Tillico Lathes - Australia

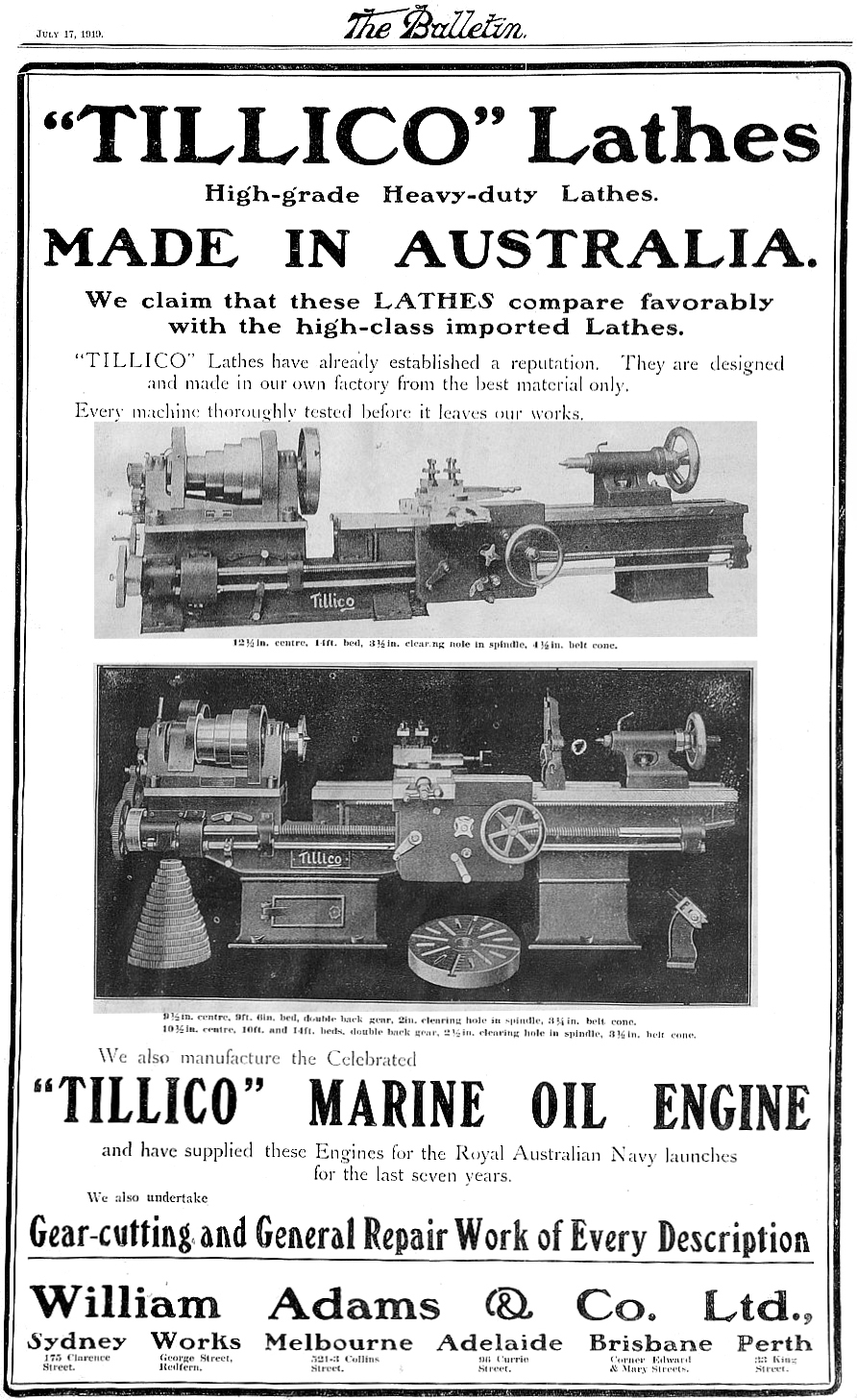

Manufactured by the J.E.Tilly Company in Australia, little information survives about the Brand. However, the maker was known for both their lathes - built with centre heights from 8 to 15 inches - and also a range of 4, 8 and 16 h.p. marine engines.

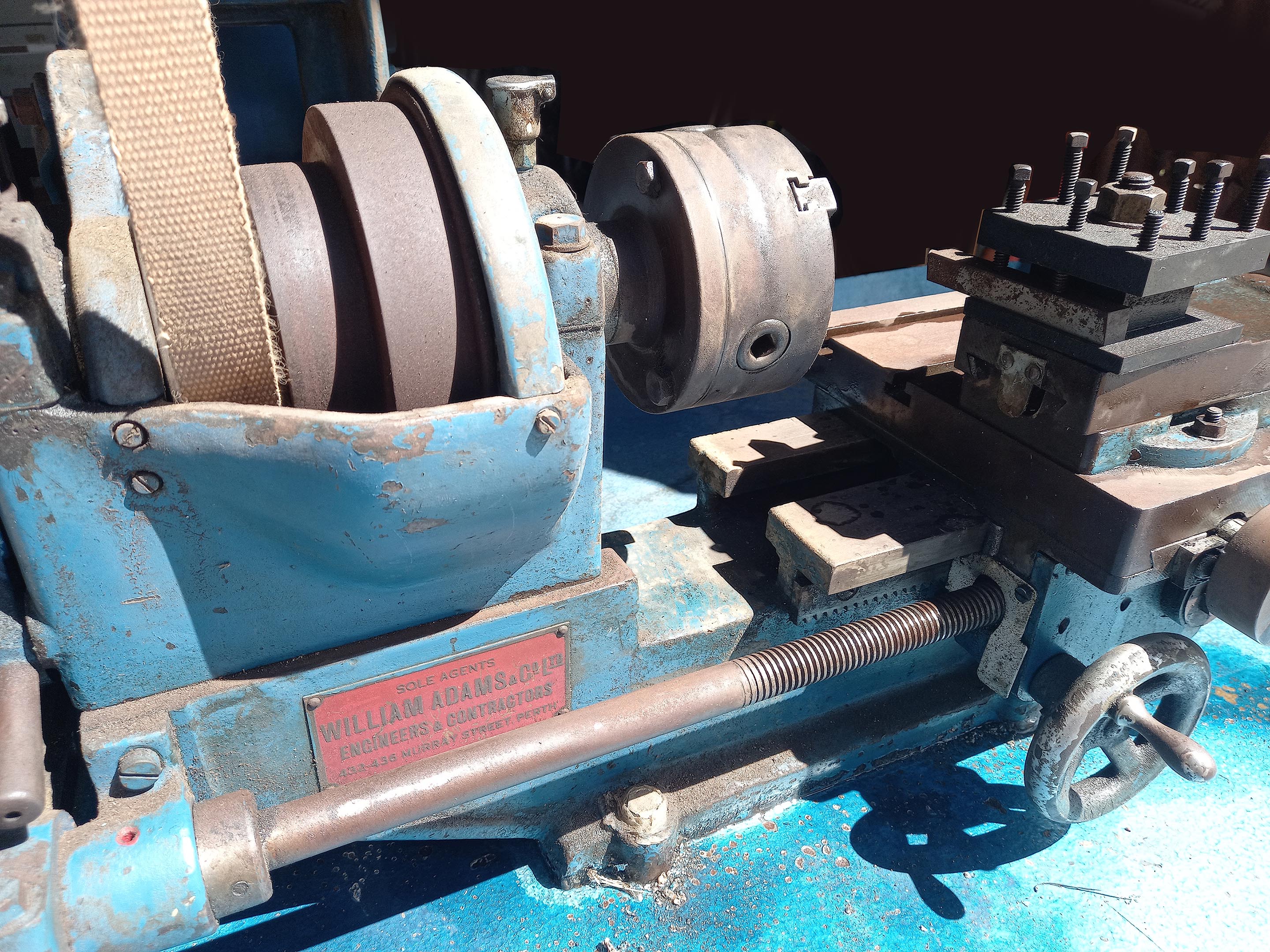

It appears that the sole selling agent was William Adams & Co. Ltd., a huge concern, founded in 1884 with a presence in Perth, Sydney, Melbourne, Adelaide and Brisbane. The company became one of Australia's leading dealers and distributors of steel, aluminium, machine tools, power transmission equipment, earthmoving and materials handling equipment.

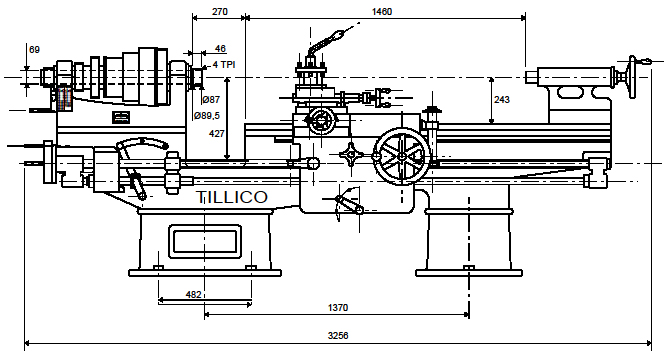

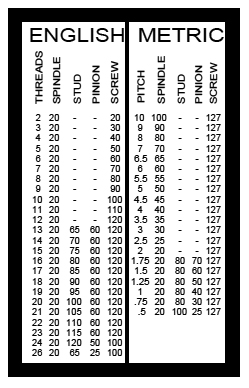

At least two surviving Tillico lathes are known - a bench-mount modelis shown below - the other, a much larger type dating from circa 1910 to 1925, had a deep gap-bed, backgear and screwcutting with a centre height of 9" and took 40" between centres. With the gap able to accommodate a disc around 33 inches in diameter, the lathe was heavily built and supported on two cast-iron plinths. Nine spindle speeds were provided, driven by a remotely-mounted countershaft - the maker recommending that it be arranged so that spindle speeds of 18, 28, 36, 43, 54, 83, 150, 230 and 350 r.p.m. were obtained. Screwcutting was by changewheels, of which a rather limited set was provided to generate pitches between 2 and 26 t.p.i and metric from 0.5 to 10 mm. Power sliding and surfacing feeds were by a separate power shaft with a simple, quadrant-lever 3-speed gearbox to give three rates for each setting of the changewheels.

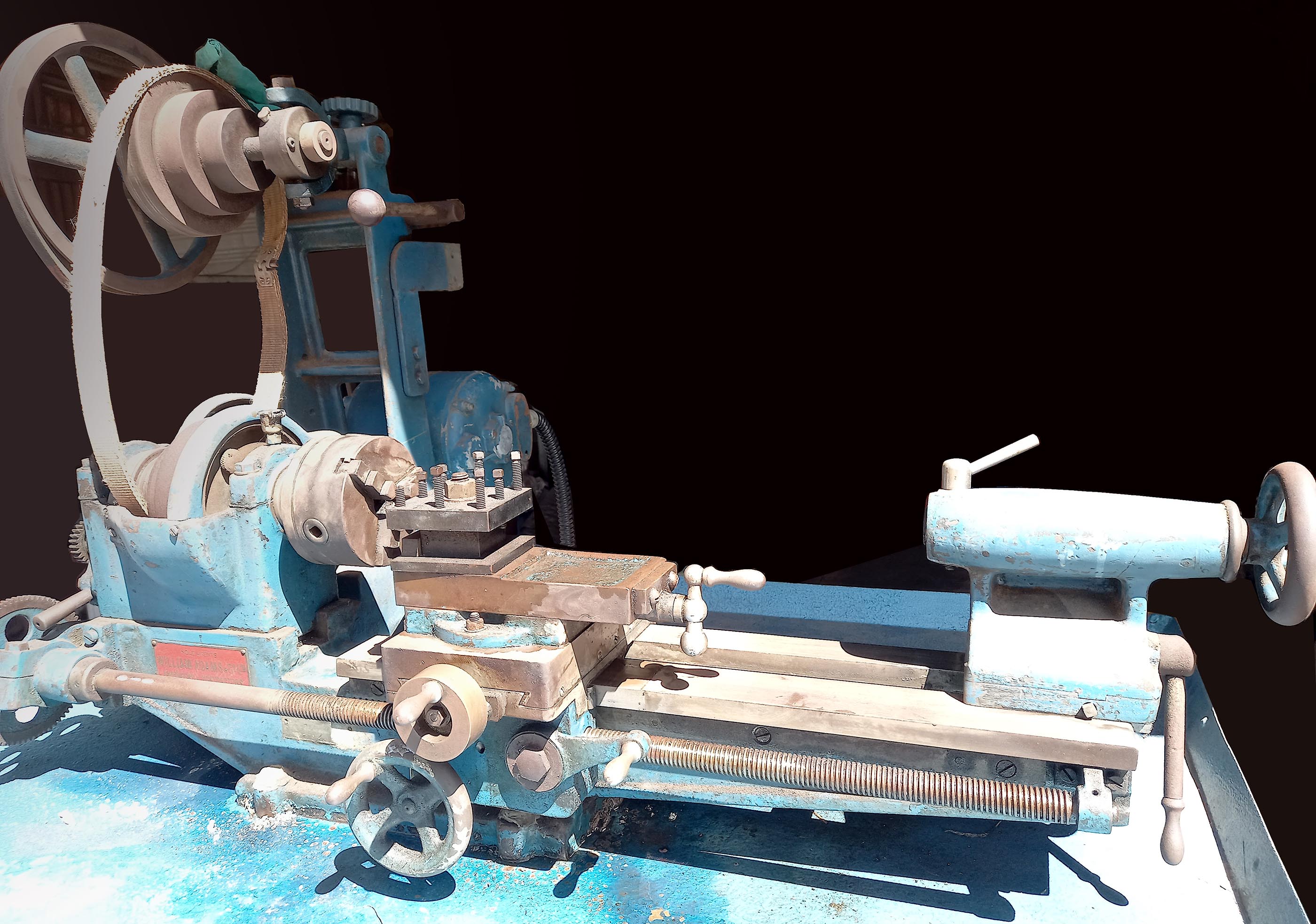

The smaller of the two known lathes appears, from its design and relatively heavy build, to have been made from the late 1920s to the 1940s. With a centre height of 4" and a capacity between centres of 14", the flat-belt drive to the backgeared headstock came from a tall but robust countershaft bolted to the back of the bed behind the headstock. The bed was identical in form to the larger lathe with what might be described as "English" pattern, rectangular-form ways; these being in a pair, set back-to-front with flat tops and narrow vertical guideways - exactly as used on the Series 7 Myford range.

Screwcutting was by changewheels, though a tumble-reverse mechanism, to a leadscrew of generous proportion - but unknown t.p.i.

Unfortunately bereft of micrometer dials, the compound slide rest assembly was heavily built, the top slide able to be rotated through 360° and carrying a 4-way toolpost, though the one fitted may not be an original part.

Unlike many small lathes of the era, this was a much more robustly constructed machine and capable of providing provided good, reliable service in the hands of less experienced operators working in repair and maintenance workshops.

If you have a Tillico, the writer would appreciate hearing from you.