|

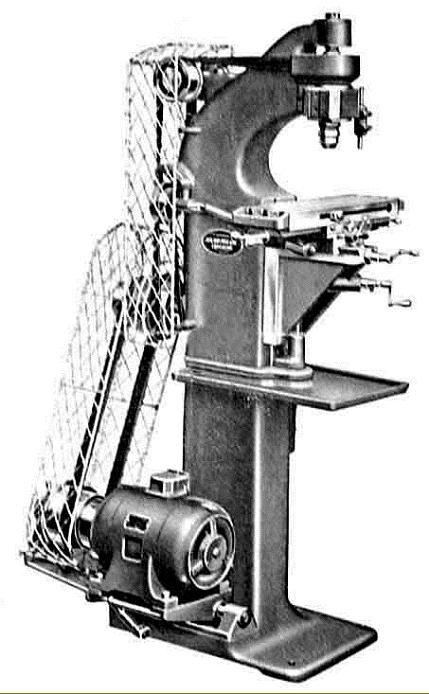

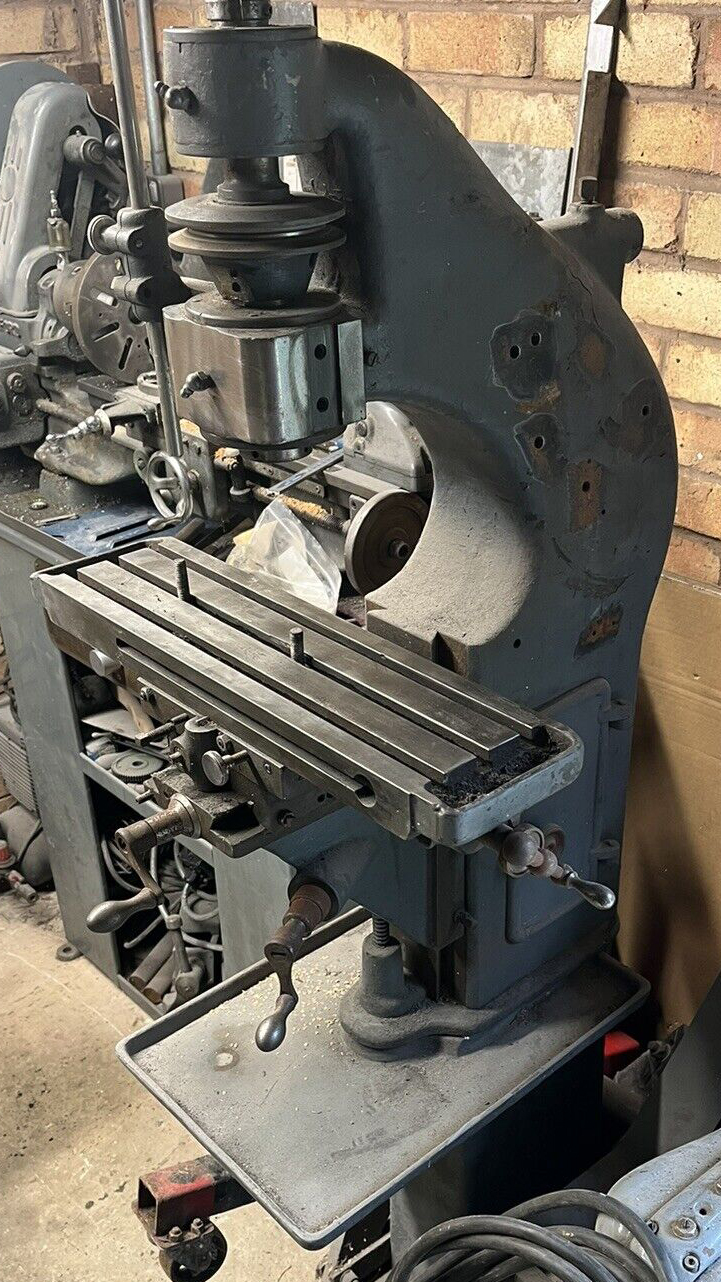

Beautifully made, rigid and heavy, numerous examples of this 60-inch tall milling machine (with its handy 17.75" x 5" table) are still to be found in amateur workshops throughout the British Isles. First manufactured by George Taylor & Son of Coventry, England, before the First World War, the machine went through several changes until its demise as a Mk. 2 version in what must have been the early 1950s. The main body of the miller was fitted to an semi-integral (cast-iron) stand that allowed drive pulleys to be mounted in correct alignment and a small chip tray to be provided. The column was open on the right-hand side and fitted with a deep, cast-iron door level with the mounting of the knee, to provide collet and tool storage; this was a convenient arrangement but one that unfortunately weakened the structure in just the place where it should have been as rigid as possible.

While very early versions of the Mk. 1 had plain bearings fitted to the main spindle, various jockey pulleys and countershaft, later models had ball races throughout leading to much easier running and far less power loss. It is almost certain that the miller would have been offered with a variety of spindle nose fittings and examples have been found with a No. 2 Morse, Brown & Sharpe and Jarno tapers - and also, incredibly, a plain bore. Almost certainly in line with the change to anti-friction bearings the spindle was further modified with a 26° taper to accept direct-mounting "double-split" collets of a type not dissimilar to the modern "ER" type. When the Mk. 2 was introduced at some point in the 1930s, a change was made to a lower bronze bearing and an upper ball race.

Of a very old-fashioned, traditional design, the drive system of early Mk. 1 machines was supplied for connection to overhead factory line-shafting with no provision made for a built-on motor. However, with the increased popularity of self-contained drives Taylor modified the miller to accept a side-mounted, two-speed 3 phase motor; the rest of the drive remained unchanged, with the belt from the motor passing to a 3-step pulley (at the back of the main column) on the inside of which was a single pulley that transmitted the drive upwards and round two adjustable jockey pulleys before wrapping round the (unguarded) spindle pulley. Later machines were much altered with, amongst other changes, an updated and fully-enclosed drive system that provided full protection for the operator from the belt runs.

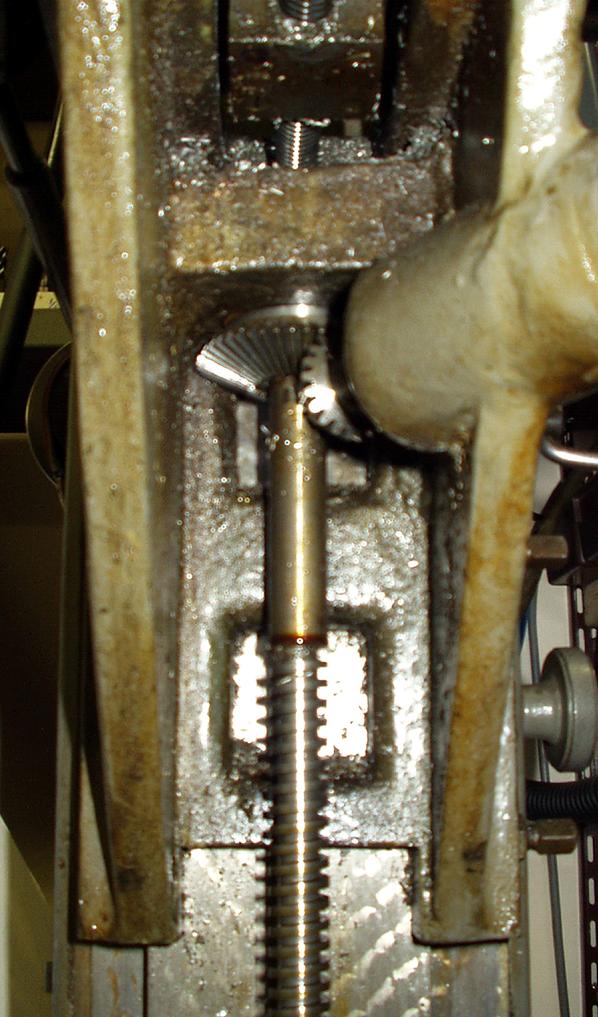

With three generously-proportioned T-slots, the table was fitted with either a 2 or 3-speed feed, driven by flat belts with the power taken from a small 2-step pulley concentric with the main input/output pulley on the back of the main column. A telescopic cardan shaft, with a single universal joint outboard of the drive pulley, transmitted the power to the table; the necessary angular movement at the table end was arranged by allowing the worm assembly to rotate around the slotted table feed screw. A pre-set, automatic knock-off arrangement was fitted and consisted of an external housing that held a tappet-like pin with a bevelled end pushed down by wedge-shaped striker plate that slid in a T slot along the table's front face. The tappet pin, which had a rack cut into its lower end to activate the release mechanism, could also be operated by a hand lever. Longitudinal travel was 9.5", across 3.5" and vertically 8.25".

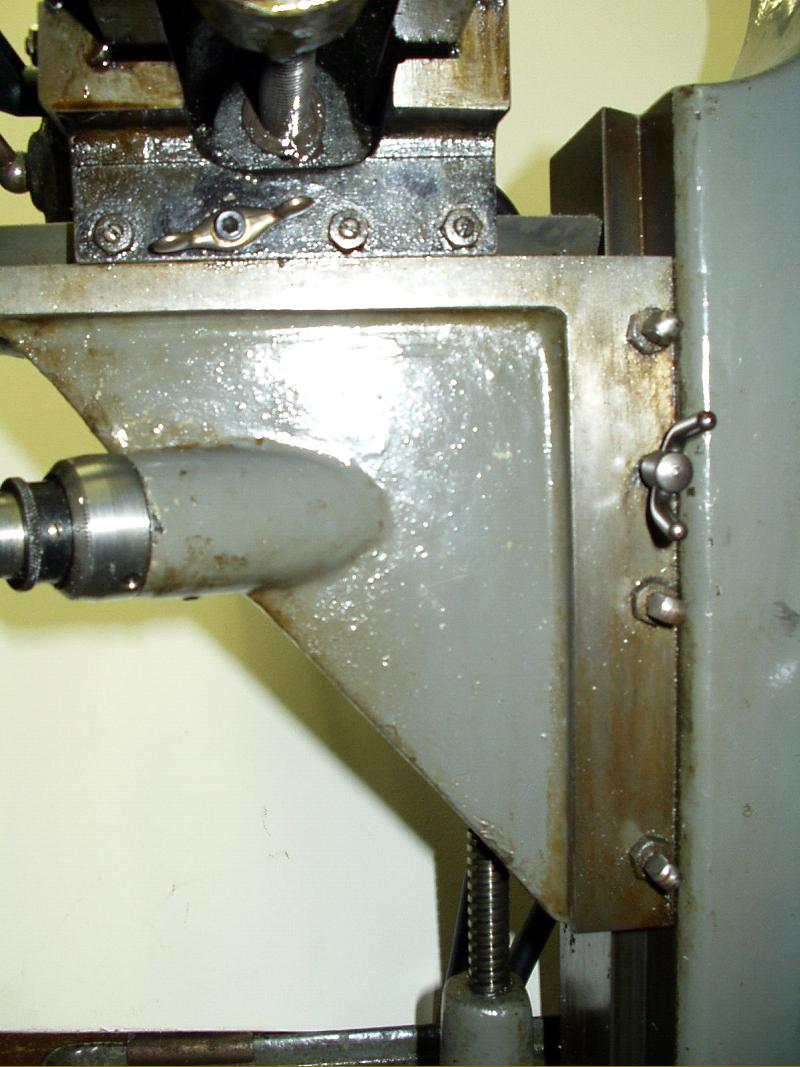

A micrometer dial was fitted only to the right-hand end of the table feed screw, although a handle was provided at the other with the screw passing through a simple support bracket that hung down from the underside of the table. The design of supporting bracket for the table-feed shaft was very distinctive and can be used as a useful recognition aid if a machine has lost its cast bronze badge to a "collector"; unfortunately the bracket was retained by two set screws, with very shallow slots across their elegantly turned faces; even using the special wide screwdrivers then common it would only have been possible to apply enough torque to make them adequately rather than securely tight.

In its original form the miller occupied a floor space of 34" x 27" and weighed about 0.25 tons.

Fitting new anti-friction spindle bearings - the following is the experience of an owner:

Removal of the spindle was straight forward enough: remove the nut from the top, turn up a dolly to prevent injury to the threads and apply hammer. The middle bearing ( upper bearing, lower yoke) separated, the inner race staying on the shaft, the outer race staying in the yoke. The race that stayed in the yoke was worn so, inner and outer race numbers noted, a new one was one ordered - a Hoffman ls12ac at (in 2021) £133. Research showed a ljt1-1/4 1 was a direct equivalent at £23.42 so that was ordered and arrived a couple of days later.

Not giving much thought to assembly sequence, I put the bearing into it's housing thinking that it would be possible to raise this spindle through the bottom yoke, place the drive key in position, lower it and position the pulley. Oh, how wrong that was! By the time the spindle is through the bottom yoke, it's through the top as well - at that point I sought your advice. So, after a good coat of looking, I realised that it must have gone together in the same way it came apart i.e. the middle bearing separated outer race into the housing and the inner race onto spindle, I could not see any other way. I then realised that the bearing I had bought was equivalent in dimensions, but not construction. The Hoffman has a solid brass cage, so all the balls are in position on assembly and it sort of 'springs' together (I've put it back together to check this). The ltj1 has a steel cage so the balls can be clustered together to insert the inner race, then spaced out and caged from either side allowing bigger lips on the races. I tried to disassemble it, to no avail. Increasingly forceful ' taps' with the hammer convinced me it was not meant to come apart and I would do damage if I continued. Another strong coat of looking at! Well, if the keyway extended to the end of the journal, the key could be fitted in the pulley and the spindle pushed up into it, if you could line it up. Out with the lathe milling slide, off with the tool post on the Smart & Brown lathe and, a few minutes later, the key way was extended.

The key was quite a force fit in the pulley so, with a chalk mark on the pulley and one on the top of the spindle, all the bits were loosely in place. With a lump of wood on the table, the vertical lift was slowly operated. I realised that the two chalk marks were unlikely to be dead accurate so, when proceedings came to a halt, I lowered the table half a turn. Then, holding the spindle still, I turned the pulley a little each way and felt it locate. Then back to lifting the table until the spindle was through far enough to put the nut on and pull the lot together.

BTW--there are felt seals in the yokes and, although these were intact, I replaced these with ordinary "O" rings with a bit of tin strip behind one which was a bit slack. The rings are holding grease at the moment--but how long they will last is yet to be seen. With the belt and guards replaced I did a couple of test cuts all was good, and it is now very quiet.

|

|