|

Machine Tool Manuals Machine Tool Catalogues Belts Accessories Books Watchmakers' Lathes Lorch Home Page Lorch Watchmakers Page 2 More information about Lorch Lathes is available in various Manuals, Parts Lists and well-illustrated Sales & Technical Specification Brochures Lorch made a wide range of high-quality watchmakers' lathes in both Geneva and WW types branding them Lorch, Lorch Schmidt and L.S. & Co. However, like most other manufacturers in the field, they were also content to market models under other names with corners cut in material quality and cosmetic finish - one of the most popular lower-cost models treated in this way being the Geneva-pattern Triumph. |

|

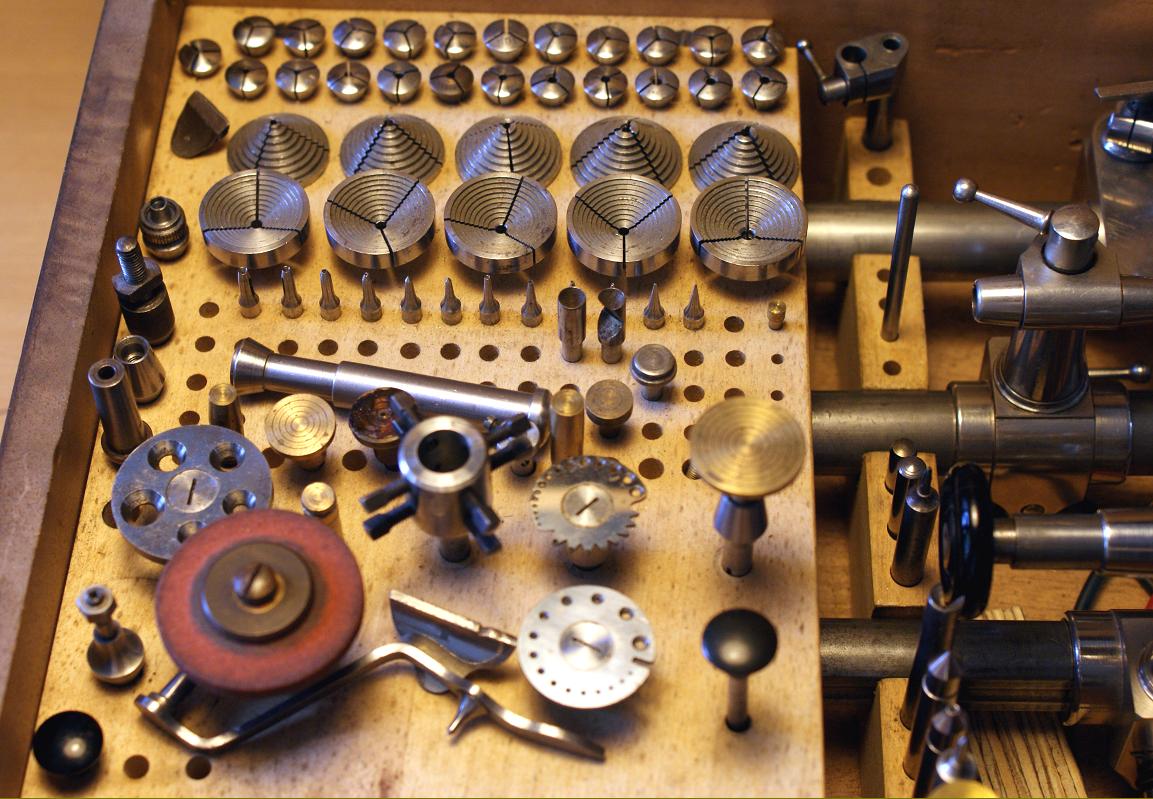

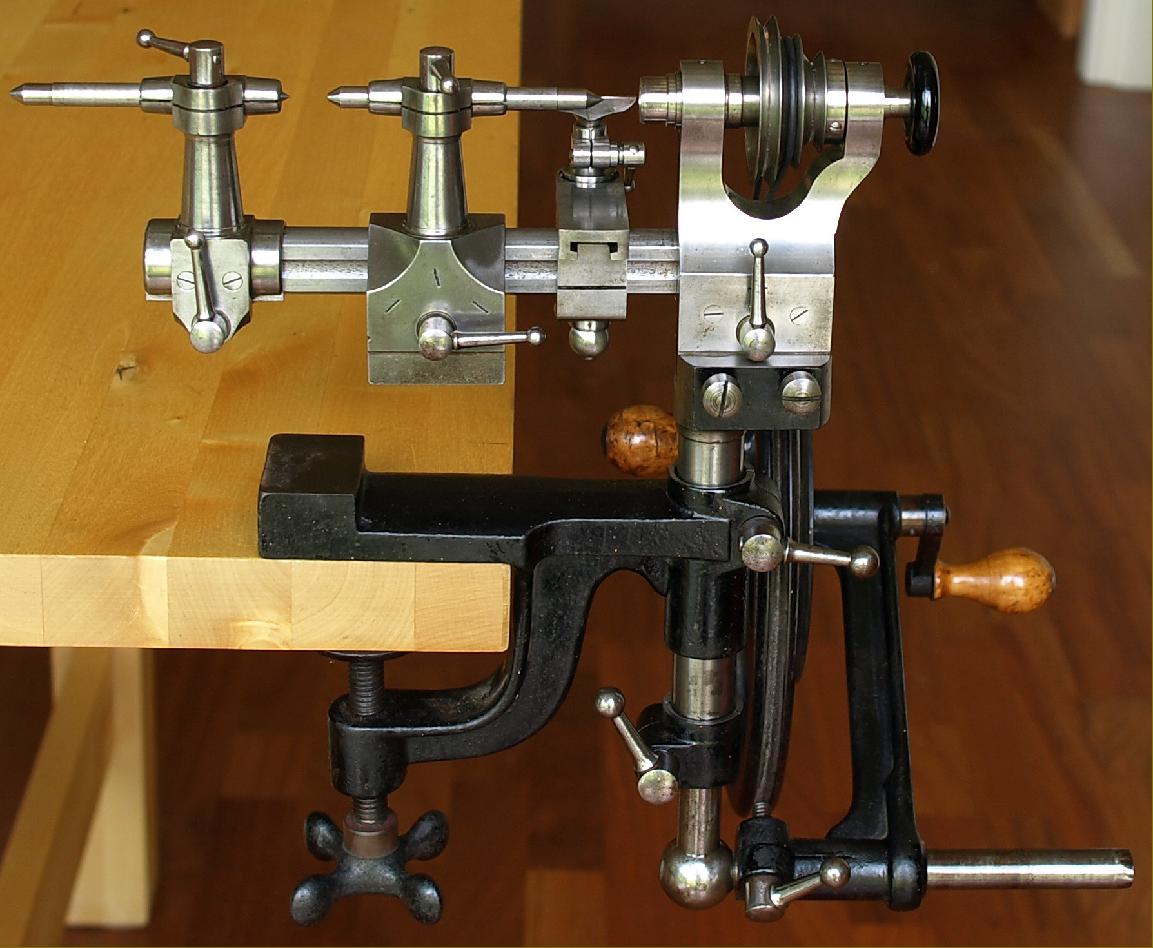

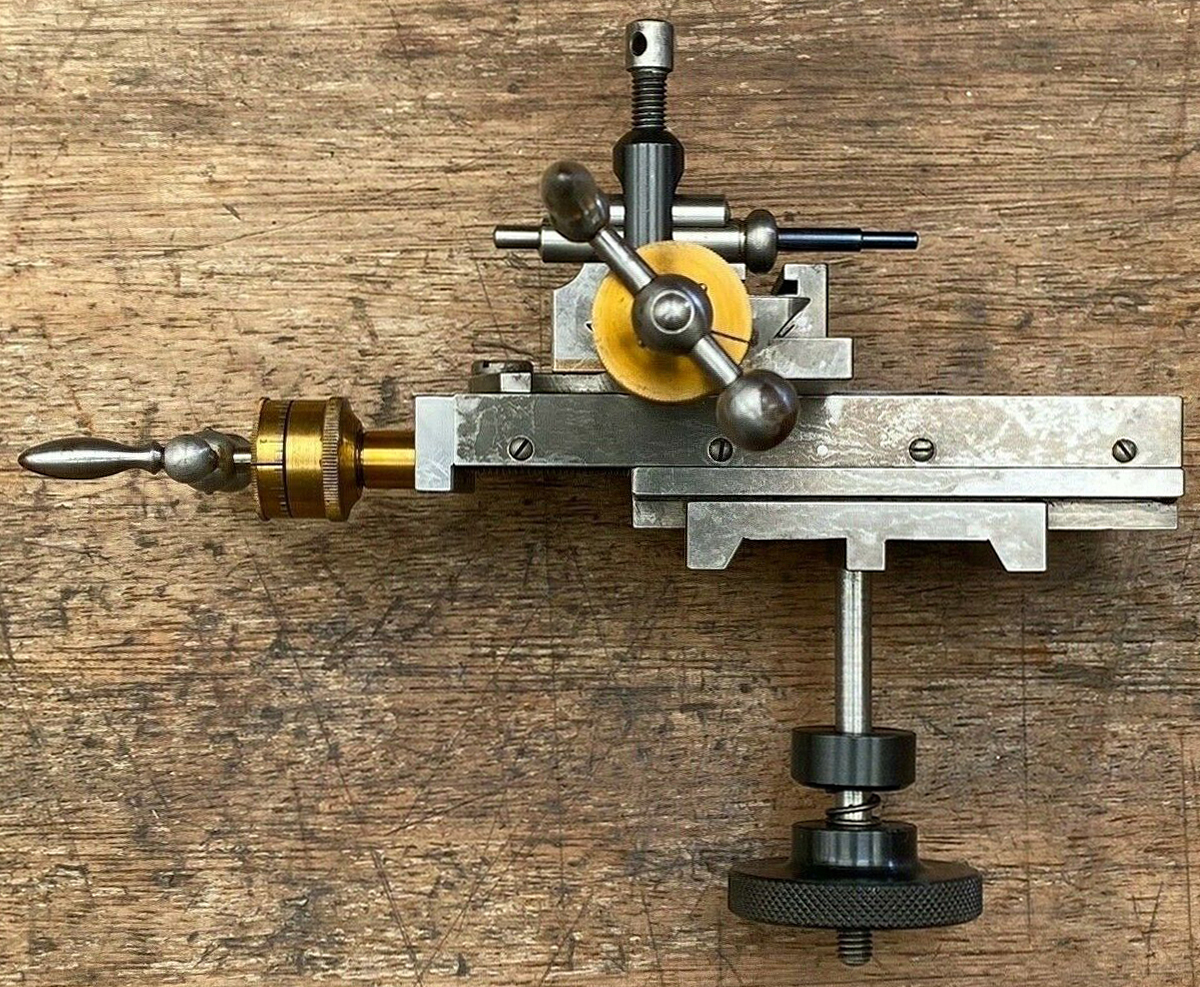

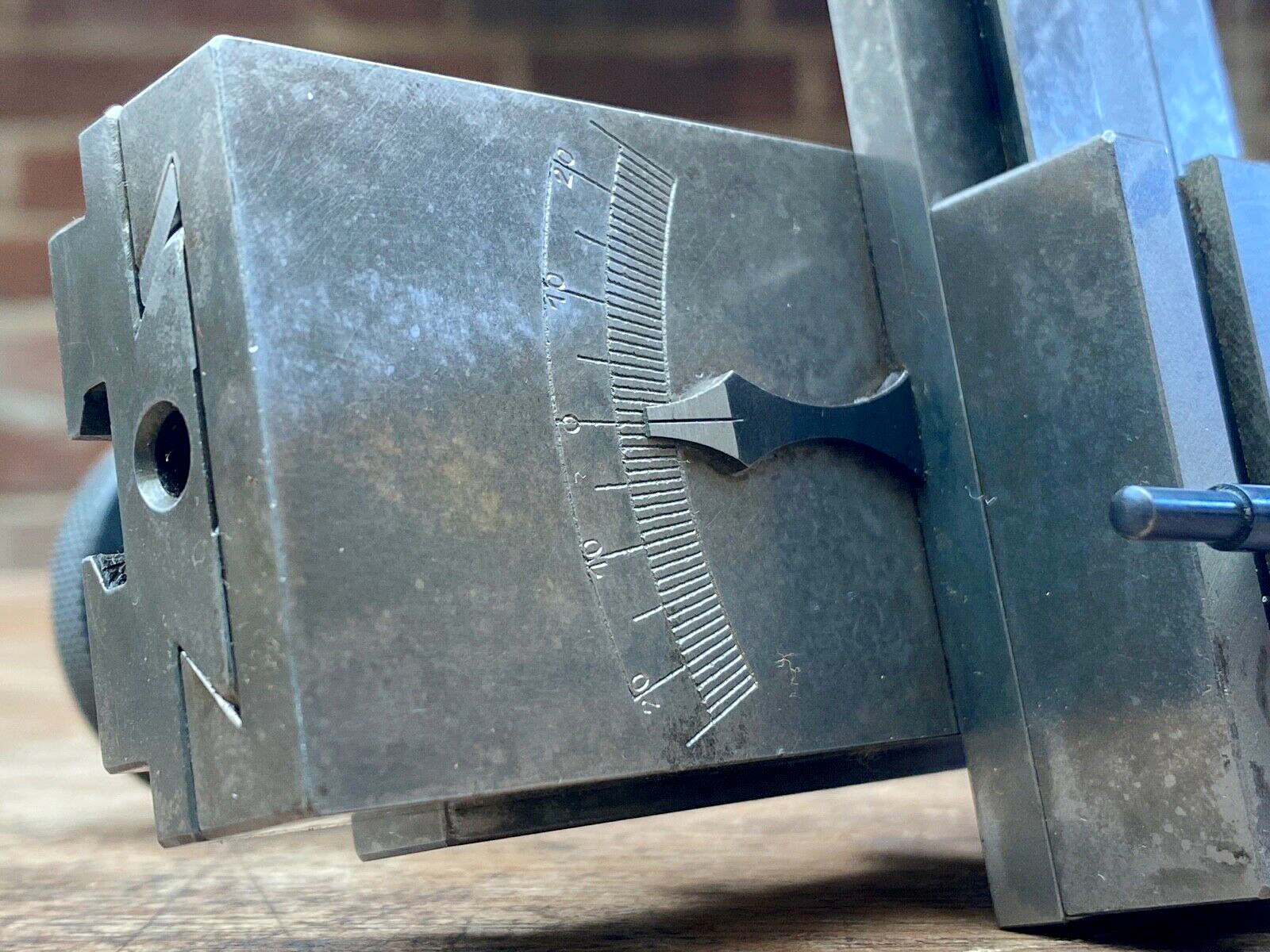

A comprehensively equipped Lorch light Geneva-pattern watchmaker's lathe set - probably catalogued as the No. 10. Both 6 mm and 8 mm headstocks are included and only a few items from the maker's extensive accessory range are not present. The next set, the No. 11, was built with a drawer to hold a vast range of collets. The designations of the boxed sets changed over the years and, as Lorch also made up boxes to order and made them available separately for fitting out by owners, it is not always possible to give sets a defini |

|

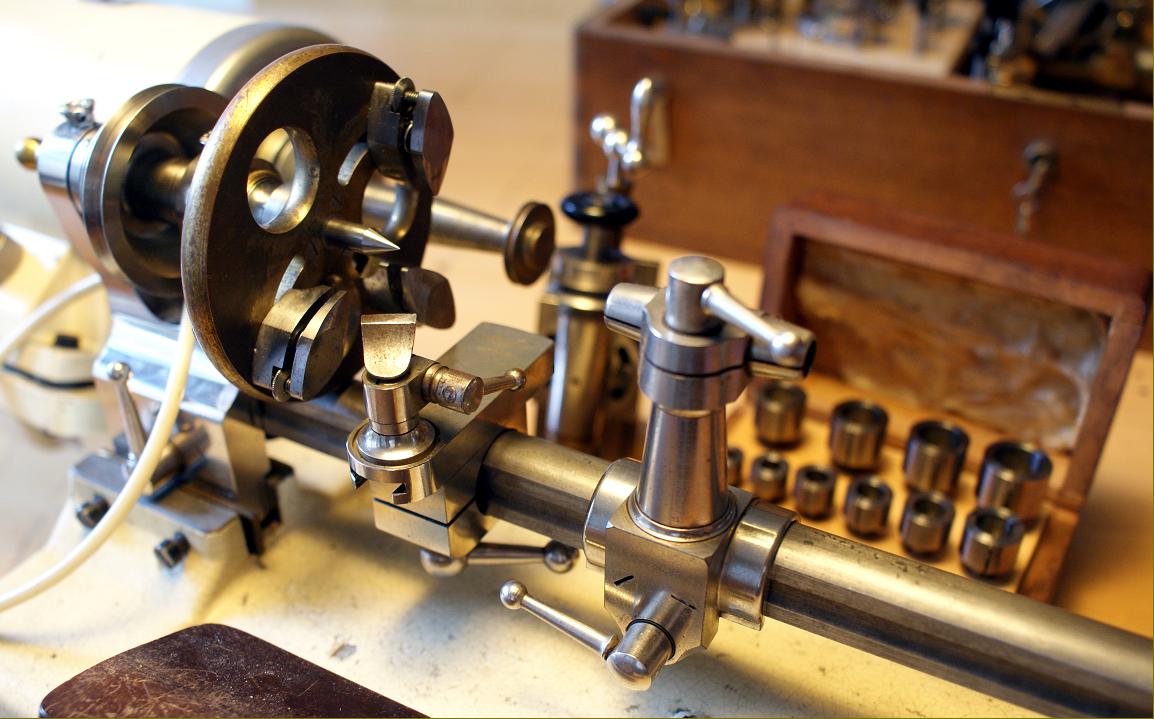

Rare and desirable Lorch Geneva-pattern 3-lathe set in the maker's fitted case. Three headstocks were provided: a standard unit, a type able to be swivelled (with an overhung pulley) and one with a permanently-fitted and hence very accurate pump-centre faceplate with clamps. |

|

|

||

|

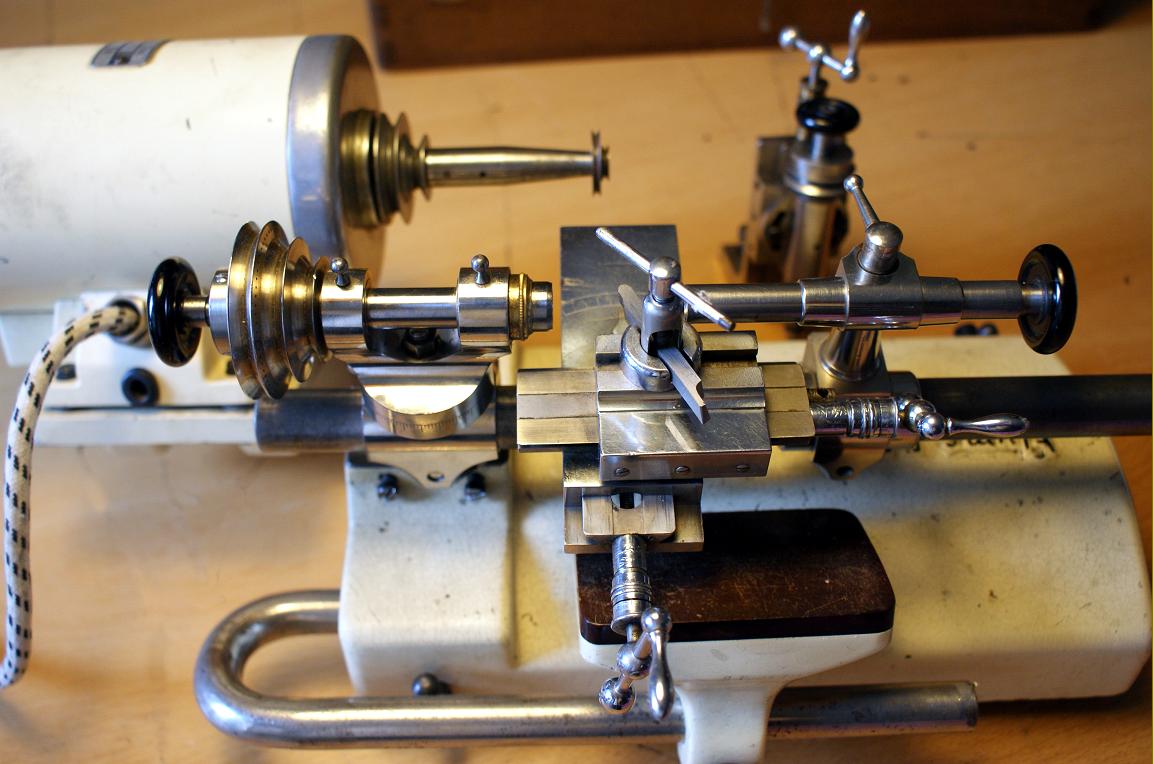

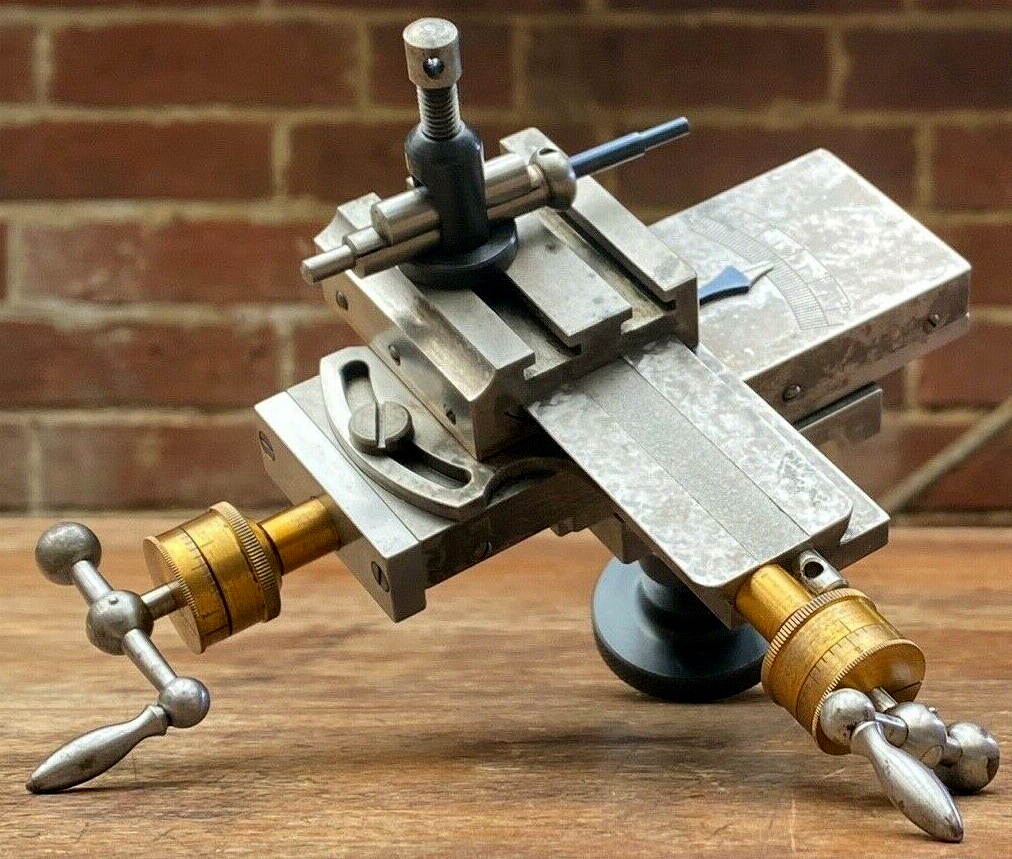

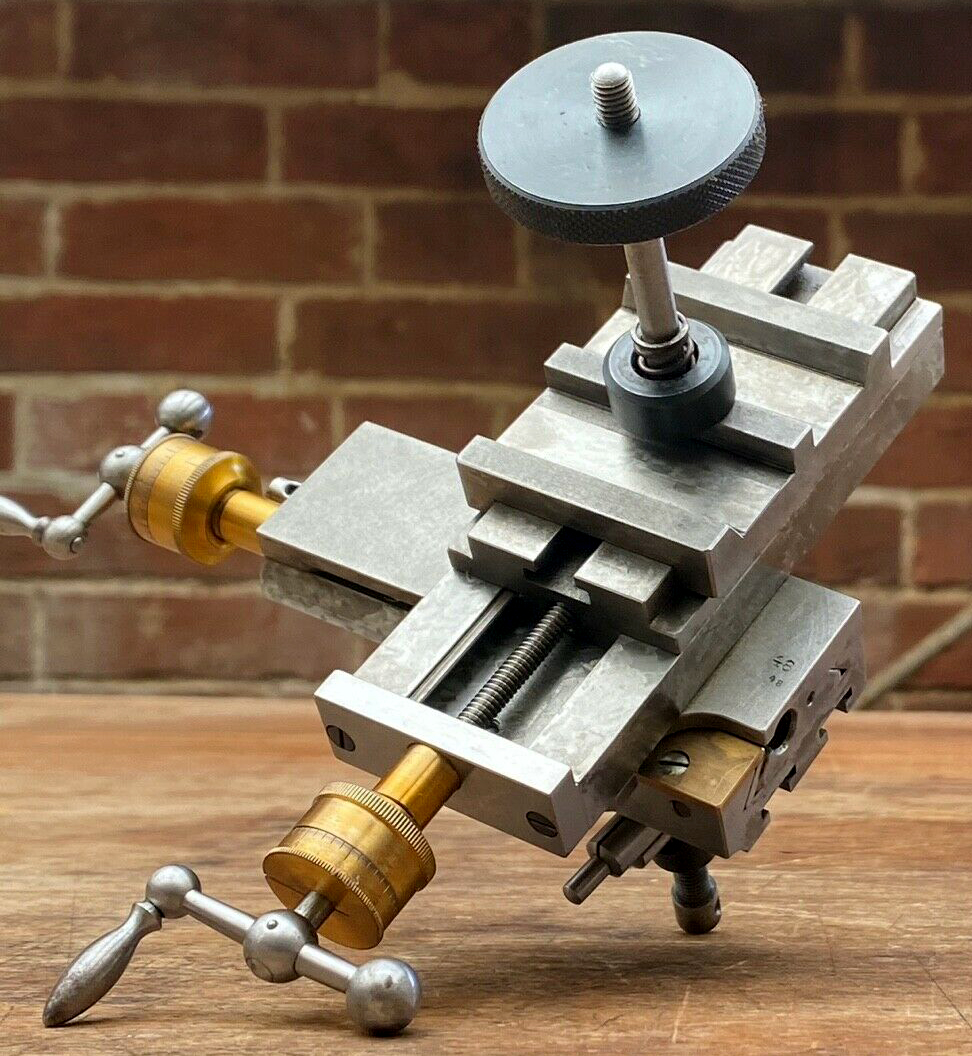

Very occasionally a late-model Geneva-patter lathe is found mounted on a motorised base. This assembly was also available as a boxed set with a choice of headstock and bed units, or all three together |

|

Geneva pattern lathe from a 3-lathe set mounted on the drive base and fitted with the headstock that, for absolute accuracy, used a permanently-mounted spindle and faceplate assembly |

|

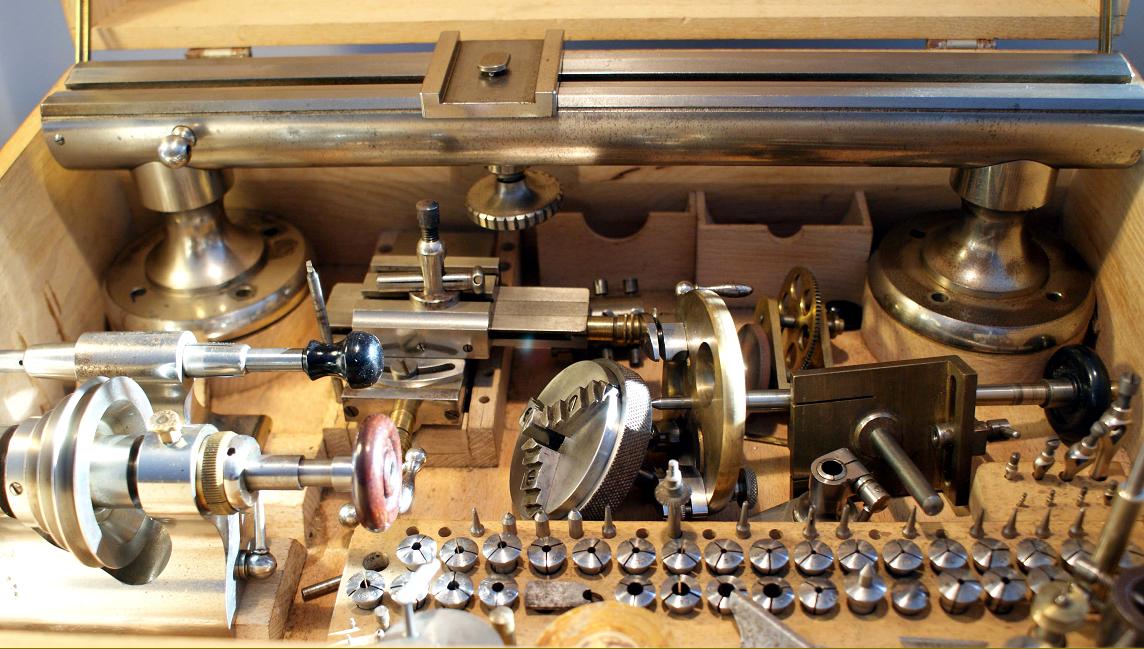

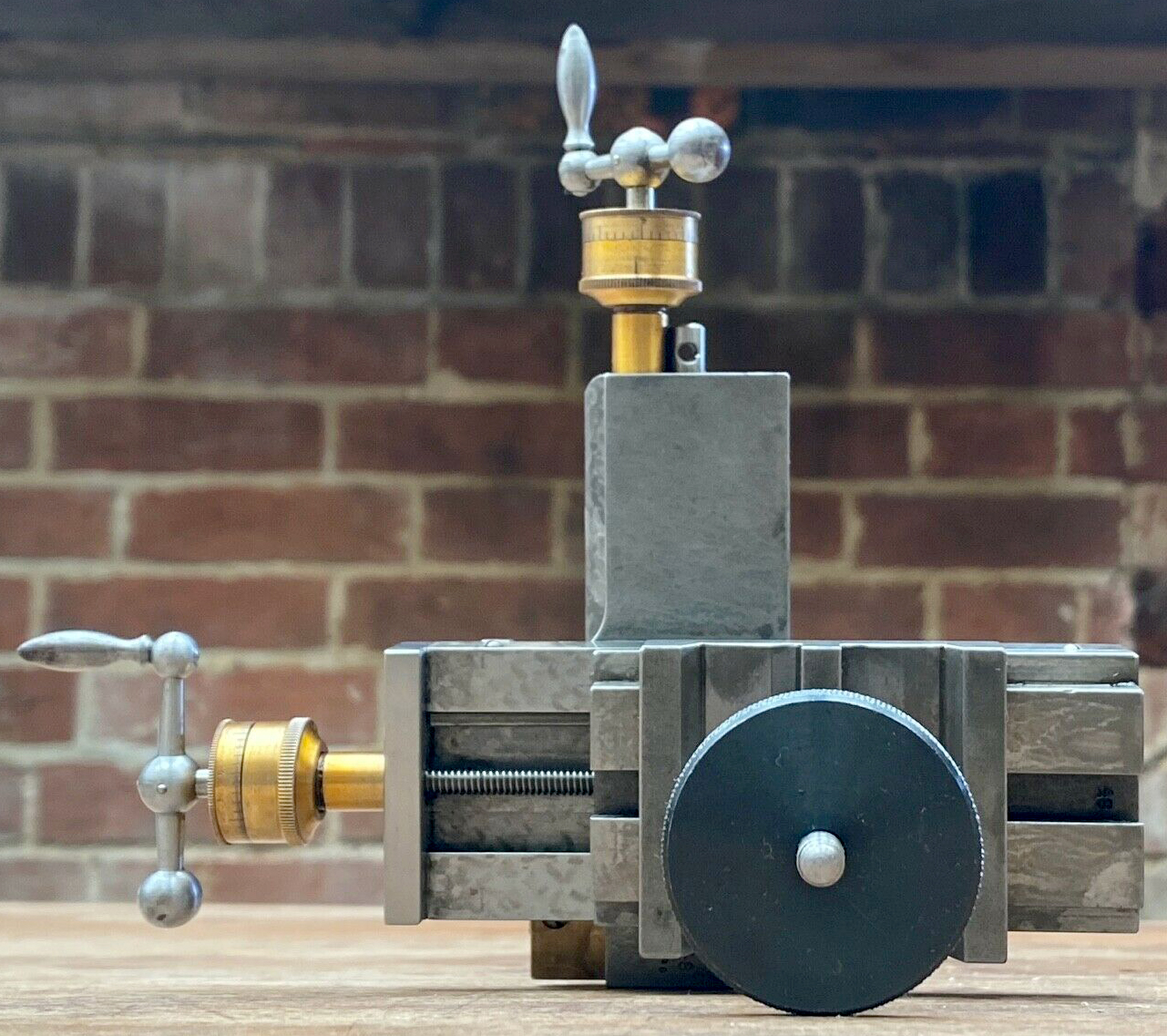

Boxed Lorch WW watchmaker's lathe. This much heavier type (in comparison with the Geneva-pattern models) is rare. Beautifully made and with a splendid plated finish this would, originally, have been an expensive though highly effective purchase. |

|

|

|

More information about Lorch Lathes is available in various Manuals, Parts Lists and well-illustrated Sales & Technical Specification Brochures Watchmakers' Lathes Machine Tool Manuals Machine Tool Catalogues Belts Accessories Books |