|

Home Machine Tool Archive Machine-tools Sale & Wanted Other Australian-built lathes: Advance, Brackenbury & Austin, Clisby Hercus, Herbert, Premo, Qualos, Macson, Mars, Nuttall, Purcell Rexman Sheraton, Tillico, T.N.C. & Veem |

|

|

|

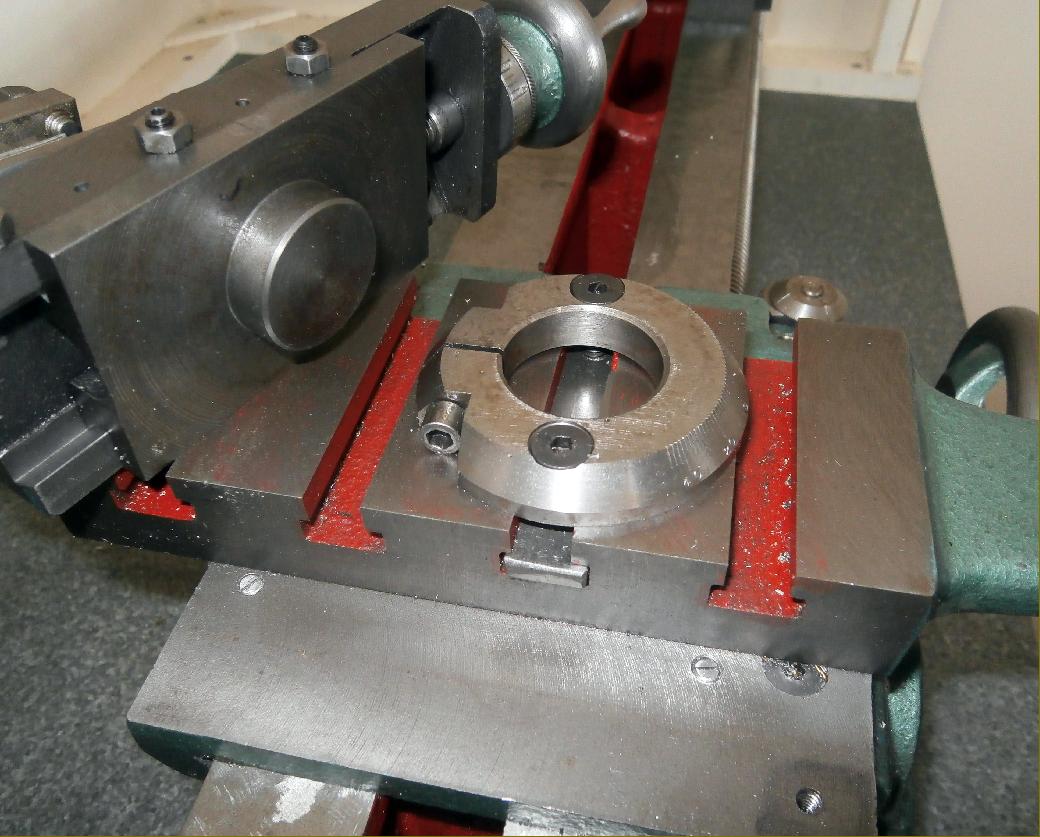

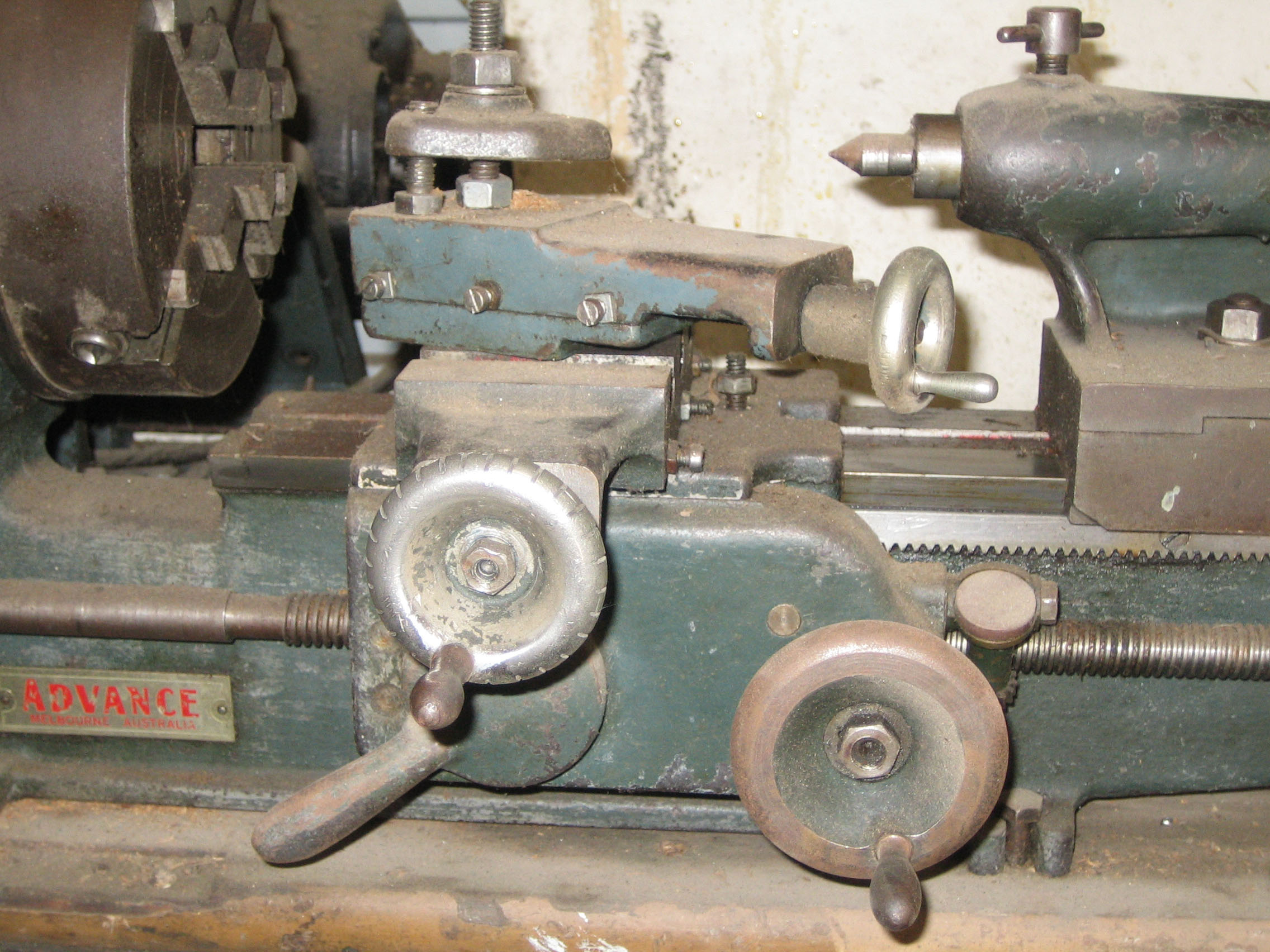

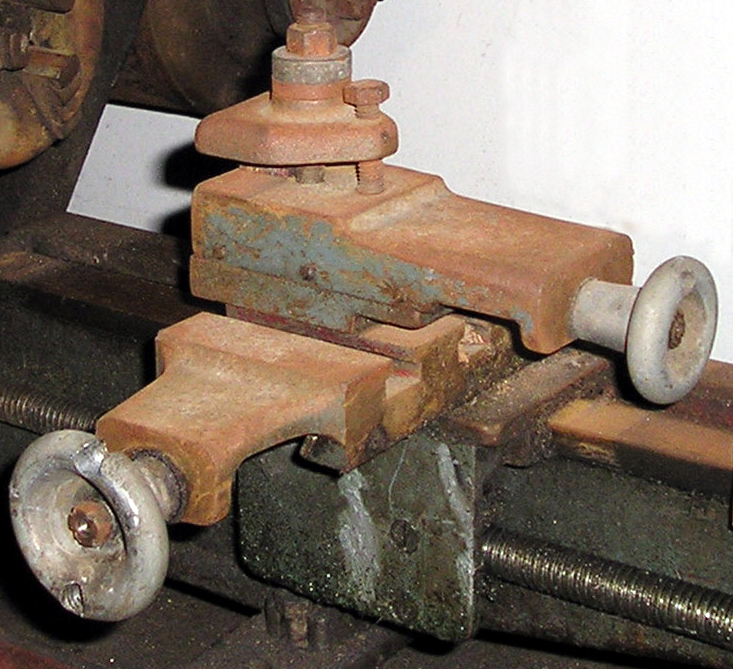

Later models of the Advance had a modified and much more rigid spigot-type top-slide fitting that replaced the ancient design of a single hold-down bolt at the rear. The only disadvantage was the rather inaccessible clamp bolt |

|

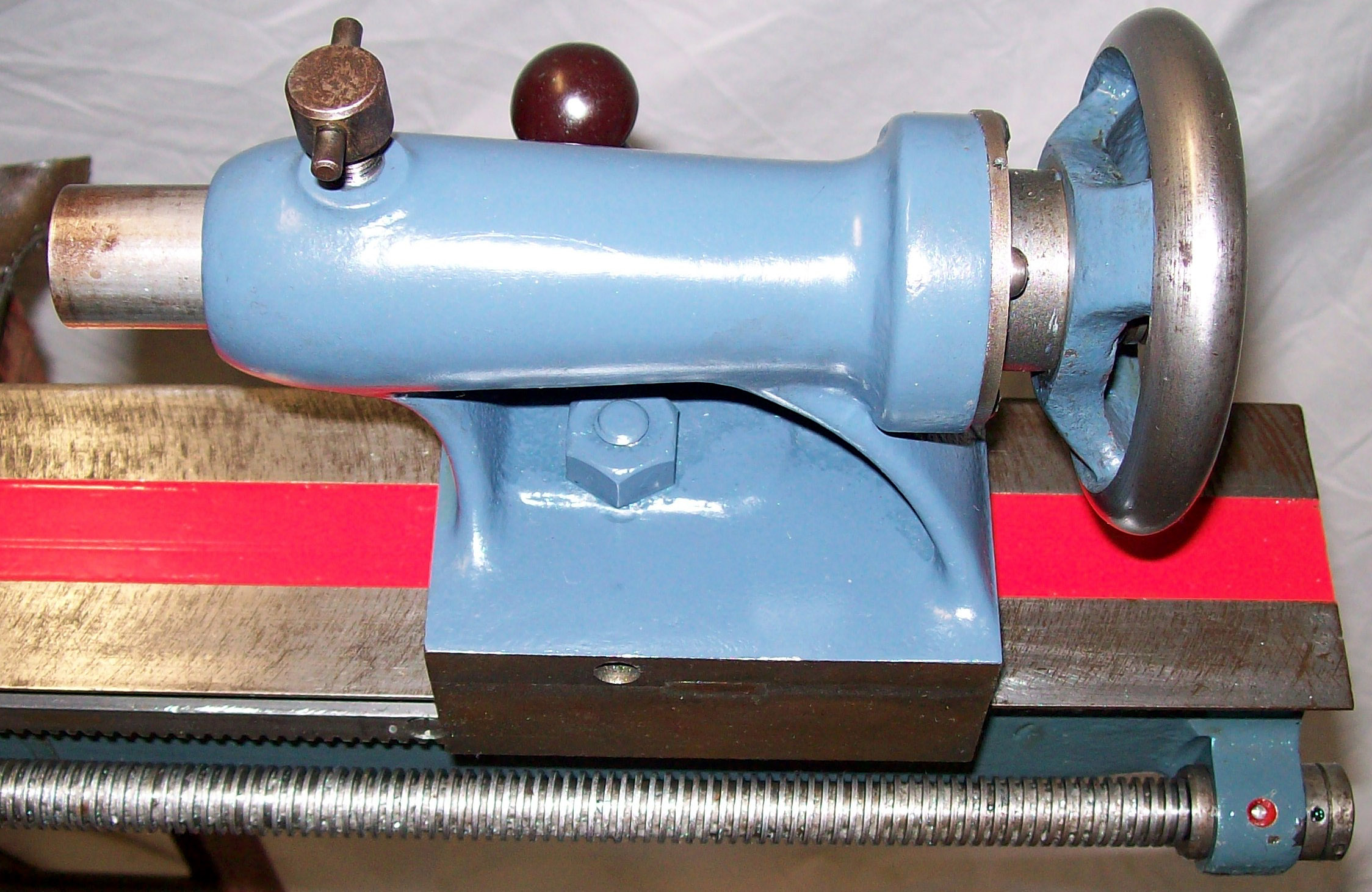

The tailstock was heavily built with a simple but effective and non-distorting side clamp at the rear - though the clamp that locked the No. 1 Morse taper barrel was that nasty design (that should only be found on the cheapest wood lathes) - a screw bearing directly against it. Like the Myford ML2 to ML4 and Ml7 designs, the barrel was bored clear through and ran through the handwheel, a design some prefer to perhaps more convenient later Advance type, when the lathe was made by Wylie Industries, which had the self-eject type where the handwheel feed screw (passing through thread in the end of the barrel) eventually impinged against the end of the Morse taper fitting to drive it out. |

||

|

|

|

|

||

|

|

||

|

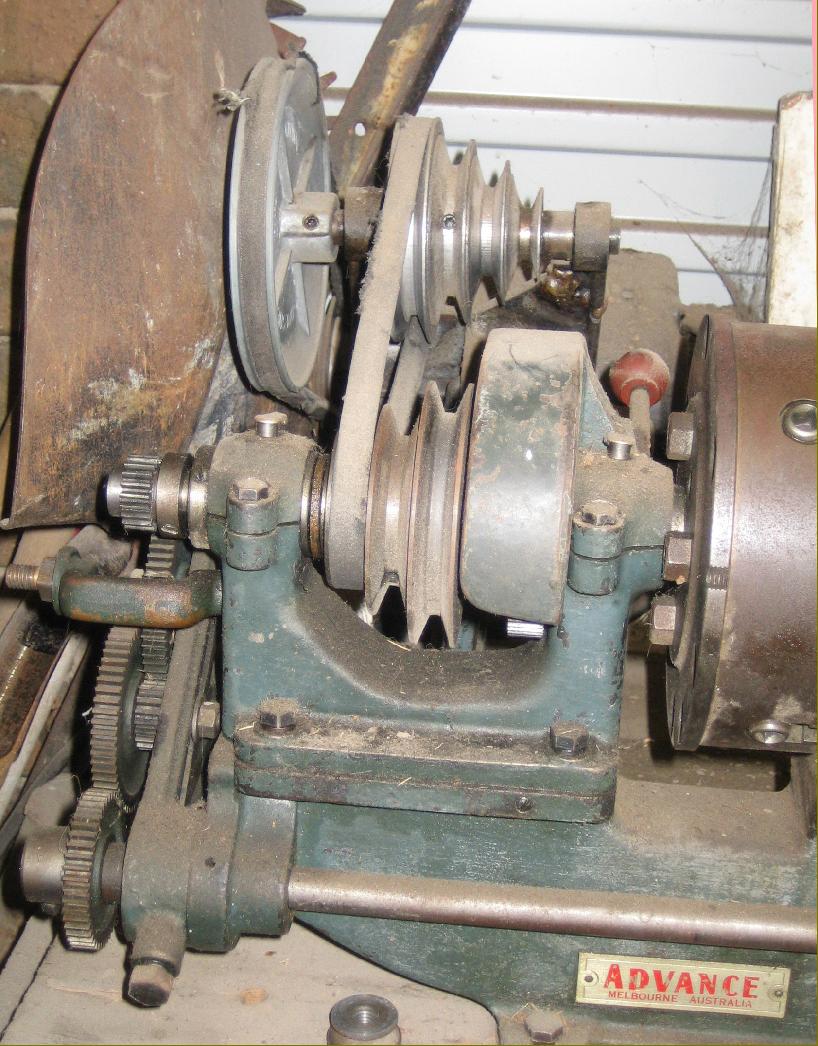

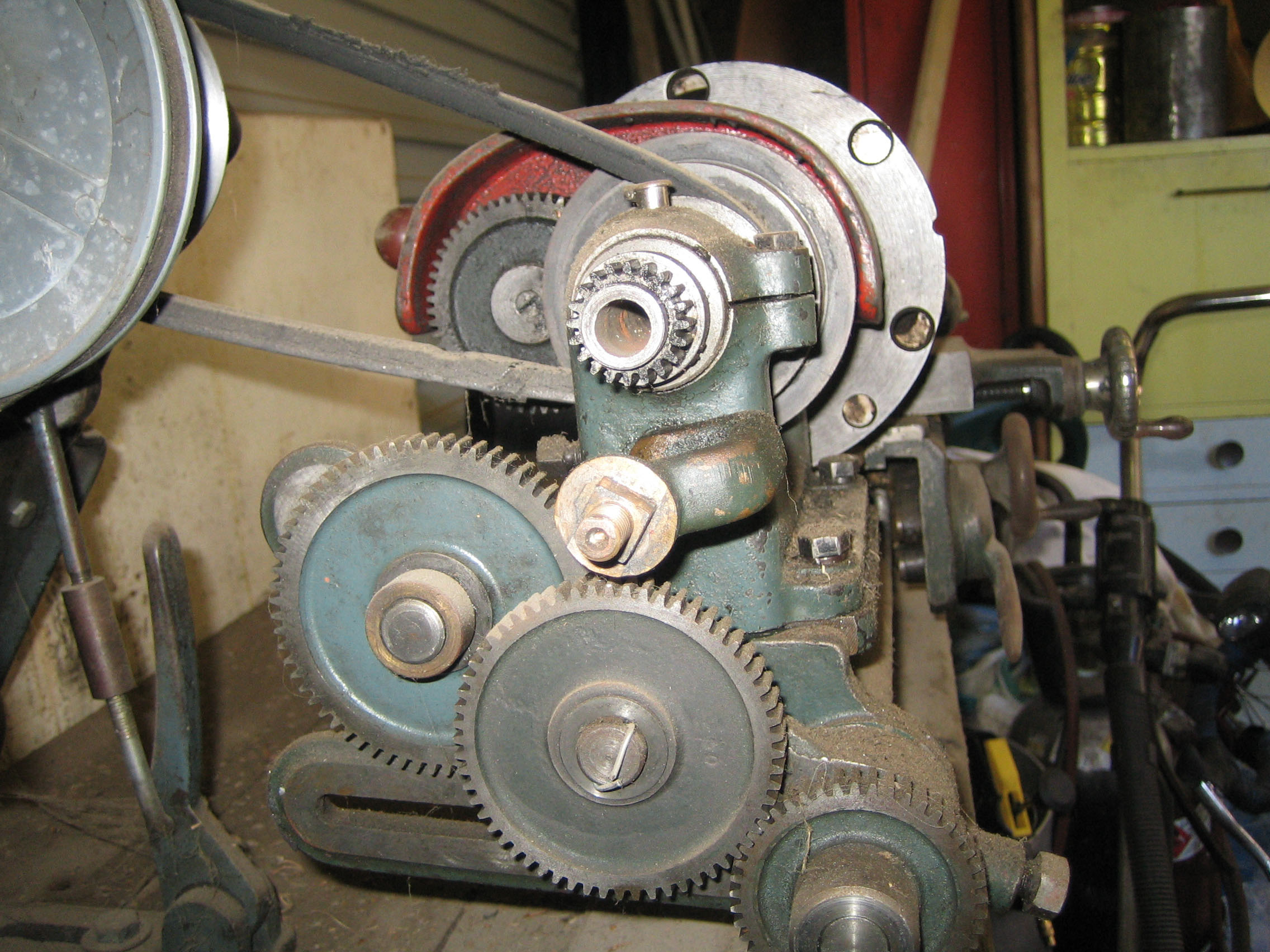

A left/right threaded bar levered the countershaft away from the headstock to tighten the final-drive belt. The outer end of the tensioning bar fitted into a hole drilled into the right-hand face of belt-guard cover with the other end arranged on a pivot that allowed the bar to be swung out of the way. This clever but simple arrangement allowed the belt tension to be slackened immediately and completely and the guard then lifted to change speeds. |

||

|

|

||

|

|

||

|

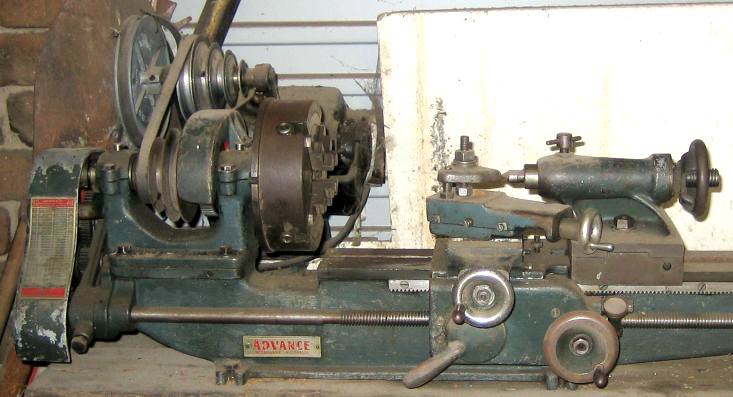

An early Advance: no tumble reverse, a short apron carrying a full nut, a dog clutch on the leadscrew, changewheels and drive belt unguarded and the tailstock with its vertical end frames and limited barrel reach. |

||

|

Early Advance: both top and cross slides were cast with integral feed-screw support brackets that gave extra travel by allowing the slides to pass well forward over their ways. |

||

|

|

||

|

Hercus, Herbert, Premo, Qualos, Macson, Mars, Nuttall, Purcell Rexman Sheraton, Tillico, T.N.C. & Veem Home Machine Tool Archive Machine-tools Sale & Wanted |