|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||

|

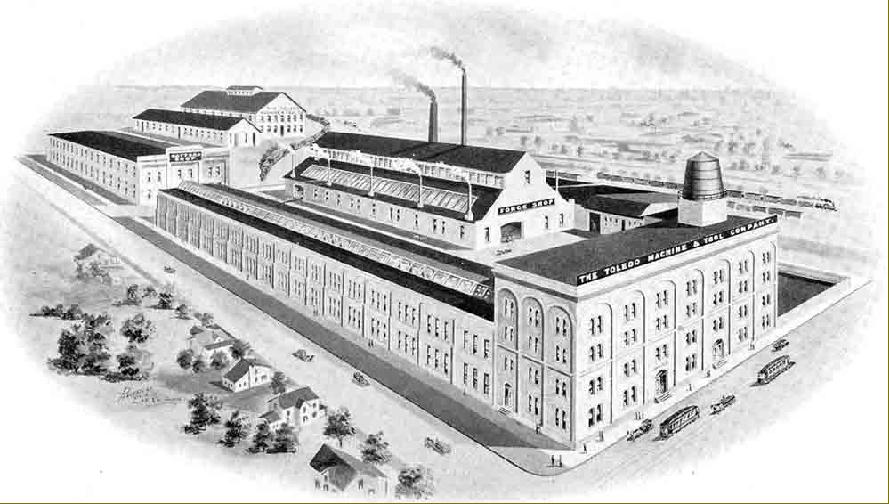

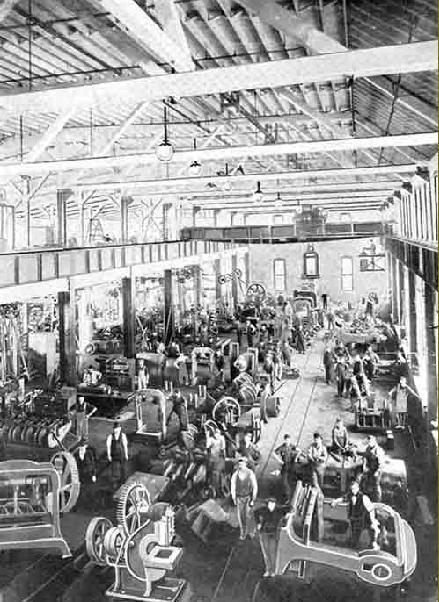

Founded in 1888, the Toledo Machine and Tool Company (of Toledo, Ohio, USA) at first specialised in heavy types of metal working equipment including open-back, straight-side, double-crank, punching and horning, toggle-drawing, screw and trimming presses, horizontal bending machines, drop hammers, shears and machinery for the manufacture of pierced tinware and stoved parts. In addition to listing a total of twenty-eight different machine types in their 1909 catalog, they also advertised the ability to construct special sheet-metal working machinery to a customer's particular requirements. The firmwas developed under the direction of Henry Hinde who, in 1890, purchased an interest in the concern when it has just 20 employees and a value of around $30,000. In November of the same year the company was incorporated and Mr. Hinde named as president and general manager. In 1897 Hinde and his brother Louis bought the company and acquired property at Hastings and Dorr Streets where a factory, named by them as the "Plant No. 1" was erected. In 1918 further expansion took place with a new factory being built at Westwood Avenue and Dorr Street, a location that also became home to a foundry at first able to produce 1200 and eventually 2,200 tons per month. By the early 1920s the company had over 1600 employees and were one of the leading producers of power presses in the United States; in 1922 a controlling interest was purchased by a brokerage house for $4,000,000 and by the 1930s the firm had been absorbed into the E.W. Bliss group. Hinde, by now a very rich man, retired. |

|

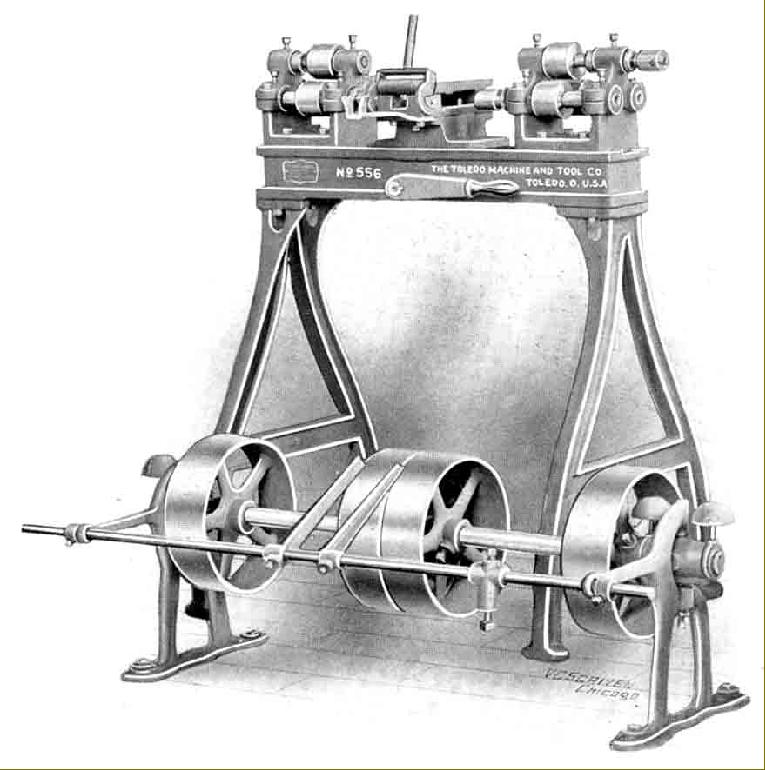

The "baby" of the Toledo lathe the 16-inch swing spinning lathe weighed a modest 600 lbs and was designed, according to the makers for: spinning, trimming, flanging, curling and wiring edges; for burnishing pressed, stamped or drawn work in brass, copper, tin, aluminium, steel or black iron. |

||

|

A specialised machine the "Double-head drilling lathe" designed to bore holes through the D part of shovel handles and able to drill two holes from each side meeting in the centre "thus making a neat, uniform appearance where the rivets enter" A fifth or extra spindle could be used to counter bore the holes so that the job was finished at one setting. |

||

|

Model 324 (No. 4) 20-inch swing 1300 lb spinning lathe with 2.5-inch wide, 3-speed flat-belt drive. The lathe is shown equipped with the "plain" tilting attachment able to both do beading (or "curling") rolls and a trimming cut |

||

|

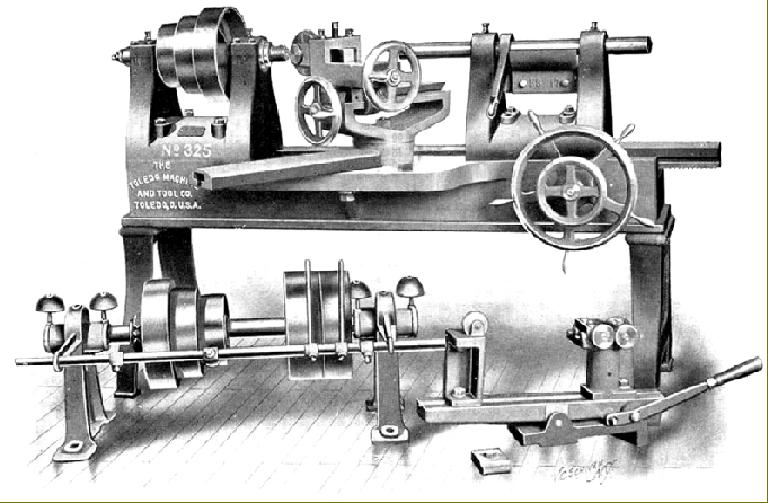

Model 325 (originally the No. 5) 24-inch swing 1900 lb spinning lathe shown complete with a range of accessories including a screw-feed compound slide rest, spinning roll, tilting attachment with beading roll, trimming cutters and an adjustable, moveable tailstock with quick-action rack-and-pinion drive. This slightly less powerful model was fitted with a 3-speed drive system that used belts 3 inches wide. |

||

|

Originally cataloged as the No. 6 lathe, this massive 3400 lb machine was subsequently referred to as the Model 326 and supplied as standard with an 80-inch long bed and a swing of 30 inches. Driven by a 4-inch wide flat belt from a 200 r.p.m. countershaft, the lathe would have had adequate reserves of power to spin thicker-than-normal work - as well as being suitable for heavy-duty burnishing and bead turning on larger diameters. |

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||