|

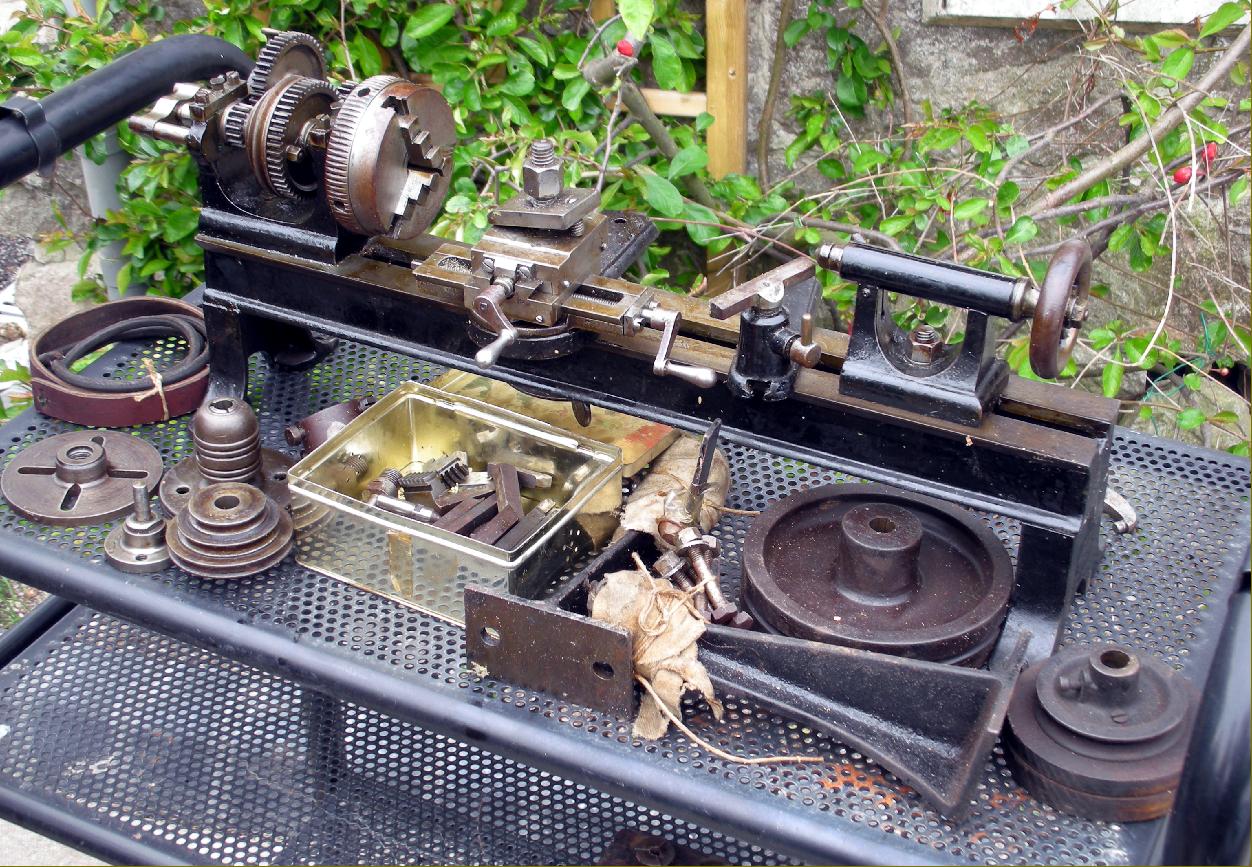

Thought to have been made circa 1890 to 1910 the Taylor 2.25" x 10" (57 mm x 250 mm) backgeared plain-turning lathe was manufactured by T. Taylor of Chester Street, Hulme, Manchester. Taylor are known to have made a range of machine tools including both hand-operated and powered planers (of which at least one version was a delightful and handy bench-mounted machine) and both screwcutting and plain lathes.

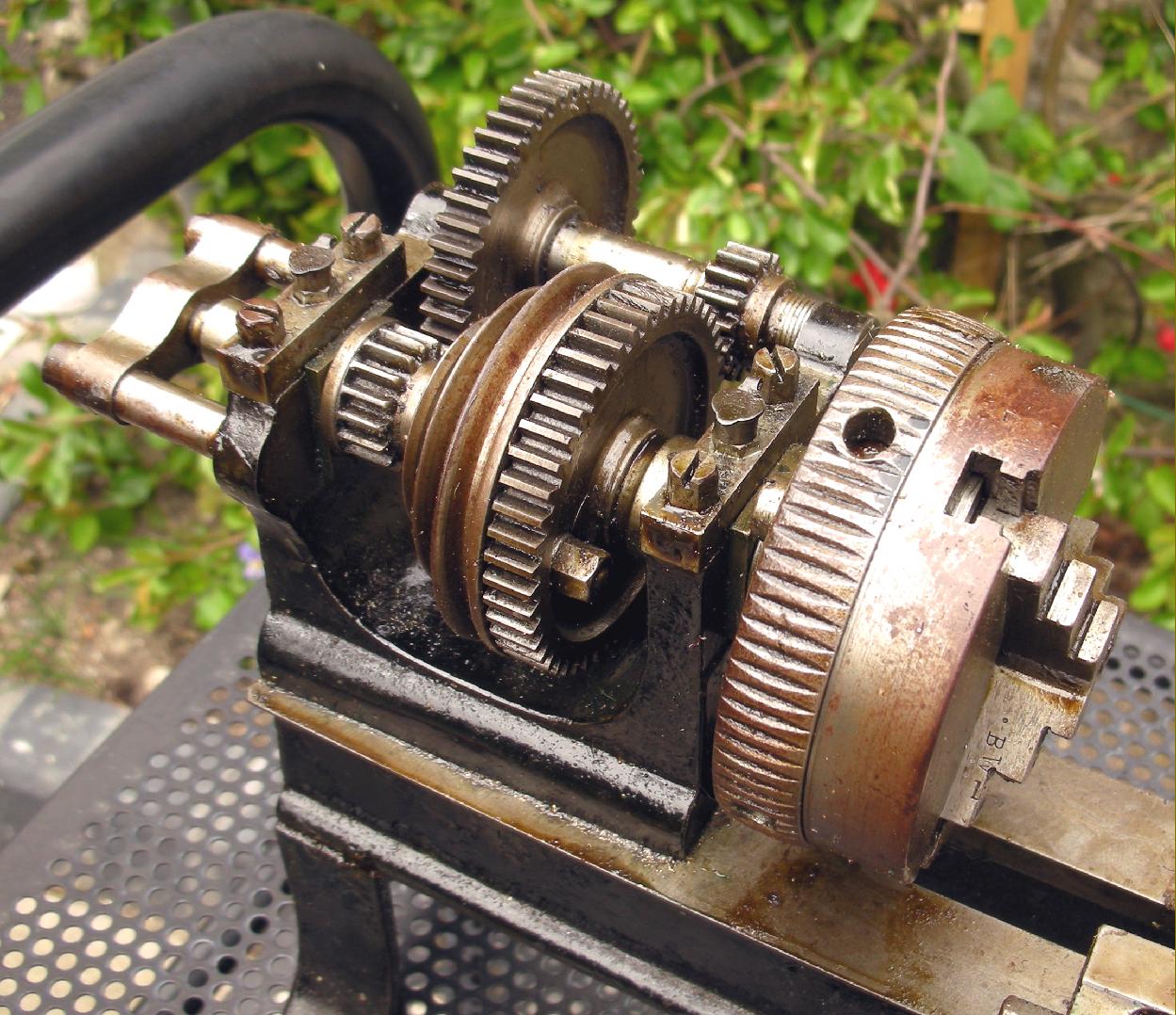

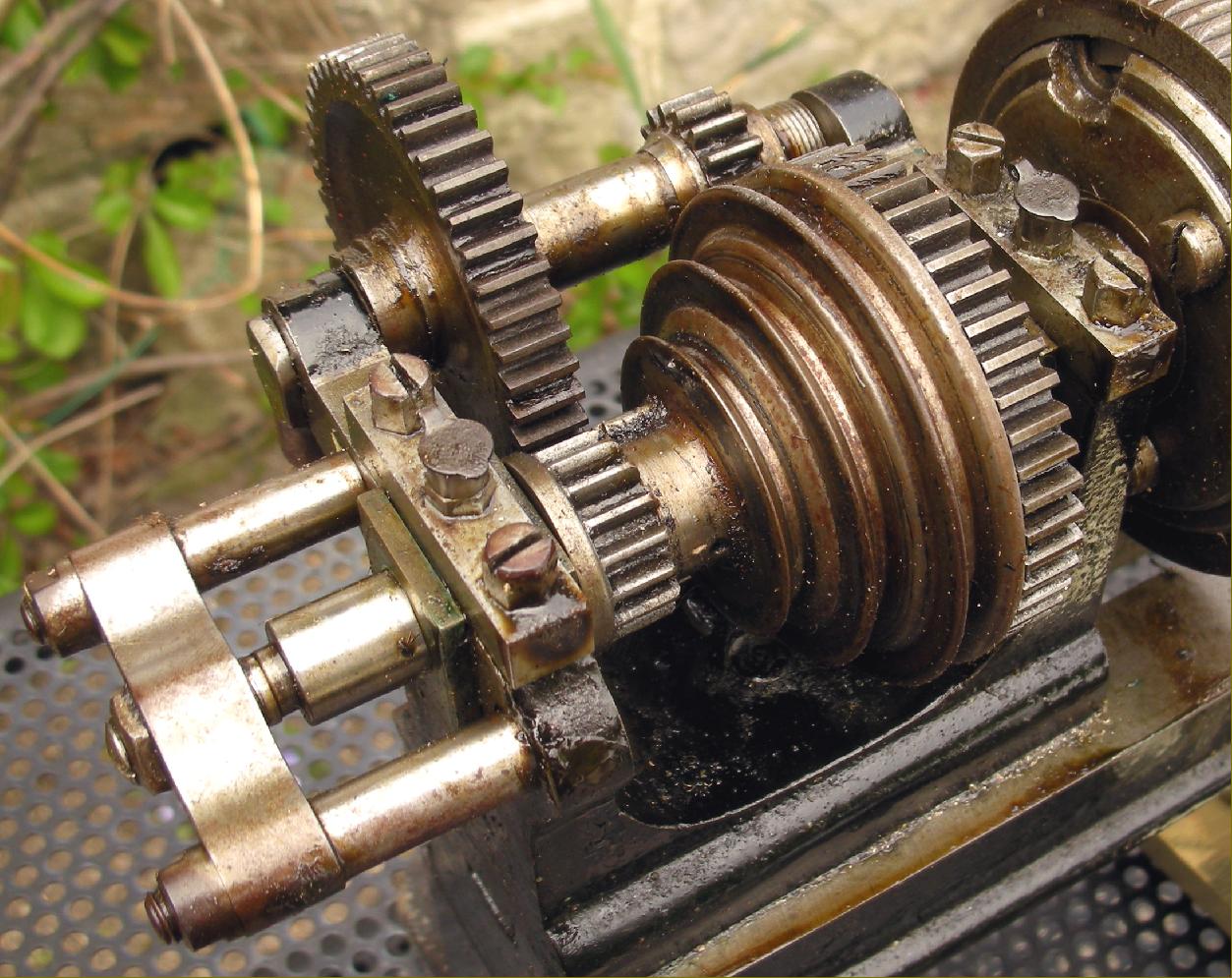

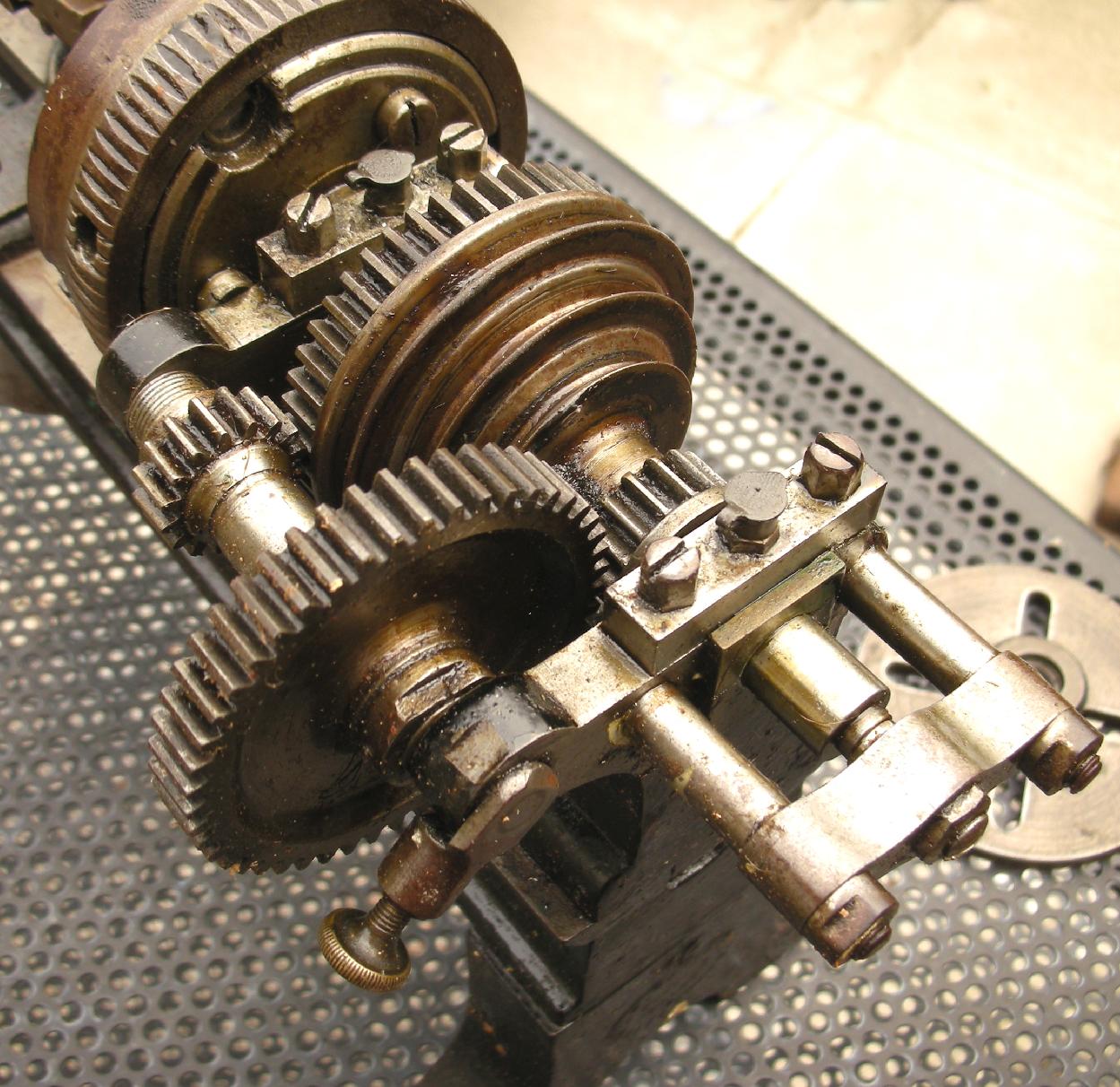

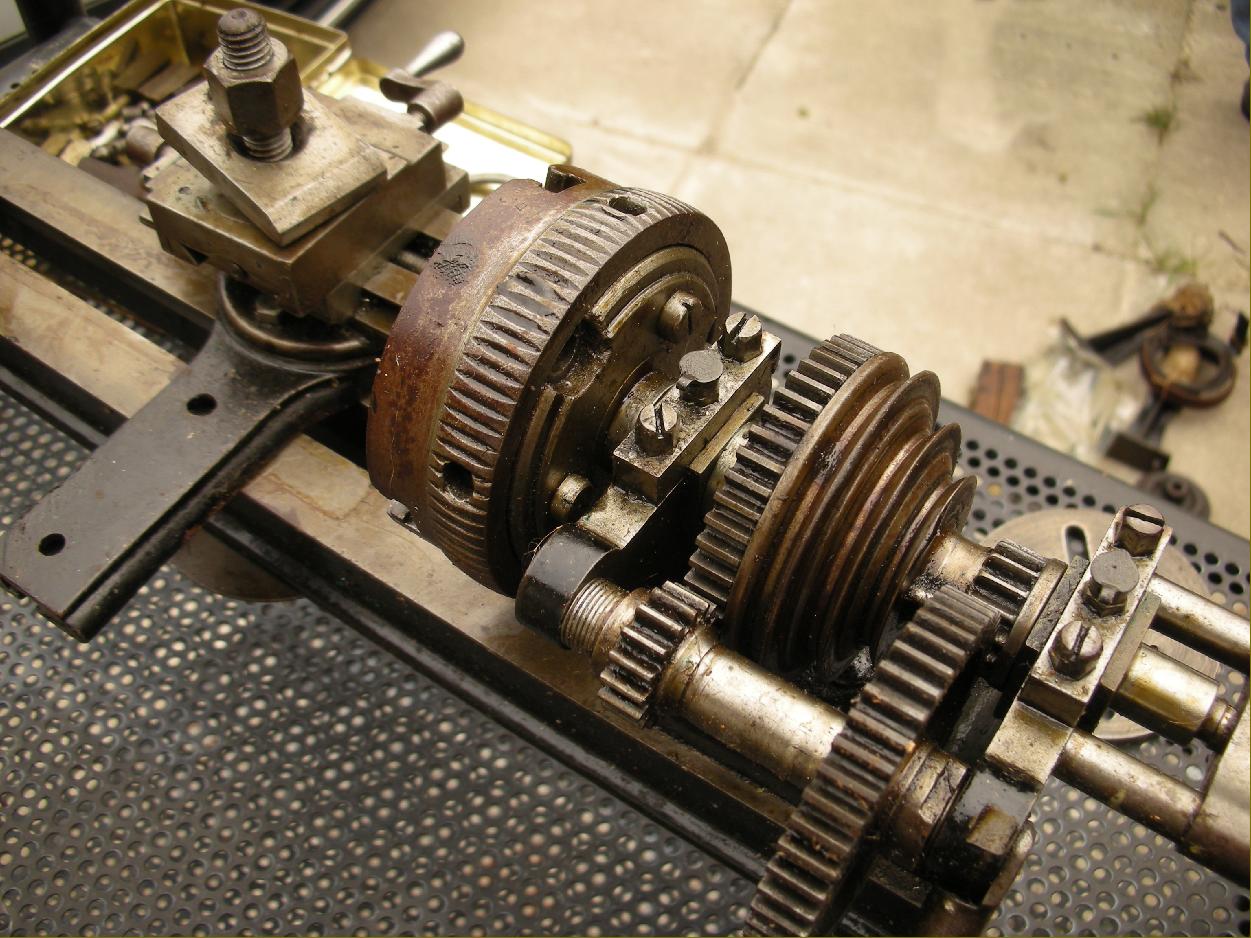

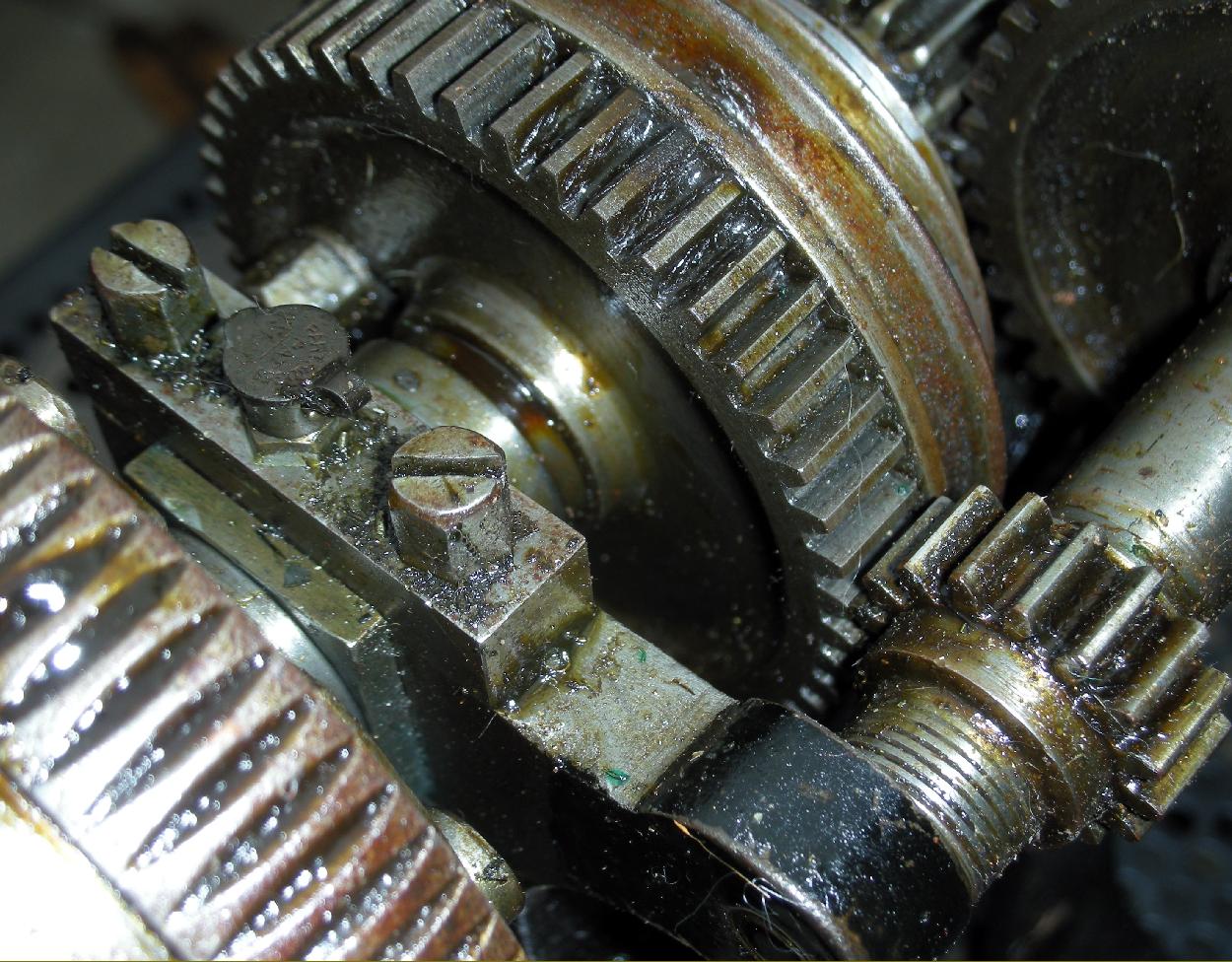

Of straightforward design, and not unlike a small version of the far more common English Britannia and (more highly specified) Holmes lathes, the T.Taylor exhibited considerable care in its construction with, amongst many other touches, a fine finish to turned and hand-made parts, a number of custom-made nuts and bolts and the smaller gear on the spindle constructed with an integral flange. The lathe would have been expensive to produce and, with its very limited capacity, at whom it was aimed is unclear. It was not in the same class as the (generally larger) German Lorch Schmidt and Boley lathes of the same era, nor would it have offered competition for the very accurate but expensive American bench precision lathes as made by Stark and others - though these latter were, in any case, imported to the UK in only tiny numbers. The general appearance of Taylor headstock was of a contemporary large lathe in miniature - even to the parallel-bore "box" type headstock bronze bearings and with the solid spindle having its end thrust absorbed against a plate supported on a pair of bars bolted to the end face of the headstock. However, one other T.Taylor lathe is known and this used (amongst many other detail differences) tapered bronze headstock bearings - a more conventional approach at the time for a miniature precision machine. Although a 6 : 1 ratio backgear was fitted - not usually a requirement on so small a lathe - no screwcutting or power feed to the carriage was provided and nor does there appear to have been any provision to fit it. Drive was by a round leather "gut" rope to a 3-step pulley - the makers providing a simple, non-adjustable countershaft and an extra pulley to match that on the headstock.

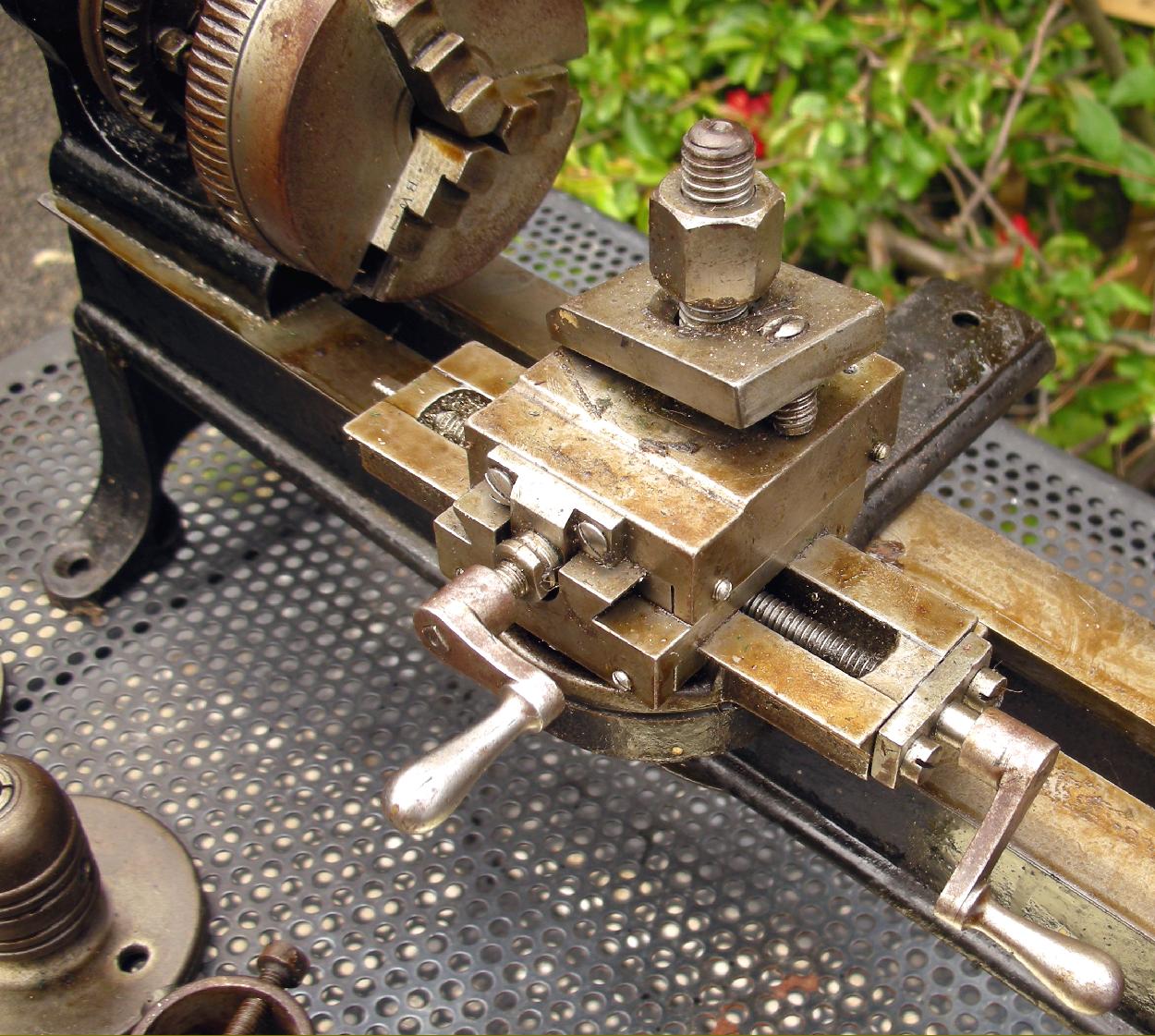

In order to give a reasonable travel to the top slide this was arranged, like those fitted to watch and clockmakers' lathes, to be of considerable length. Strangely, the cross slide had only a little over an inch of movement before the upper section ran off the lower casting and the gib strip (with only two adjustment screws set at the very ends of the slide) became unsupported. However, this serious shortcoming was compensated for to some extent by the ease with which the very long base of the compound could be slide forwards and backwards on its securing T bolt. Life for the operator was not easy for, typical of most other small lathes made at the time, the feed screws lacked micrometer dials and were fitted with simple crank handles - especially difficult things for the operator to control on fine work.

Supplied with the usual hand T-rest the makers confirmed their opinion of the lathe as belonging to the precision class by including (probably at extra cost) a split collet set together with a spindle nose compression holder.

If any reader has a machine tool by T. Taylor (the name was cast into the bed feet) the writer would be interested to hear from you.

More pictures of the T.Taylor lathe here and their planer here..

Below is some additional and very interesting information posted by the machine-tool expert "Asquith" on http://www.practicalmachinist.com/vb/antique-machinery-history/very-old-t-taylor-lathe-anyone-know-anything-167171/

I take a great interest in lost Manchester manufacturers (they're nearly all lost now, sadly), and T. Taylor gave me something to get my teeth into. A photo of a Taylor lathe and of Rammerc's(?) planer on Tony's site helpfully show the address as 74 Chester Street, Hulme. From the various old trade directories that are online, together with some maps, and with Mrs Asquith's probing of the old census returns, we can pretty well pinpoint Taylor's premises at particular times. We know he was at No. 74 in 1861 and 1876. In 1861 and 1863 he was listed as a cutler. He was born in Sheffield, the epicentre of English cutlery making. In the 1871 census he was listed as a mechanic, and as a master mechanic in 1881. The 1876 trade directory has him as a tool maker, still at No. 74.

In 1879, 1883 and 1886 he was also listed as a tool maker, but now living across the street at No. 65 Chester Street. At the moment, the trail has gone cold after 1886. Unfortunately, Thomas Taylor was a very common name in Manchester.

We can conclude that a machine with No. 74 in the address was built before 1879, but how much before, we don't yet know. We know that Nos. 65 and 74 were where he lived, and we know that 74, at least, was his business address. Did he actually make the machines there? We know that No. 74 was subsequently occupied by a hairdresser and a fried fish dealer, which gives an idea of the type of property. In fact the whole area consisted of mean little terraced houses and shops, with a few small industrial buildings.

I have managed to find an old photo which almost pinpoints No. 65, the Global HQ of this maker of long-lived machine tools:- http://images.manchester.gov.uk/web/...e&refirn=58479 Impressive, eh? Let me present the evidence: we know from the old trade directories that Nos. 65 & 67 were on the south side of Chester Street, straddled by Duke Street and Kingston Street. No. 67 was occupied by a coal dealer. Reference to the highly detailed 1844 Ordnance Survey map (an excellent Alan Godfrey Maps reprint), shows a building about 60 ft by 40 ft, next to a Coal Yard.

The photo in the link above was taken in 1933, and I'm fairly certain that it is taken from Chester Street, with Kingston St on the right, and what appears to be a coal dealer in the foreground, with its little carts for customers' use. The building to the left of it, I believe to be No. 65. It is typical of the 'corner shops' of that time and place, familiar to viewers of TV's 'Coronation Street'. We know from the directories that No. 65 did become a shop, and at one time 65 & 67 were owned by a dairyman.

It's hard to believe that the machines were made there, but based on my findings of other old Manchester engineers, I certainly would not rule it out. If he bought the castings in, and wasn't too ambitious with his order book, what's to say he didn't make them there?

Incidentally, just 500 yds south west of here was an unimposing factory where Henry Royce made electrical equipment, cranes, and the first Rolls-Royce cars:- http://images.manchester.gov.uk/web/...e&refirn=27102

500 yds north of Taylor's was Galloway's engine works, and 600 yds north east was the Crossley Brother's first engine works.

came across another example of a T Taylor lathe, now in use for wood turning:-

My old lathe a T.Taylor from the turn of LAST century! : Wood Turning - Lathes - UKworkshop.co.uk

An interesting feature is the finish on the bed ways, as machined with a broad-nosed planing tool.

Moving on: Looking at the 'sold' adverts on Tony's website, I came across this:-

SOLD: TAYLOR lathe - 2.25" x 10" (55 mm x 250 mm) miniature backgeared plain-turning lathe. The only known example as manufactured by T.Taylor of Chester Street, Hulme, Manchester. ……. this lathe was, until recently, in the possession of the Gardner family of diesel-engine fame and stored unused for many years.

Those familiar with Gardner engines will be aware of their quality. Lawrence Gardner started off in a small way, and early products included coffee roasters, hot air engines, and dentists' chairs! Bear with me, it gets a bit more relevant.

went to a superb book, L Gardner & Sons Limited - Legendary Engineering Excellence by Graham Edge (available again, highly recommended) and learned that Lawrence Gardner started on his own in 1868. 'His first premises were rather basic and cramped, being located in adjoining cellars under four houses in Duke Street, off Stretford Road, Manchester. Machinery such as a boiler and lathe had to be lowered into the cellars through a trapdoor in the pavement. ….. Lawrence, Anne, and their children lived in one of the houses above the workshops and the others were sublet.' Note the reference to Duke Street, Thomas Taylor's premises also being adjacent to Duke Street. In fact the old directories show that Lawrence Gardner was listed under 'Engineers & Machinists' and also 'Sewing Machine Makers' at 7 Duke Street (Upper). This was 300 yards south of Taylor's, and as far as I can make out from the old maps, the premises were very similar in layout to Taylor's at 65 Chester Street. Gardner's Upper Duke Street property was at the end of two adjacent rows of terraced houses which faced onto Dale Street and Bonsall Street. To my mind this similarity strongly reinforces the likelihood that Taylor's machines were made in those unlikely-looking premises.

It would be nice to think that the little lathe, that someone bought off Tony's website, had been saved by the Gardner family as a memento, and used by Lawrence Gardner himself..

|

|