|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mail: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

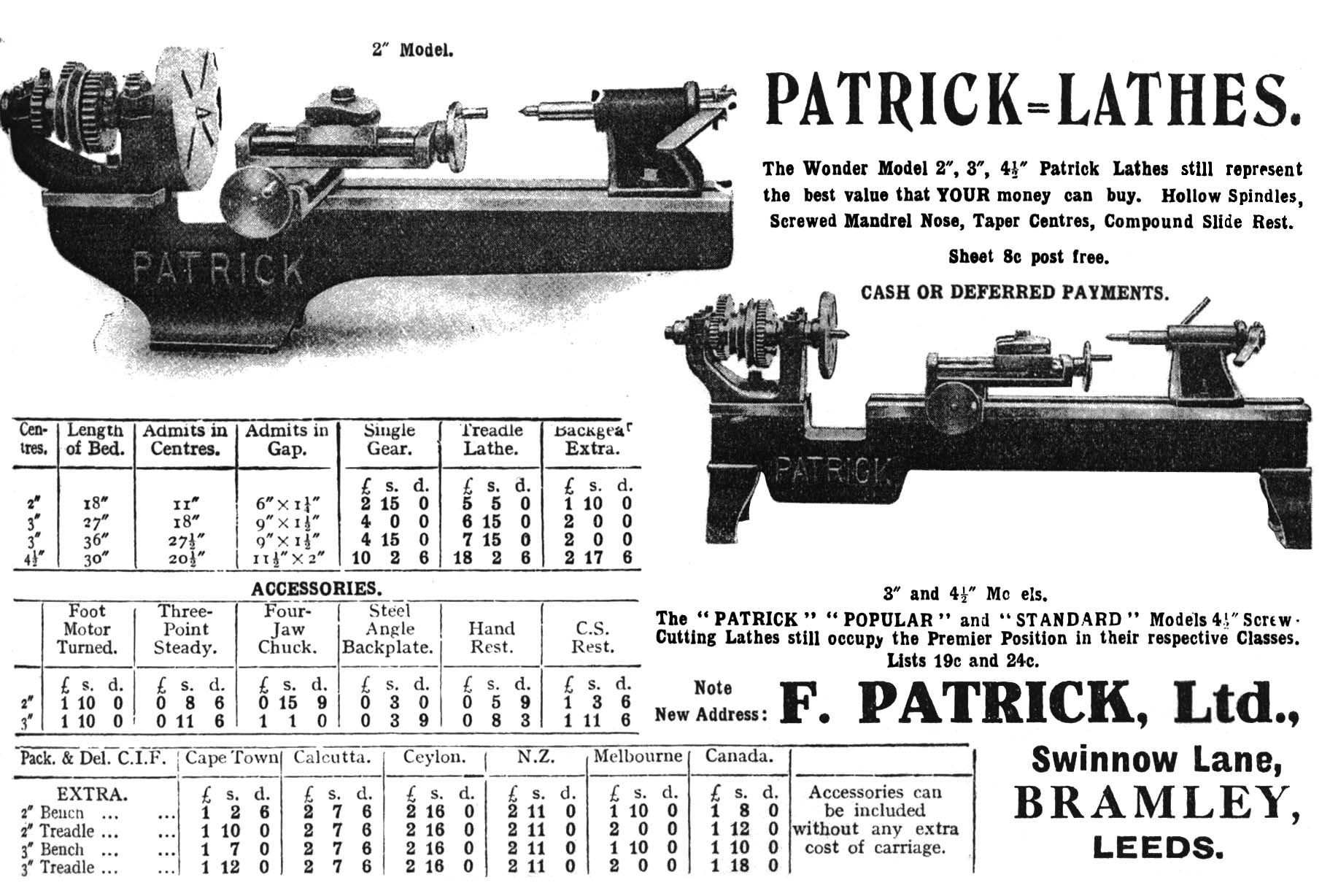

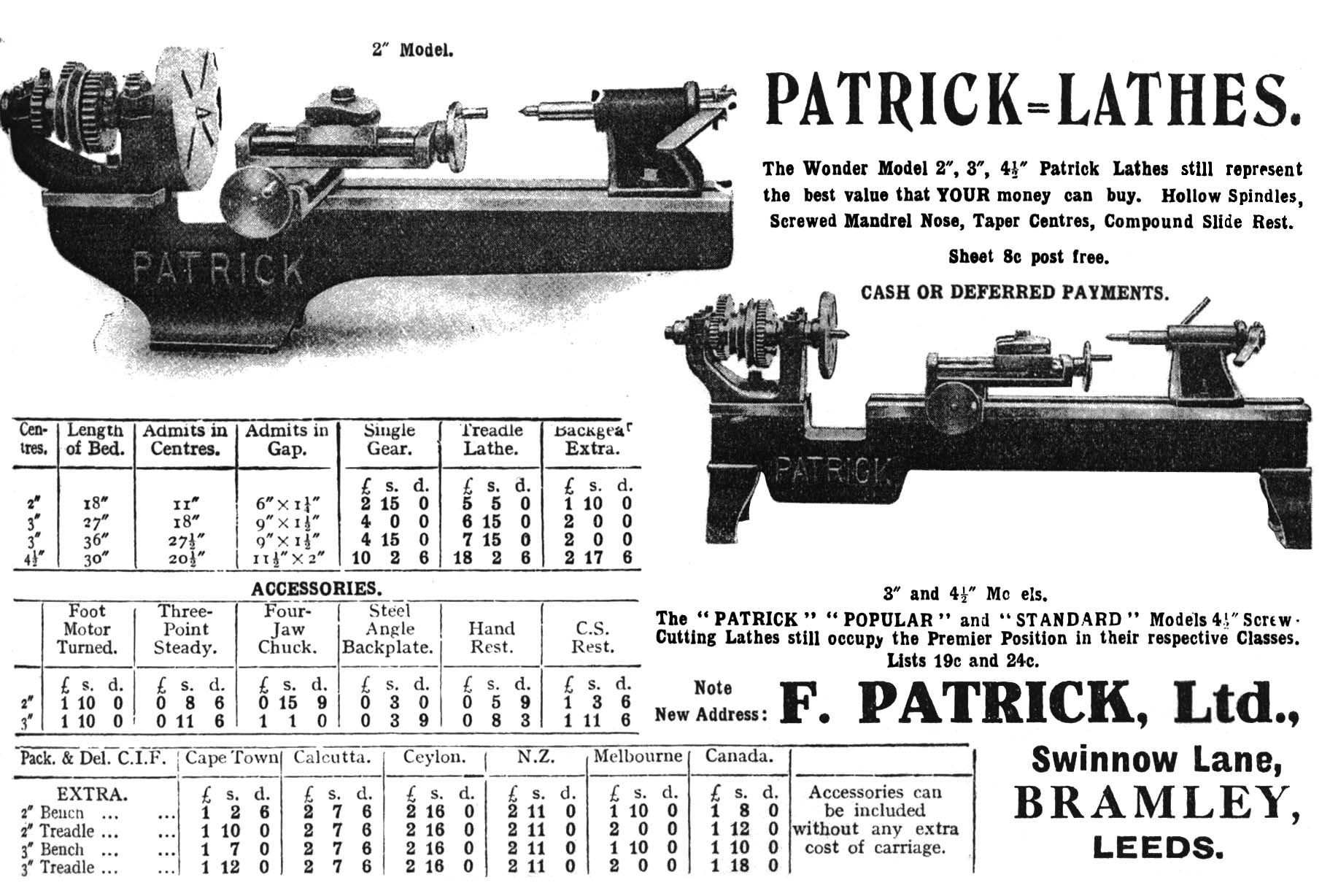

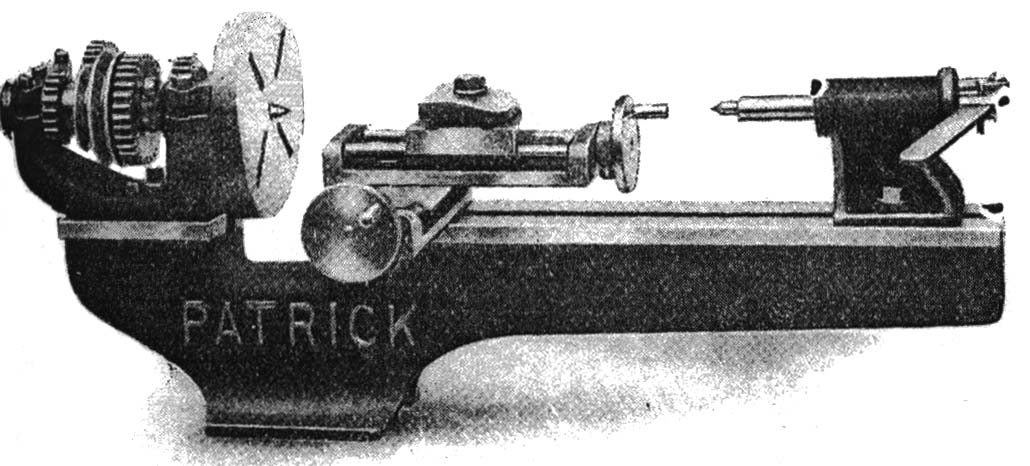

Patrick "Wonder", "Standard"

"Popular" and "Special" Lathes - Page 1

Patrick Home Page This page continued here

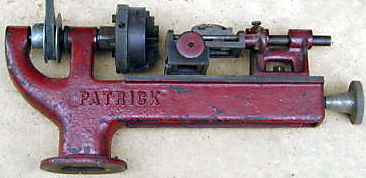

A One-family-from-new Patrick

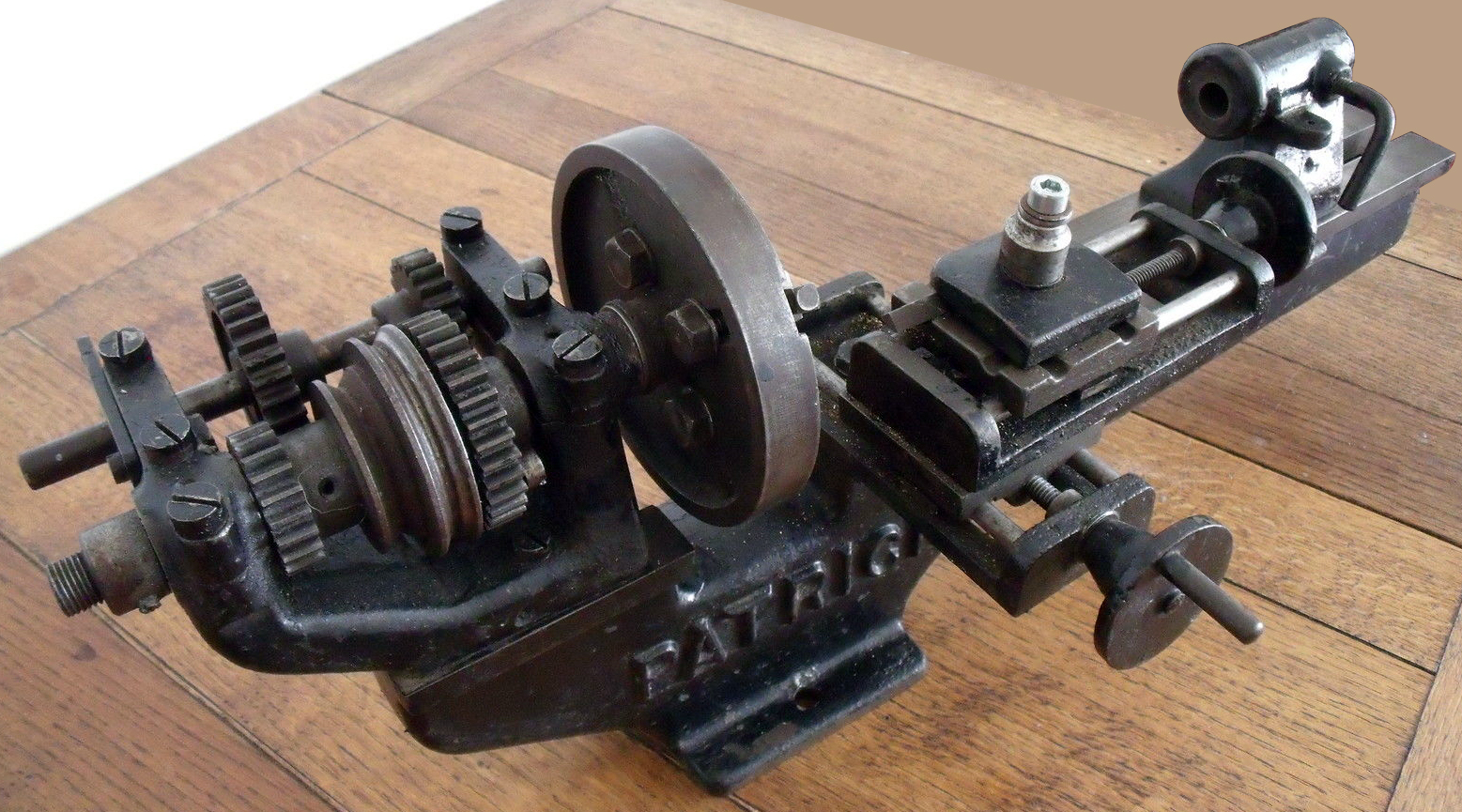

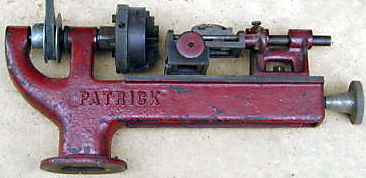

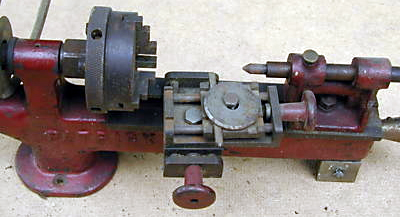

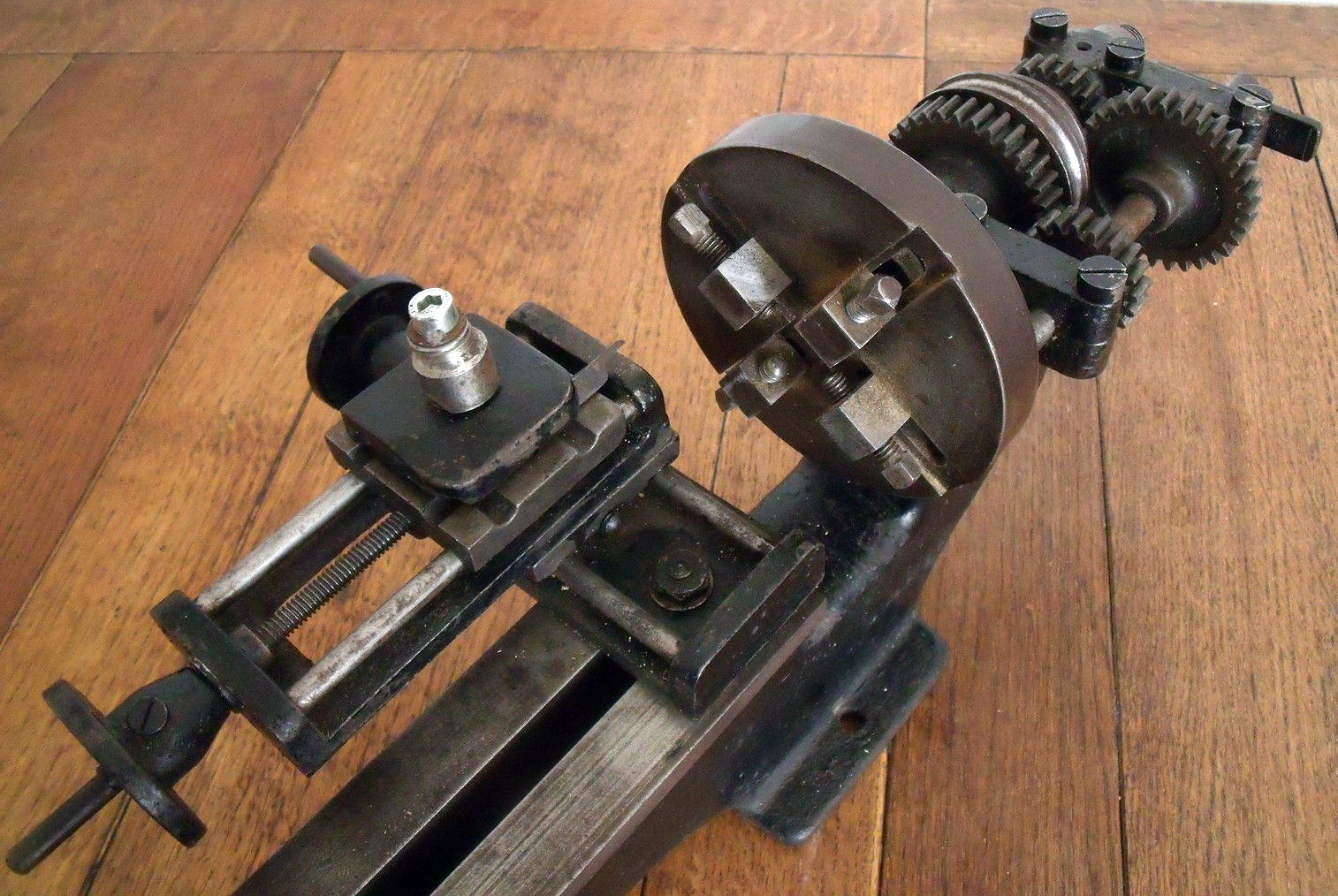

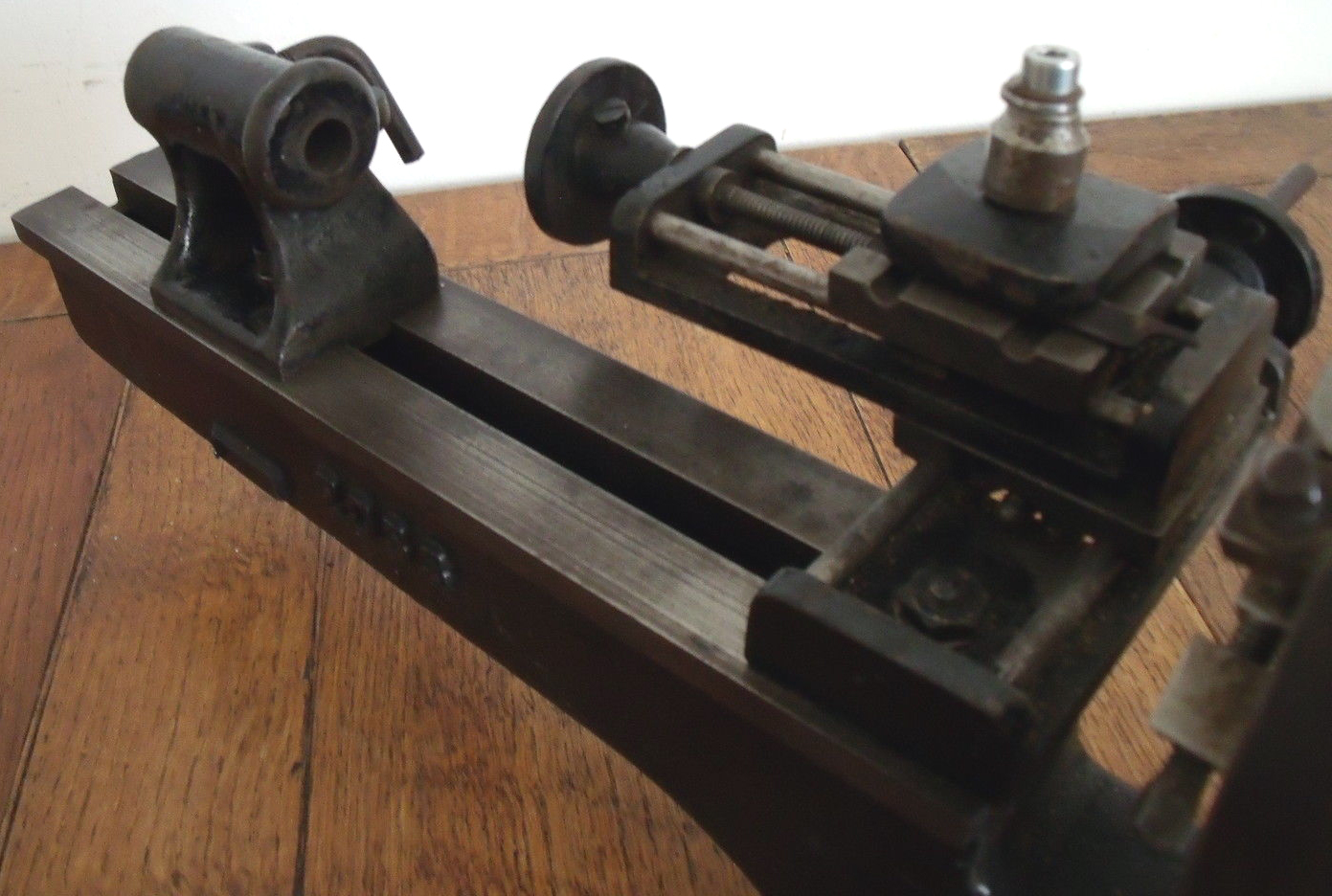

At least two versions of the little Patrick plain-turning "Wonder" lathe were produced, one with simple cantilever bed in a 2-inch centre height and the other with a bed having feet at both ends. Each of the types was manufactured with a separate headstock - or with bed and headstock cast as one - with a number of different between-centres capacities offered as indicated by the advertisement reproduced below. Confusingly advertised as to which model was which, all appear to have shared components and were designed along very simple lines to give the hard-up enthusiast the chance to own a small but robust machine with a useful range of movements. Although not backgeared in standard form (though this was available as an extra) and having only two flat-belt or round "gut" drive speeds, the headstock had unusually long bearings that promised a long life. The slide rest was of the compound variety and hence so much more useful than the "single-swivelling" type so often found on machines intended to compete at the bottom end of the market. The economical construction of the compound, built with steel-bar ways, was very similar to that on the contemporary Drummond "Little Goliath" lathe and subsequently on the very popular the Emco Unimat SL1000 and DB200 of the 1950s and 1960s. The lathe was available as an ordinary plain-turning model with the compound slide rest positioned by hand and locked down, or driven down the bed by a leadscrew placed centrally below the bed ways and activated by a large handwheel at the tailstock end (the remains of such a machine being shown below). This arrangement, though simple, provided the operator with a sporting change of getting a decent finish and was a good deal easier to operate than a carriage handle operating driven by a gear that engaged directly against a bed-mounted rack. Unfortunately, on some versions (but not all), instead of employing the well-separated front and back outer faces of the bed to guide the saddle the Patrick used the narrow and close-together inner and under surfaces of the gap between the front and back ways. As a consequence, the saddle rested on the full width of the front way - but on only part of the rear.

Some high-resolution pictures - may be slow to open

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

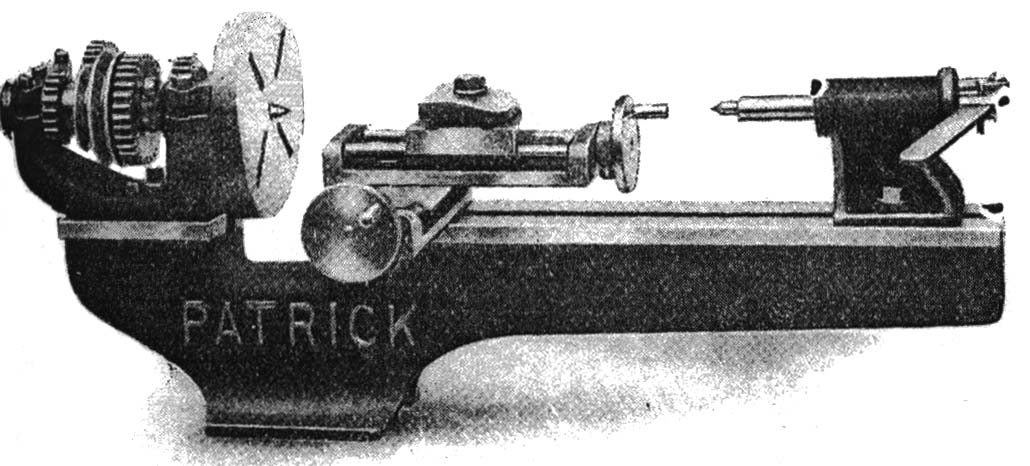

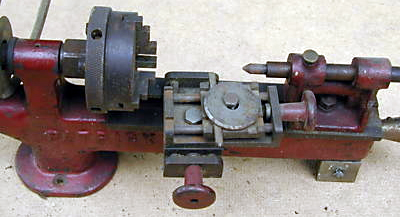

The 2-inch Patrick "Wonder" model

|

|

|

|

|

|

|

|

|

|

|

|

|

|

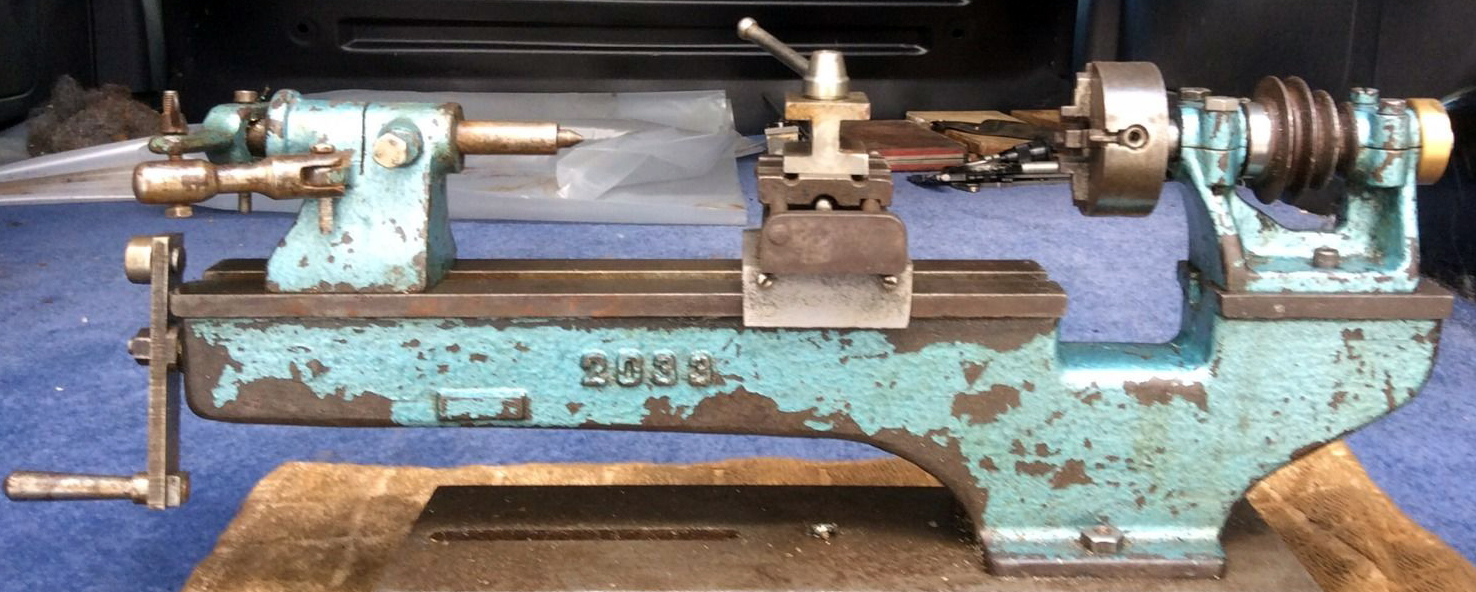

Patrick 3 and 4.4-inch models were identical apart from centre height

|

|

|

|

|

|

|

|

|

|

|

|

|

|

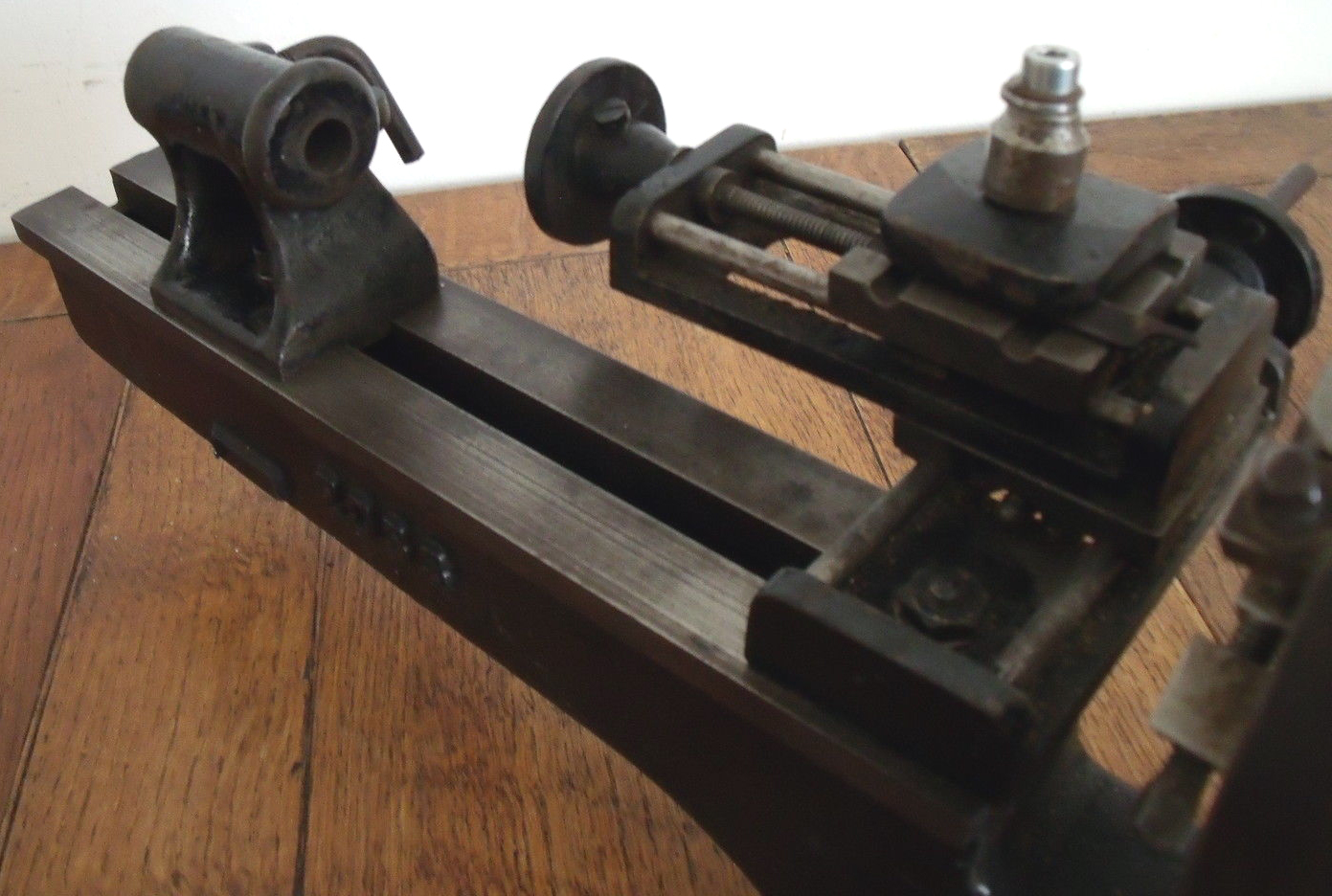

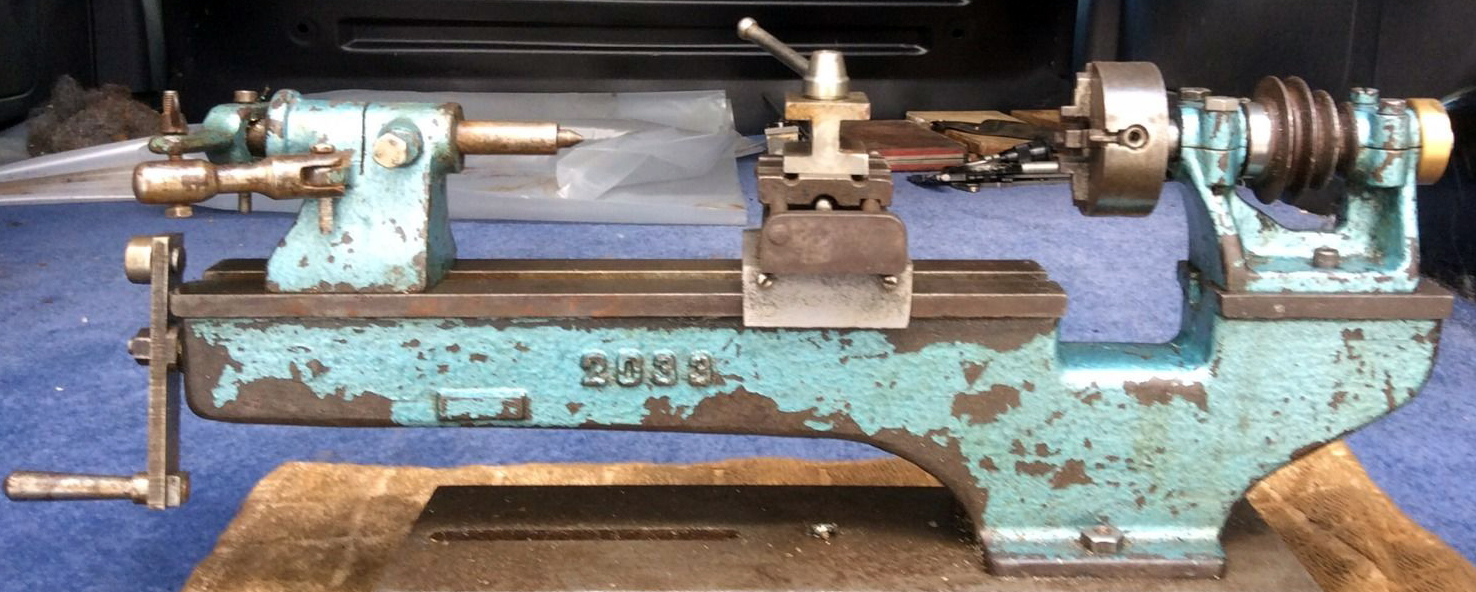

A simple Patrick plain-turning lathe from the 1920s--note the distinctive tailstock and shape of the handwheels. Unfortunately, instead of employing the well-separated front and back faces of the bed to guide the saddle, the Patrick used the narrow and close-together inner and under surfaces of the gap between the front and back ways. As a consequence, the saddle rested on the full width of the front way - but on only part of the back.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

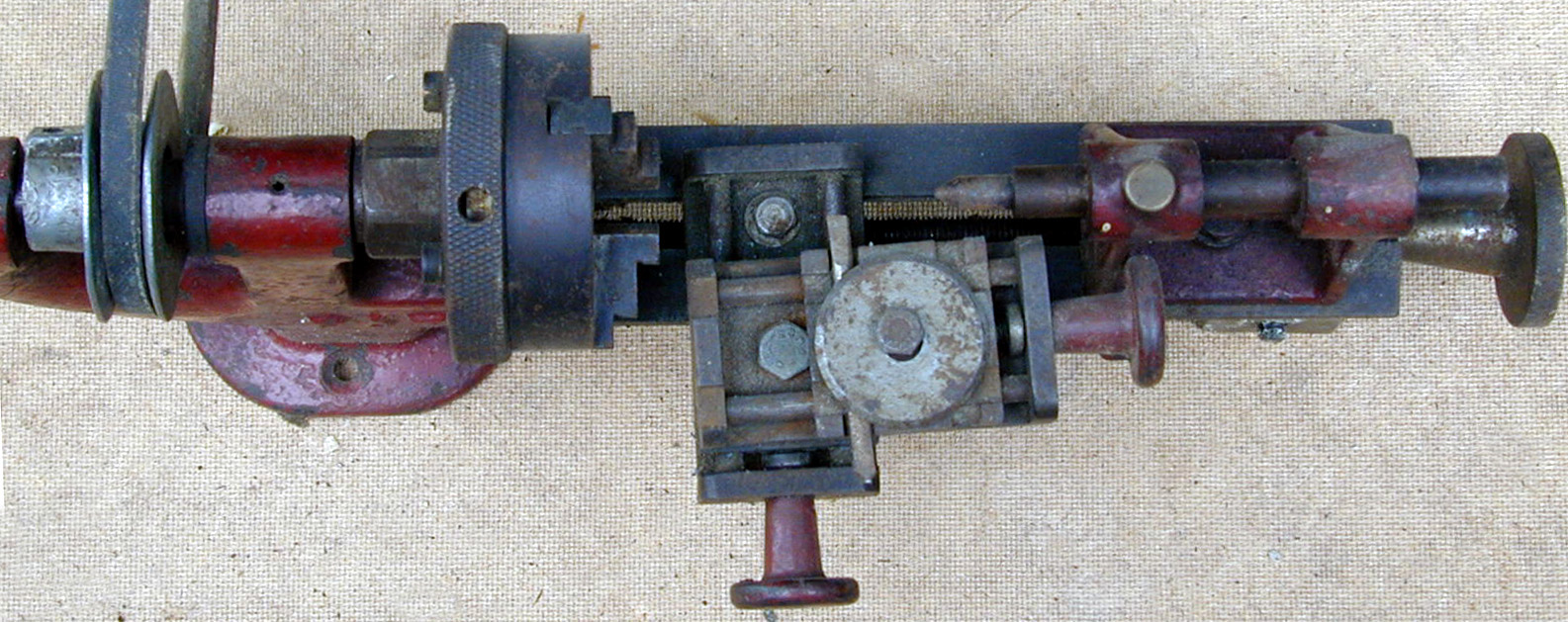

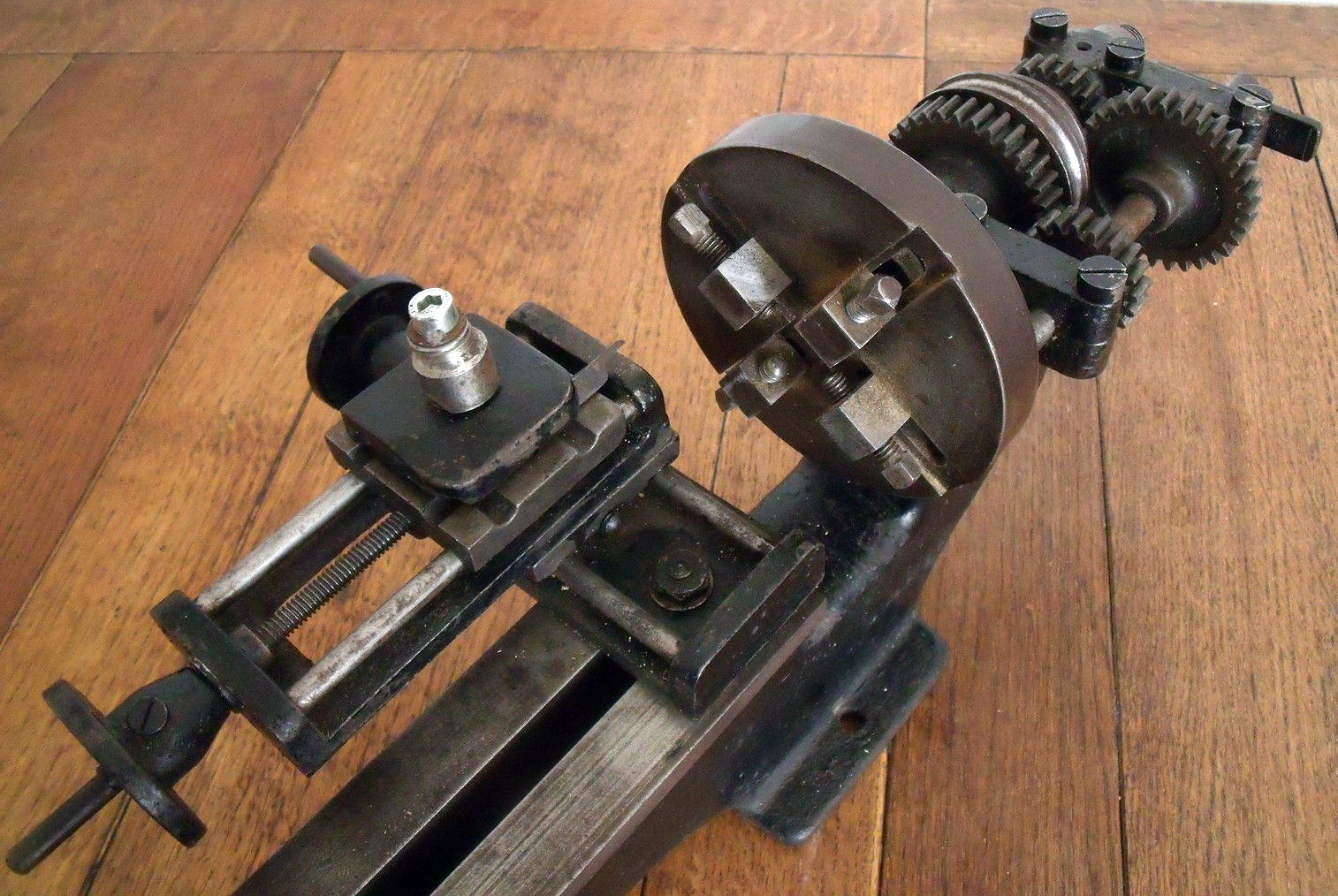

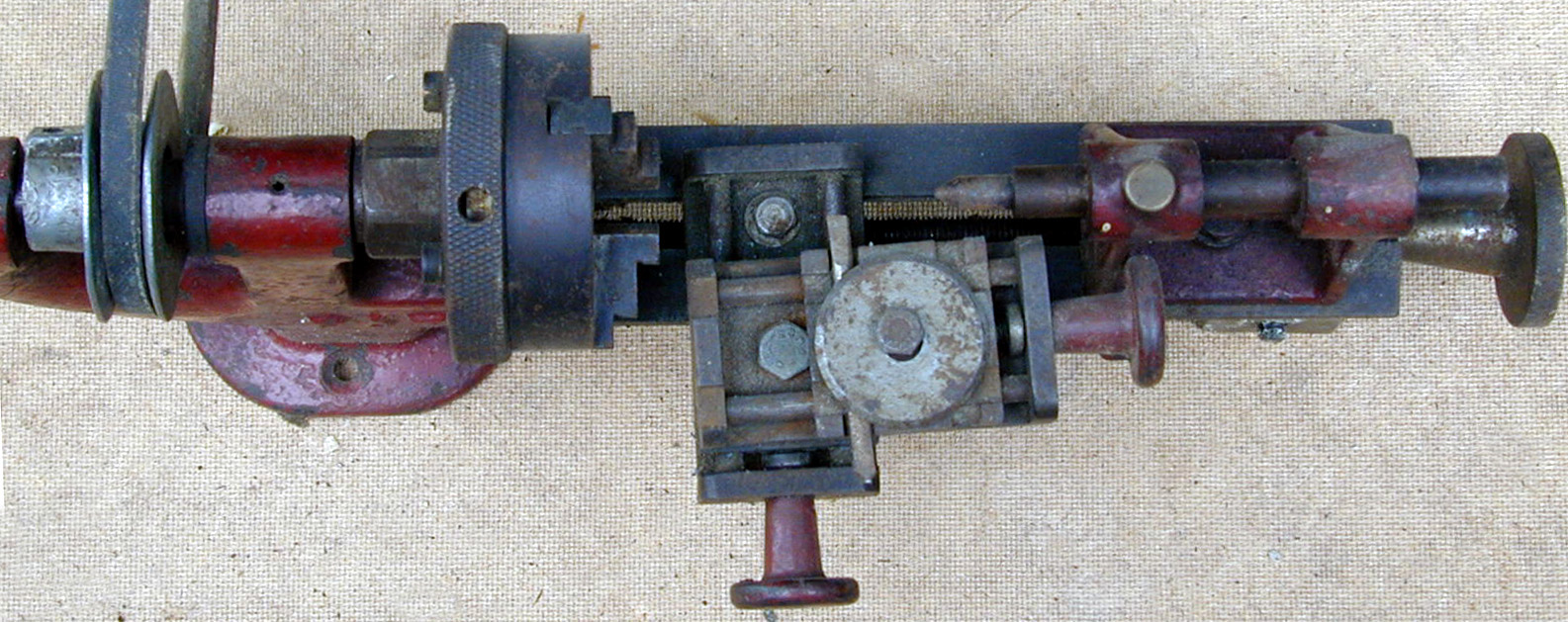

The economical construction of the compound slide rest assembly, built with steel-bar ways, was very similar to that on the contemporary Drummond "Little Goliath" lathe and subsequently on the very popular the Emco Unimat SL1000 and DB200 of the 1950s and 1960s.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

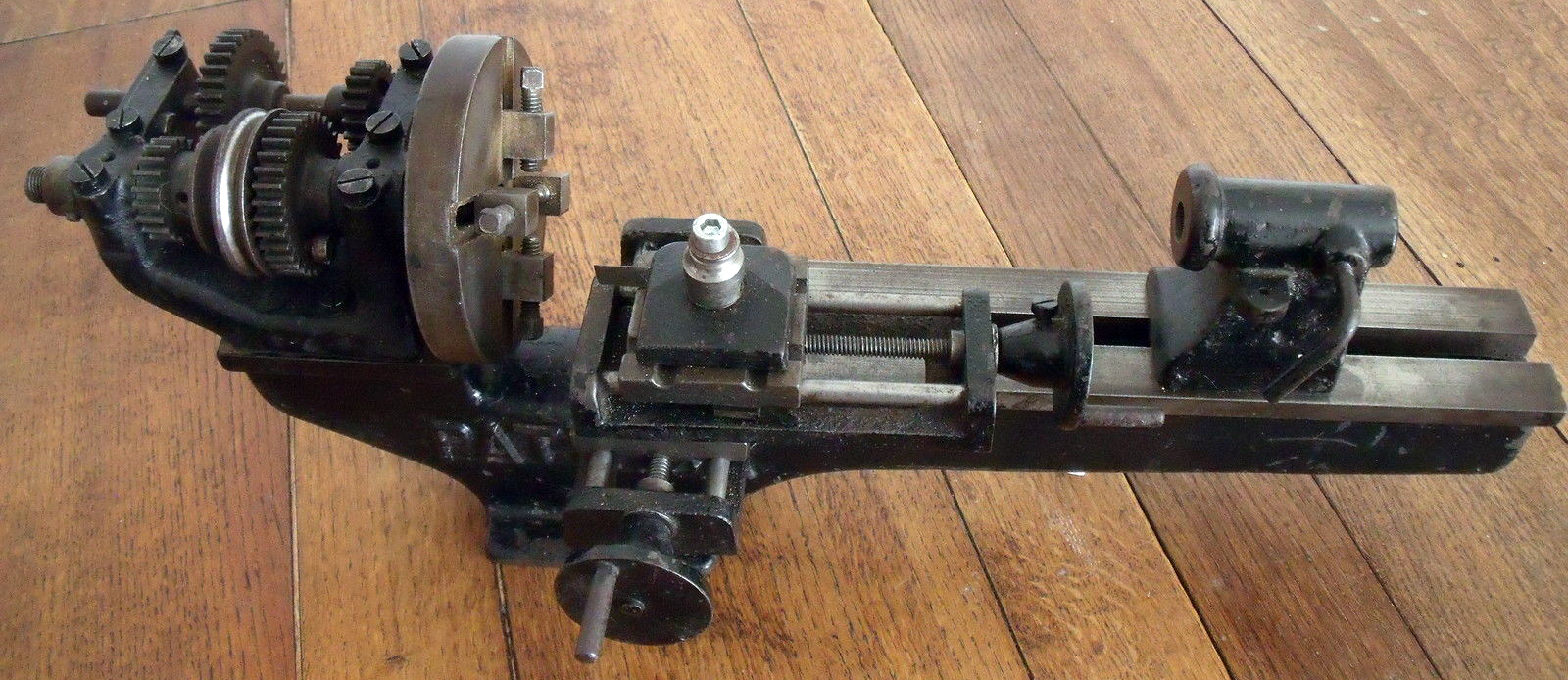

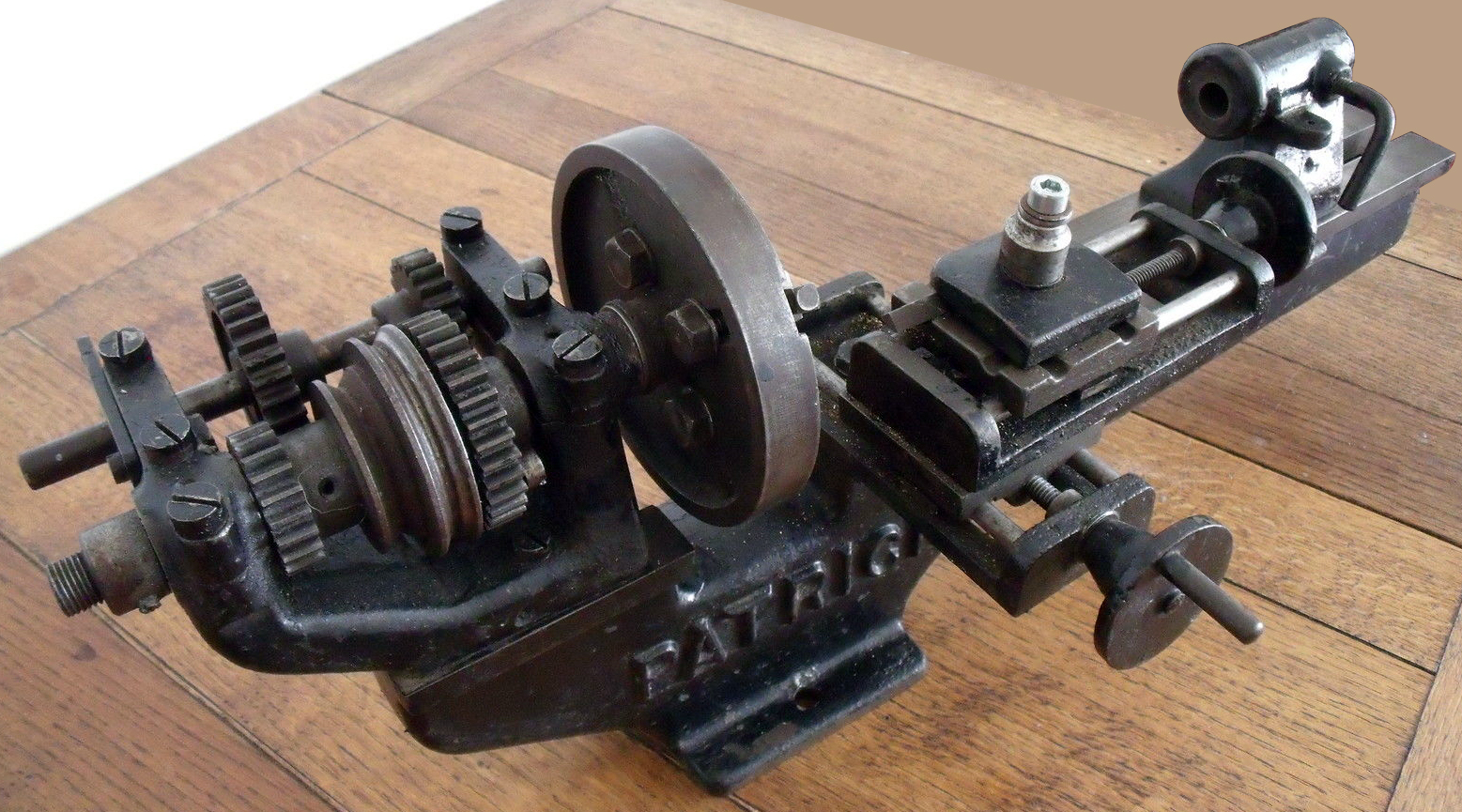

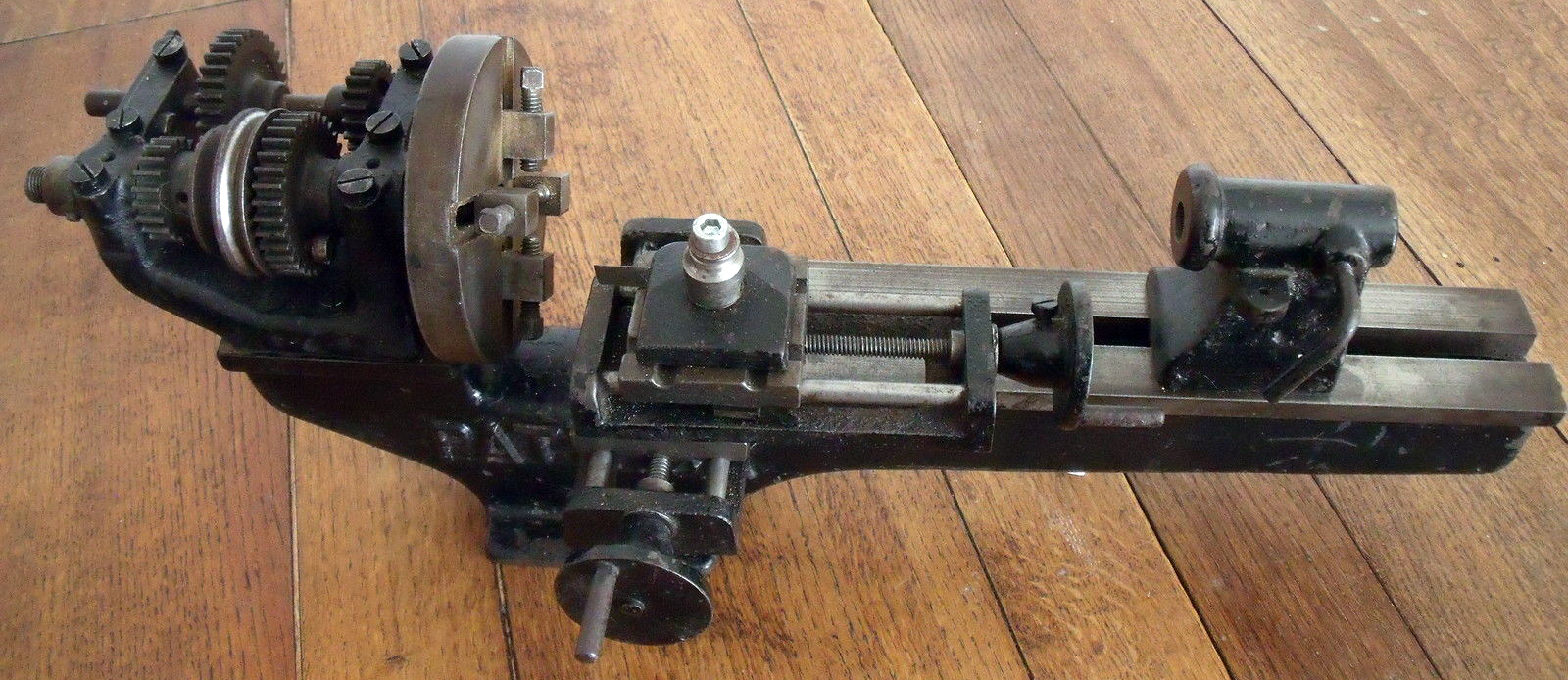

Backgeared Patrick "Wonder" lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|