|

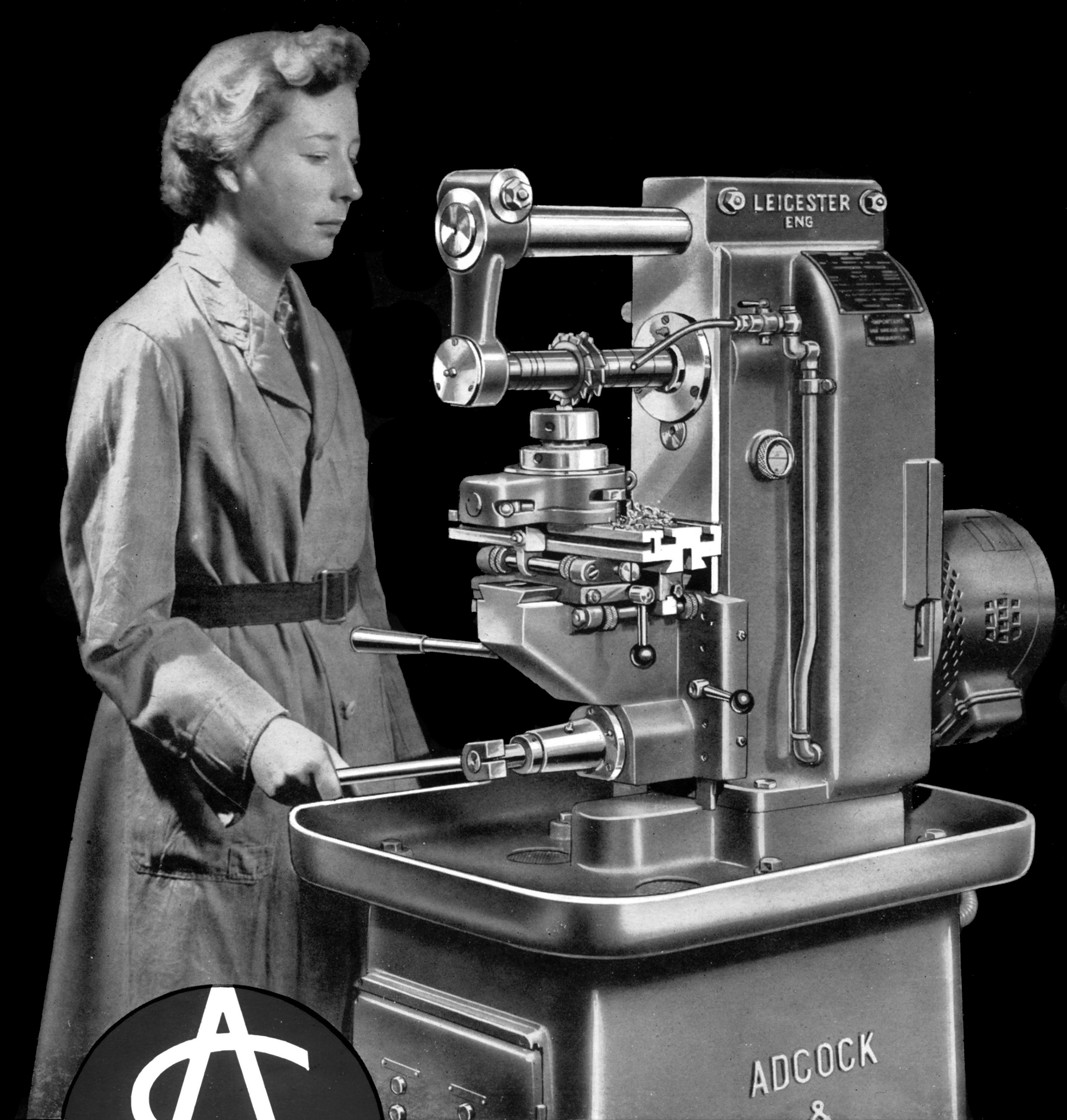

Adcock & Shipley Ltd., based in Leicester, England was a company that, over many decades, produced an enormous range of milling and drilling machines. Their horizontal milling machines, widely employed in manufacturing, were marked by a no-nonsense approach to both design and build quality; these were industrial machines, designed for the rigors of impatient use by semi or unskilled operators working for "piece-rate" wages.

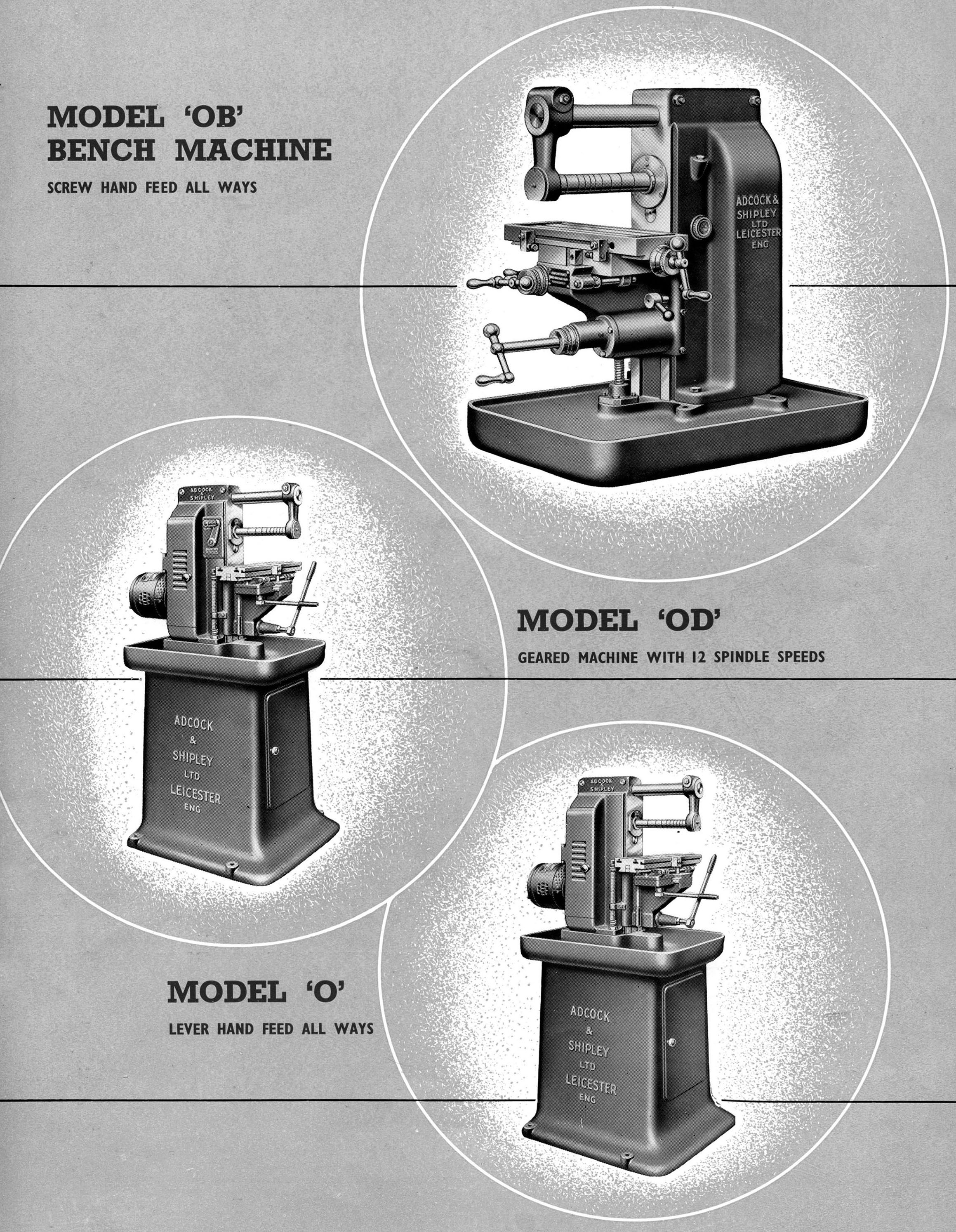

Today, the most commonly encountered A & S horizontal millers are the Models "1E" (introduced in 1962), "1ES" (introduced in 1970) and the older "0" to "4" versions from the 1930s, 1940s and 1950s, a range that also included various sub-divisions and specialist machines based on standard machines.

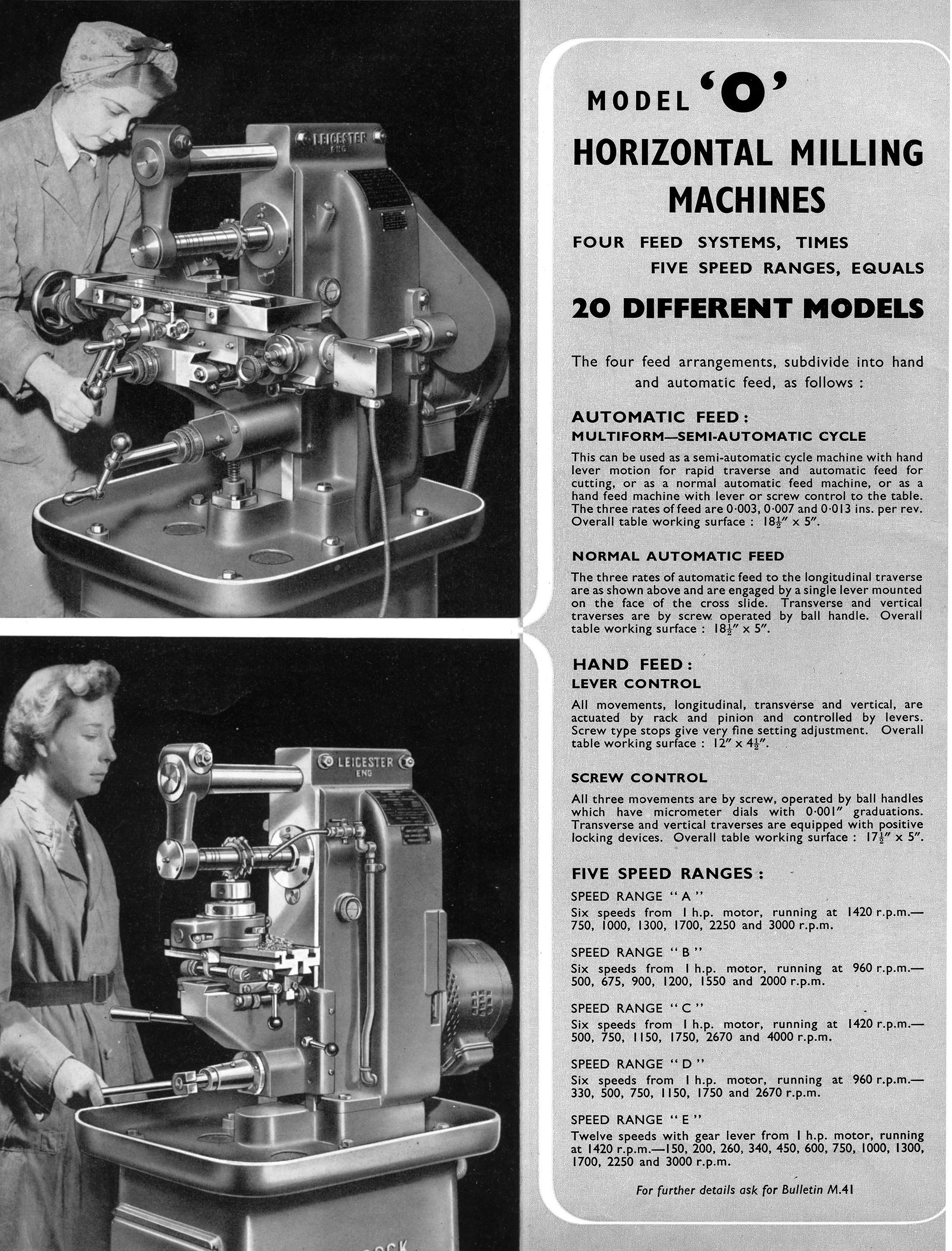

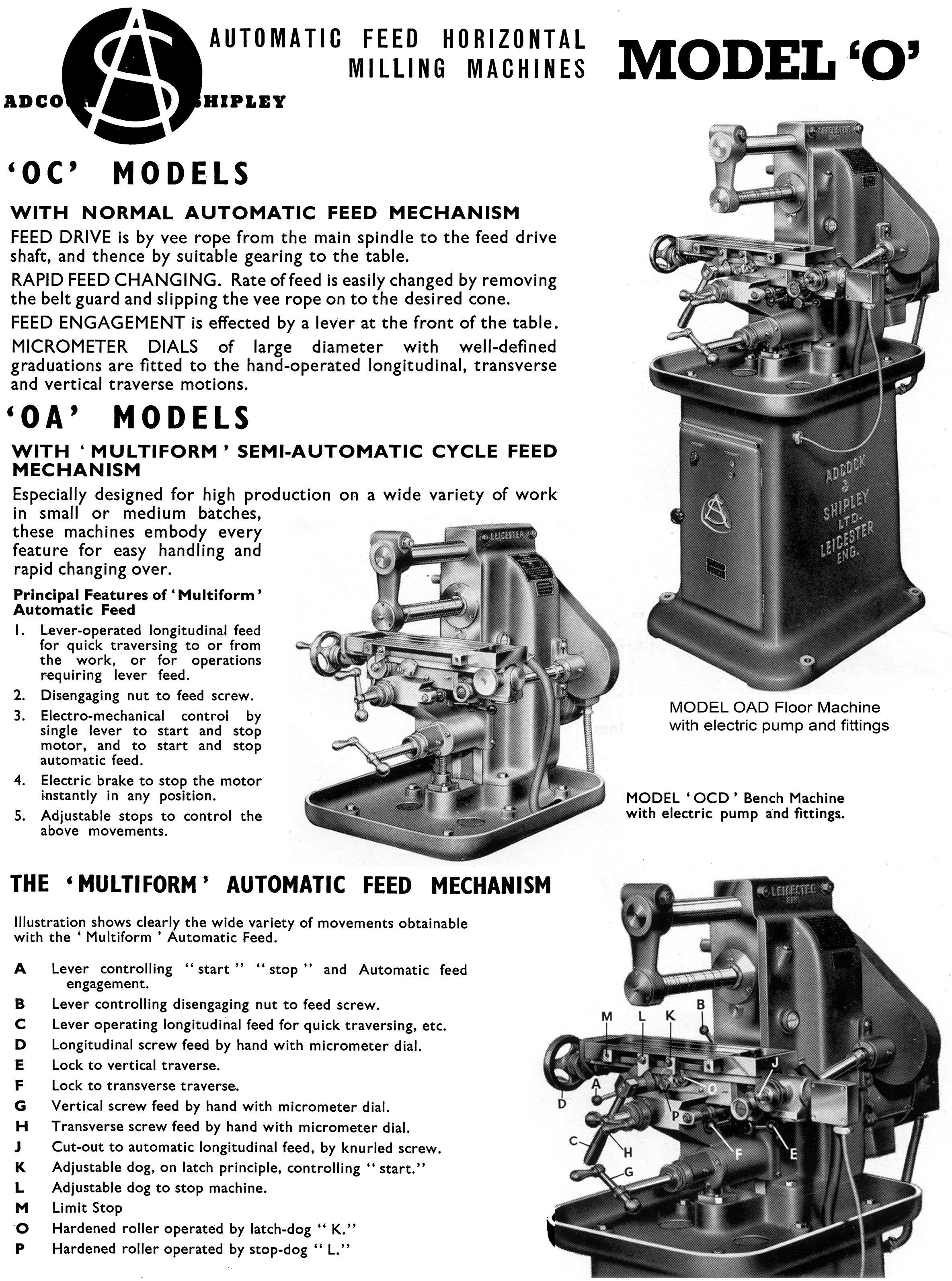

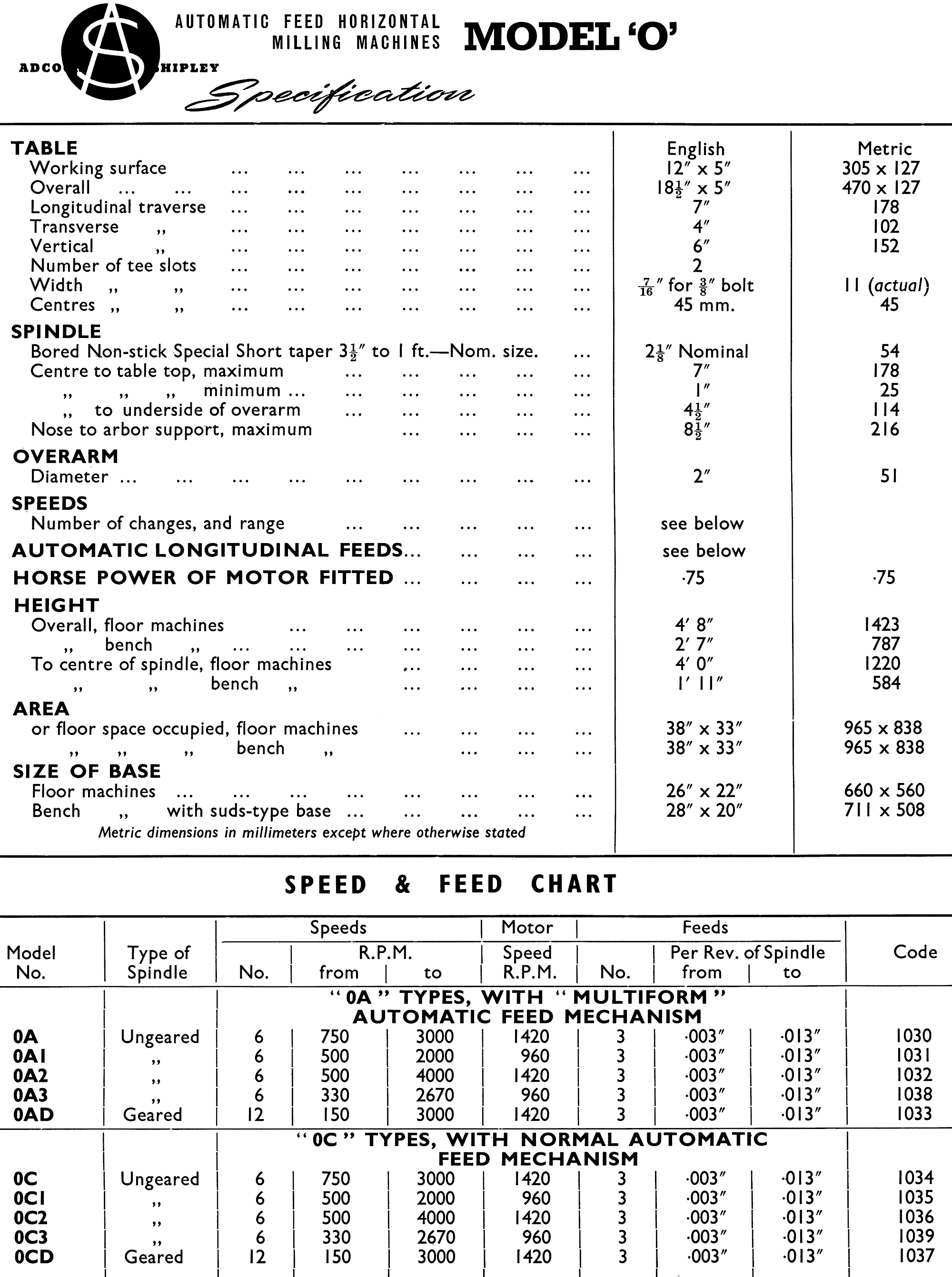

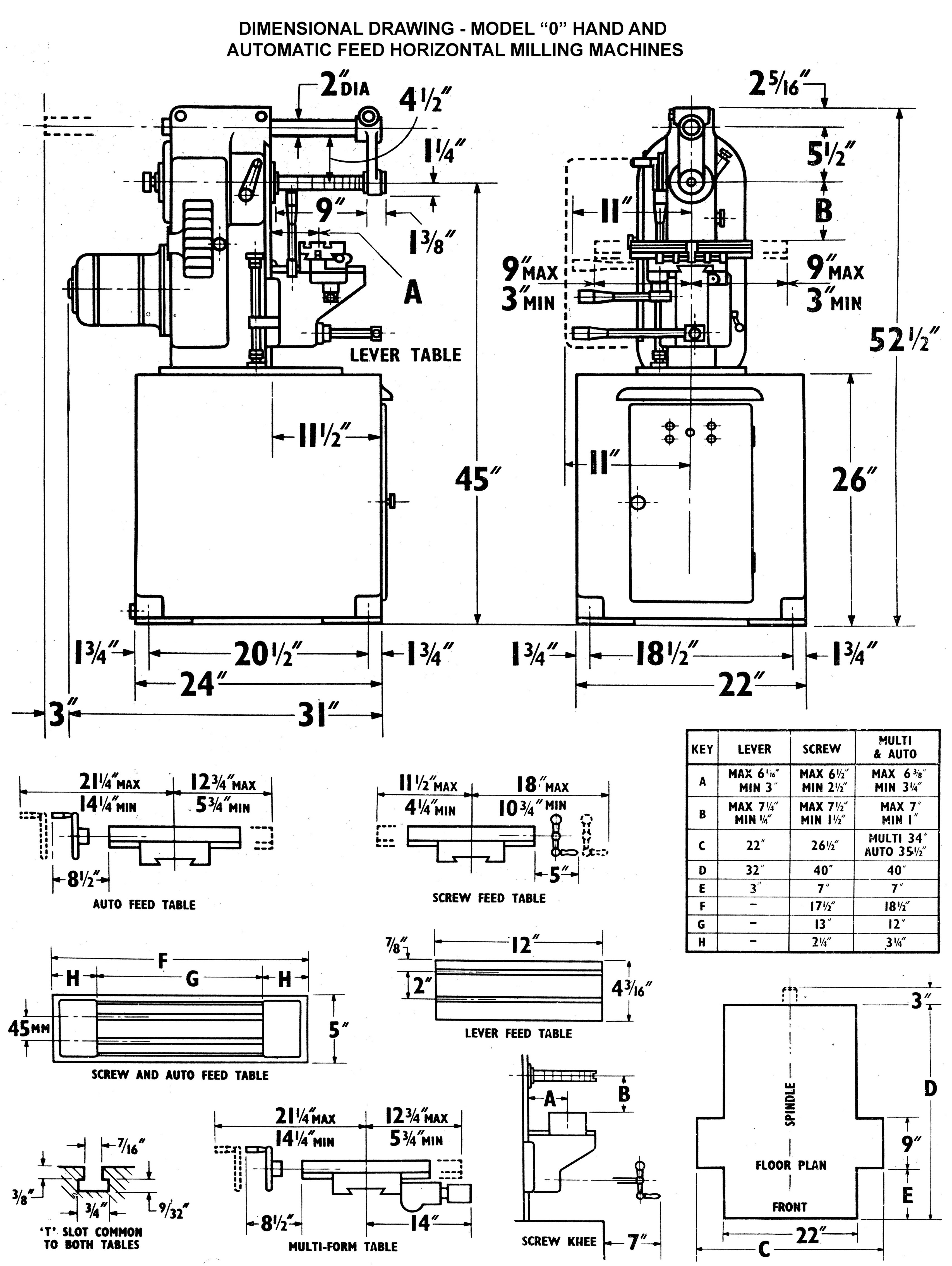

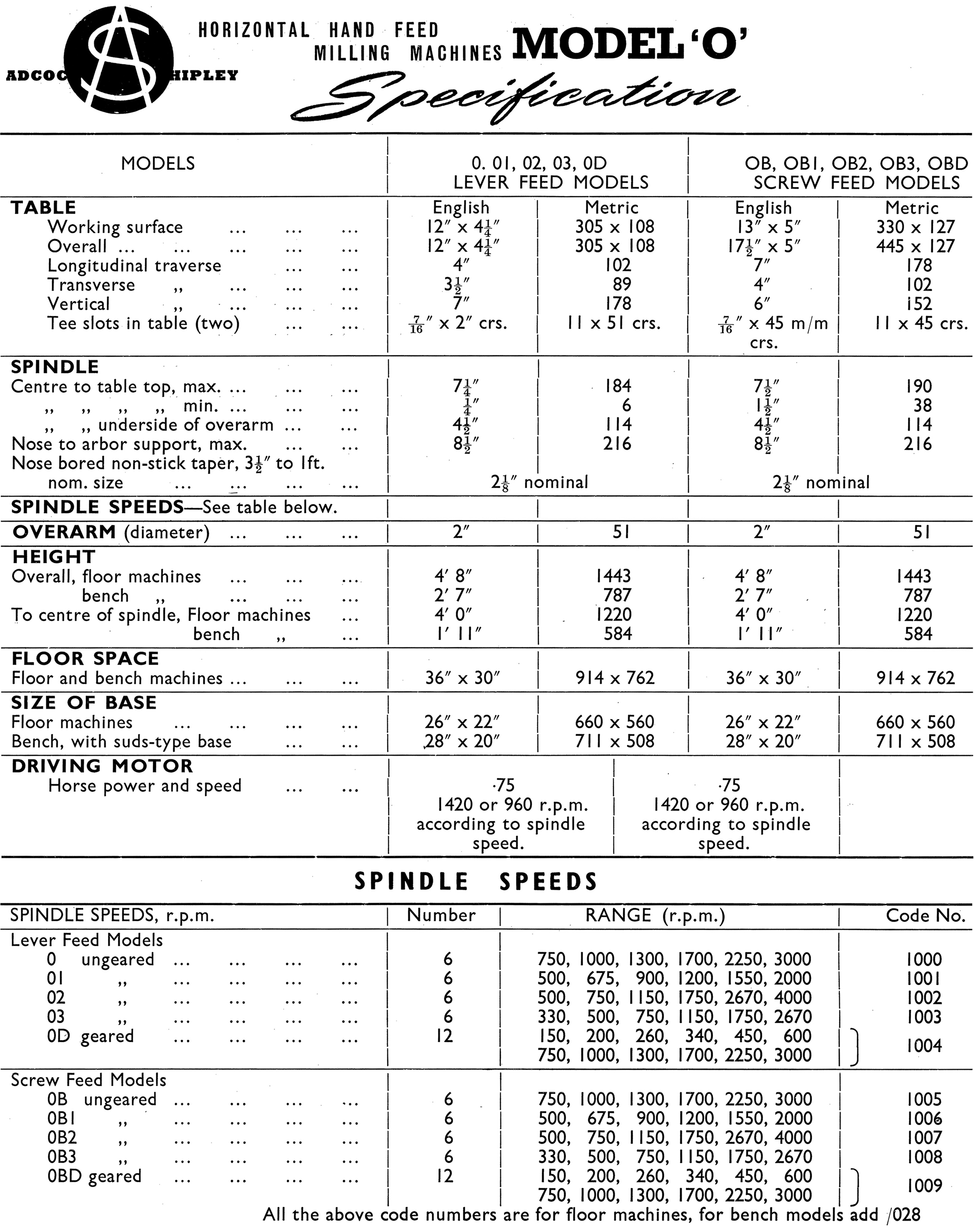

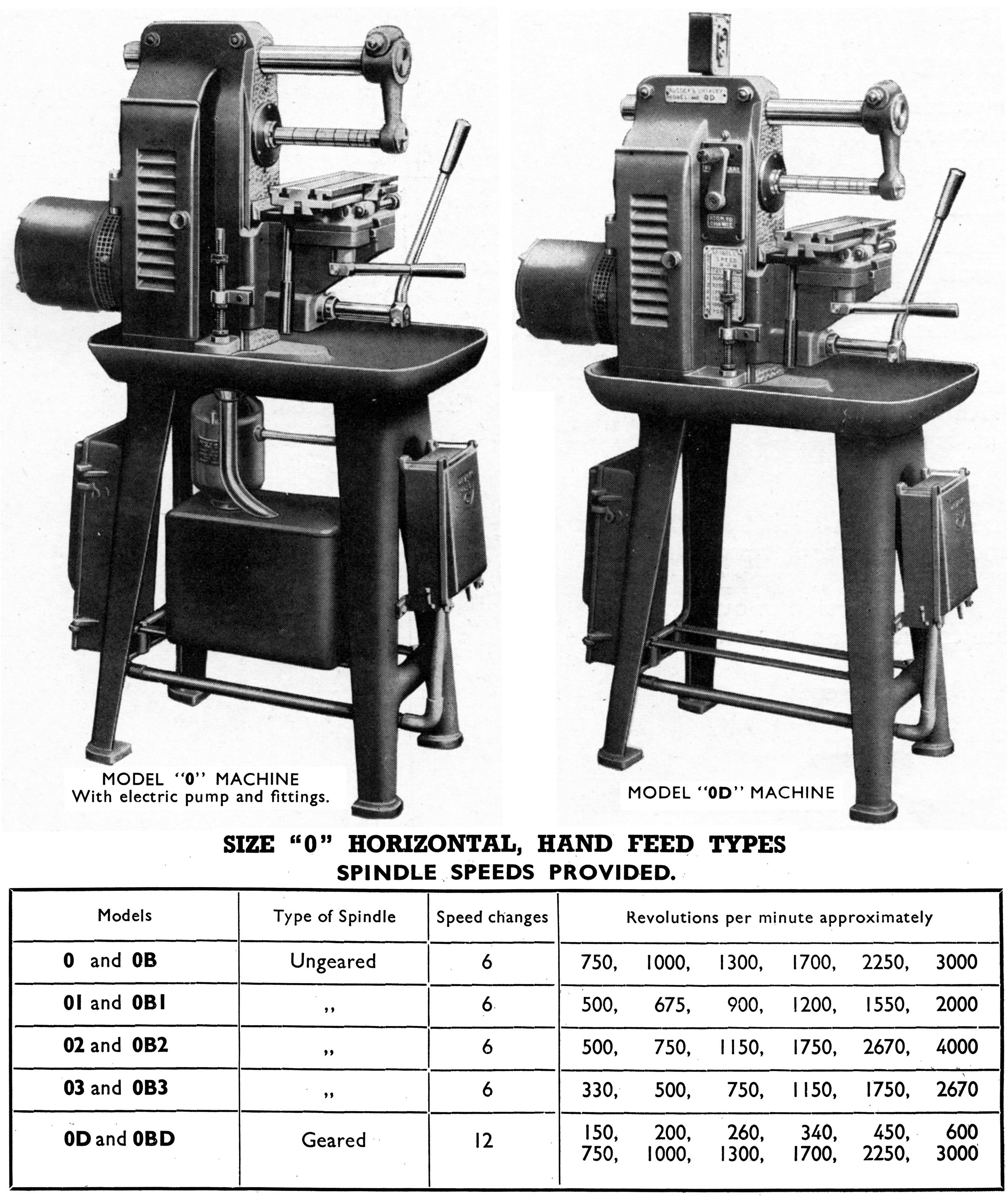

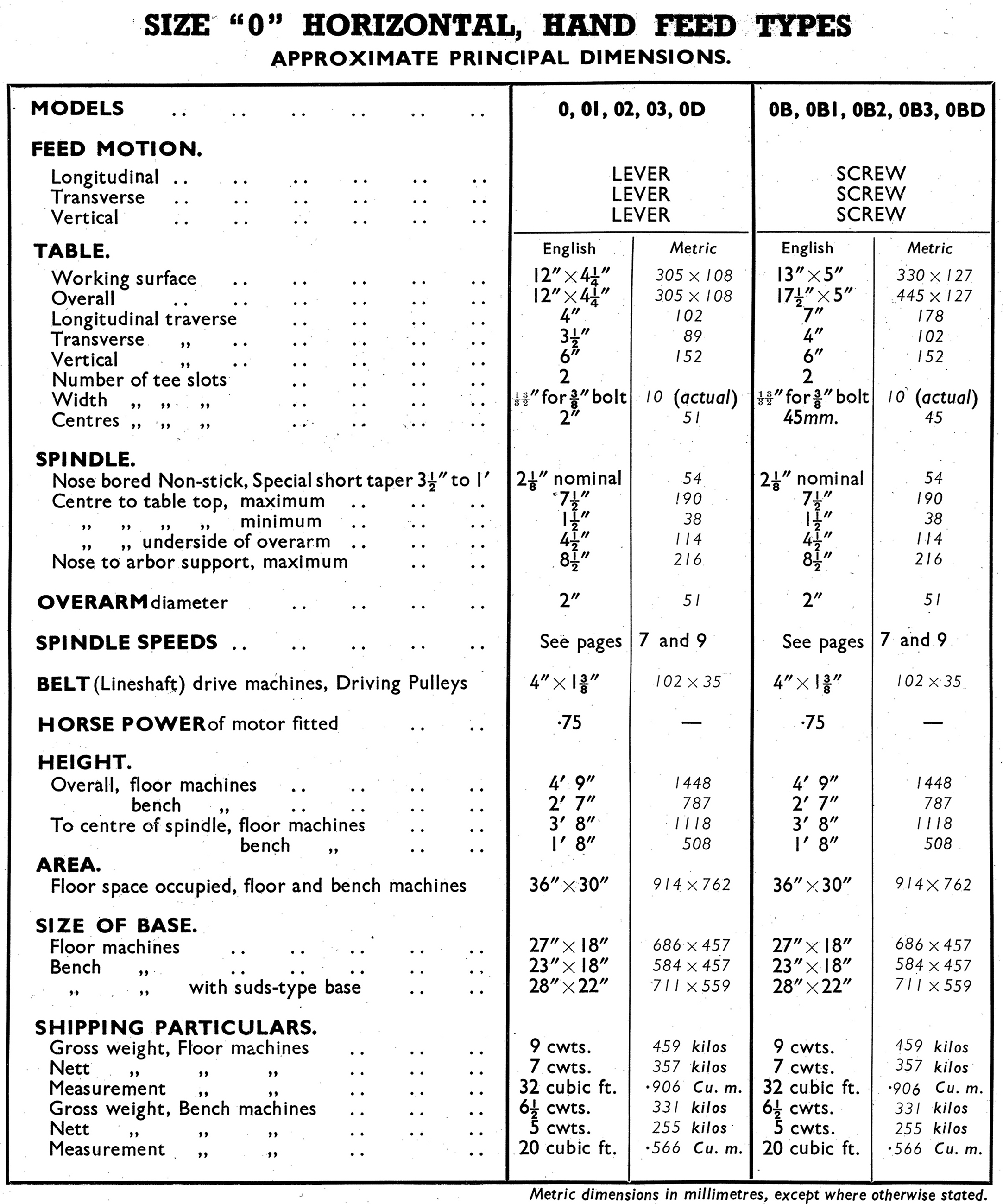

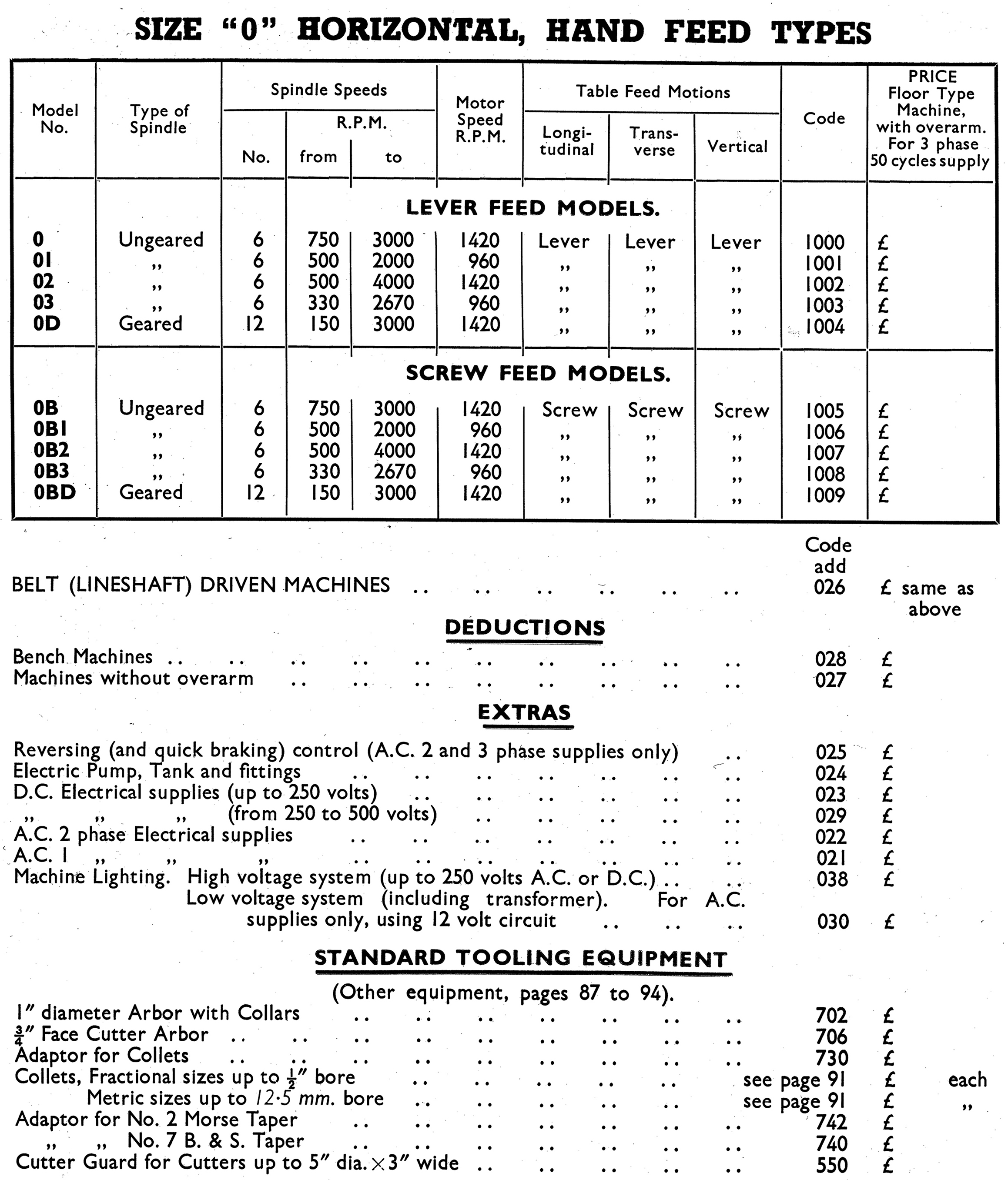

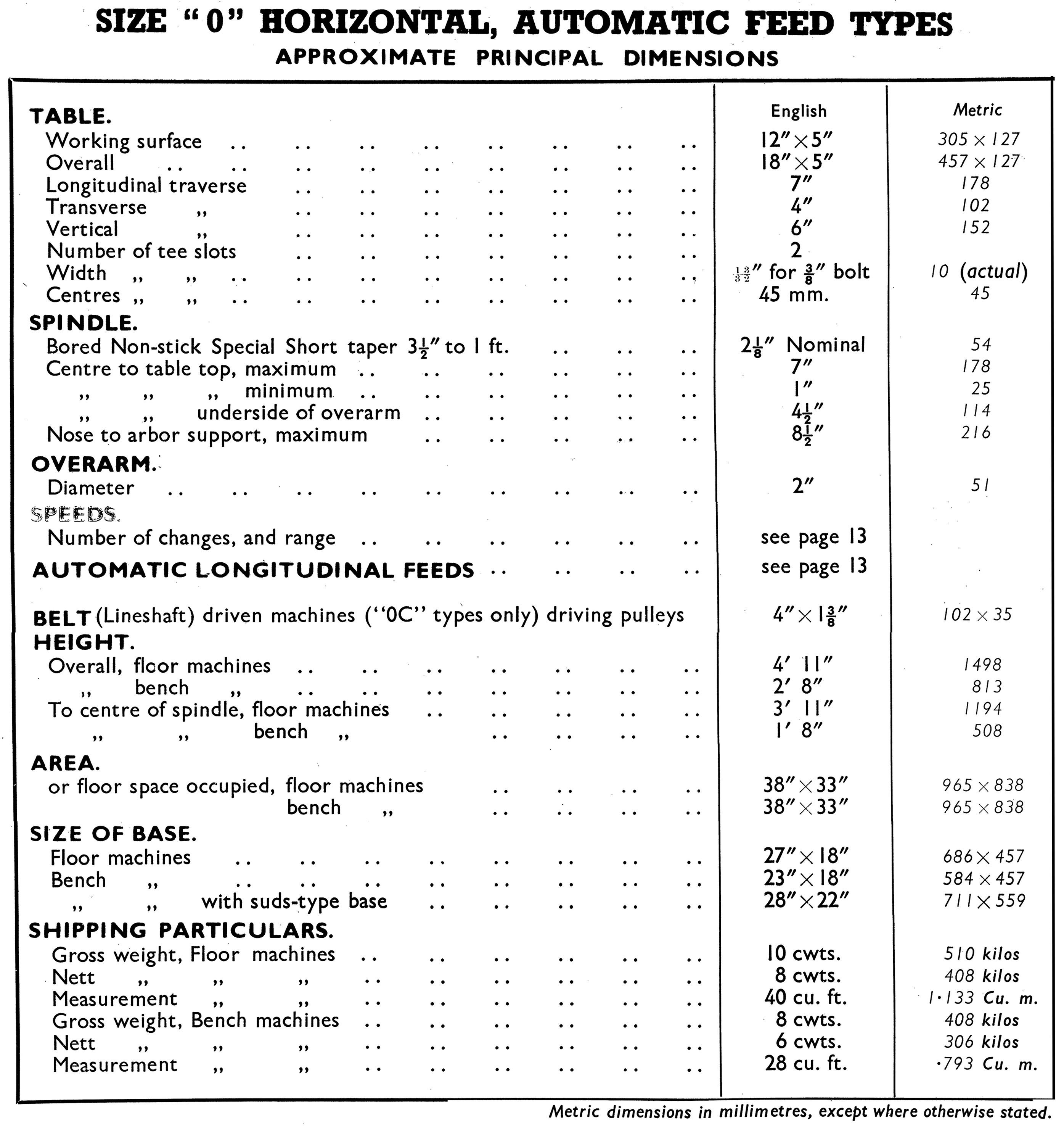

The millers in the smallest range, the "0", were available from 1934 to the late 1940s in their ordinal forms and then, into the 1950s, somewhat modified and brought up to date. In general, they can be found with four different feed systems - hand-screw, hand-lever, standard-power or semi-automatic cycle - and with five different speed ranges from a 1 h.p.3-phase motor.

"A" Speed Range (1450 rpm motor): 750, 1000, 1300, 1700, 2250 and 3000 rpm.

"B" Speed Range (960 rpm motor): 500, 675, 900, 1200, 1550 and 2000 rpm.

"C" Speed Range (1450 rpm motor): 500, 750, 1150, 1750, 2670 and 4000 rpm.

"D" Speed Range (960 rpm motor): 330, 500, 750, 1150, 1750 and 2670 rpm.

"E" Speed Range (1450 rpm motor): twelve speeds through a lathe-like "backgear" assembly: 150, 200, 260, 340, 450, 600, 750, 1000, 1300, 1700, 2250 and 3000 rpm.

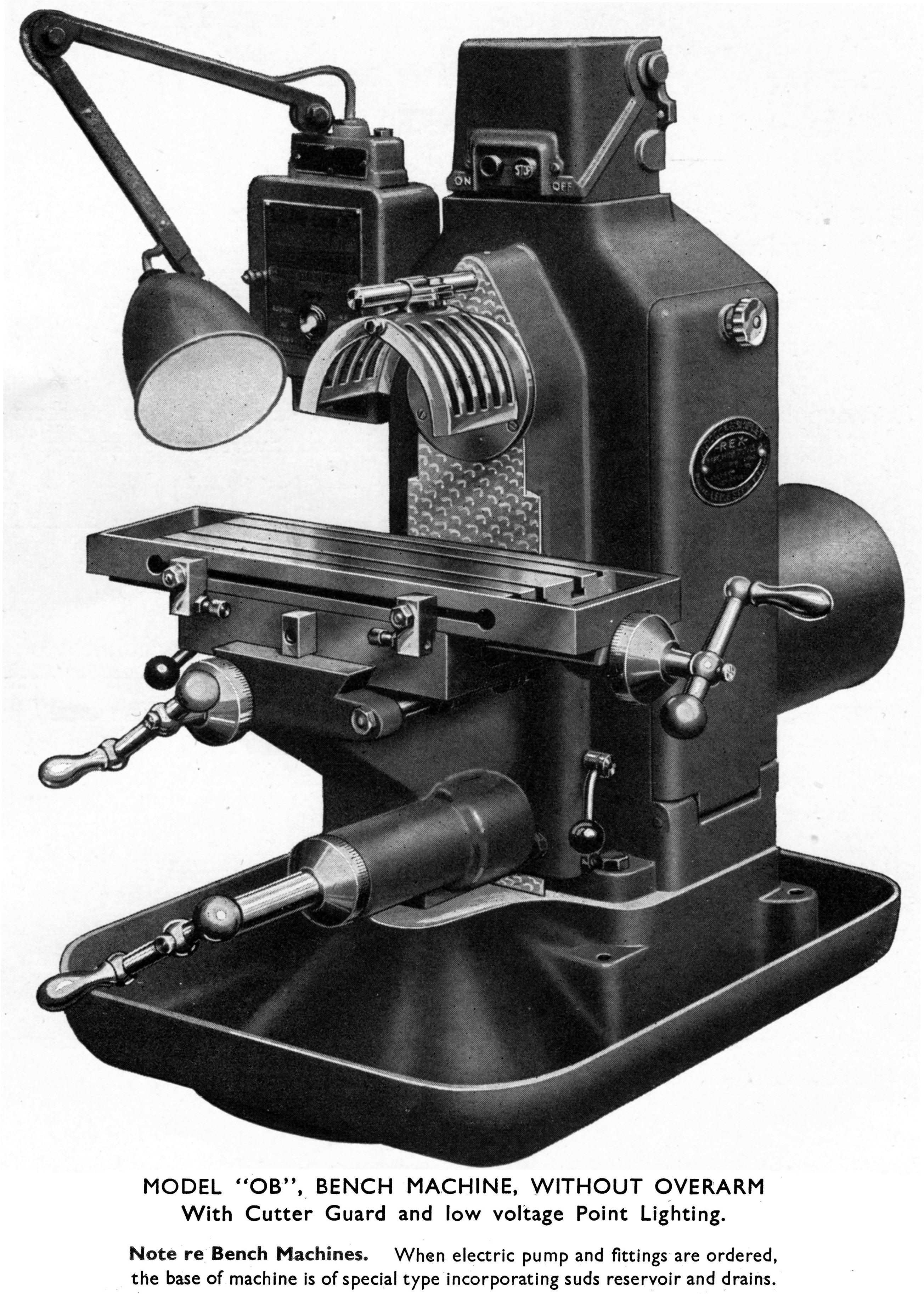

The latter machine, when fitted with the optional and very sturdy vertical head, is a strong and useful machine for the amateur workshop, albeit with a rather limited capacity for its size and weight. The plain vertical head (without a quill feed) used the same slideway as the knee. It was dropped into place from the top and driven by twin V belts from a pulley mounted on a 30 International Standard Taper stub arbor carried in the horizontal spindle.

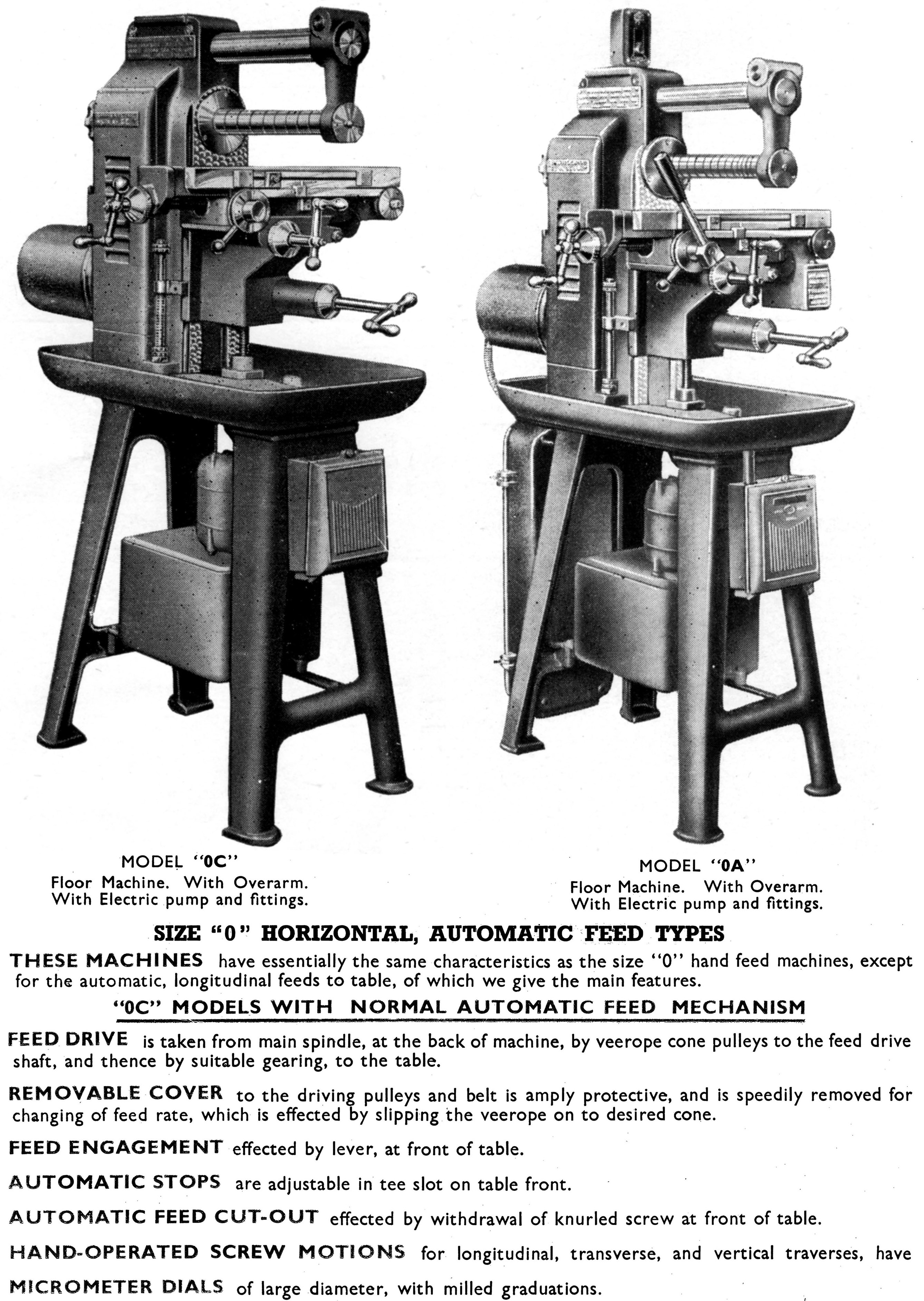

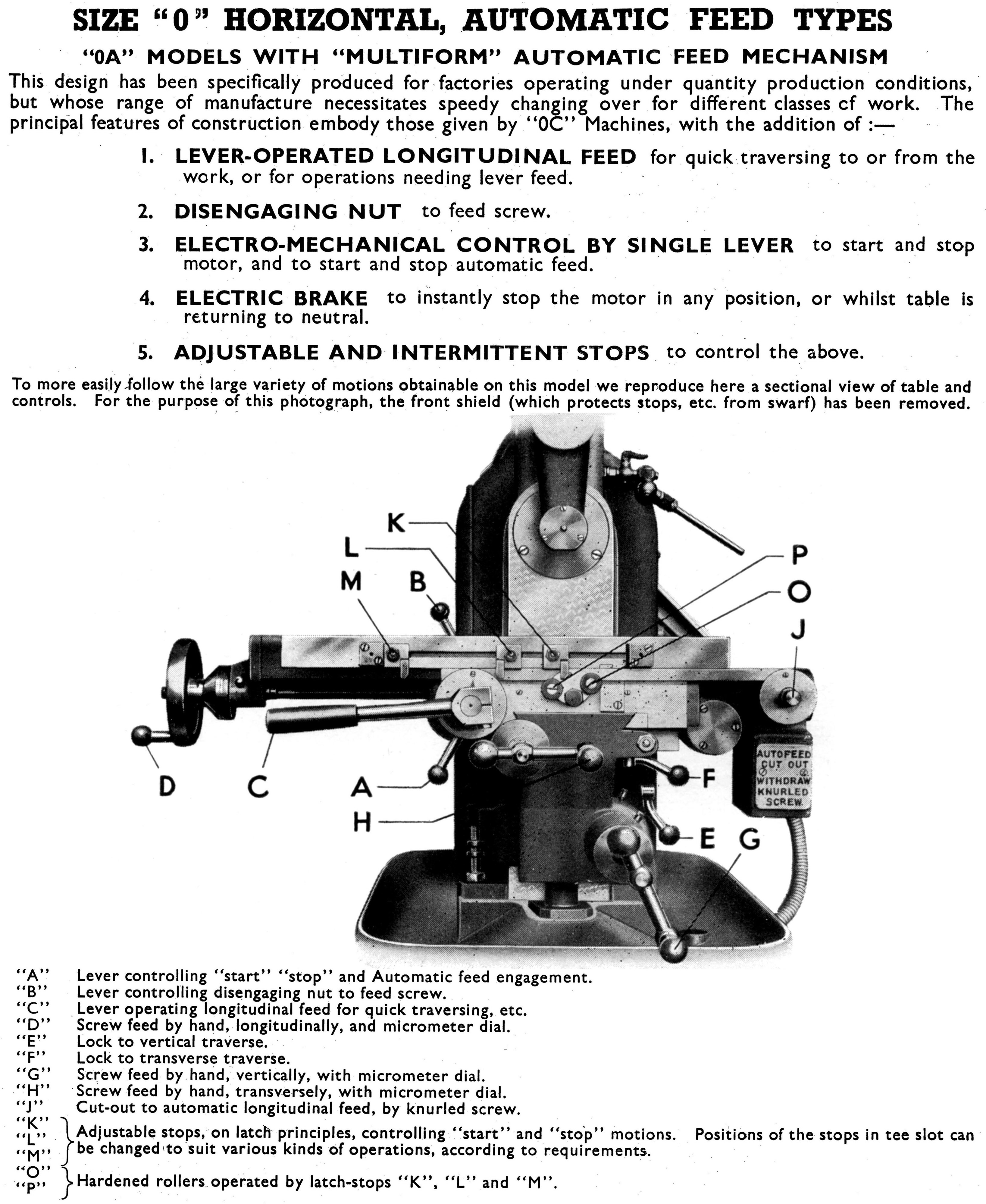

Various sizes of tables were available including, most commonly, a 18.5" x 5" and a 12" x 4.5". An ordinary form of power feed was available, as was a control system (shown in the first picture below) which allowed the miller to be used as a Semi-Automatic Cycle machine with a hand-lever control for rapid traversing and power feed - with three different rates - for cutting. This particular model could also be used with either power or hand-feed - with a choice of either lever or screw feed to the table.

Simpler combinations of features were also available and many "0" millers were supplied with lever-feeds on each axis which, when used with a combination of table stops and table-mounted jigs, enabled the machine to be integrated into "production-line" style machining processes operated entirely by unskilled workers; although perfectly useable by the home-shop machinist when equipped like this, a screw feed (or better still, a combination screw and lever-feed machine) is generally considered the much-preferred option..

|

|