|

Machine Tool Manuals Catalogues Belts Accessories Books & 3-inch "Super" Lathes |

With centre heights of, respectively 4 and 3.5 inches, and available in two models and several forms - in the normal, very confused Portass manner - the X.L and X both enjoyed a specification rather superior to that normally found on other Portass lathes of the early 1930s. In later catalogues, the Model Type was over-stamped "MARK U", though why this was done is a mystery, as it appeared contrary to the usual Portass naming nomenclature - save for the "MARK V". In addition, there was yet one more model in the range, this being listed as the "3-in Super S.C.B.G." - a machine that we will return to at the end of the article.

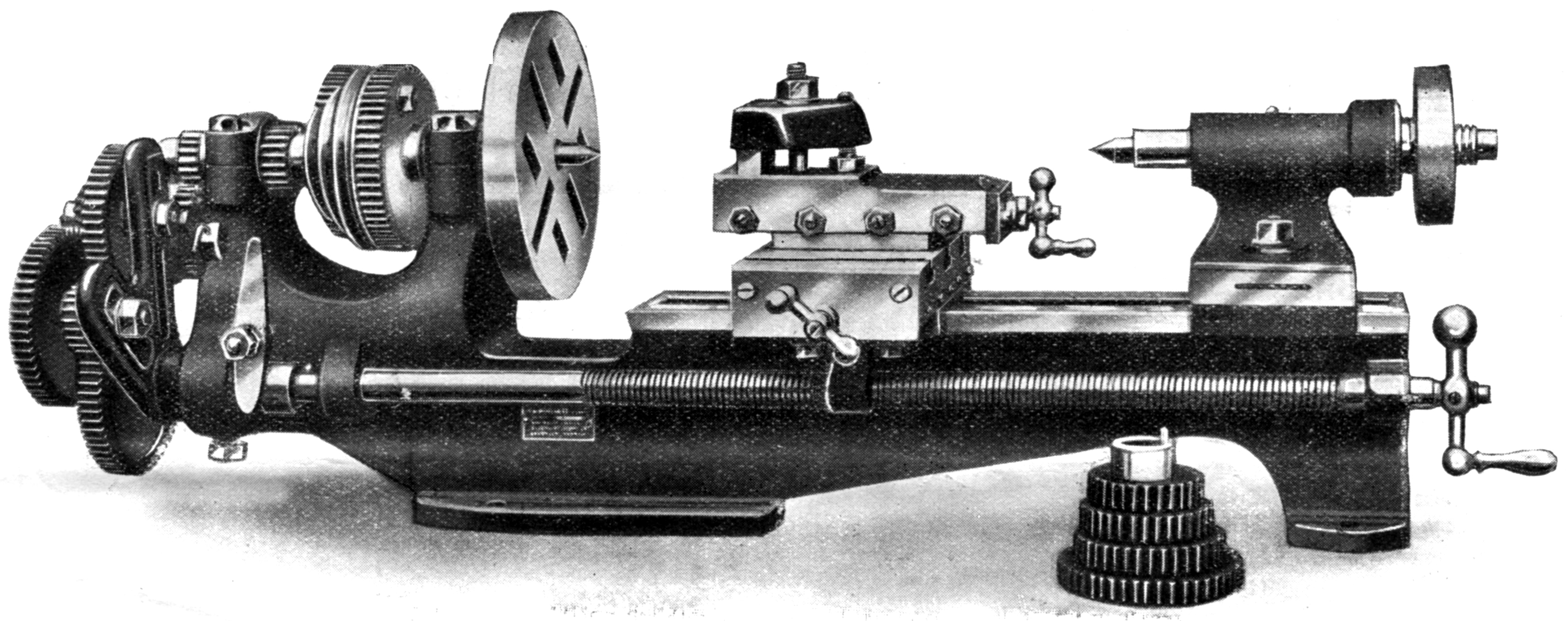

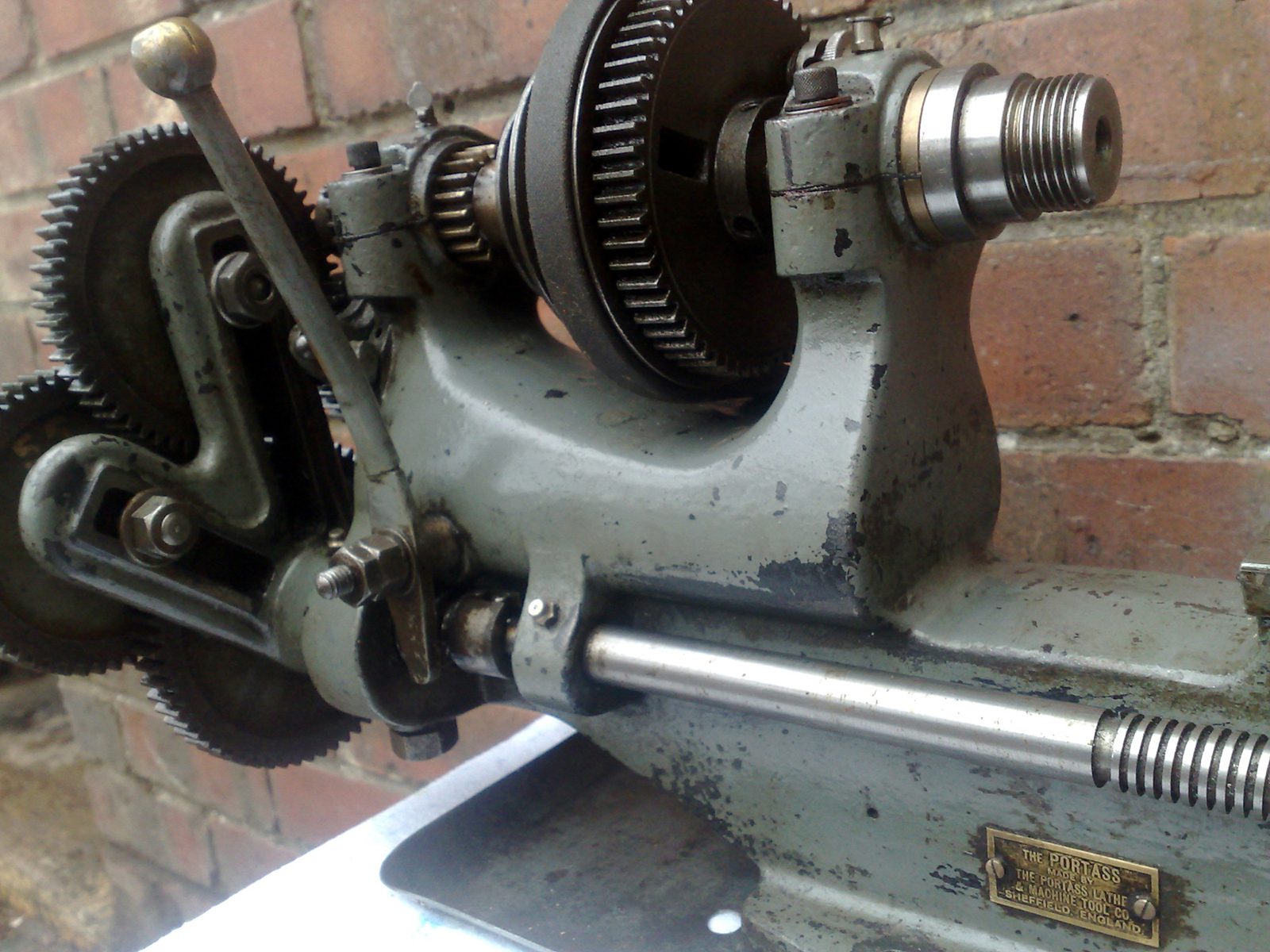

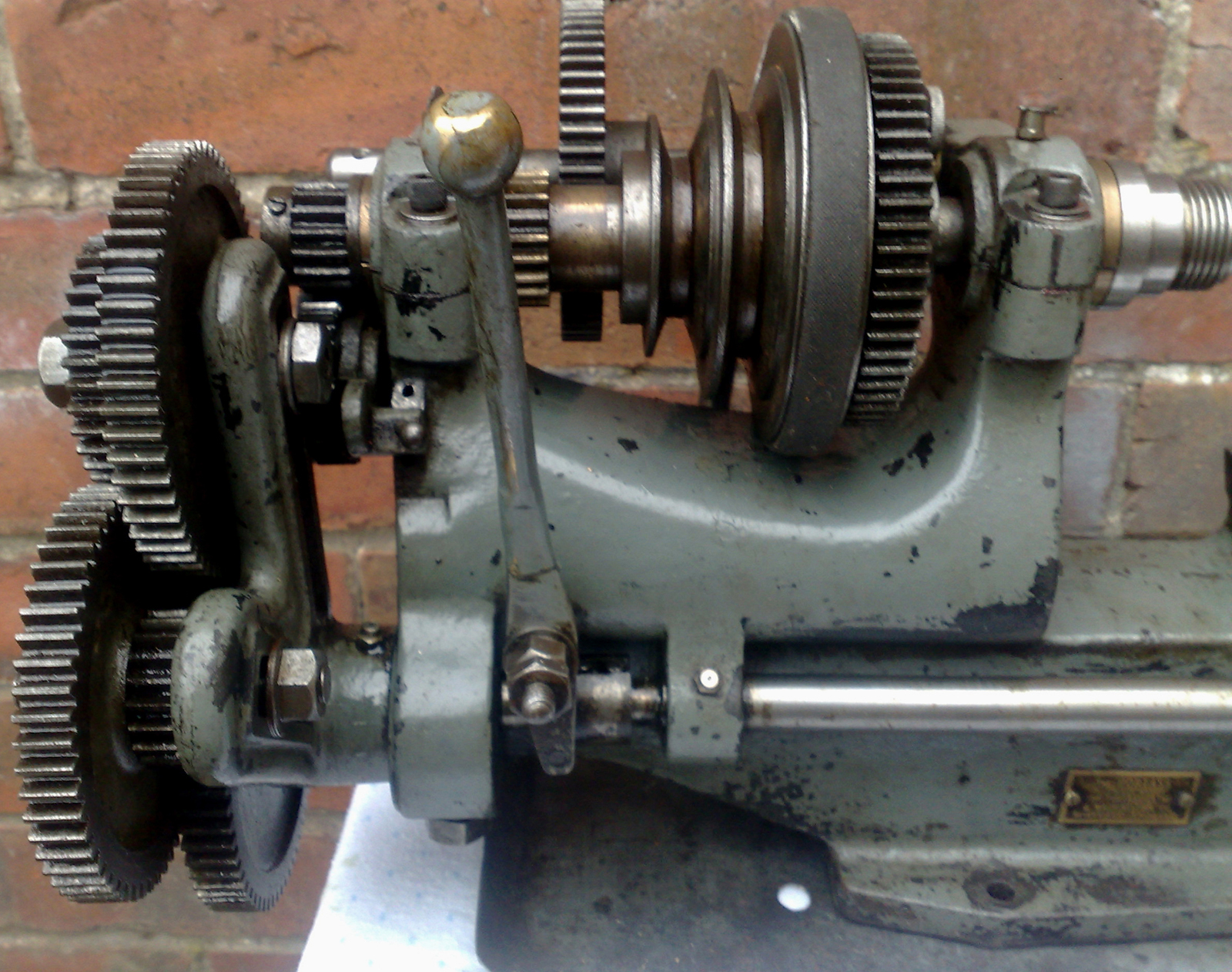

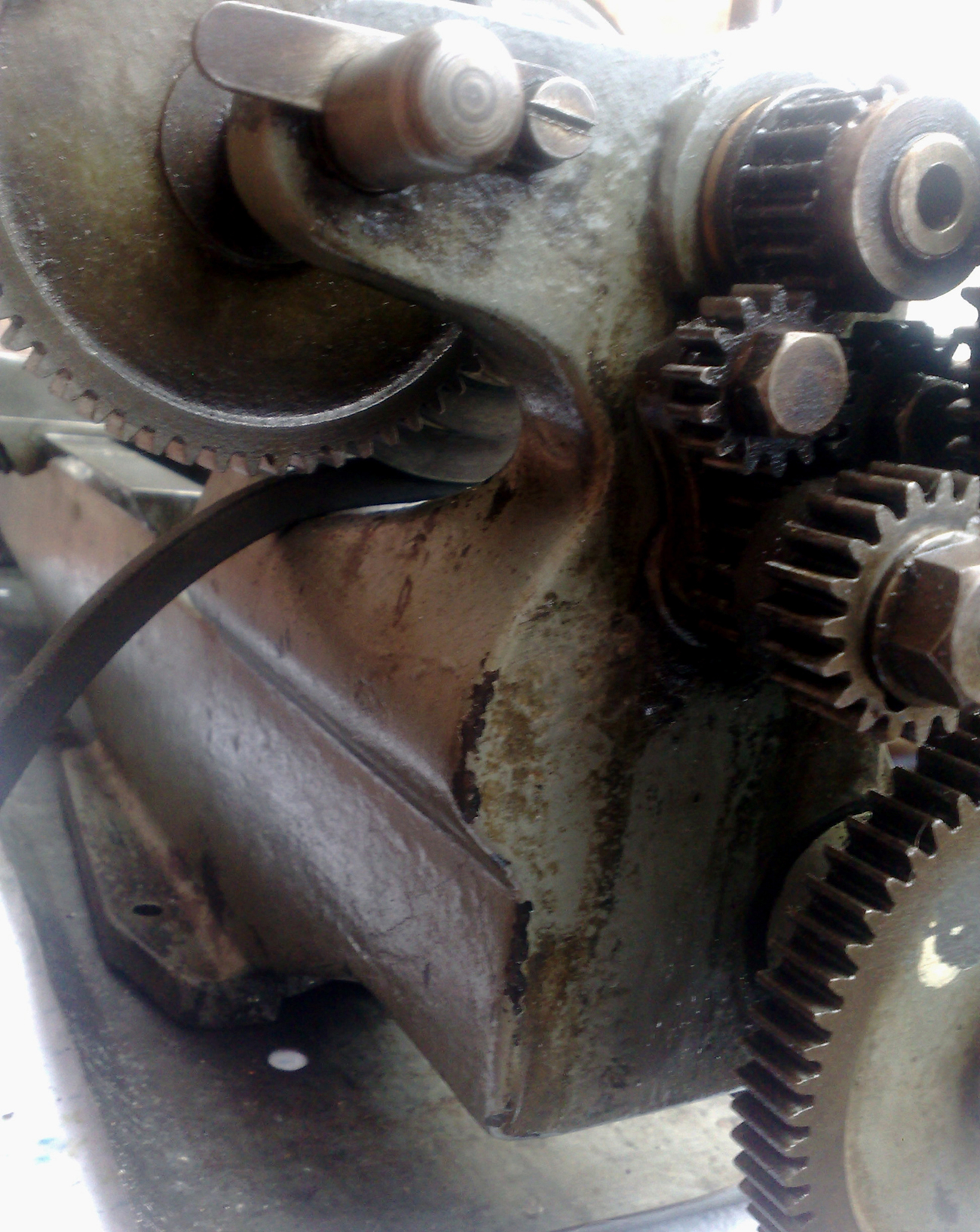

On the X.L. and X the headstock and (gap) bed were cast as as-one; a forked and not the usual single-slot changewheel bracket was fitted, the slide rest was a proper compound type with a swivelling top slide, backgear was at a ratio of 6 : 1, a dog-clutch as fitted to the leadscrew and, most surprising of all, the option was available of tumble reverse to the leadscrew drive. If Portass could have saved another half-penny on the tumble reverse lever assembly, he would have been pushed to do so; it was, to be blunt, crude in its execution.

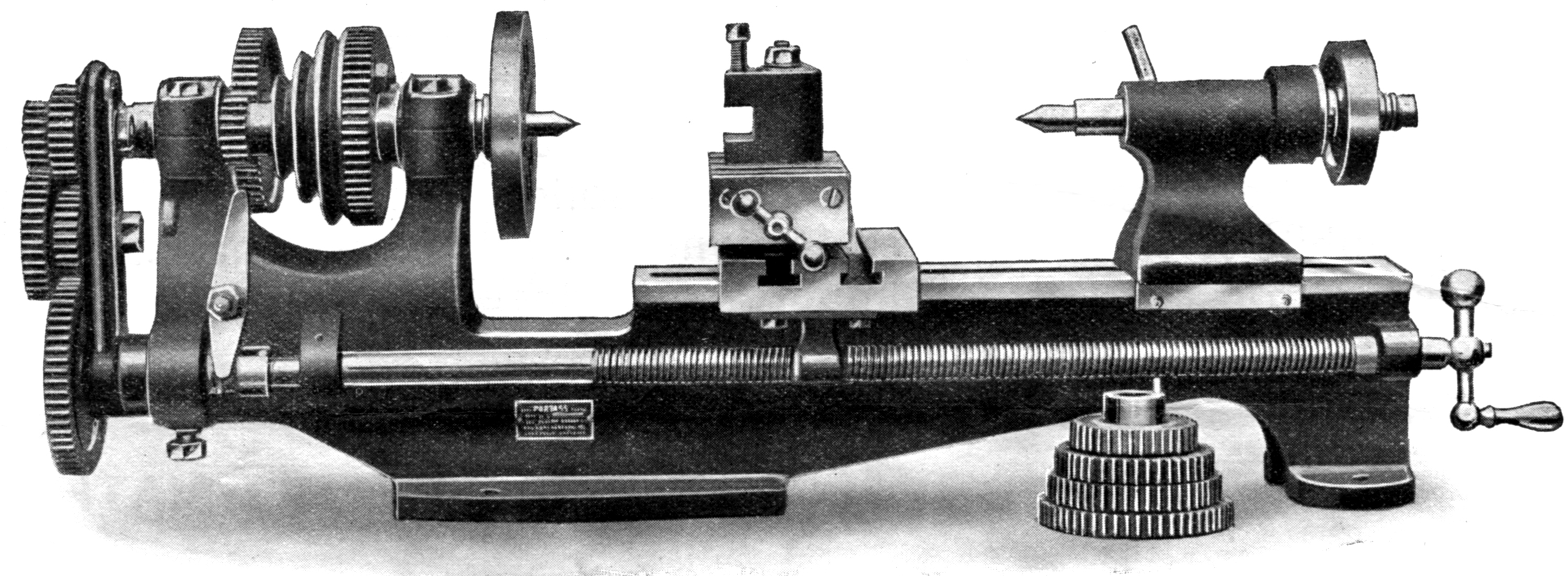

The centre height of 4 inches and with either 12.5 or 18 inches available between centres the lathe had most of the capacity the average owner could have wished for. If overtime had been in short supply - or the wife angry that the children's shoes were once more in need of replacement - also listed was a cheaper model, the "X", with a centre height of 3 inches. However, it's likely that, as some catalogues had the 3-inch version also listed as the "3-inch Mod. X.L." some were 4-inch as well. Based on the X.L, the X lacked all the features that made that model so useful and made do with a single, swivelling tool slide, no set-over to the tailstock (though this has been seen on several examples so must have been available as option), no tumble reverse (though some headstocks have casting designed to take it), a spindle running direct in the cast-iron of the headstock and, to make screwcutting more difficult to set up, a single-slot instead of a forked changewheel bracket.

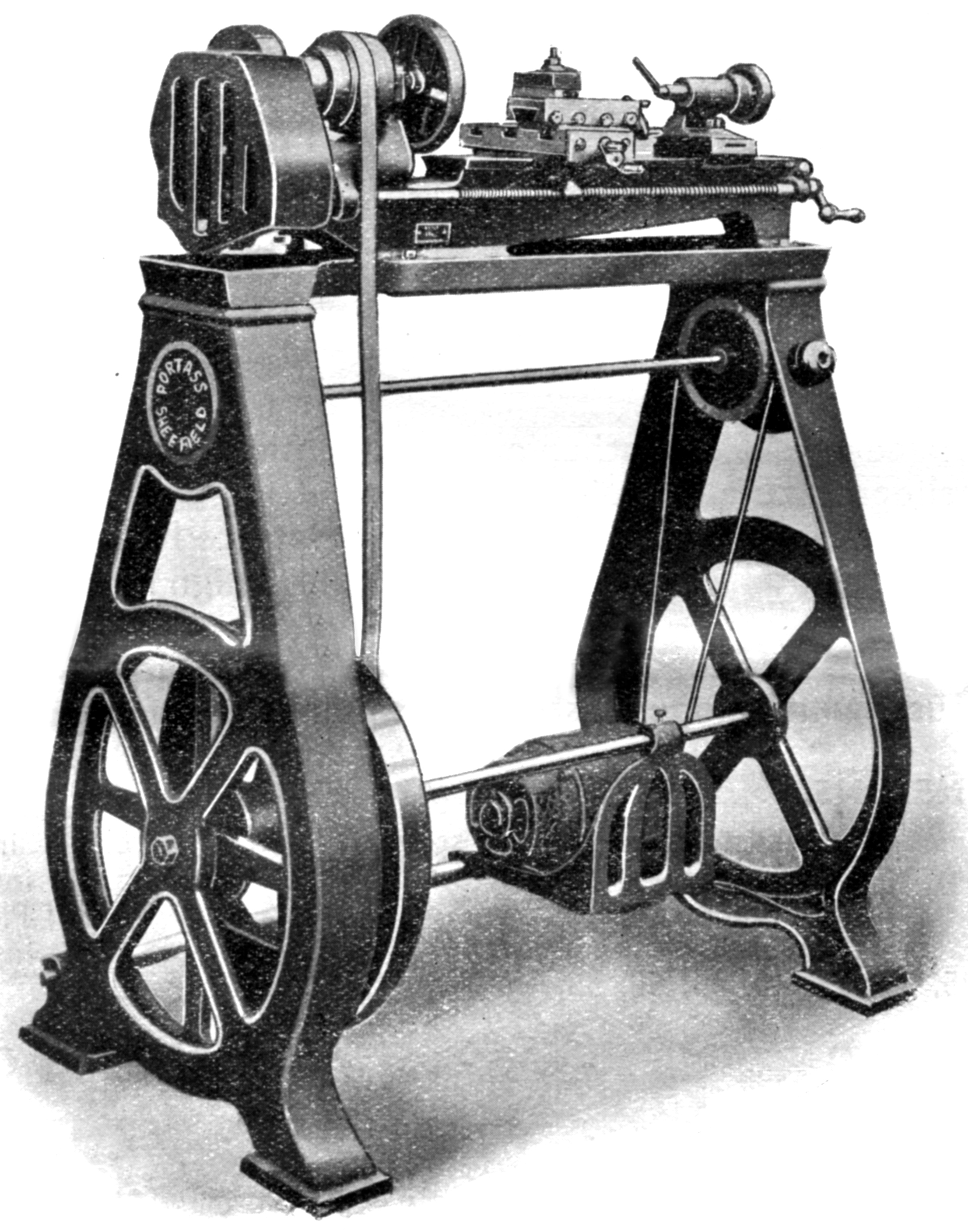

Bored through 3/8", the No. 1 Morse spindle ran in parallel split gun-metal (bronze) bearings nipped down by screws. While early examples were fitted with a 3-step headstock pulley designed to be driven by a 5/16" round leather rope, later types had the no-cost option of a 3/8" flat-belt drive - and so a more useful work capacity. The lathe was often supplied fastened to a substantial cast-iron chip tray - and sometimes complete on cast-iron standards (legs) - the headstock-end one of which carried a treadle-operated flywheel or, very rarely, when a customer must have worked lots of overtime, he might have ordered his lathe with a self-contained electric drive. This model, instead of using an ordinary countershaft system, had the treadle-type flywheel assembly left in place (as on some Dreadnaught models) and used in the drive system. Consequently, with a heavy flywheel rotating, when wound up to full speed, such a set-up would have taken a considerable time before any job, even a lighter one, came to a stop. A cut-out in the chip tray - in line with the headstock pulley - gave clearance for the drive belt - with round-rope and flat-belt versions similarly equipped.

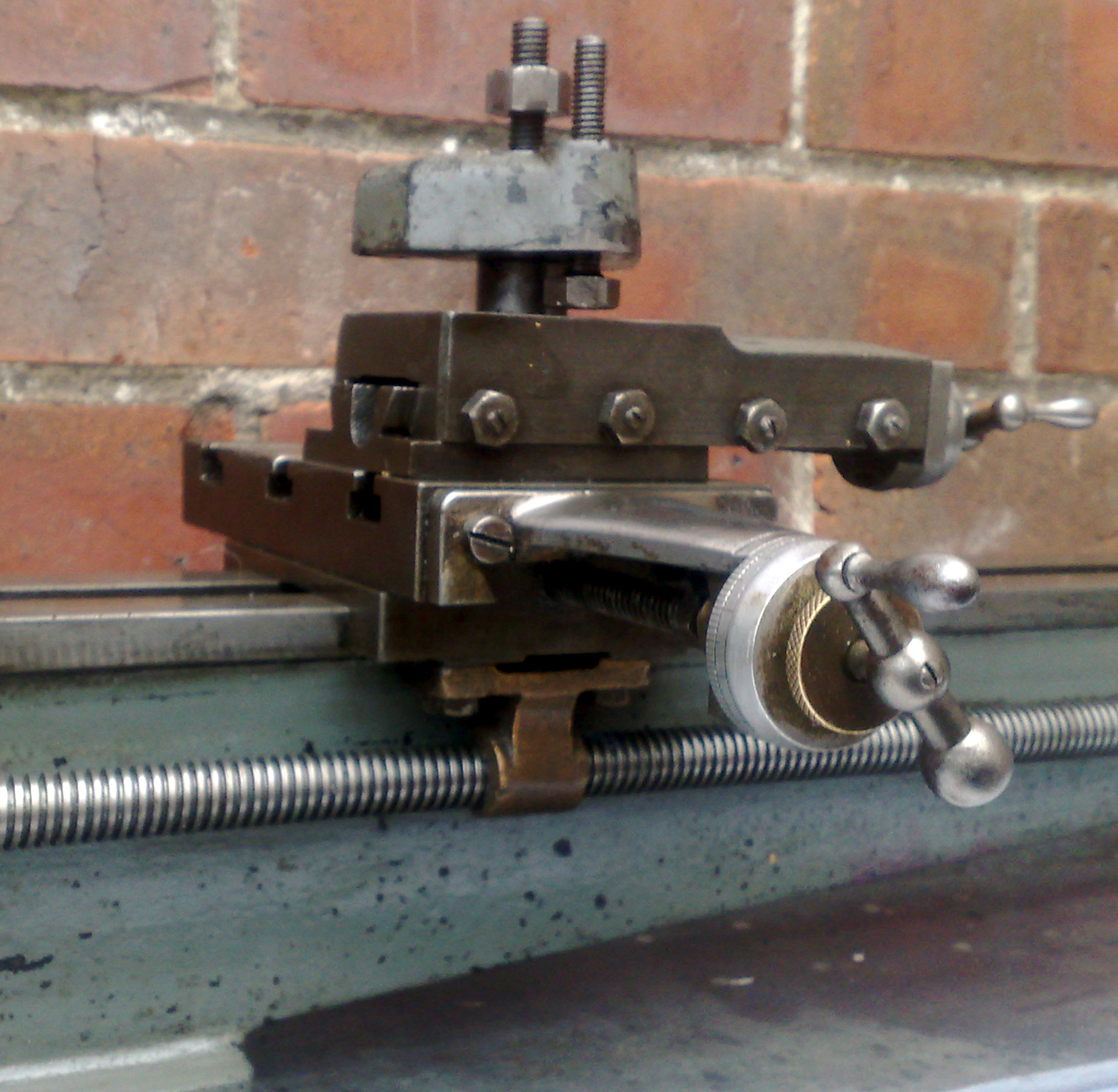

Driven along the bed by an 8 t.p.i. square-thread leadscrew - fitted with a dog clutch at the headstock end and a balanced handwheel at the other - the carriage had a proper compound slide rest, the cross slide of which was T-slotted - but the tool slide retained by just a single bolt on which it could be swivelled. In line with other contemporary Portass lathes, no micrometer dials were fitted to either slide.

Was this the first-ever Portass to be fitted with tumble reverse to the leadscrew drive? It would appear so; the Model X, shown in the photographs below, has the correct castings in place - but no gearing - while the X.L. has the complete mechanism in place. Unfortunately, the tumble gears were of a very coarse pitch and, although strong, must have caused quite a racket when run at speed.

Supplied with the lathe was a full set of machine-cut screwcutting changewheels of 20, 20, 25, 30, 35, 40, 45, 50, 55 and 60t.

Prices, in the lathe 1930s, were £10 :10s : 0d for the short-bed X.L., £12 : 0s :0d for the 18-inch model, with an extra £4 : 4s : 0d for the flywheel-equipped stand and a charge of 7s : 6d for backgear guards and the same for a changewheel cover. Somewhat cheaper, the inferior Model X was listed at £7 : 16s : 0d for the short-bed and £9 : 6s : 63/4d for the long.

The X - and possibly the XL - were also badged as the "Altona", as was the Portass Model S. However, to date, no Altona models have ever been found in the UK, all residing in Australia.

Portass "3 in Super S.C.B.G"

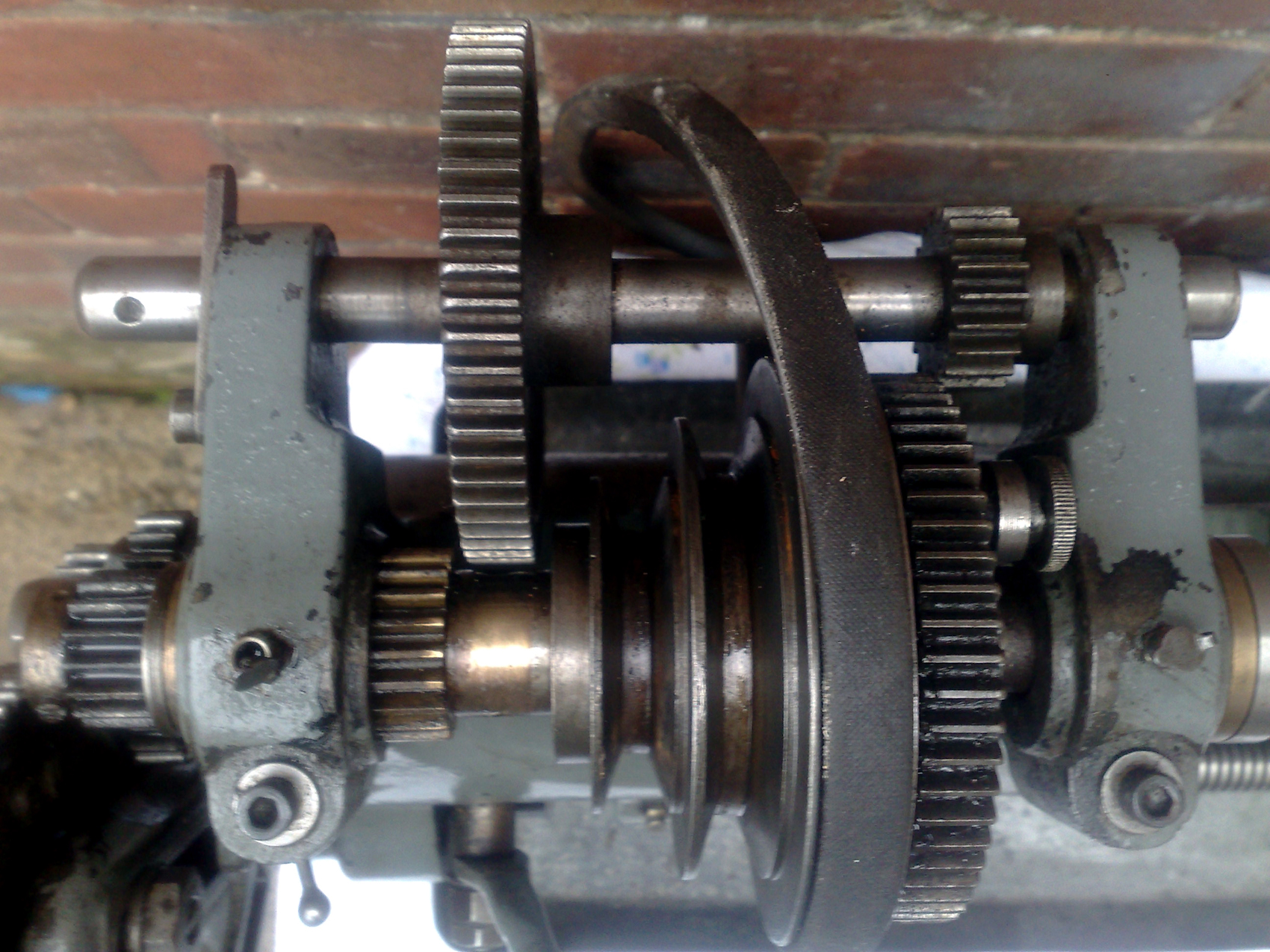

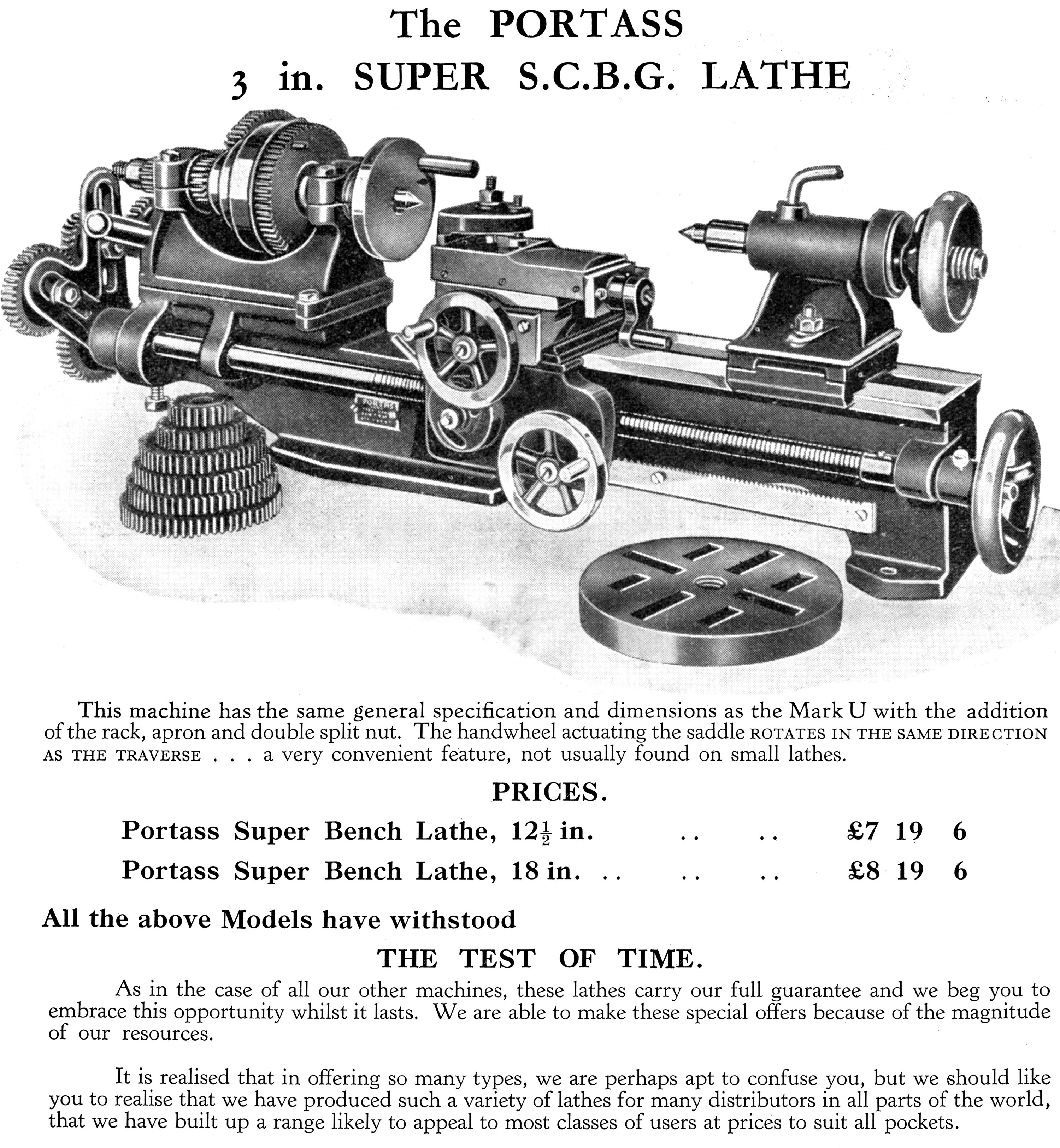

Although, according to Portass, "having the same general specification and dimensions as the Mark U", this 3-inch centre height, Screw Cutting and Back Geared was of an entirely different design. The headstock bolted on, the tailstock had a separate base allowing the top section to be set over for the turning of slight tapers, the leadscrew was equipped with double clasp nuts (obviating the need for a dog clutch) and the carriage was not only driven by racking and pinion gearing, but also incorporated reduction gearing that gave a smoother, slower movement and meant that the carriage moved left and right in the same direction as the rotation of the handwheel. The Portass "Super" is shown at the bottom of the page.

|

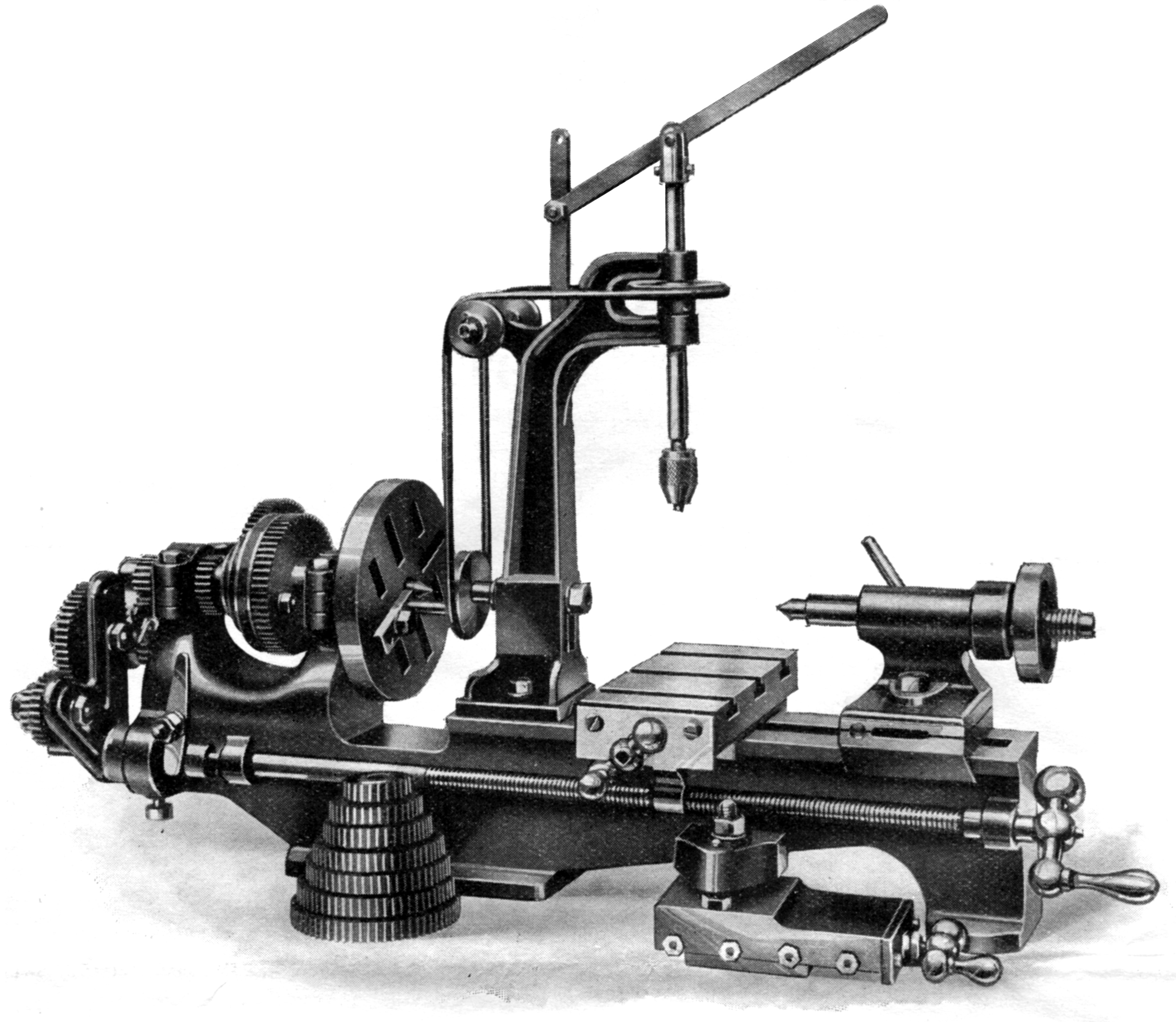

Portass Model XL. The bed-mounted co-ordinate drilling attachment, driven from a peg carried in the faceplate, was offered by Portass as an accessory for many years. The picture has been heavily "art worked" to improve the machine's rather "as-cast" ex-factory finish. Photographs of a Zyto version here. |

||

|

|

||

|

|

||

|

Portass Model X.L. on the maker's motorised stand. Instead of using an ordinary countershaft system Portass (as on the Dreadnaught machines) left the flywheel assembly in place. Wound up to full speed, such a set-up would have taken a considerable time before any job, even a lighter one, came to a stop. This model was listed with both 4 and 3-inch centre heights. |

|

ornamental stand with foot-operated treadle and flywheel drive |

|

|

||

|

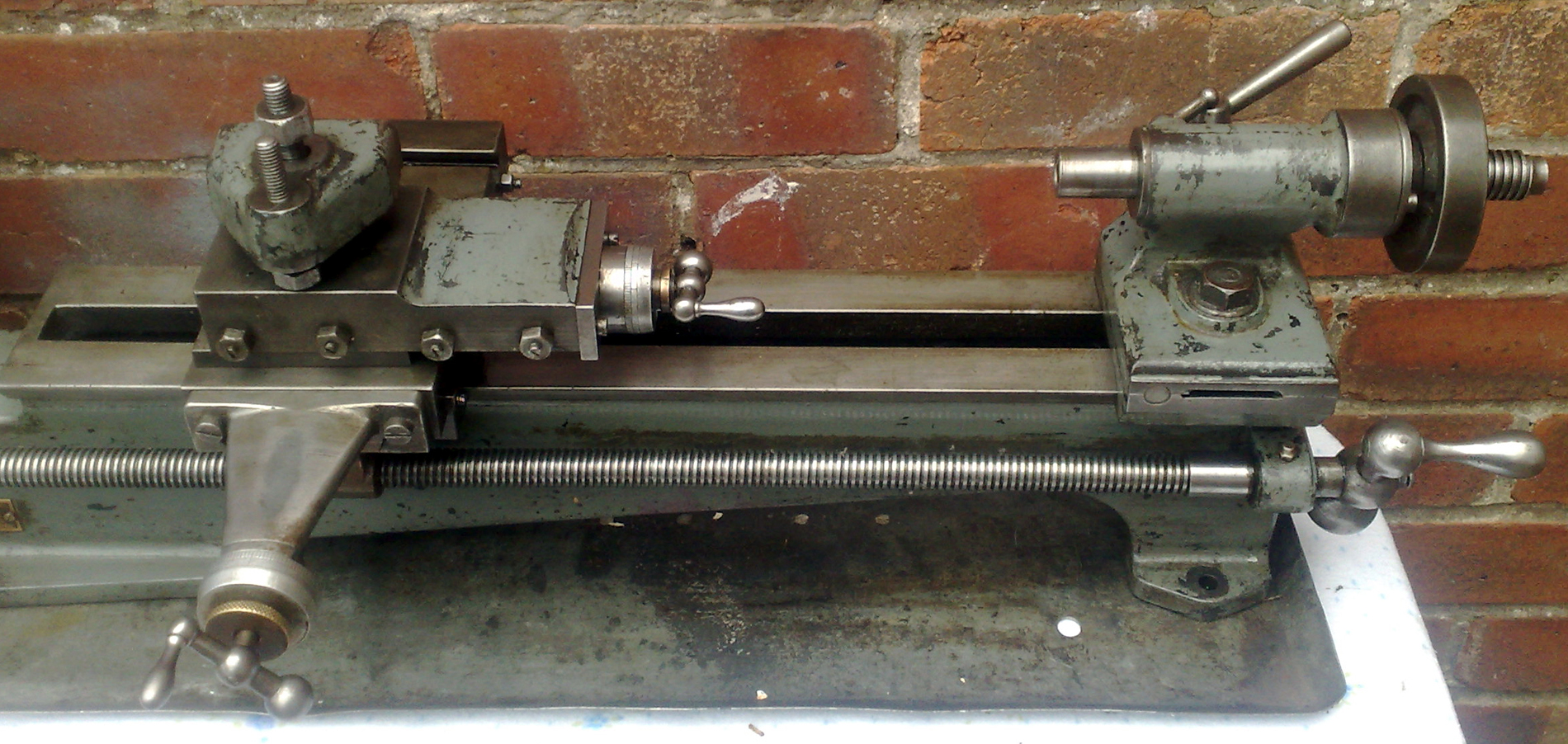

Portass X. Inexpensive engineering: there is apron on the carriage and the leadscrew "full nut" is bolted to the underside of the saddle. There was no quick-action rack-and-pinion carriage drive but twin T slots in the saddle allowed maximum flexibility in positioning the swivelling tool slide |

||

|

|

||

|

front of, or behind the headstock spindle, is open to debate |

|

Unfortunately the tailstock barrel was locked by a simple pusher screw; however, this was probably a good deal more satisfactory (and with better long-term reliability prospects) than using that other favourite of the inexpensive (and sometimes not so inexpensive) lathe maker - a bolt that attempted to clamp together a split in the tailstock casting |

|

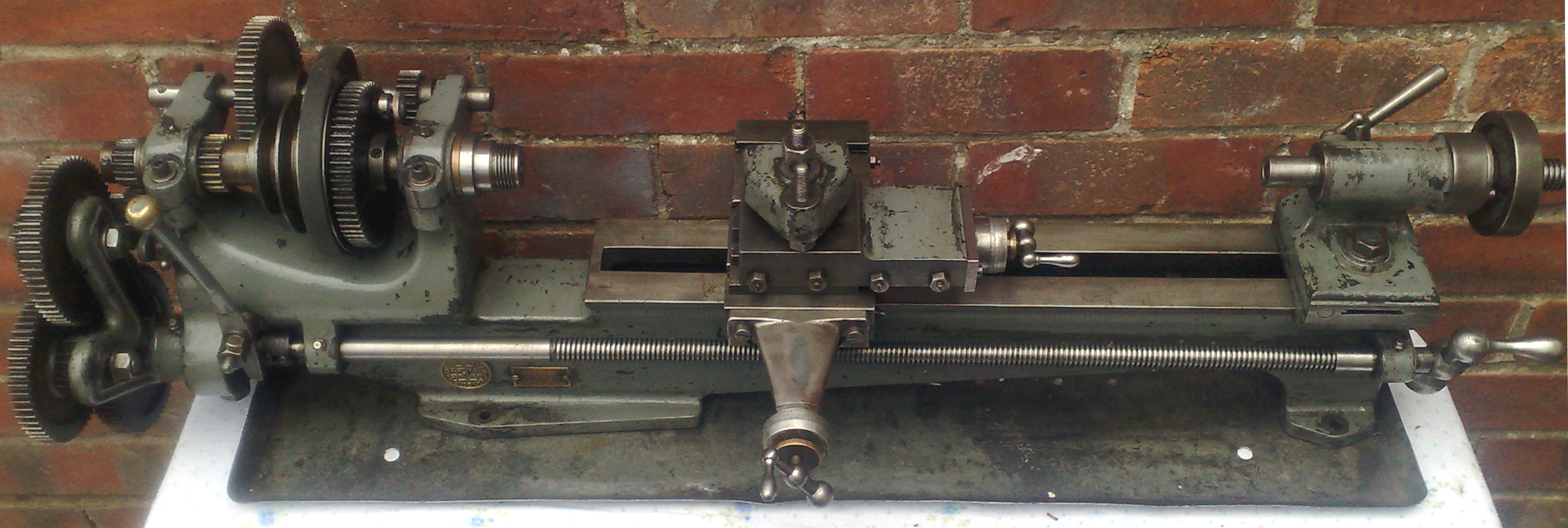

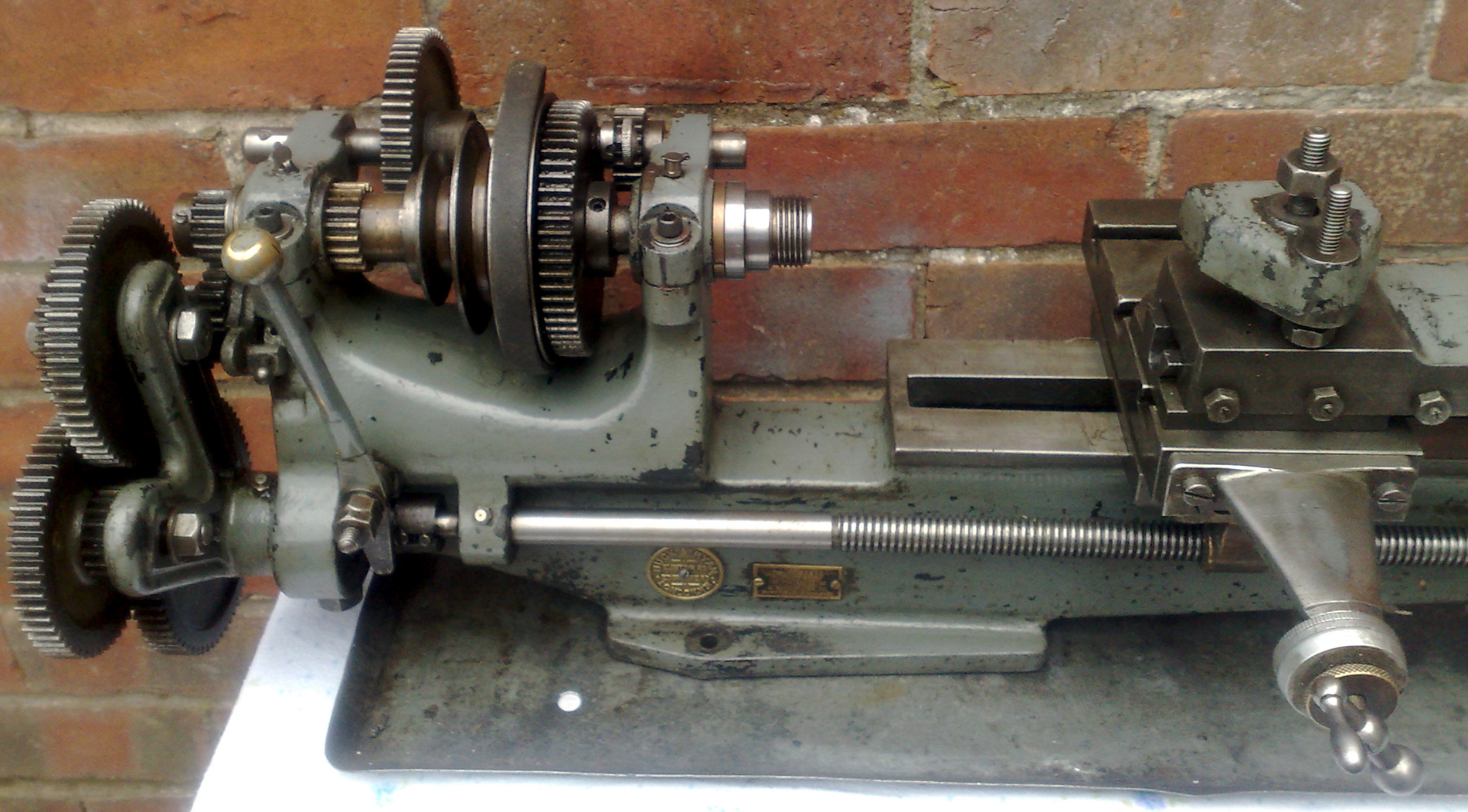

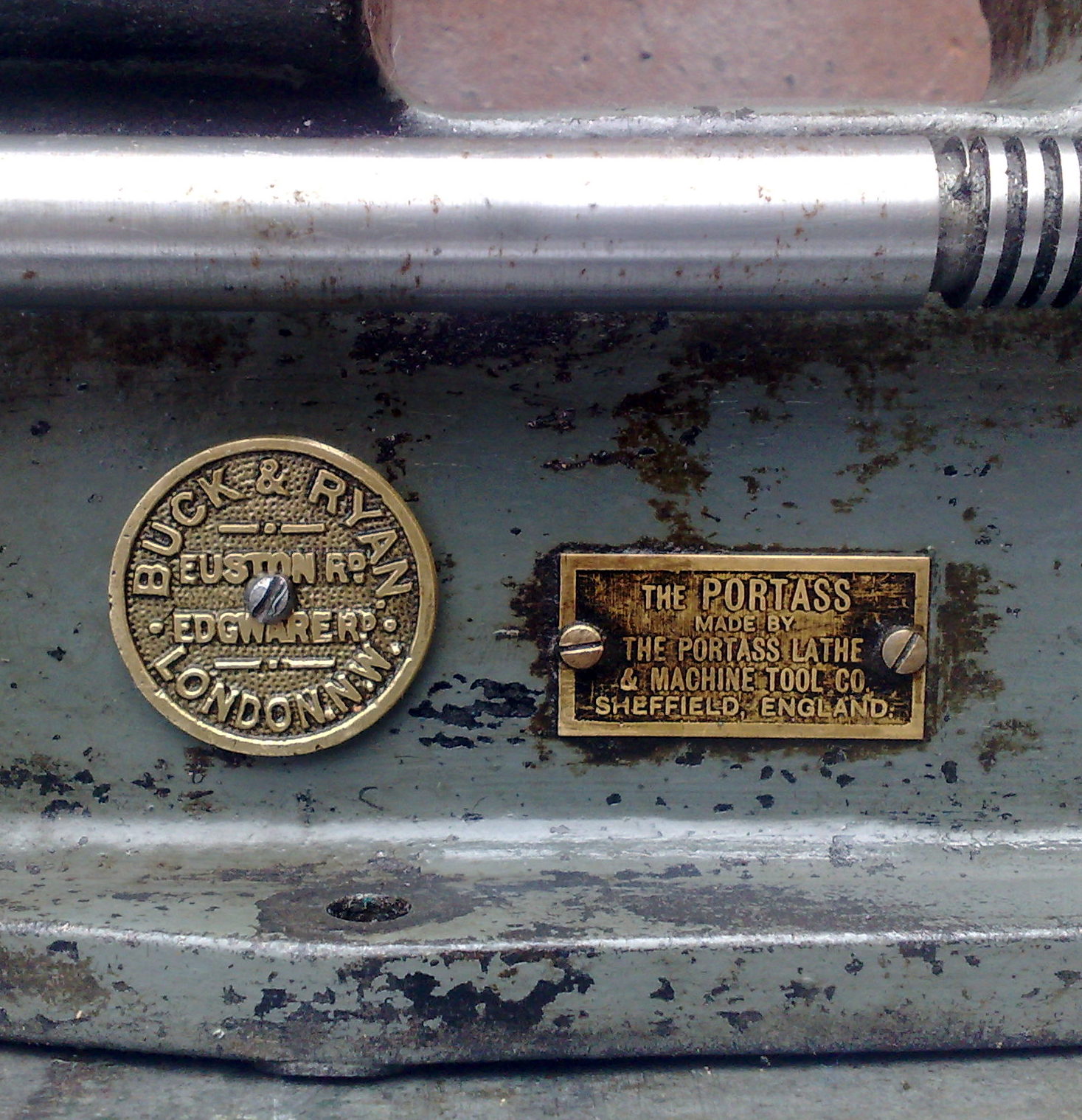

Yet another well preserved Portass from the late 1920s to the late 1930s - a rare long-bed 4" x 16" Model X.L. This example, although modified by a previous owner, still has a variety of features quite at variance with normal Portass practise: the centre height is four inches (unusually generous for the maker) with sixteen inches between centres; bed and headstock are cast as one - though this is in line with the maker's early miniature lathes, the first Model S and the Type V - and fitted with a tumble-reverse drive to the leadscrew. The headstock pulley is obviously intended for a Z-section 10 mm belt (and not a round rope drive) and the spindle nose, with a 1.125" 12 t.p.i. nose is either a modification by a previous owner or a quite-out-of-character move by Mr. Portass. The bronze leadscrew nut is full, and obviously of the maker's type, through the handle on the dog-clutch is not theirs. Oddest of all, though quite possibly a modification, is the well stepped-out cross-slide screw support bracket, the micrometer dials and (for a Portass) the unusually delicate T-slotted cross slide. With the extra rearwards slide travel obtained by the screw bracket, all these fittings combine to equip the lathe perfectly for the mounting of a vertical milling slide, However, even if these items were replaced with ones from an ordinary Portass, the lathe would still appear sufficiently novel to stand out. Just possibly, it might have been built for the then famous tool and machine-tool distributors Buck and Ryan; their badge is attached to the lathe and they would have had the buying power to purchase a batch of machines made to their exact specification. However, having decided upon tumble reverse, one wonders why they did not specify a proper apron with clasp nuts for the leadscrew and a rack-and-pinion hand drive for the carriage ? And could they have neglected to specify at least backgear guards when all other small lathes were decently covered up? |

|

Spot the fiddly tumble-reverse lever... |

||

|

Machine Tool Manuals Catalogues Belts Accessories Books |