|

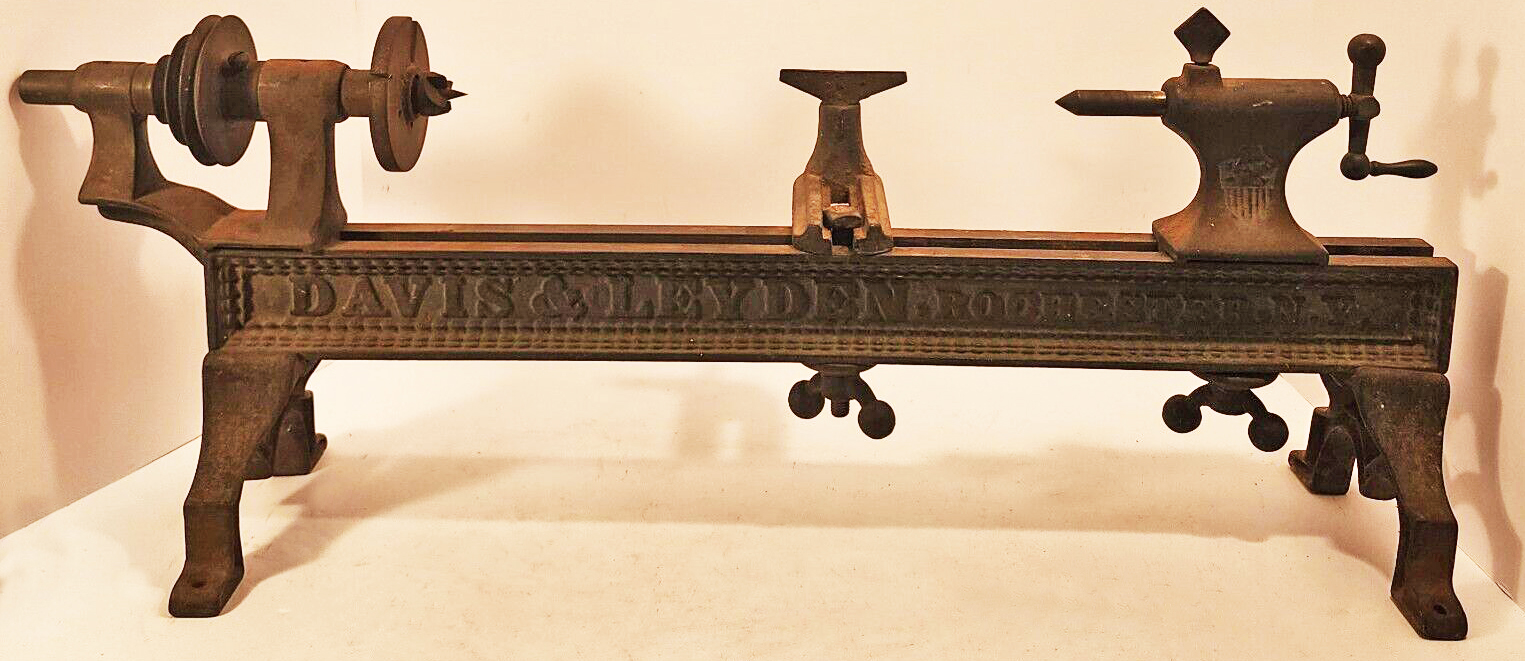

We learn from the splendid Vintage Machinery.org website that this firm "...began as Davis & Brother sometime after the US Civil--roughly 1864--as a partnership of brothers George P. Davis and Charles A. Davis to make dental supplies. They reportedly succeeded the firm of Walter & Field. Five years later, local dentist Maurice Leyden joined the firm and Charles took on a reduced role; the name changed to Davis & Leyden. Under that name they made a small dental lathe." More about the company can be read here on the Vintage Machinery website

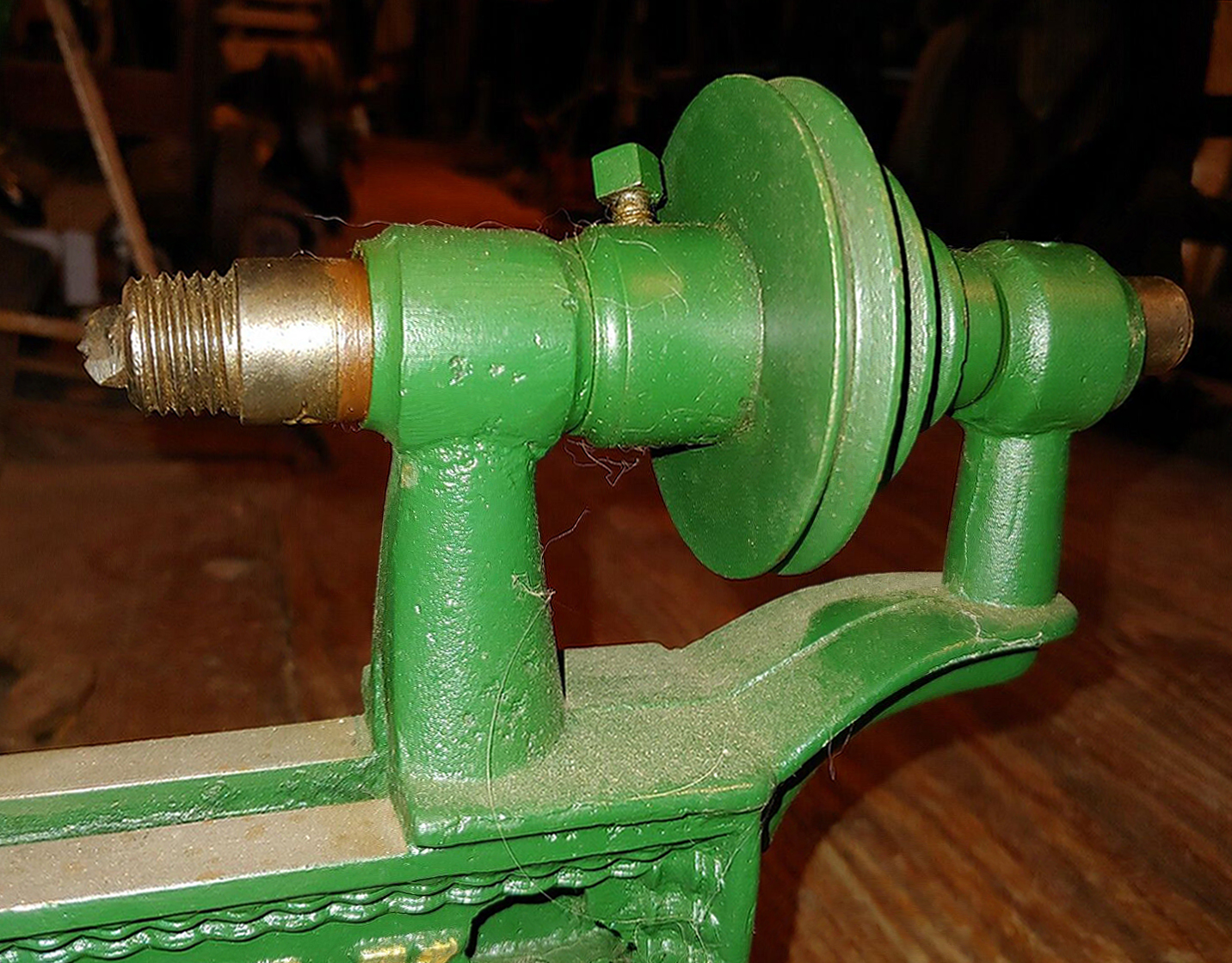

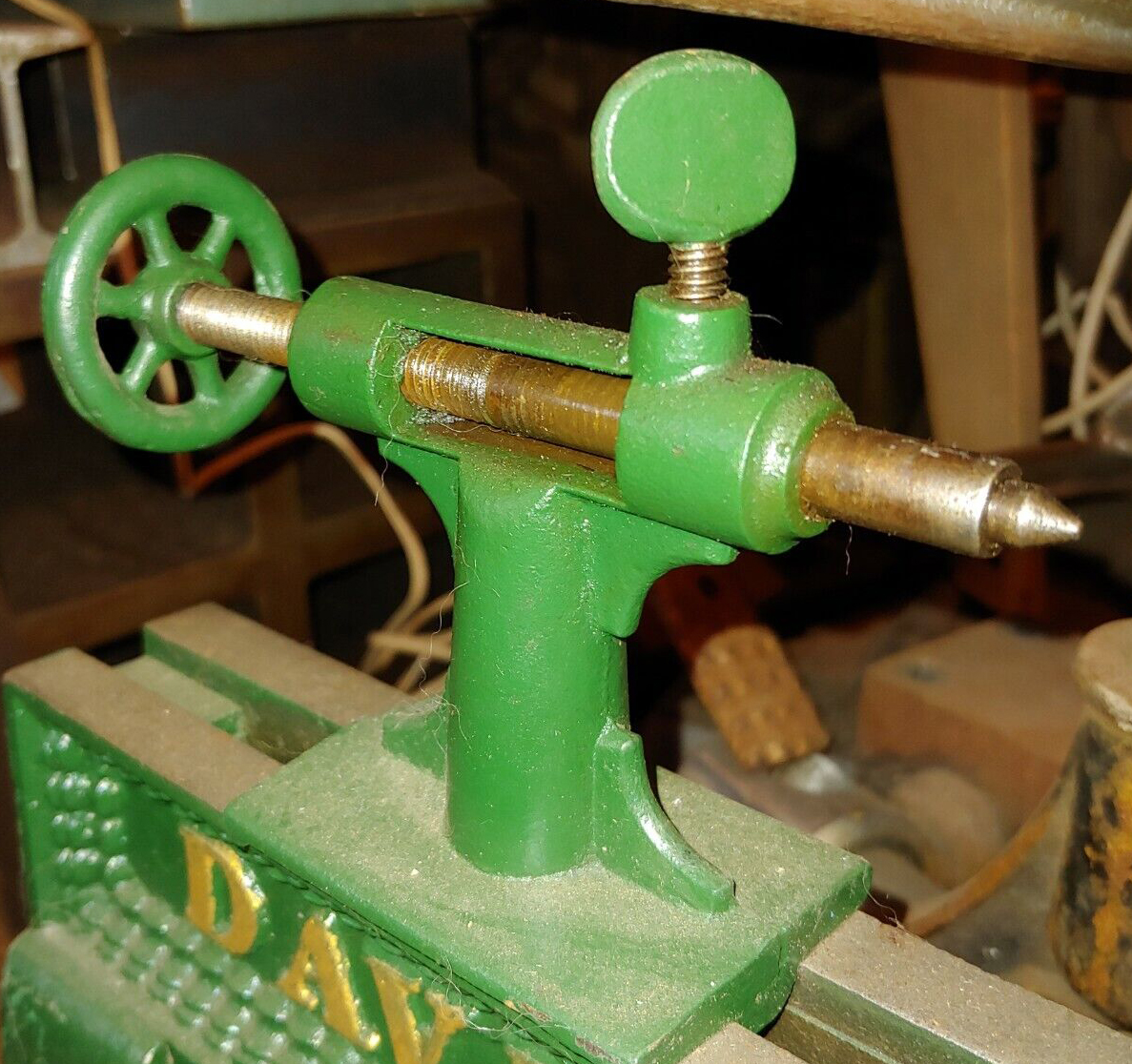

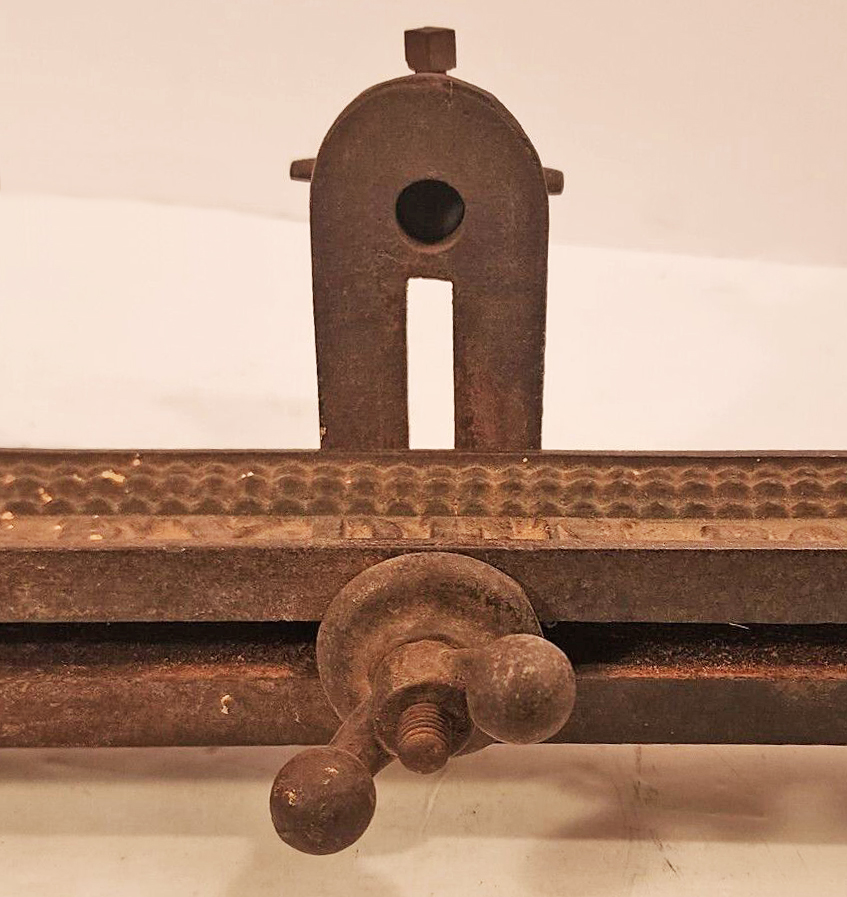

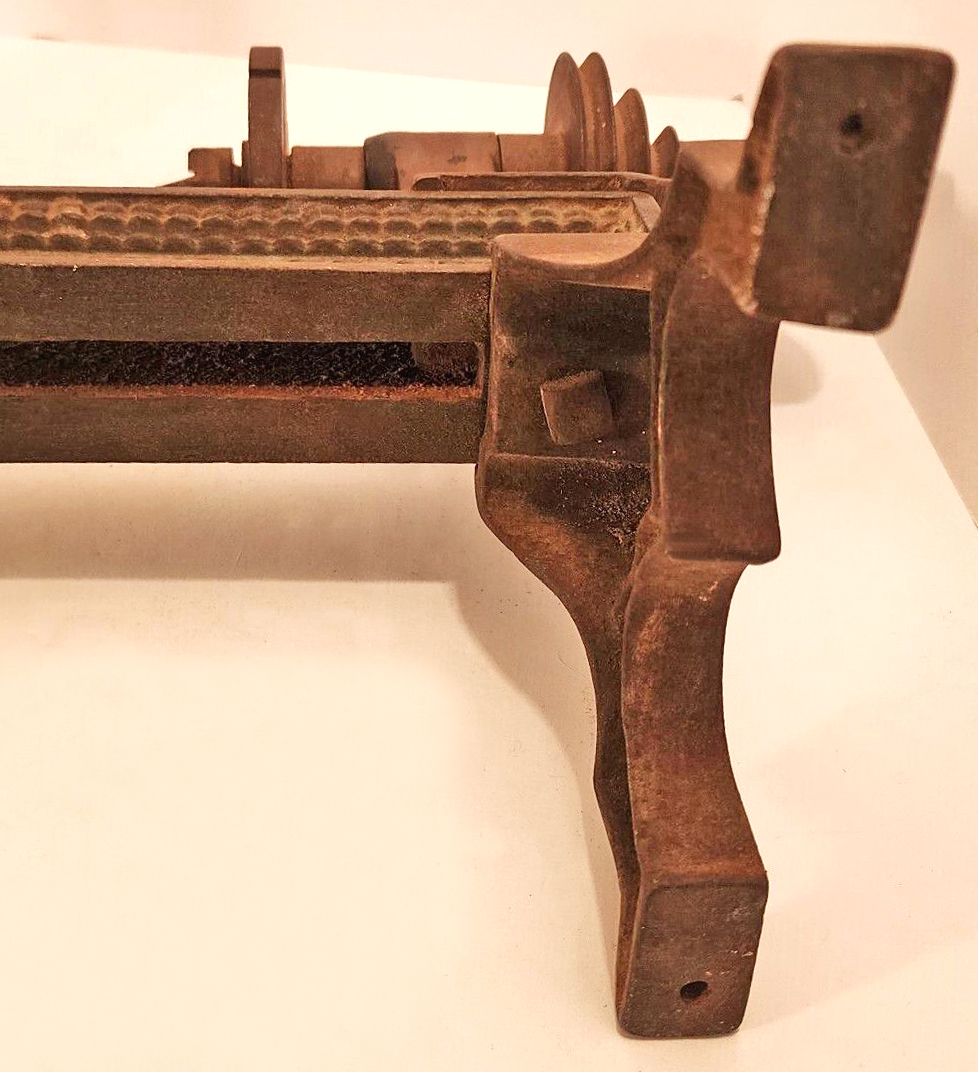

While perhaps marketed for use by a dental technician, the following 20 pictures show two very slightly different versions of a small, plain-turning type - of around 3 inches in centre height - so typical of its time and usually bought by amateurs for wood-turning. The shape of the castings used for the headstock and tailstock of the two lathes differ, the one painted green appearing to be slightly more robust than the one in its 'natural-rust' finish.

While dental lathes were advertised during the 1800s and into the early 1900s, these were often just regular lathes that had been branded for sale carrying the name of a distributor of dental equipment. Examples of lathes advertised for dental work include Claudus Ash, Bonwill, Redman, Poor, Quattlebaum and Jones - the latter with an ingenious pumped-water solution for recovering particles of precious metals such as gold and platinum.

As with other similar lathes (and dental drills), one problem was setting up a suitable drive system. In the 1800s, small electric motors and a suitable electricity supply were both expensive and hard to come by, so the alternative usually involved some type of treadle-driven flywheel that employed a round-rope "gut" belt. The usual solution offered by manufacturers was a stand that incorporated all the necessary parts, such as those by Chapin and Sanderson for their watchmakers' lathes or the one employed on the Marsh wood-turning lathe. The problem with this answer was that any neatly integrated drive system usually doubled the price of the basic lathe, though a less expensive arrangement could be found in the use of one's own bench in combination with a simple foot motor, like this by W.A.Johnston.

|

|