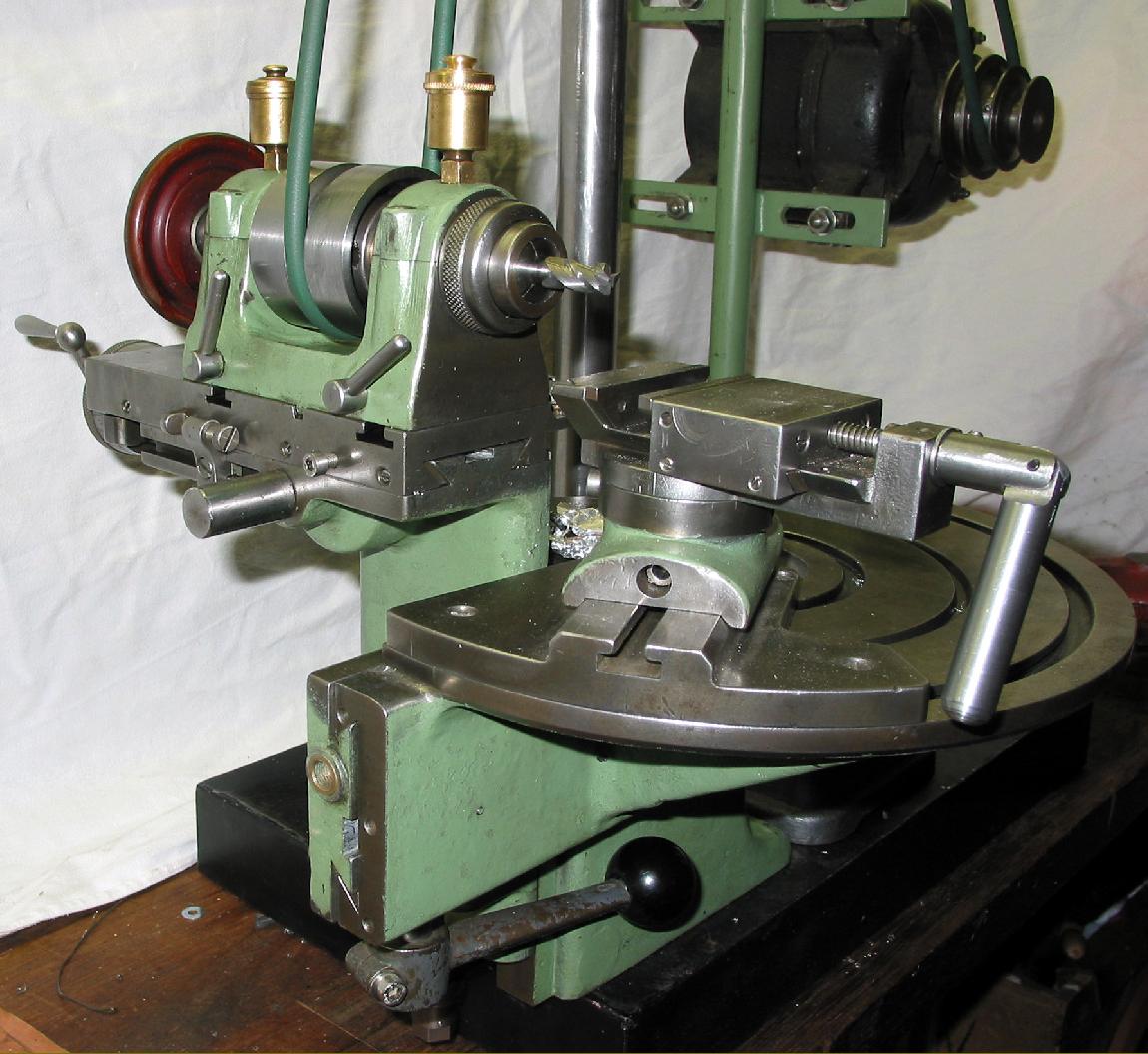

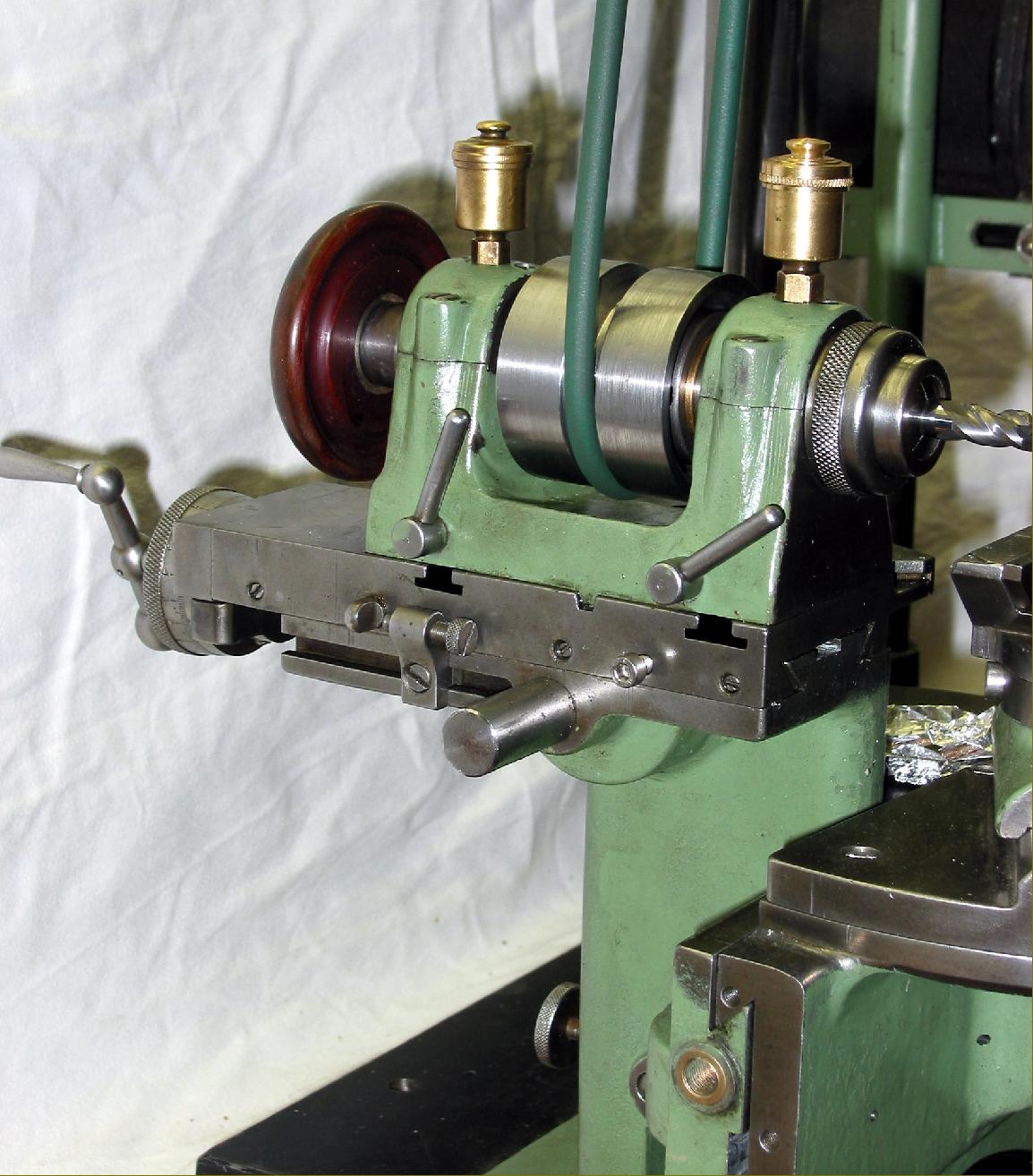

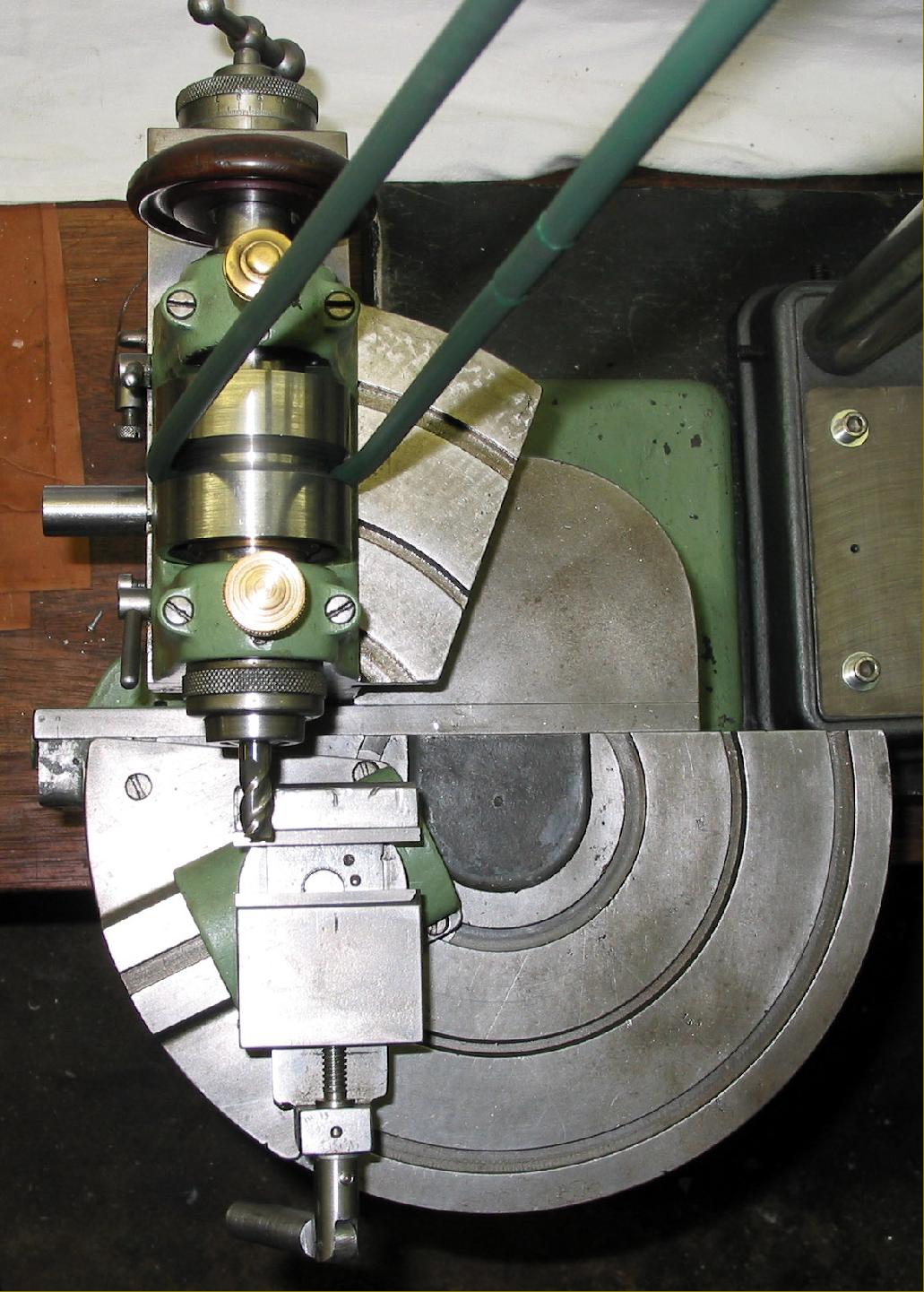

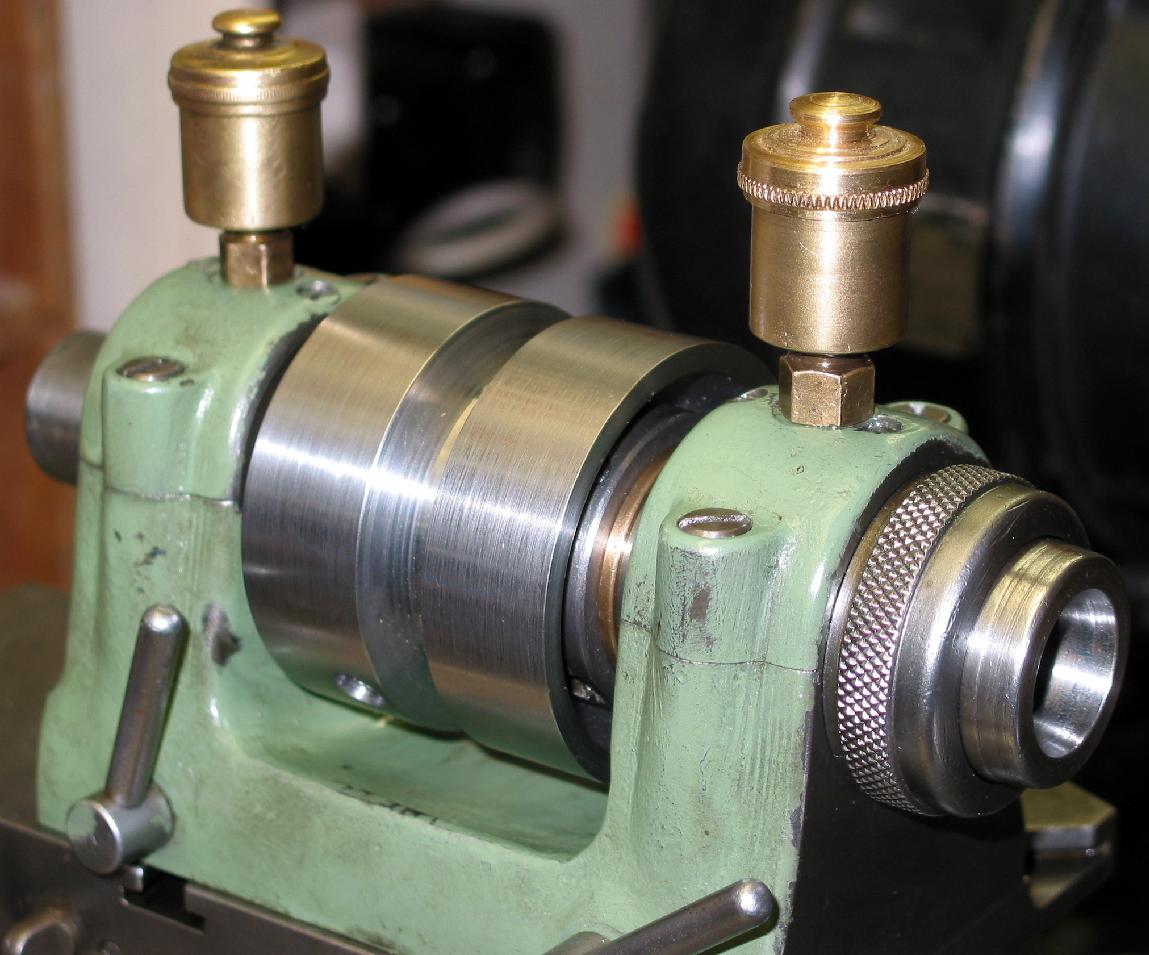

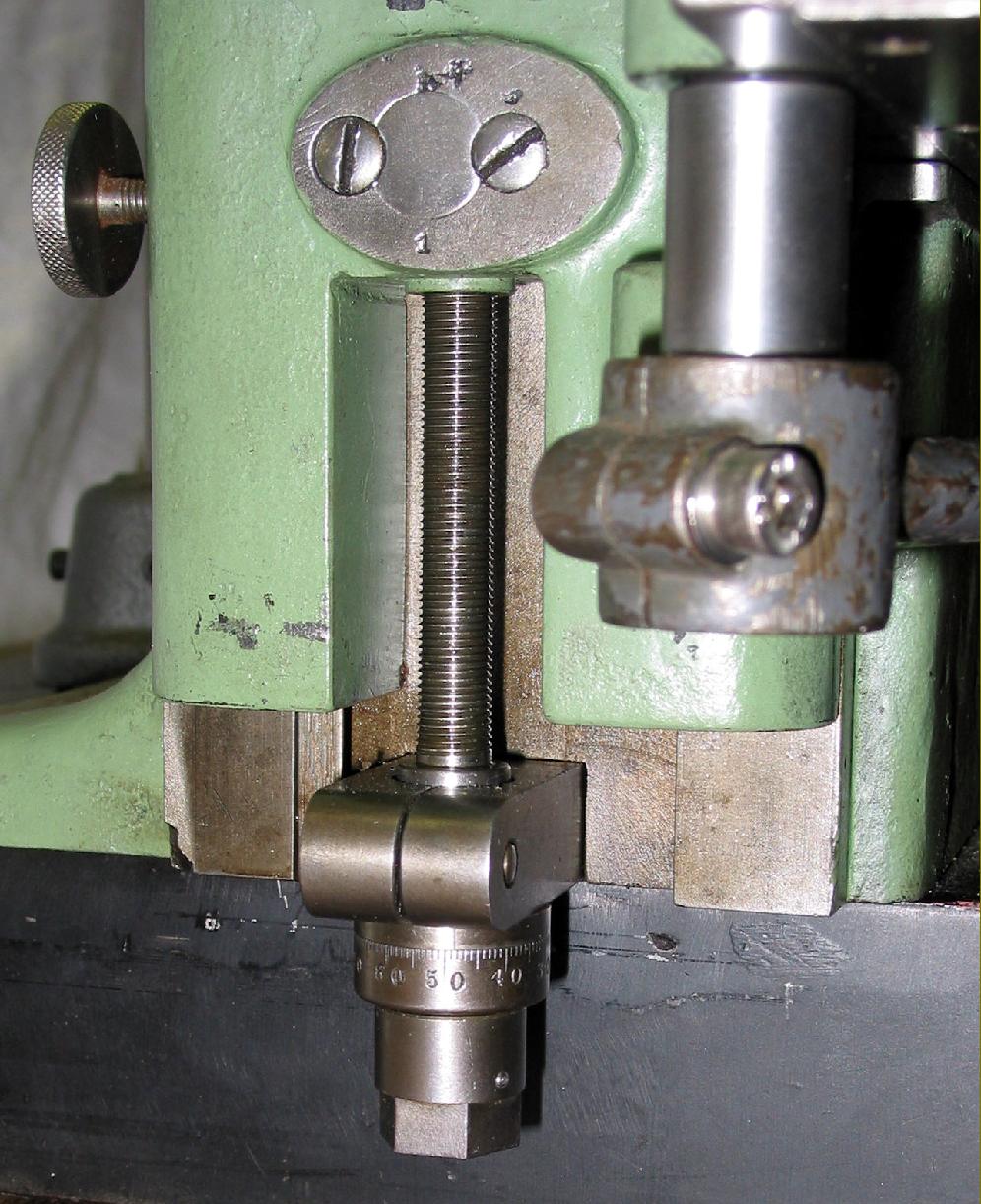

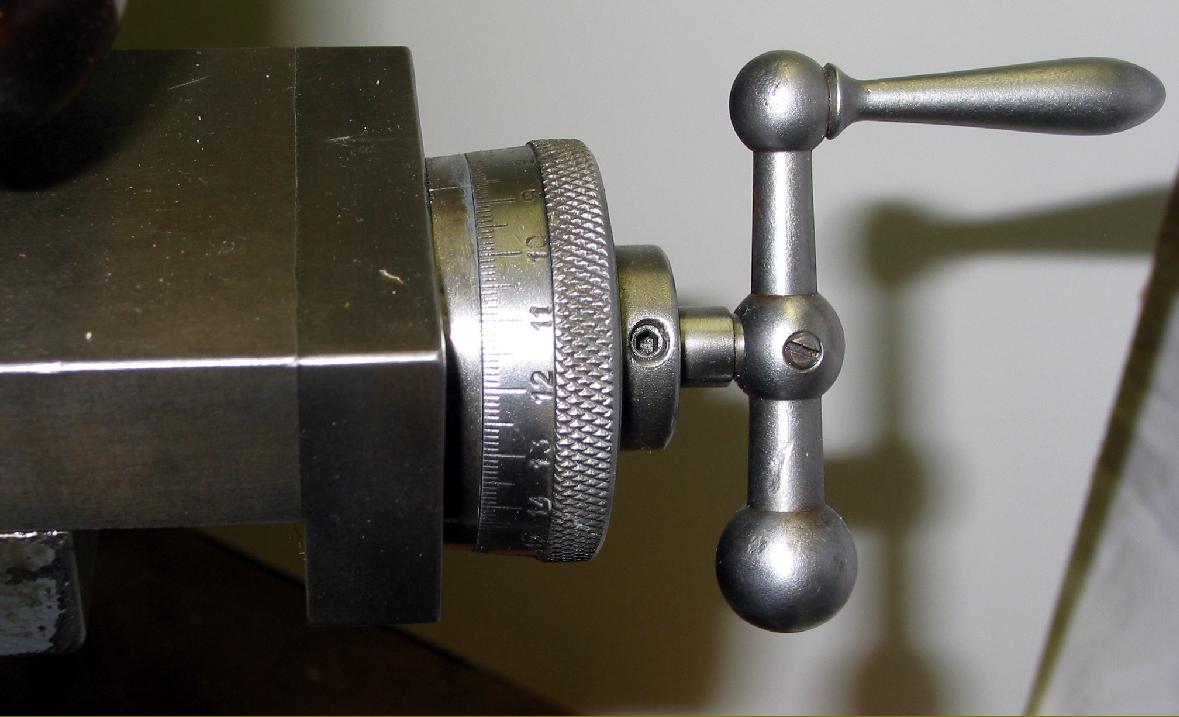

Beautifully built, from high quality materials, the machine was of unusual design and may have been intended for a special manufacturing process, rather than as a general-purpose tool. The head was secured to the top of the machine, by T-bolts, to an intermediate plate fitted with short curved T-slots. It could be swung sideways a little and also moved forwards and backwards over the top of the main column by either a feed screw, with a large micrometer dial, or by quick-feed rack-and-pinion gearing. Stops could be fitted into a T-slot that ran along the left-hand face of the slide's lower casting - another pointer to its likely use for repetition work. It was also possible to raise and lower the assembly that held the head, though this was by a screw, formed with a hexagon end (with a small micrometer dial) set in an awkward-to-reach position at the side of the column. Sized to accept Schaublin W15 collets the spindle was a substantial affair - with even the modern Sixis miller (a substantially larger machine) only able to take a W12 size.

Modified on the example illustrated to take a Polycord belt, the originally spindle pulley would have been a full-width type, slightly domed for a wide, flat belt. The choice of an unusually wide pulley was because of its small diameter - it being notoriously difficult, otherwise, to get enough grip. Had the machine been intended for grinding rather than milling (and some of this type were) the drive would have been by a round rope "gut" belt.

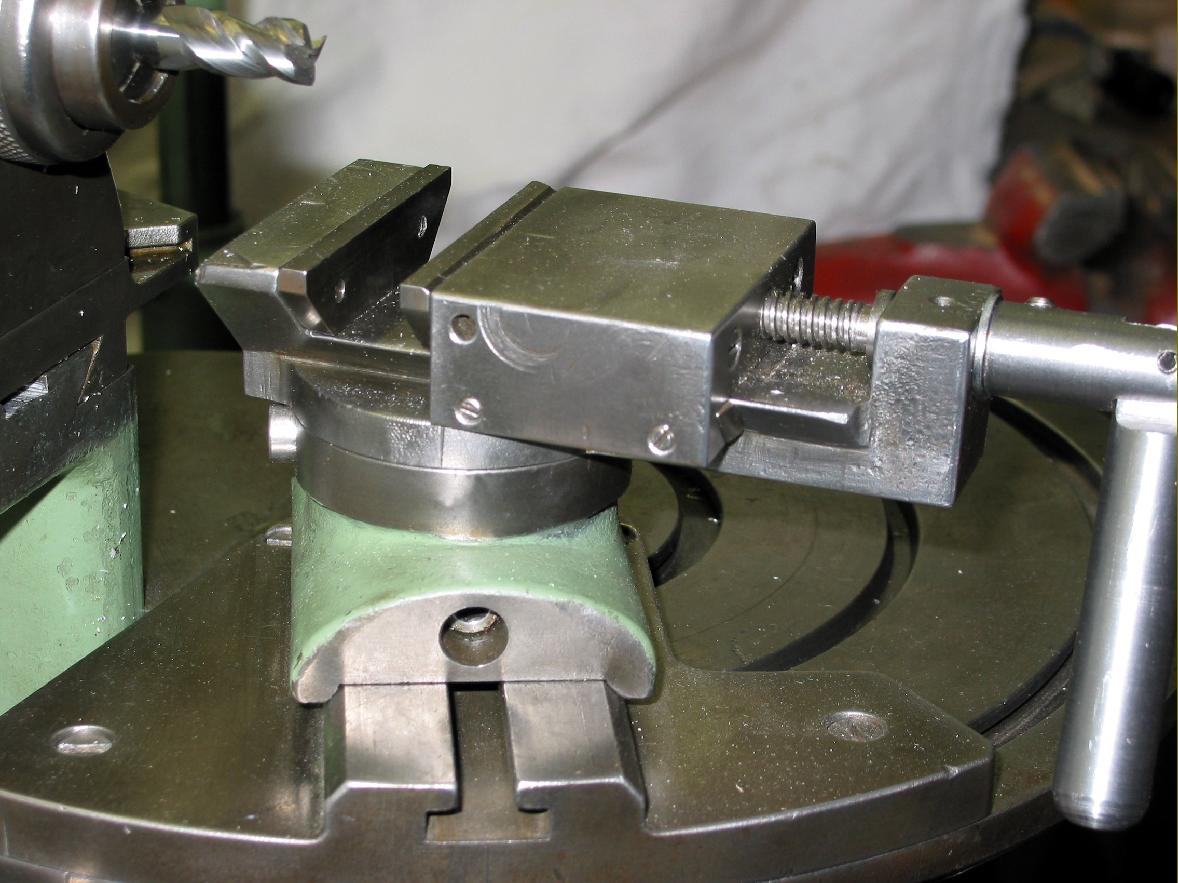

Carried on V-ways at the front of the column, the knee was fitted with a horizontal slide - with both screw and lever feeds - to which was fastened a semi-circular work table complete with curved T-slots. Fitted to the table was a casting, able to be swung from side to side, formed as a section of lathe bed - a flat top and bevelled edges. This would have been able to carry a variety of fittings from the maker's other machine tools including a machine vice (as illustrated) as well as dividing and indexing heads and even the powered milling and grinding heads then commonly available for attachment to the top slides of precision lathes.

*Including some of the following: Levin, Bottum, American Watch Tool Company, B.C.Ames, Bottum, Hjorth, Potter, Pratt & Whitney, Rivett, Wade, Waltham Machine Works, Wade, Pratt & Whitney, Rivett, Cataract, Hardinge, Elgin, Remington, Sloan & Chace, and (though now very rare) Frederick Pearce, Ballou & Whitcombe, Sawyer Watch Tool Co., Engineering Appliances and Fenn-Sadler..

|

|