Other makes of "bench precision" lathe

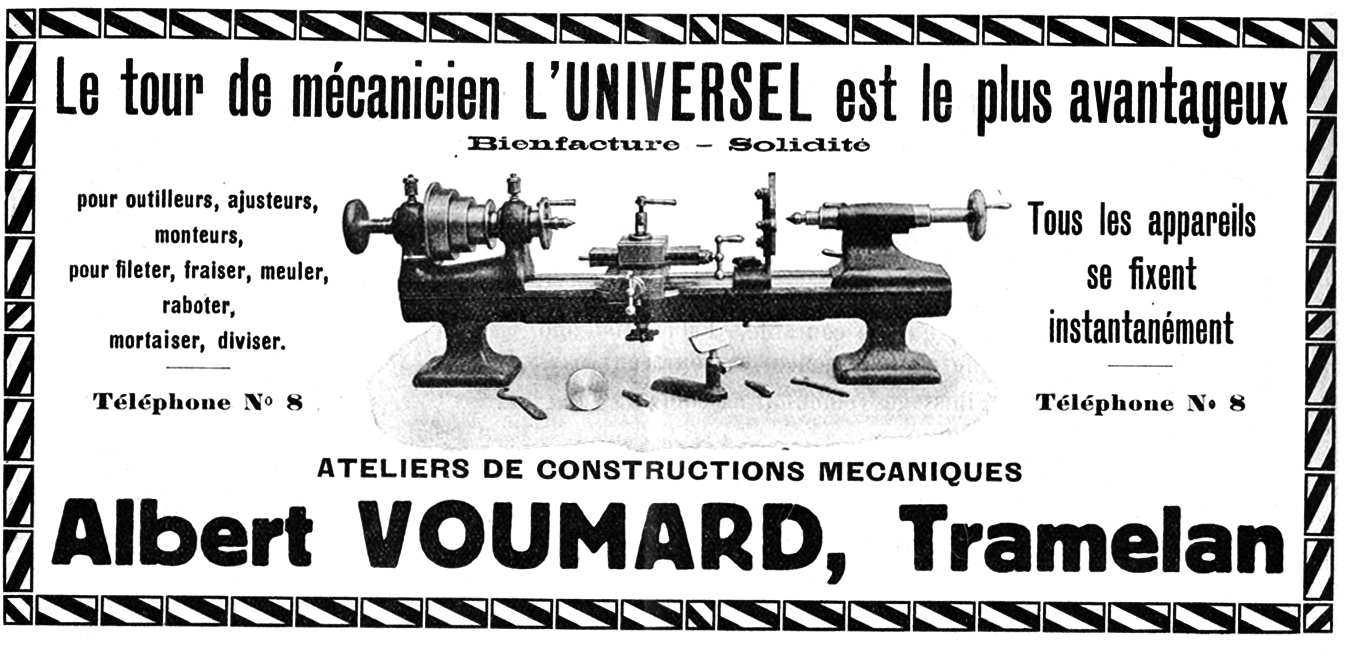

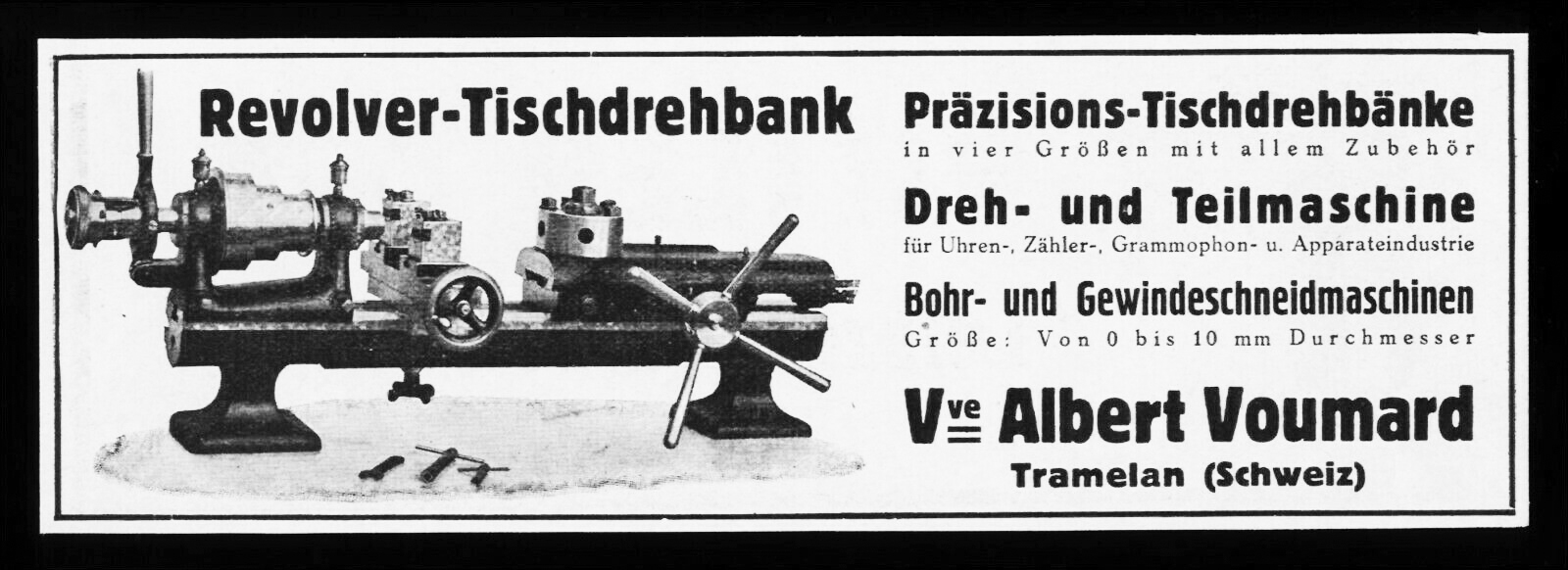

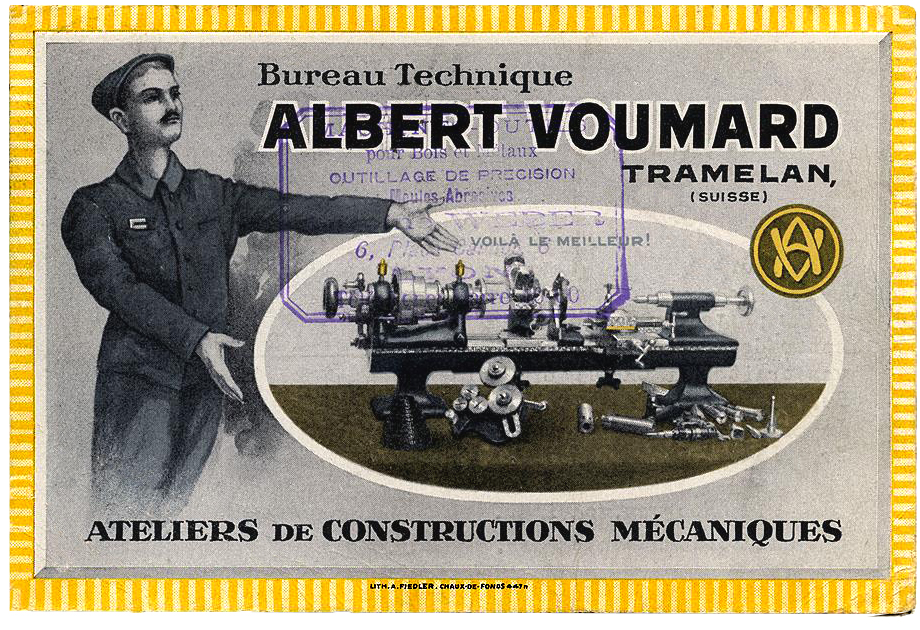

One of the lesser-known Swiss makers, Albert Voumard, made a range of lathes - of which, unfortunately, few details have so far been found.

One precision, plain-turning bench lathe has, however, come to light, a lathe that looks remarkably like, in many of its details, a Schaublin or Simonet. With a 100 mm centre height and an overall length of about 865 mm it was undoubtedly a high-class machine - though few ever appear for sale.

Like most lathes of this type, it would have been arranged to perform three distinct roles: toolmaker (as shown below), second-operation, and production capacity. The toolmaker's type, intended for one-off precision jobs by a skilled turner, was equipped with a screw-feed compound slide and tailstock (and often a collet draw tube for collet holding), while the second-operation version (sometimes called a "finishing lathe") had slides, tailstock and collet closer driven by screws, quick-action levers- or a combination of the two. Production models were usually equipped with a bed-mounted 6-station capstan unit and had a choice of lever or screw-operated cut-off slide rests and a quick-action collet closer - the latter sometimes of the foot-operated kind. By the simple means of changing the fittings mounted on the bed, any version (or combinations of versions) could be assembled in a matter of minutes and pressed into service with a minimum loss of time.

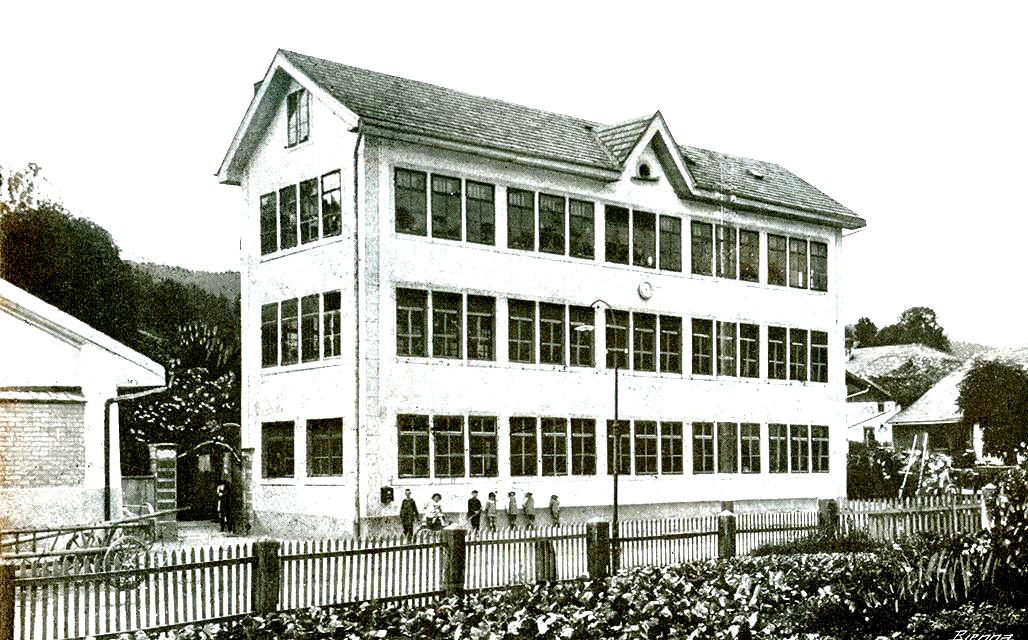

Voumard was based in the town of Tramelan, in the French-speaking Bernese Jura. The Jura, often cut off in the winter and with the farmers little to do, had emerged as an area of watchmaking where home workers turned out hand-crafted parts for larger establishments - a sort of home industry on steroids. Eventually, the production of watches began to move to dedicated factories where quality control was easier to manage, and so quality improved. During the 1800s, Tramelan was one such town where factories were built and, by the 1890s, around 2,500 workers (home and factory-based) were involved in watchmaking and its associated trades. To support the watch factories, machine-tool and makers of specialist production machines sprang up, their products being, naturally, of high precision and often of great complexity. In addition to producing machines of special design, lathes were, of course, a mainstay of their output. By the mid-1950s, around 75 manufacturing plants - watchmaking and machine tools - were active and employed around 1,400 workers.

Voumard was one such concern, and their small factory could turn its hand to conventional and specialised machinery.

If you have a Voumard lathe, the writer would be pleased to hear from you.