|

"EPVJ" is believed to stand for Ecole Professionnelle de la Vallée de Joux, a Swiss technical training institution that had, over time, a number of different names including, until 1935: Ecole d'horlogerie; from 1935 to 1966 it was known as the Ecole Professionnelle de la Vallée de Joux; from 1966 to 1972 the Ecole Professionnelle Technique de la Vallée de Joux and from 1972 to date the Ecole Technique de la Vallée de Joux (ETVJ).

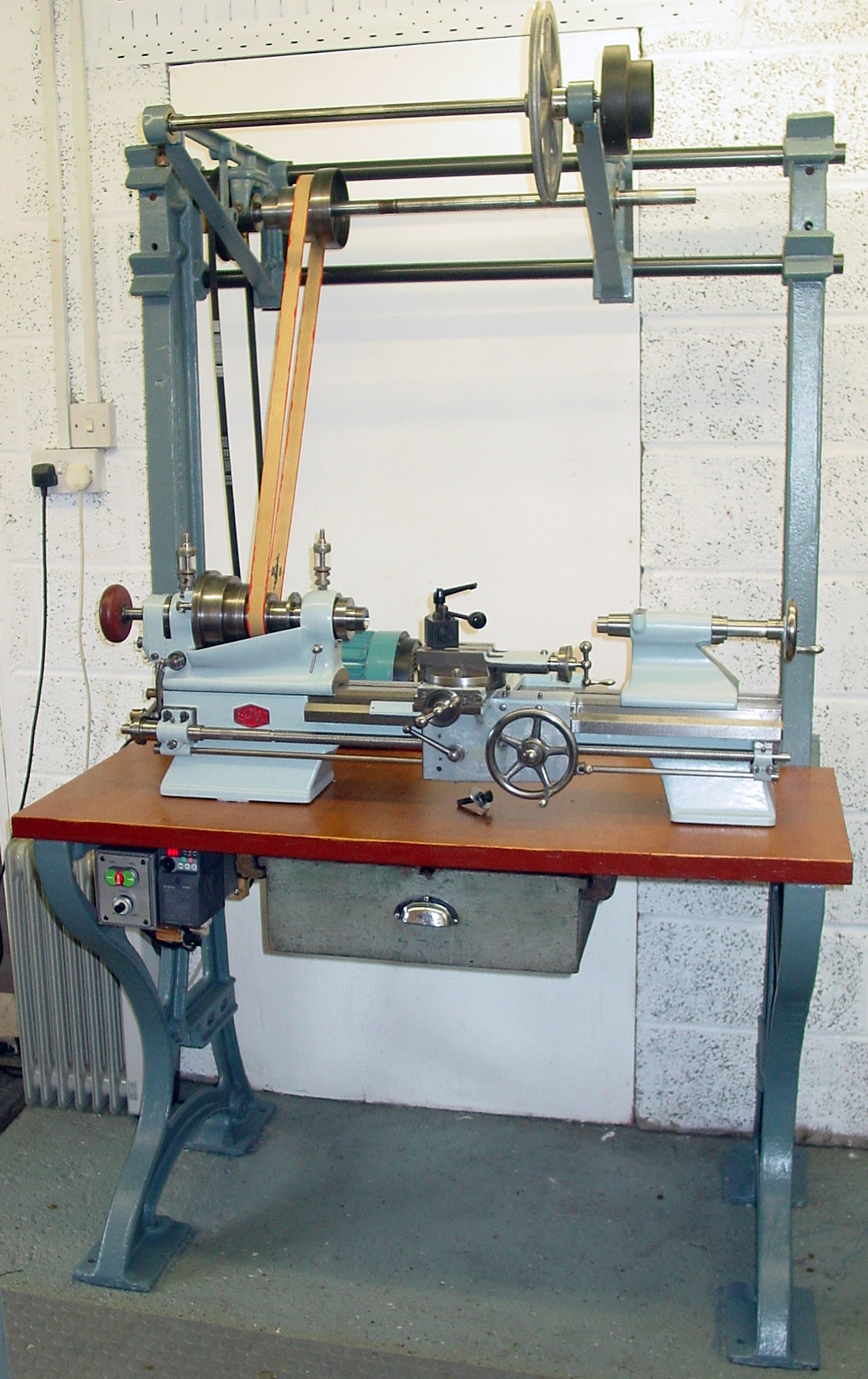

Probably manufactured in small batches from around 1938 (the lathe does reflect some aspects of the Schaublin 102 as made during the 1930s) this splendid precision screwcutting lathe does confirm the Swiss practice of technical colleges actually making complete machines; another example believed to have been the EML Ecole des Métiers Lausanne.

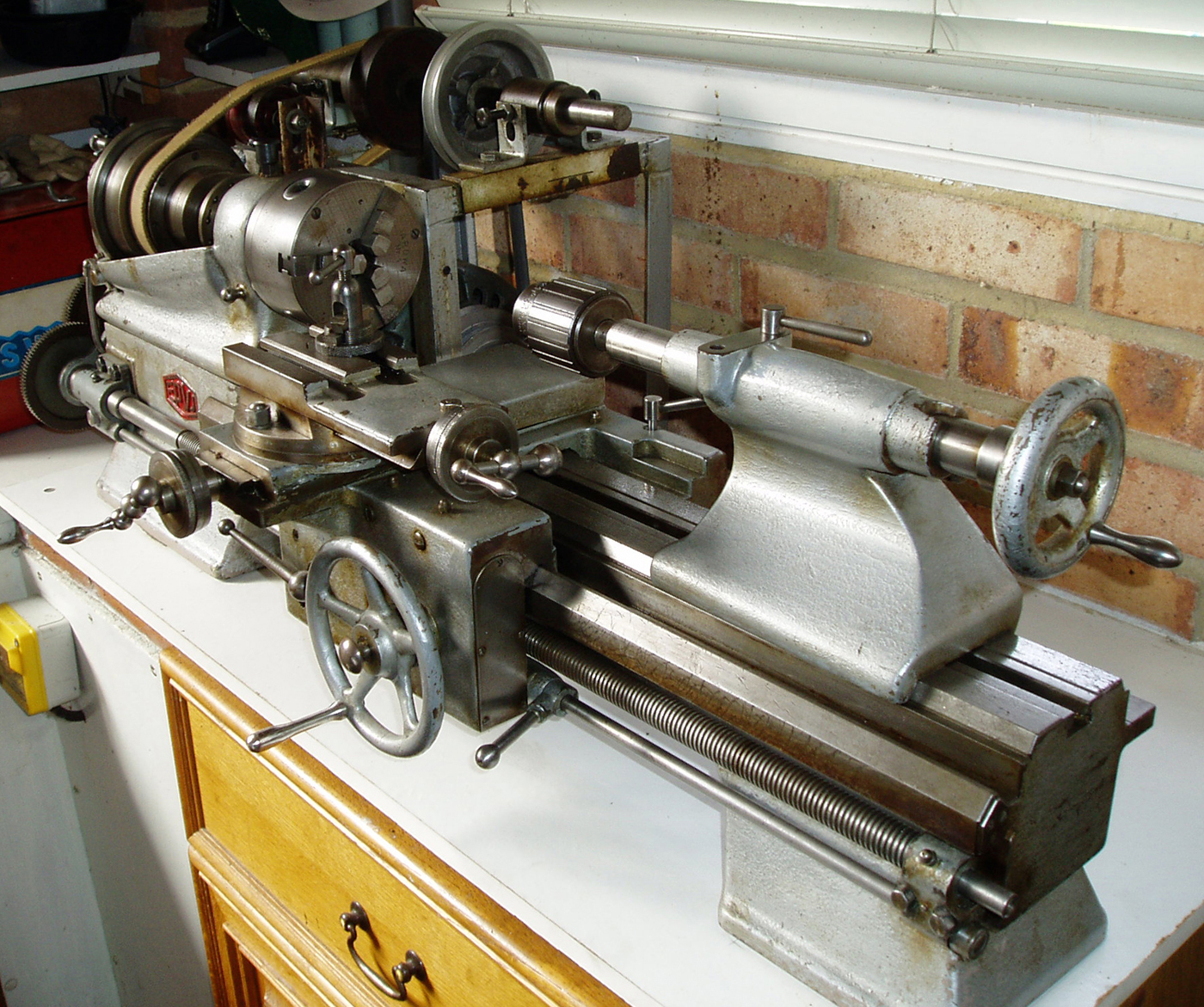

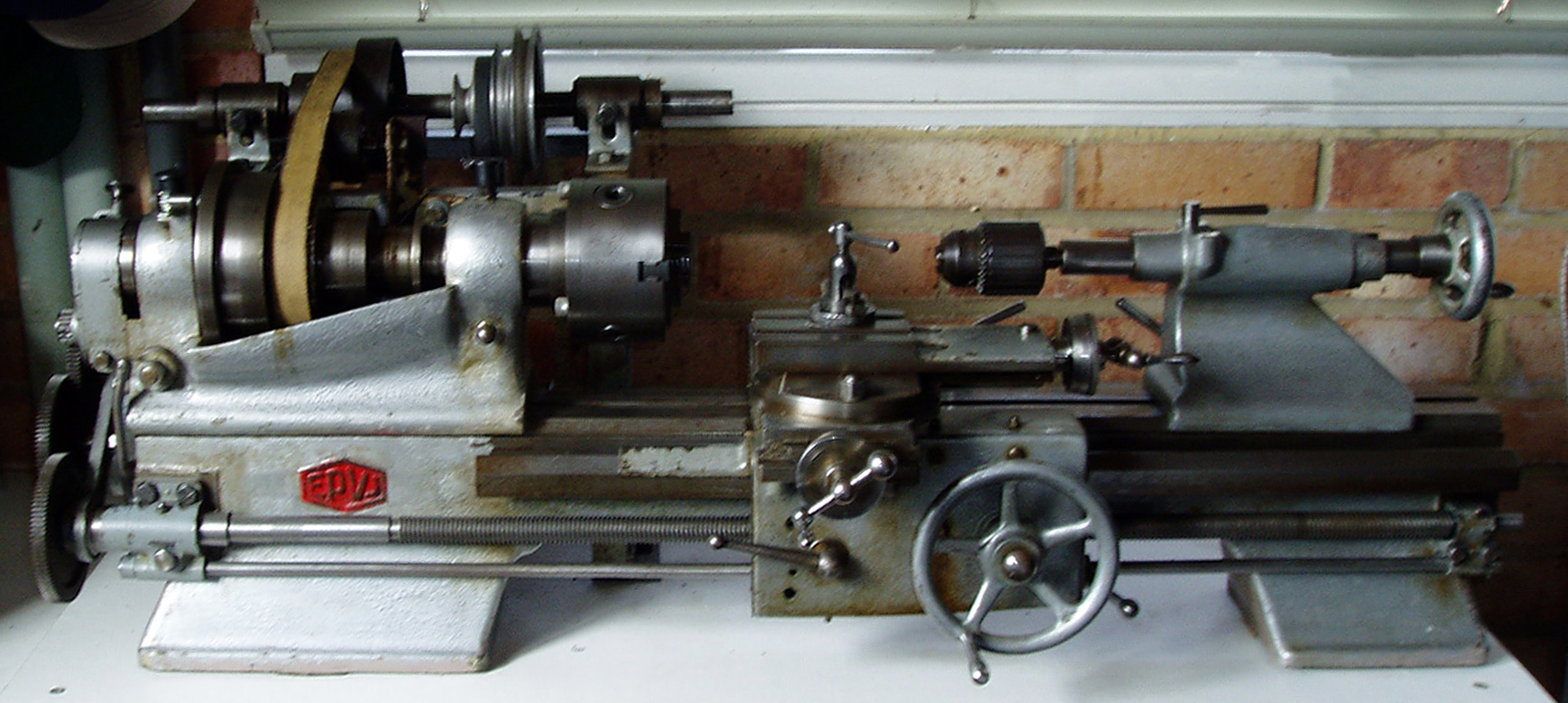

Not only was EPVJ was of complex construction and very high quality, but also bore a passing resemblance to the Swiss Haibegger TDLE "Neotor", having much the same capacity - the centre height being 102 mm (4 inches) and the capacity between centres approximately 500 mm (20 inches). The bed was built with unusually large, integral feet at each end and its central ways formed in the same style as found on many other traditional precision bench lathes - a flat top, bevelled edges and a central T-slot used to locate headstock and tailstock. The carriage (moved by a very large handwheel that could be disengaged while screwcutting) ran on ways, like those of the Schaublin 102, formed as extensions to the bed's front and back walls with the front V-shaped and the back rectangular.

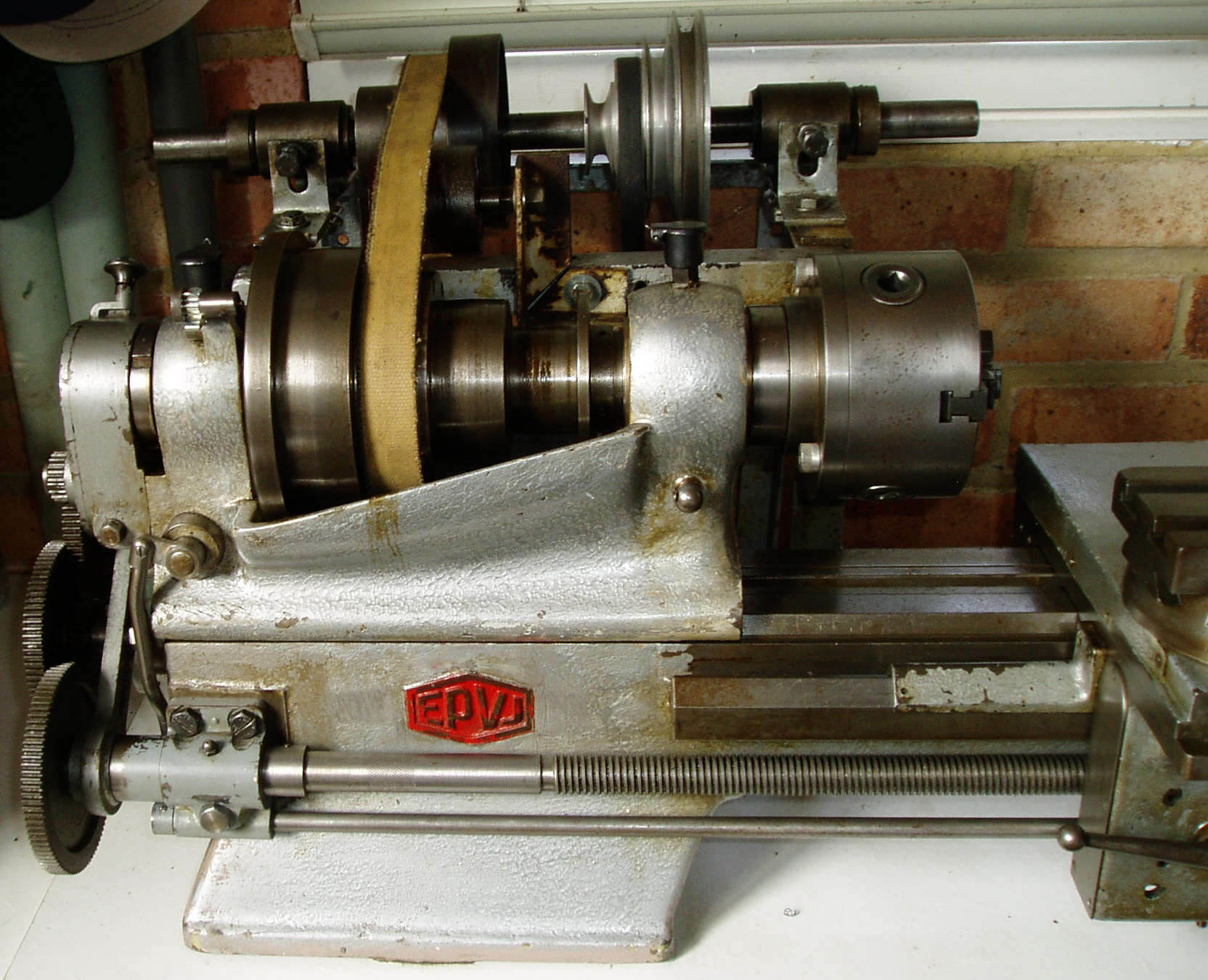

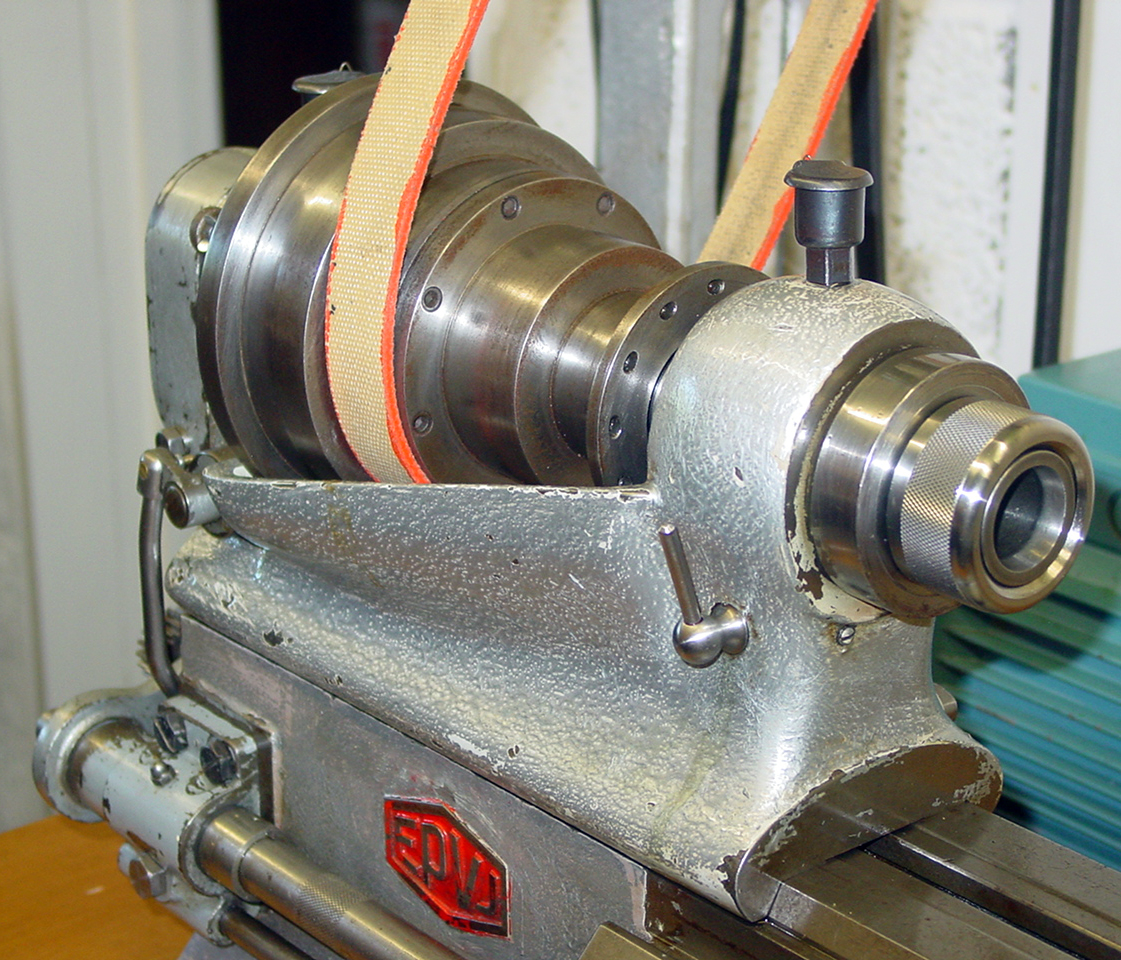

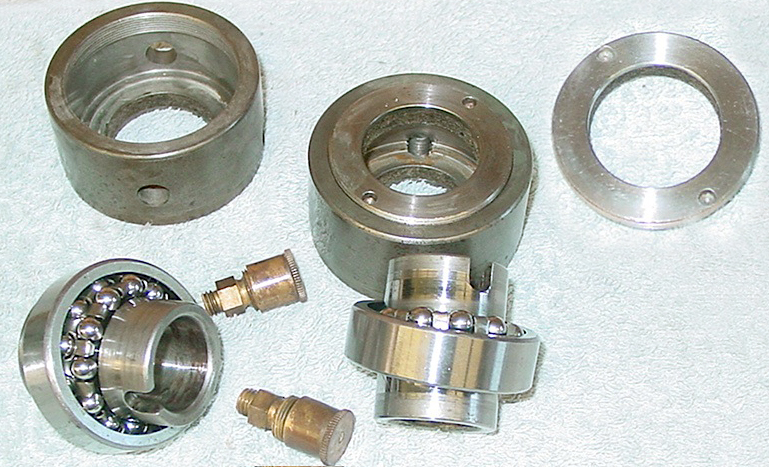

Hardened and ground headstock, the headstock spindle carried, on its nose (as might have been expected) a taper to take Schaublin W20 collets - but was otherwise of an unusual design with the front bearing surface formed as a double taper and running in 2.5-inch long bronze bearings that extended forwards, the spindle being fitted with a sort of "labyrinth protector" over this section. The bearings could be adjusted with great precision by means of ring carrying a very fine thread of around 60 t.p.i. That was locked in place by a ring of four socket-headed screws, However, more complexity, for these were not of the usual hexagon pattern, but square - and obviously not of a commercial nature but specially made in the college workshop. The rear bearing, a split bronze cone, must have been set up on assembly, for a packing piece was used - the original still in place on the lathe below - lapped to give a clearance of just 0.01 mm. The current owner of the EPVJ reports that the spindle assembly as no wear whatsoever and is "like new". As was usual on this class of the lathe, the headstock spindle carried its flat-belt pulley with the smallest diameter to the right, so allowing the all-important front bearing to be surrounded by as great as a mass of metal as possible. Four, rather than the more usual three steps were provided, the smallest being made only a little larger than the diameter of the spindle to produce a higher top speed. However, although only slightly unconventional in this latter respect, the pulley also had what might well be a unique feature - a two-part construction with the inside fully machined and the two halves joined together by an 8-bolt ring. Why machine the inside of the pulley? Possible to obtain perfect balance?

Very Schaublin-like, the compound slide rest used the same design of good-sized, bevelled-edge zeroing micrometer dials with balanced handles and a top slide machined with two parallel T-slots arranged so that the bolts could be withdrawn either to the front or rear.

Screwcutting was by fine-pitch, 1.25 MOD changewheels with, instead of the expected tumbler reverse to reverse the direction of the sliding feed, a lever that engaged either drive or neutral through a changewheel mounted on an eccentric stud carried on the outer plate of the changewheel cover. Carriage movement to the left, right and neutral was obtained by a mechanism within the apron, control being by a 3-position lever operated a single-tooth dog clutch.

Like that fitted to most precision lathes from the 1860s onwards, the tailstock carried a barrel (spindle) that passed right through the housing, thus being fully supported by the surrounding casting, even when fully extended. A proper compression clamp lock was fitted and, to the front of the machined surface in front of the lock, a reservoir and dipper rod to apply the (now banned) white lead with which to lubricate the centre.

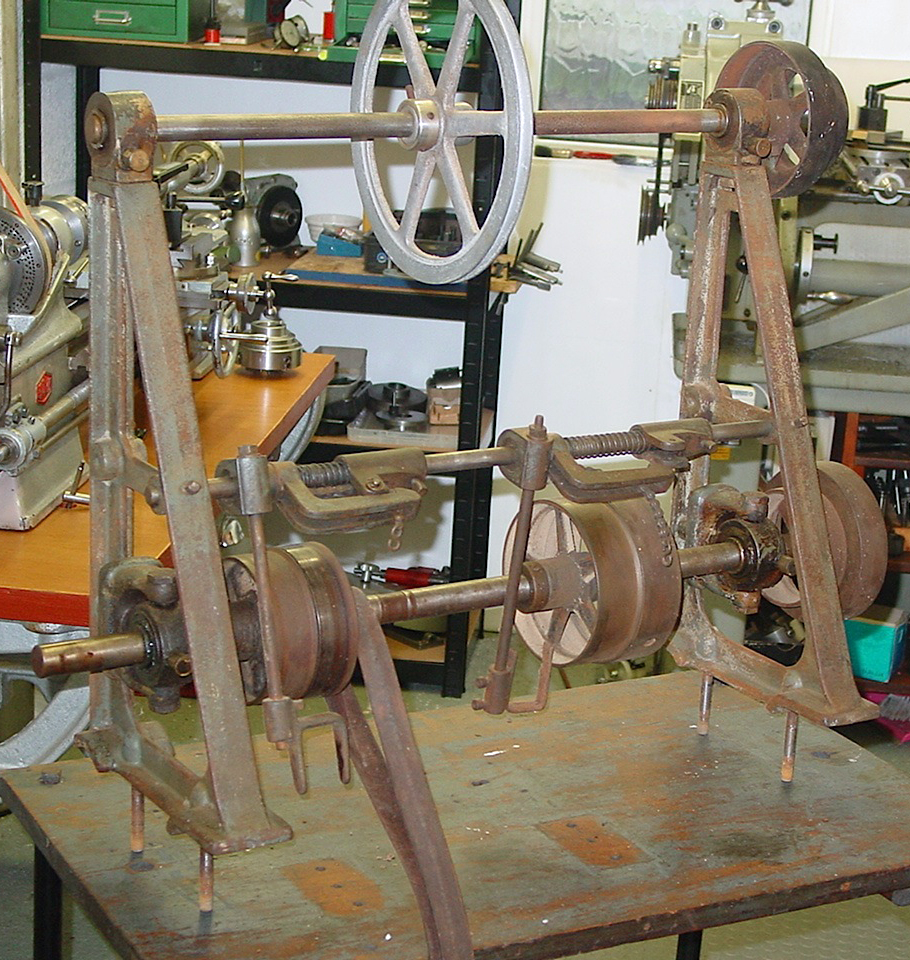

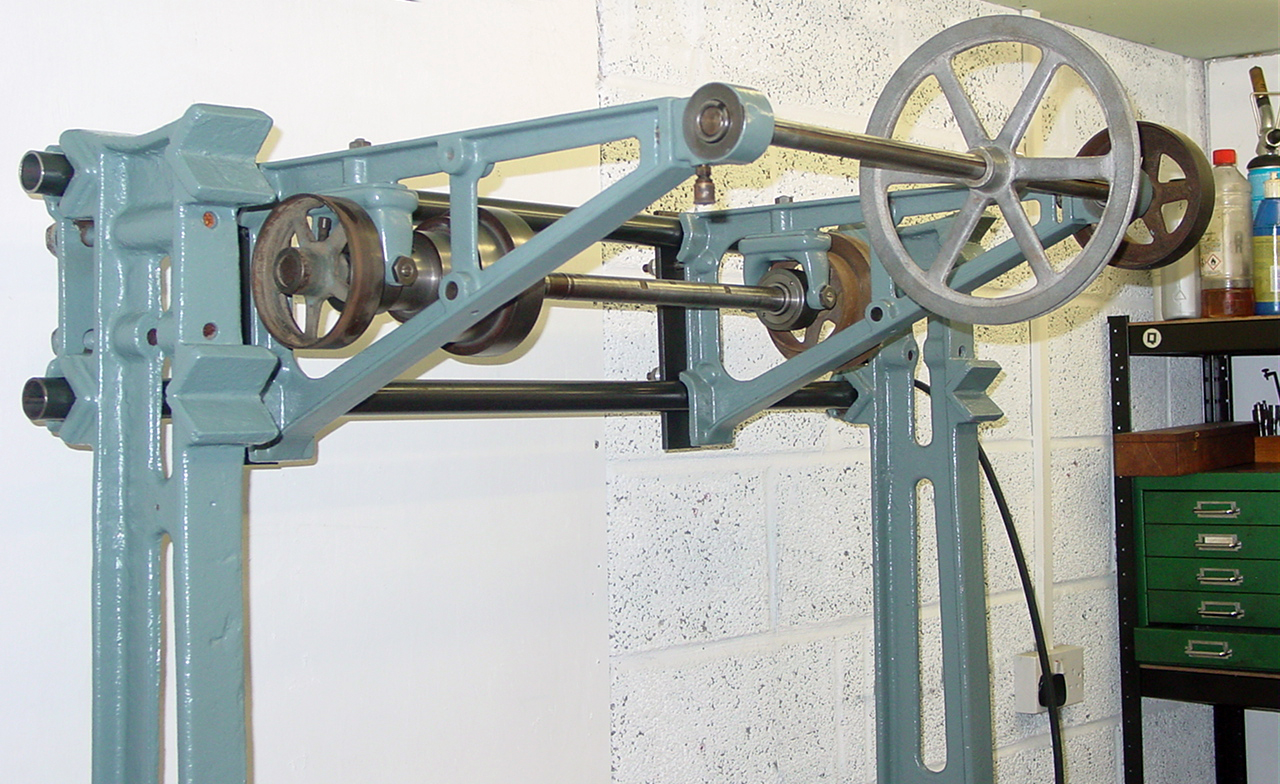

The current owner of the fine EPVY shown below has found a suitably "vintage" stand with integral overhead countershaft assembly of massive proportions - it transpires that is was made by Schaublin for a pre-WW2 Model 102 lathe, all the parts being marked with Schaublin part numbers. Contemporary sales catalogues list stands like this with plain bearings as standard, though this has the optional - and doubtless very expensive - Swiss-made double row, self-aligning ball races.

If you have a EPVJ lathe or other machine tool, or knowledge of their origins, the writer would be very interested to hear from you..

Some pictures below are high resolution and may be slow to load

|

|