|

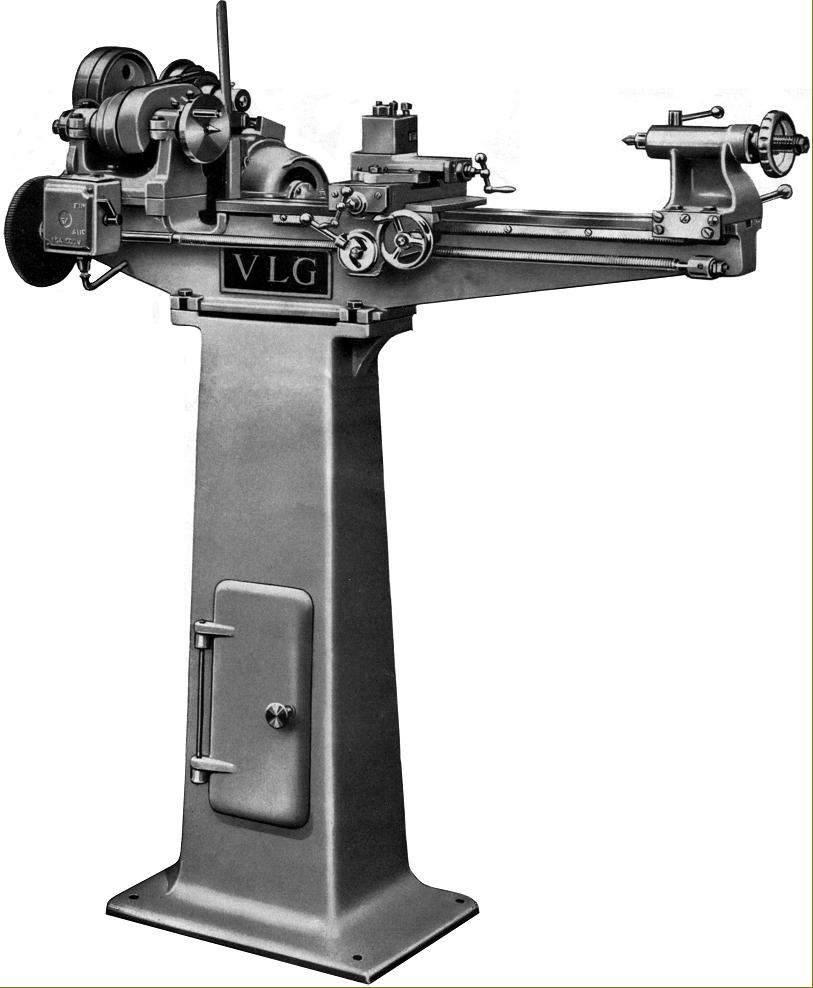

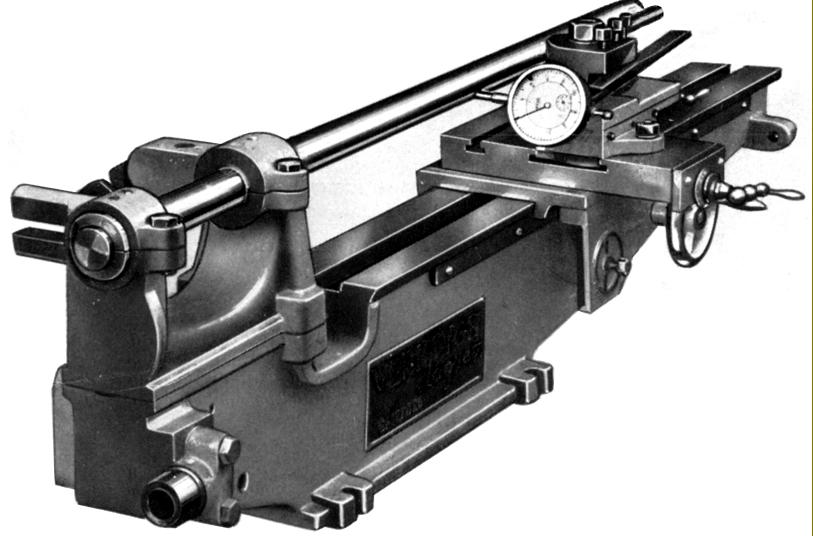

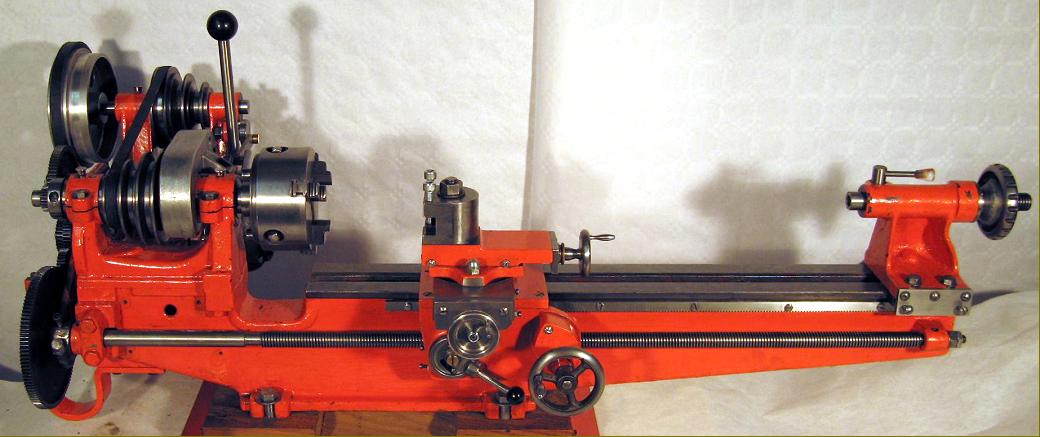

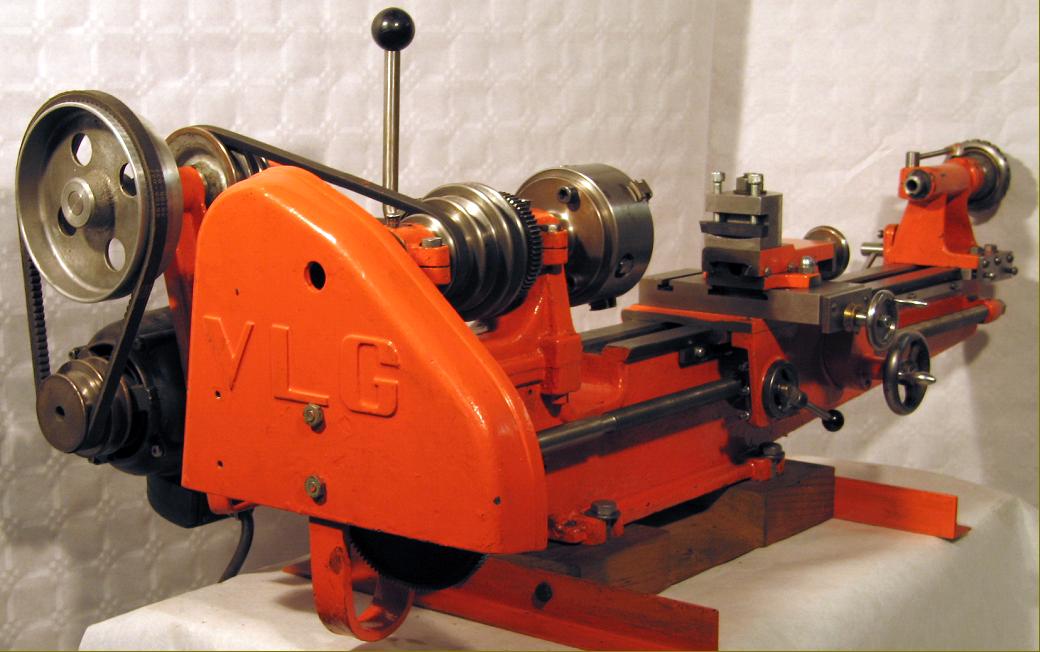

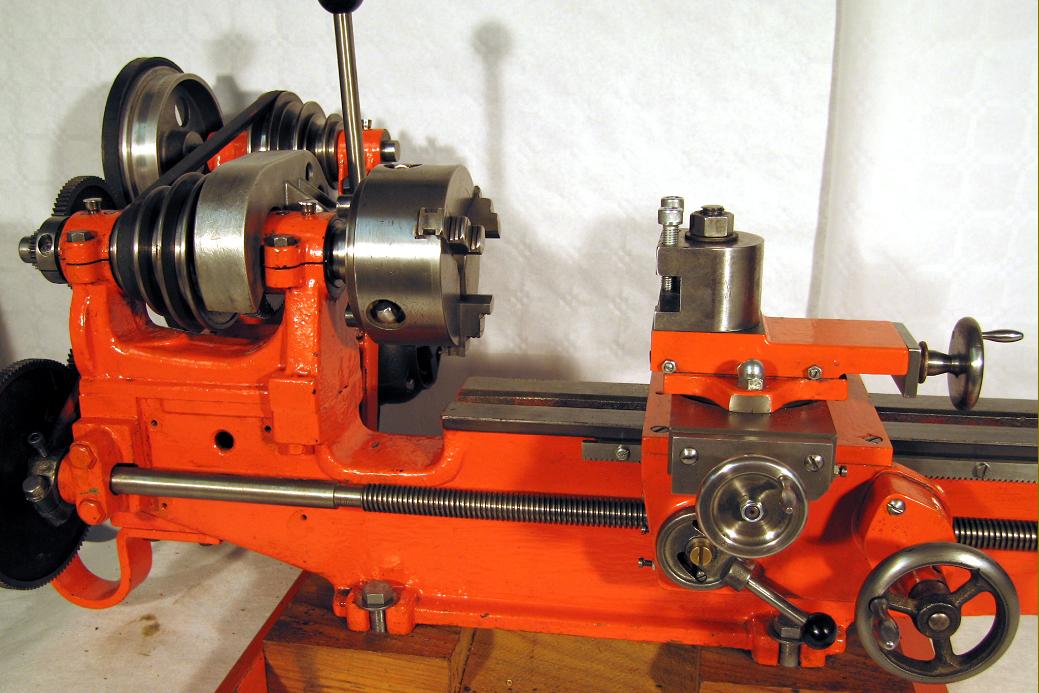

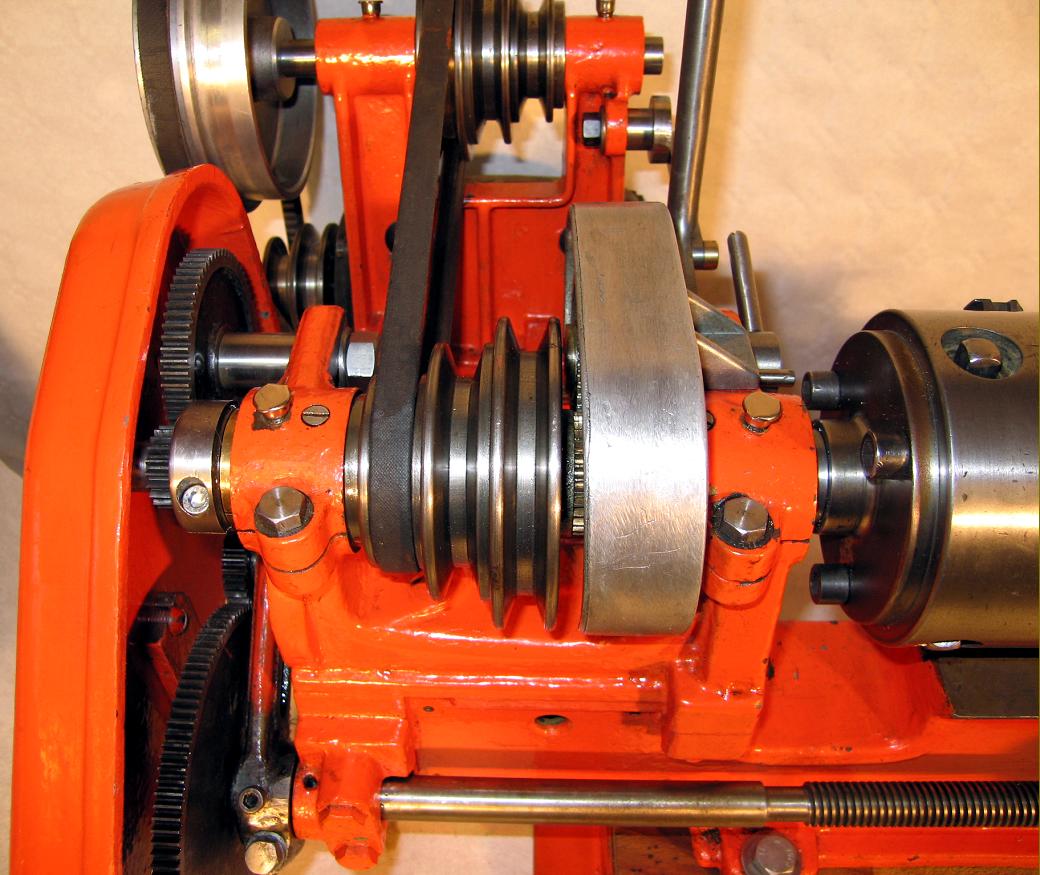

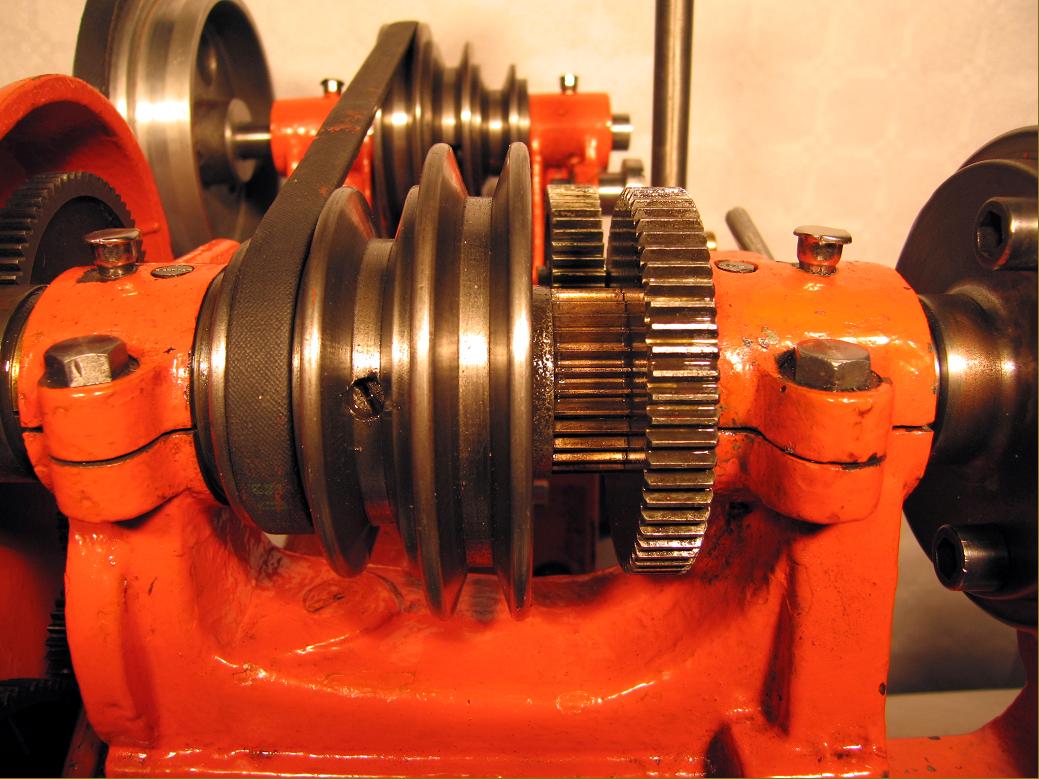

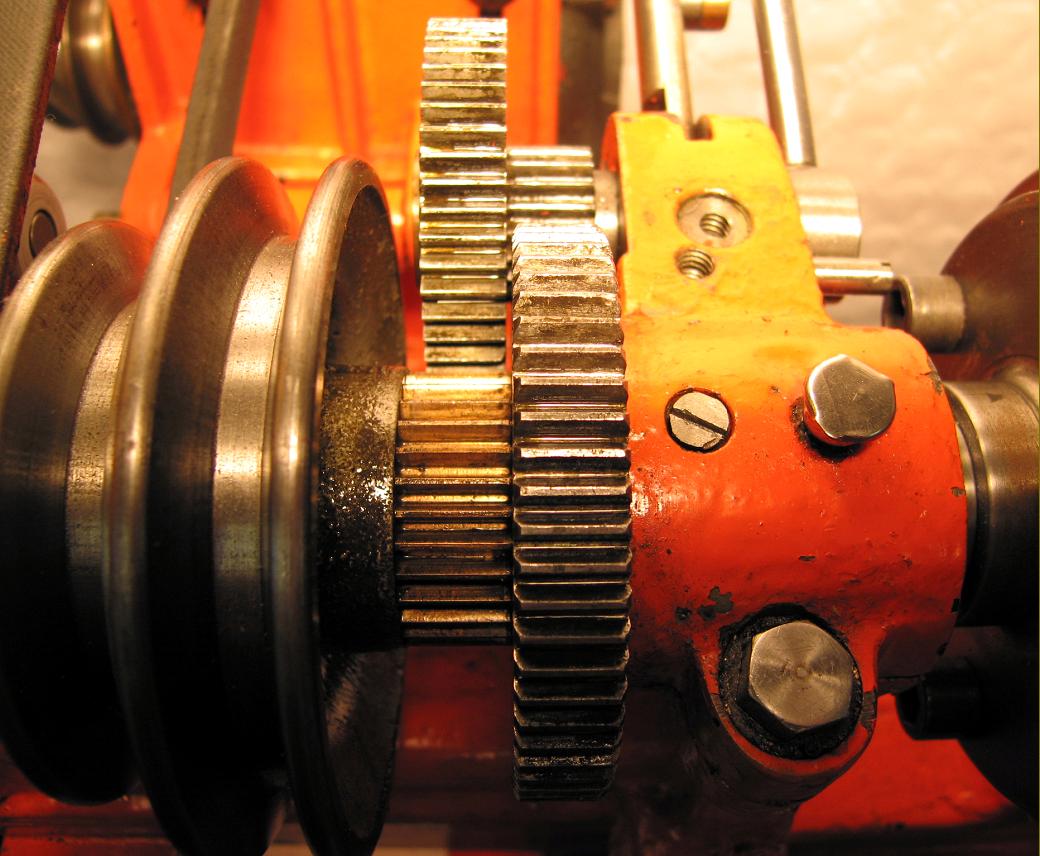

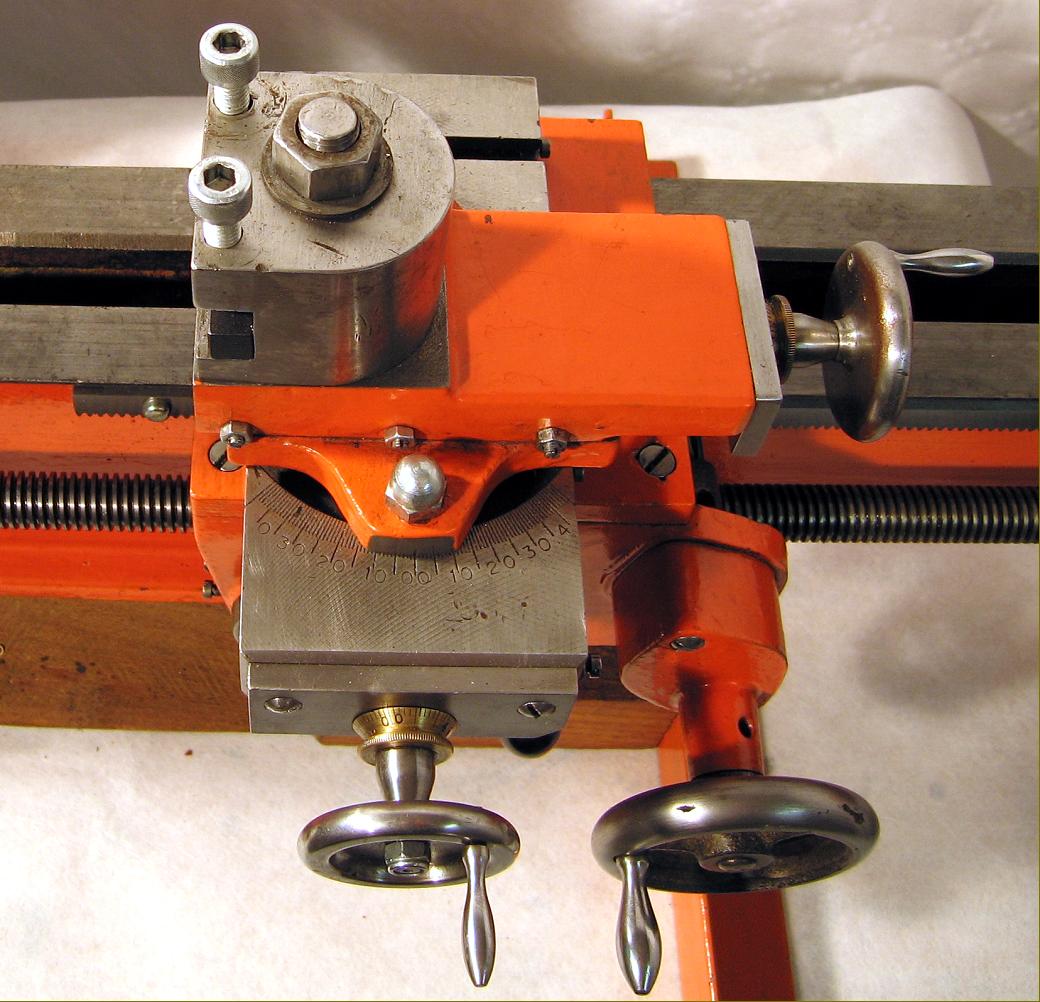

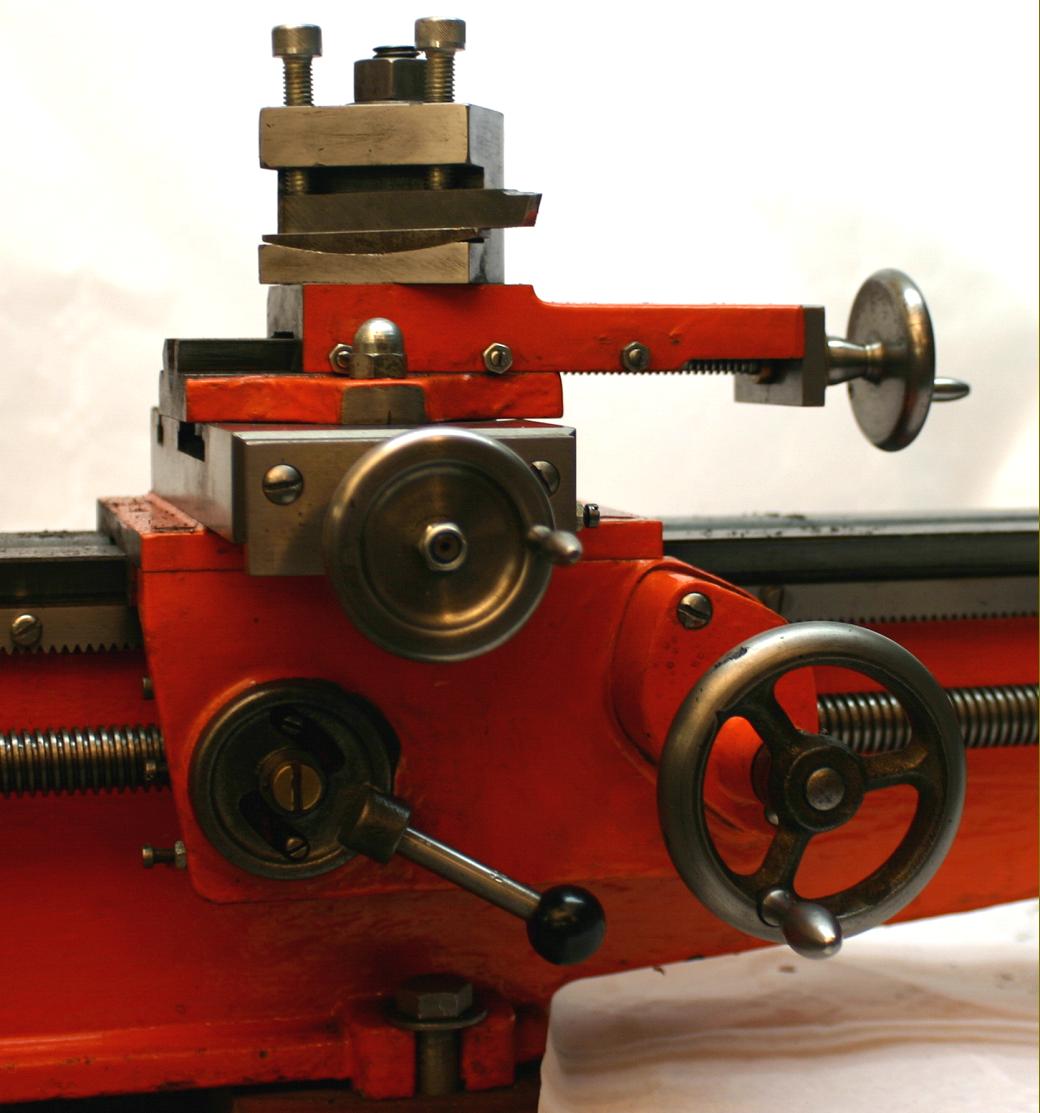

Looking remarkably like a Myford ML4 from the 1930s and 1940s, the 90 mm x 600 mm (3.5" x 23.5") VLG lathe was manufactured in Sweden during, it is believed, the 1950s and early 1960s. Thought to have been Myford agents, the Company offered two between-centres capacities with the shorter having a bed of cantilever construction and the longer with a supporting foot under the tailstock. Closely following the design of the Myford, it even retained the inadequate and flimsy design of the original No. 1 Morse taper, 80-mm travel tailstock - instead of the much-improved post-WW2 type that Myford offered as a replacement (though the otherwise similar English Perfecto and Australian Advance lathes both had improved designs). The VLG also lacked tumble reverse though, as on the Myford, it may have been available as an unlisted option, the necessary bulge in the headstock casting being present. Nor was an opportunity taken to address deficiencies in the cross slide with its short casting and relatively limited travel of 115 mm - where just the fitting on an extension piece, instead of a flat plate, to support the end of the feed screw would have given greater travel and made it so much more useful when fitted with a vertical milling slide. However, despite these drawbacks, the lathe did offer some advances, including the option of full-size, A-section V-belts (in place of flat) together with a neat, built-on countershaft with a 2-step pulley on motor and countershaft to give twelve speeds of 39, 60, 78, 121, 155, 242 in backgear and 232, 362, 465, 725, 930 in direct drive; a full-circle handwheel on the carriage drive together with reduction gearing to give a finer, more controllable rate of feed; small but crisply engraved micrometer dials attached to 12 t.p.i Acme-form feed screws; engraved degree marks on the cross slide to set the top-slide swivel and a top slide that was bolted down at both front and back.

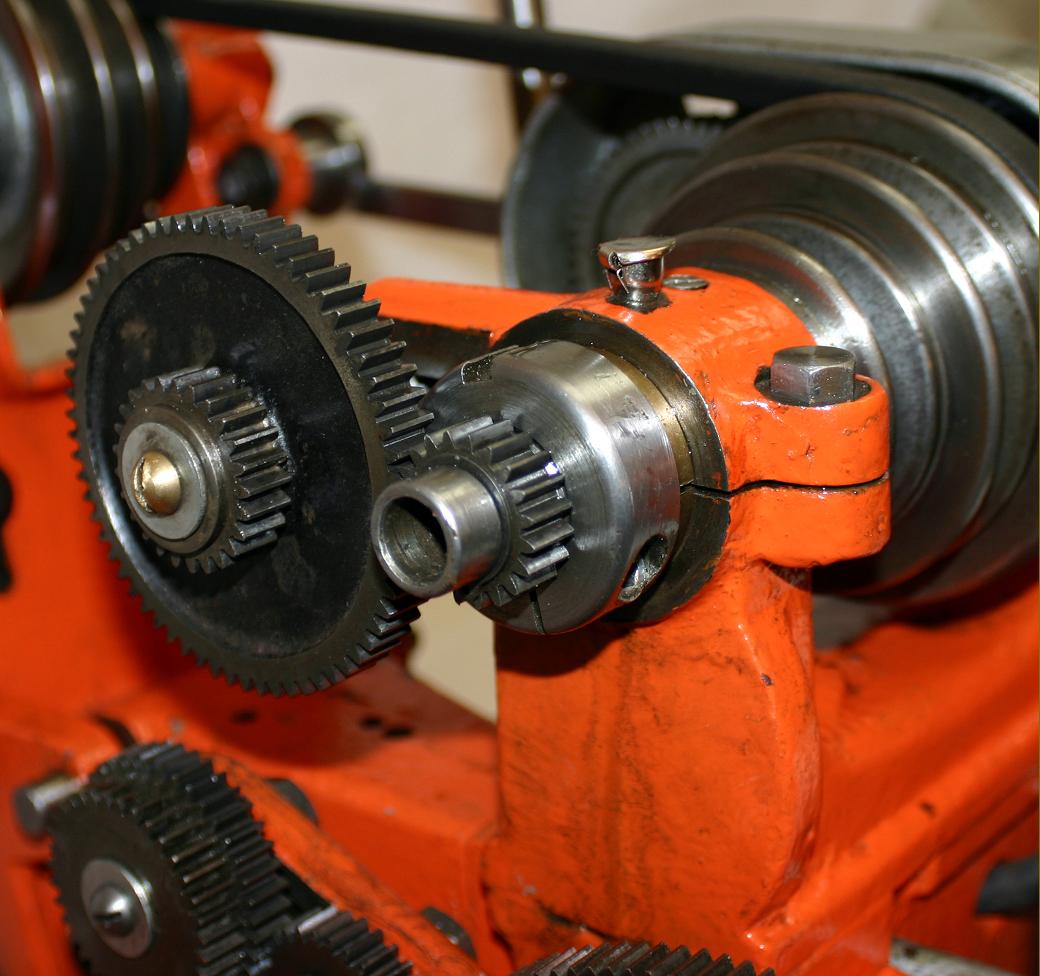

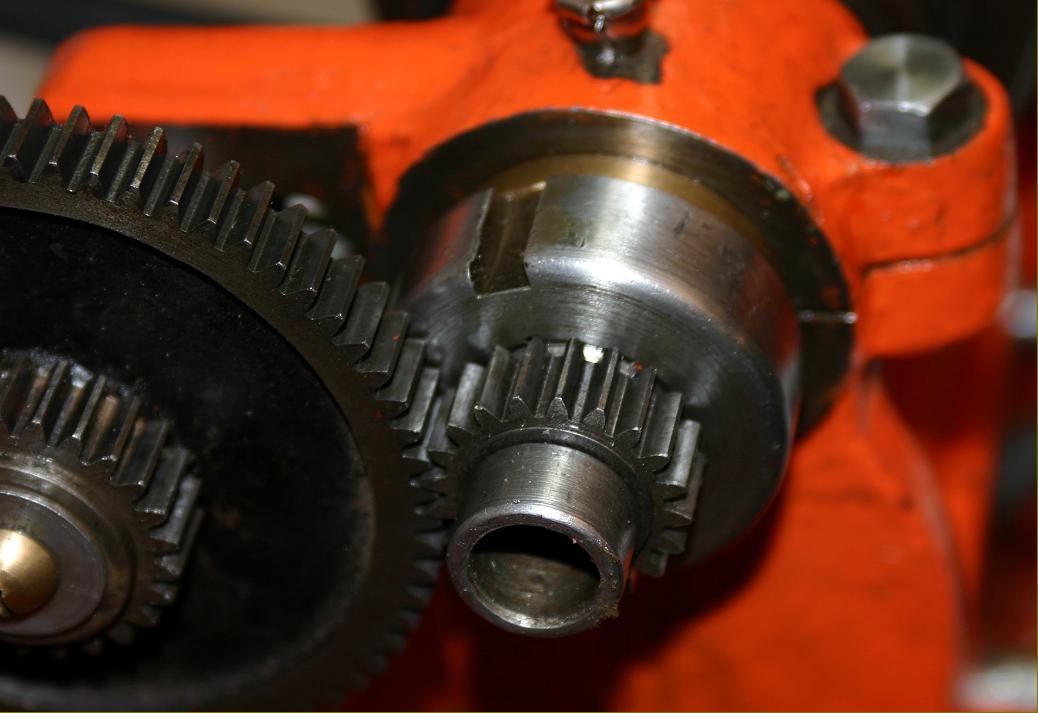

Running is split plain bearings closed down by clamp screws, the 25-mm diameter spindle was bored through 13 mm and could be had with a choice of either a No. 2 Morse or No. 6 Brown and Sharp taper. Backgears, at a ratio of 6 : 1, were in steel (instead of cast iron as on the Myford) though arranged in exactly the same way, clustered just inboard of the front spindle bearing.

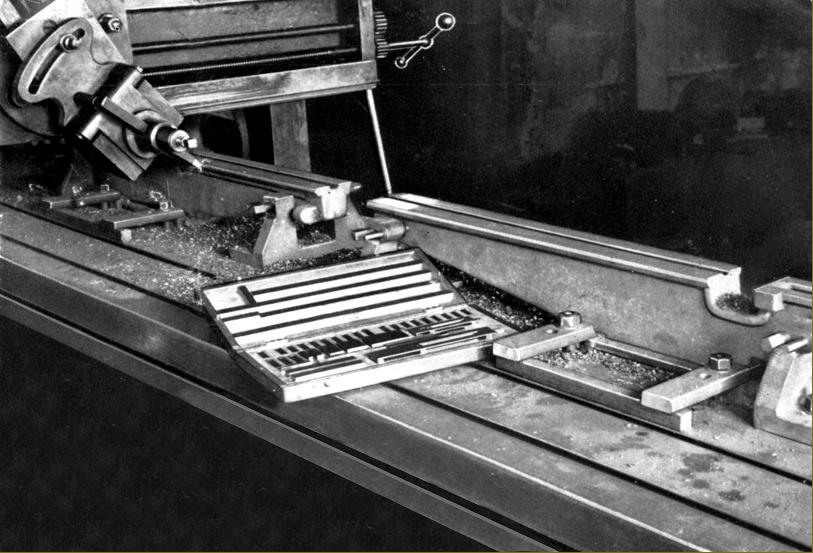

Grasped by a pair of snail-cam-activated split nuts, the leadscrew was cut 8 t.p.i. Acme-form and, in conjunction with the supplied set of fourteen ML7-type keyed changewheels (2 x 20t, 25t, 30t, 35t, 40t, 45t, 50t, 55t, 60t, 65t, 80t, 95t and 120t) gave a range of English pitches that spanned 4 to 136 t.p.i.

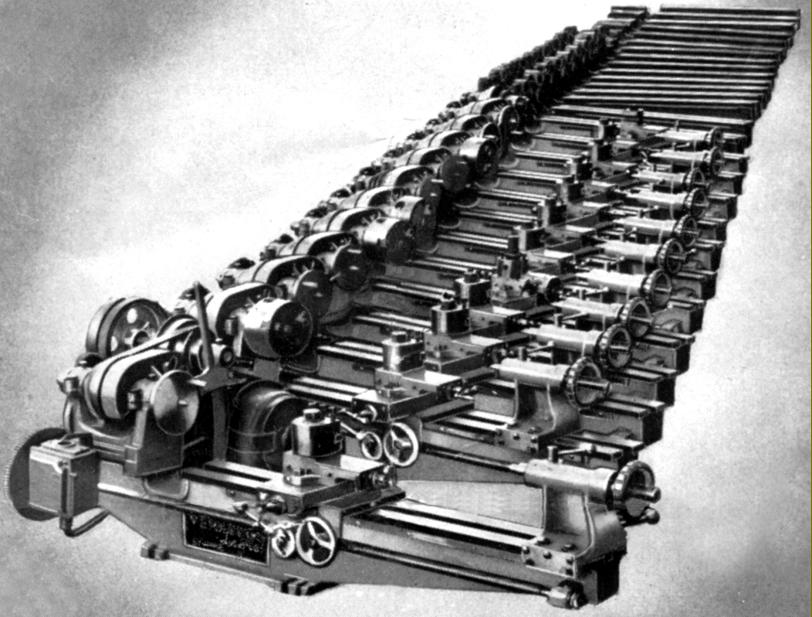

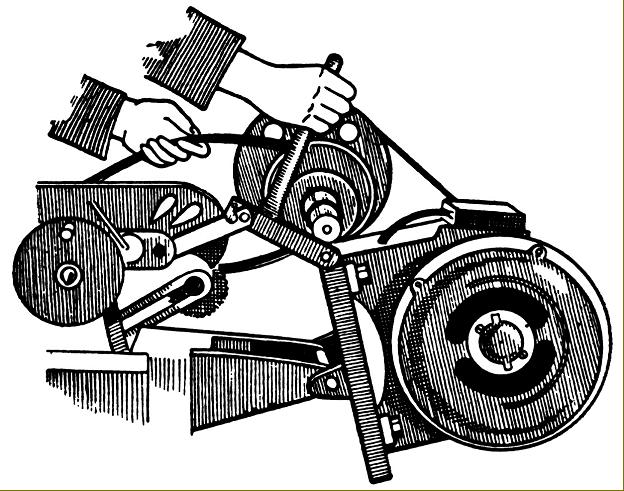

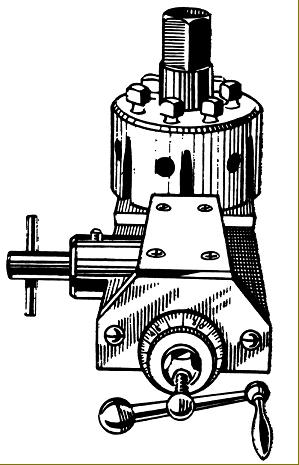

On the options' list was a selection of useful items that (apart from a missing milling slide) included the expected 3 and 4-jaw chucks, fixed and travelling steadies, 4 and 6-way toolposts, a thread-dial indicator, metric/English screwcutting translation gears and turning tools. Also available was a very heavy cast-iron "trumpet stand", a 6-station bed-mounted capstan unit and a built-on 12-speed all-V-belt drive countershaft. A choice was also offered between flat and V-belt drive and wall and ceiling-mounted countershaft units, the latter pair complete, if requested, with fast-and-loose pulleys and belt strikers to give a clutched drive.

When new the basic bench-mount VLG was listed at Kr 450 with a 3-phase motor, although this rose to Kr 830 if the buyer opted for the built-on countershaft unit - plus an extra Kr. 50 to replace the standard-fit 3-phase motor with a 1-phase type. The rather fine cast-iron "trumpet" stand added a further Kr 85 and a 3-jaw chuck and backplate Kr 85.

If any reader has a VLG lathe, or any literature about the Company who made them, the writer would be interested to hear from you.

|

|