|

Home Machine Tool Archive Machine-tools for Sale & Wanted Parts - a Photographic Essay - continued on Page 4 |

|

|

||

|

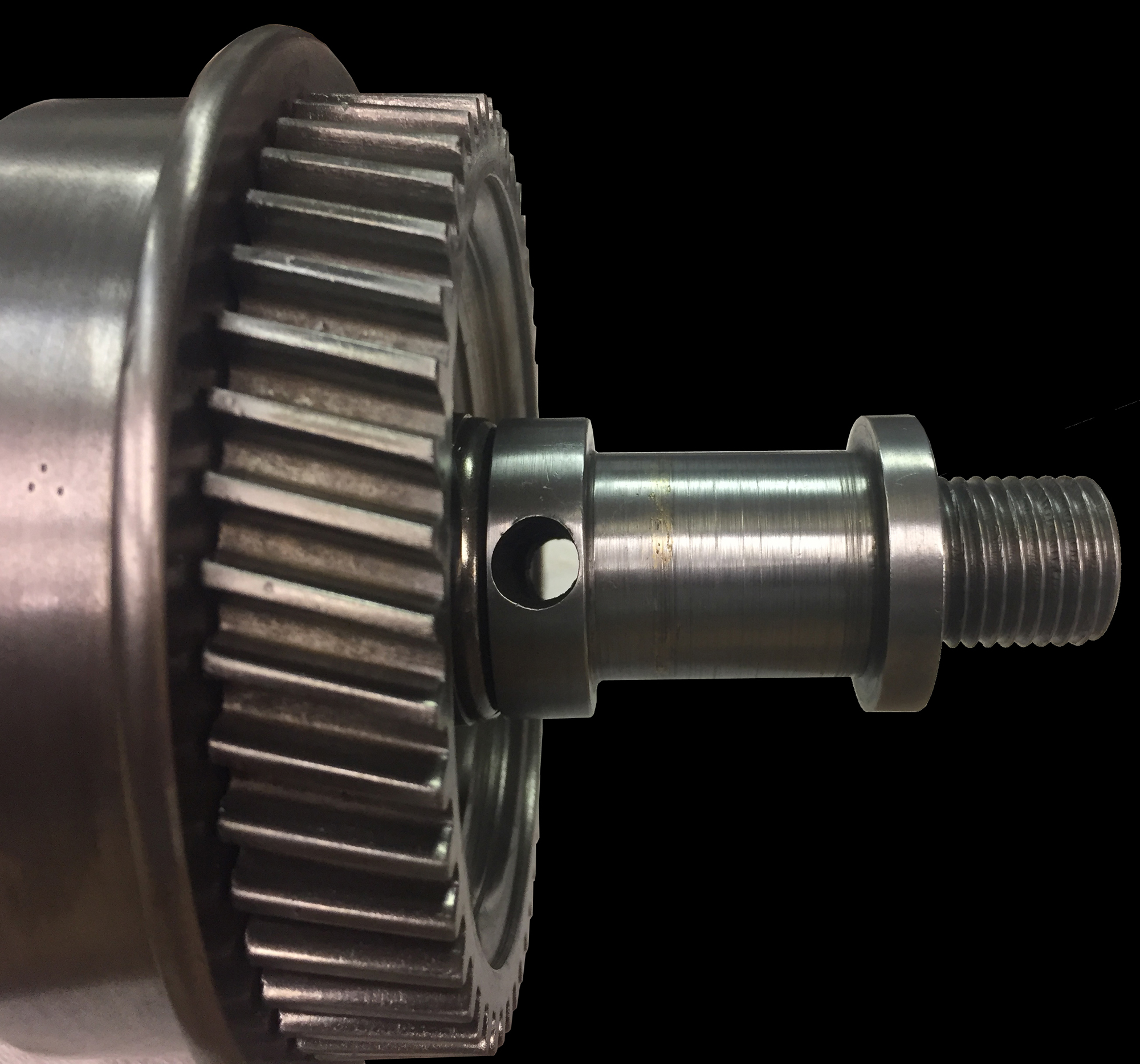

Headstock spindle end with its 13/16" x 12 t.p.i. thread and, usefully, a hole drilled the inner boss that allowed a bar to be inserted and the spindle locked for the removal of fittings |

||

|

|

||

|

|

||

|

|

||

|

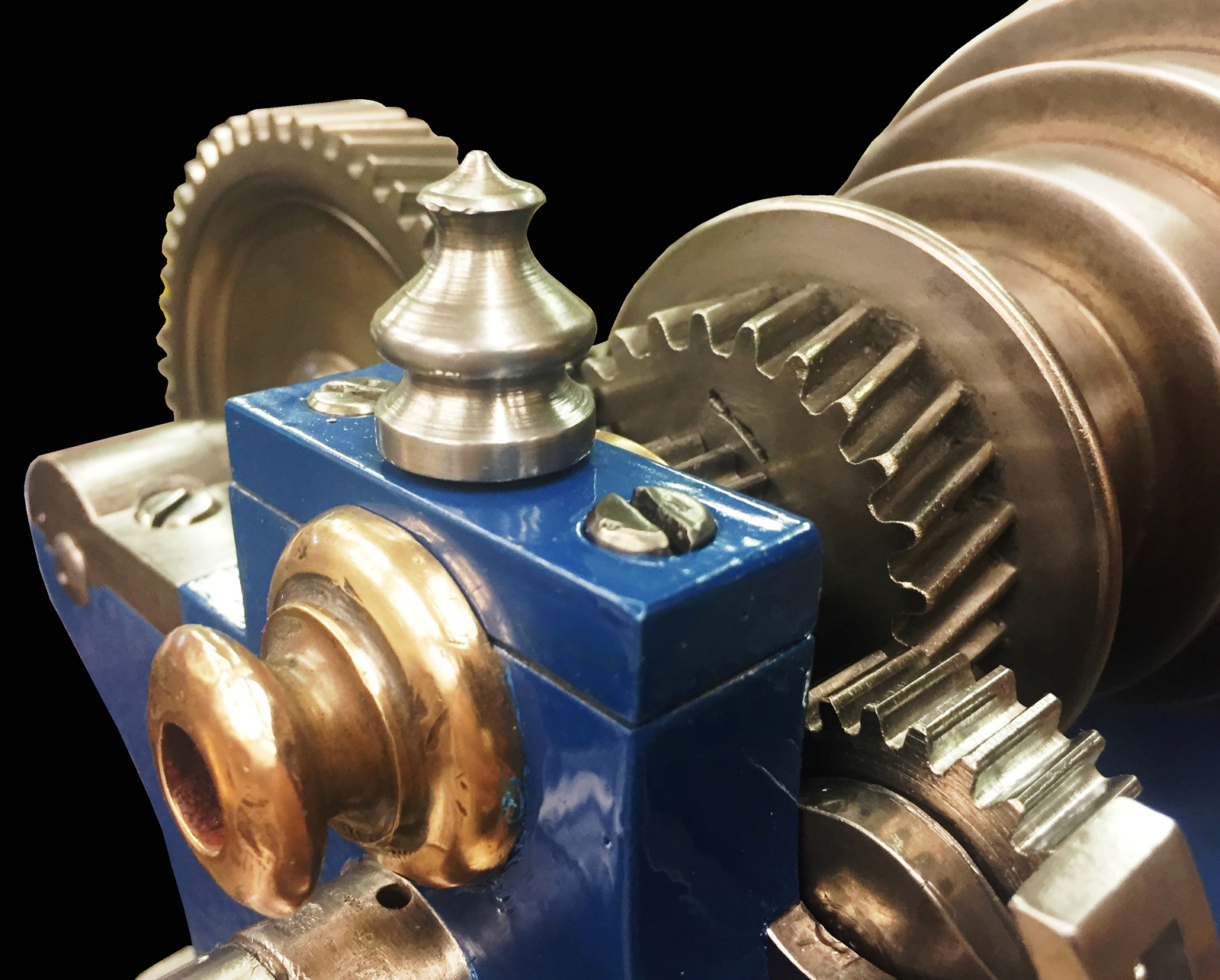

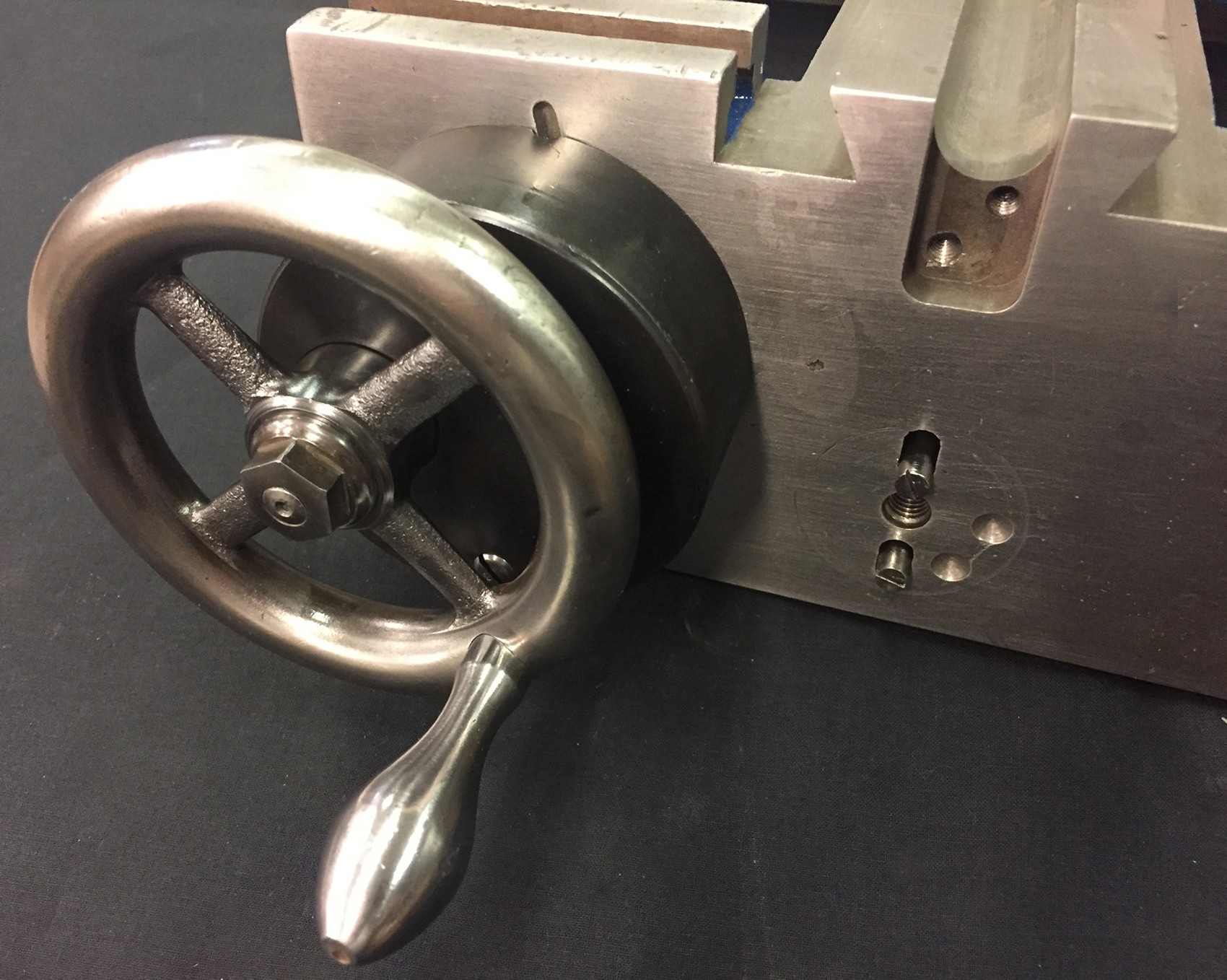

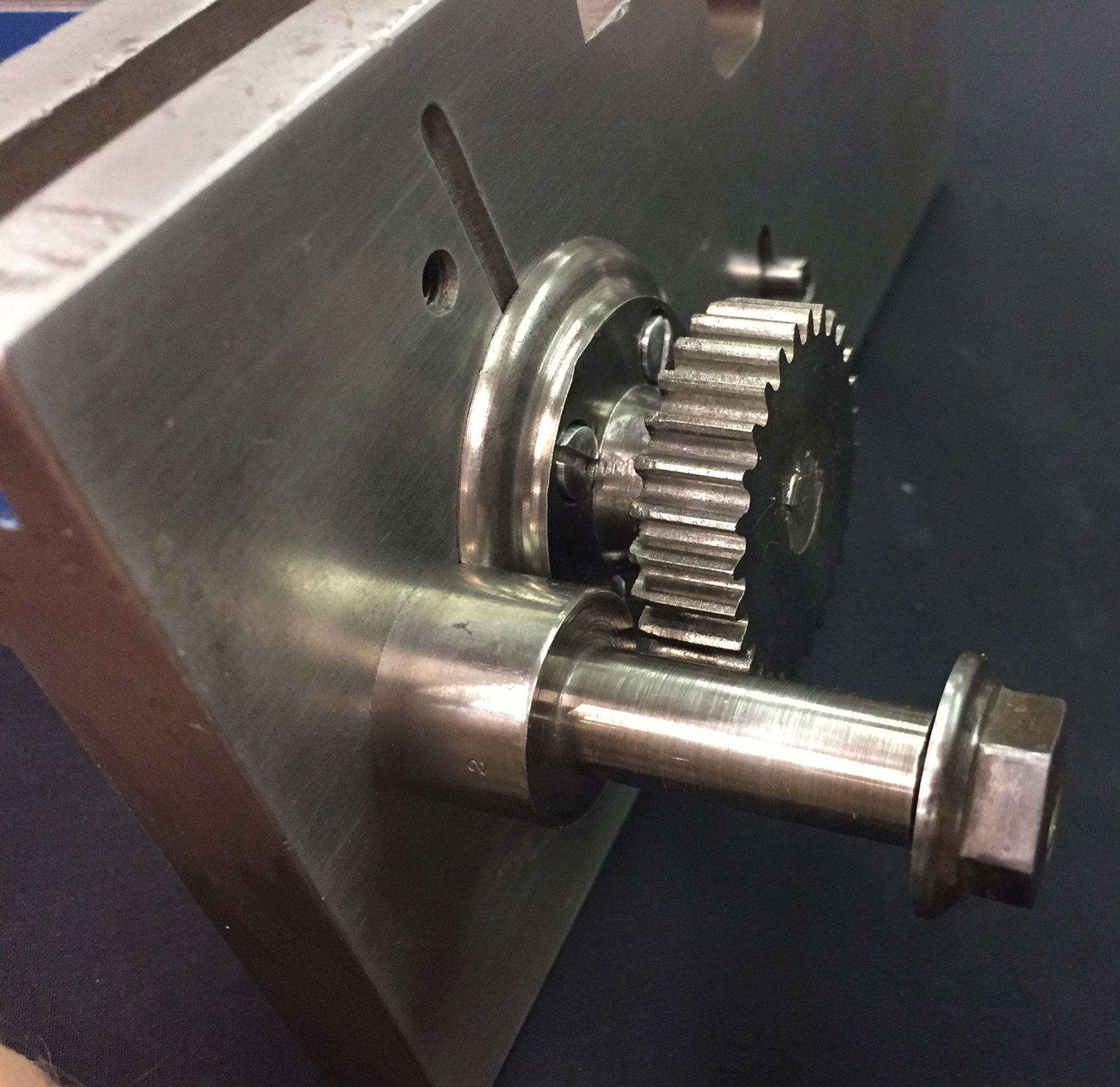

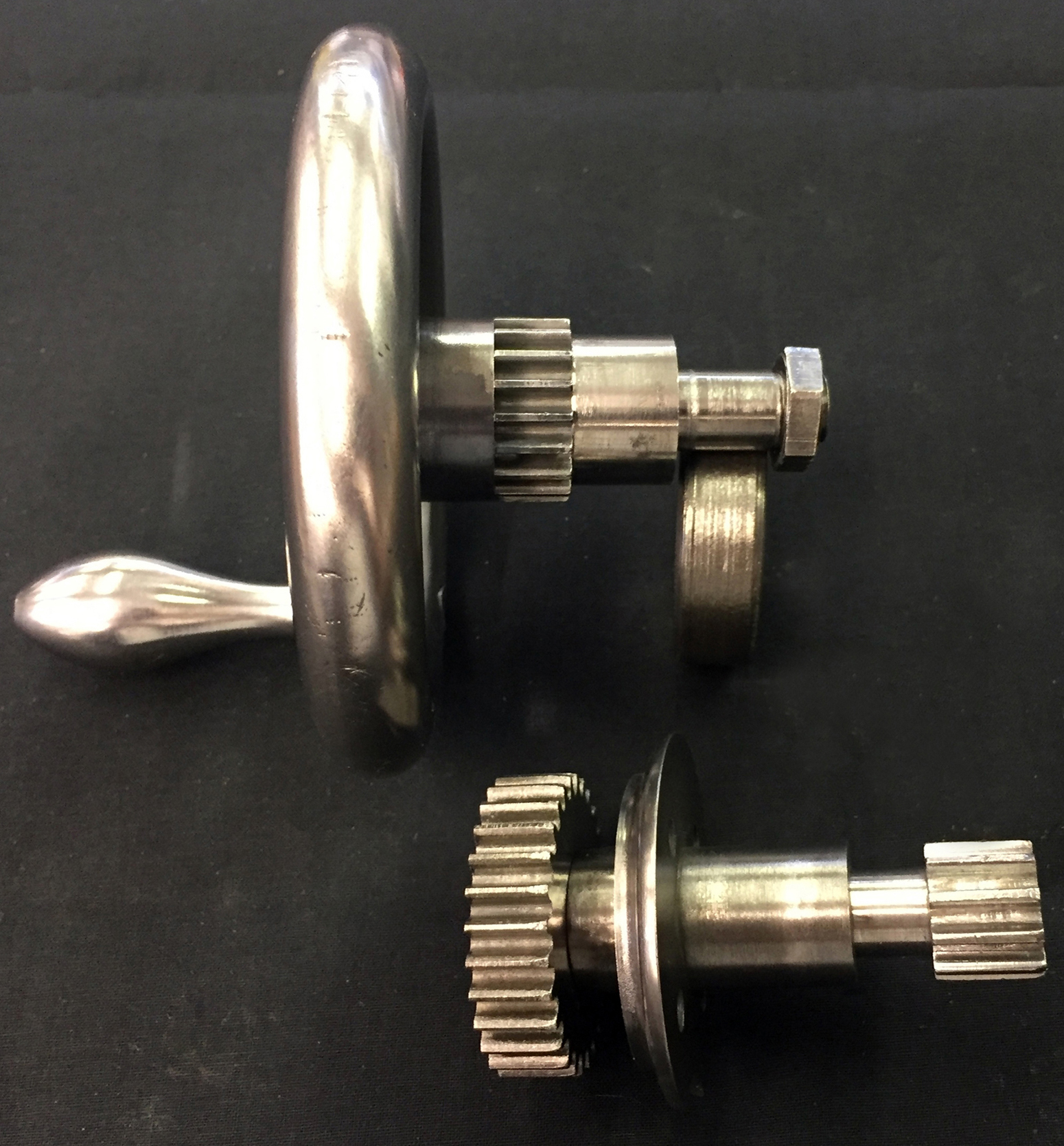

Carriage traverse handwheel cover from the apron that contained a set of reduction gears to give a fine and steady feed to the hand feed (a system that was very unusual at the time when a quick-action, awkward-to-use crank handle would have been expected). The cover, instead of being a simple, prosaic affair was made from a casting of the very finest grain and appeared to have been either gun blued or treated to some contemporary "slow-to-rust" finish. |

|

|

||

|

Parts - a Photographic Essay Home Machine Tool Archive Machine-tools for Sale & Wanted |