|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

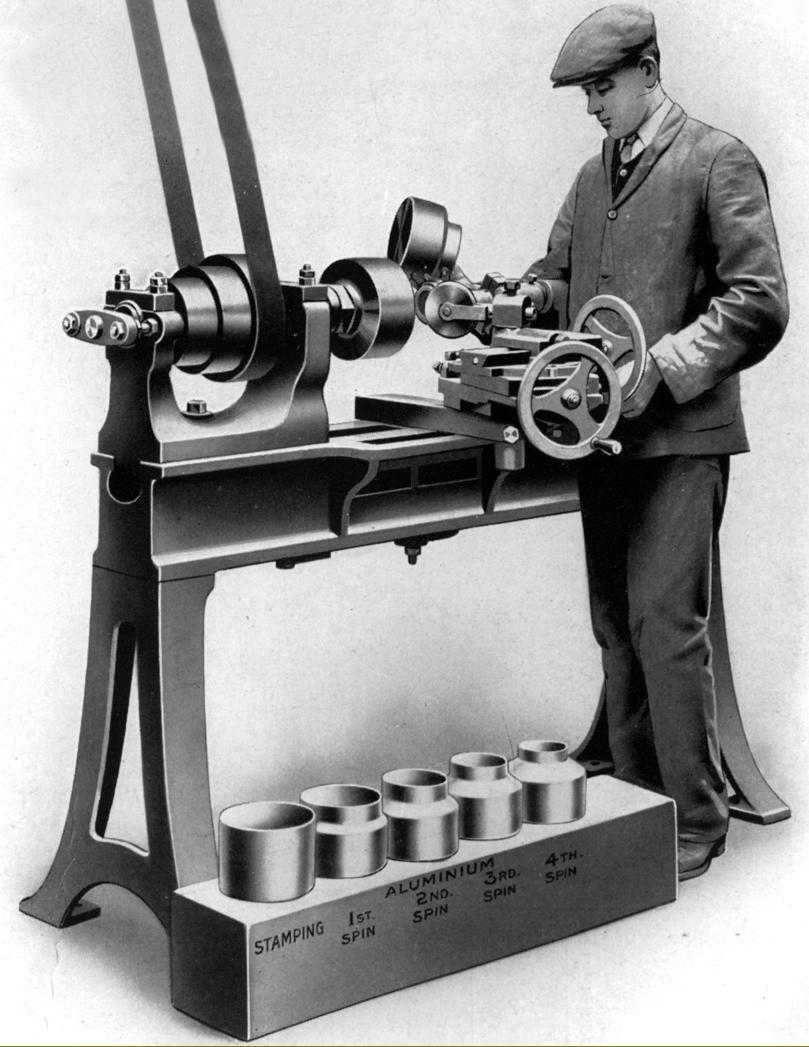

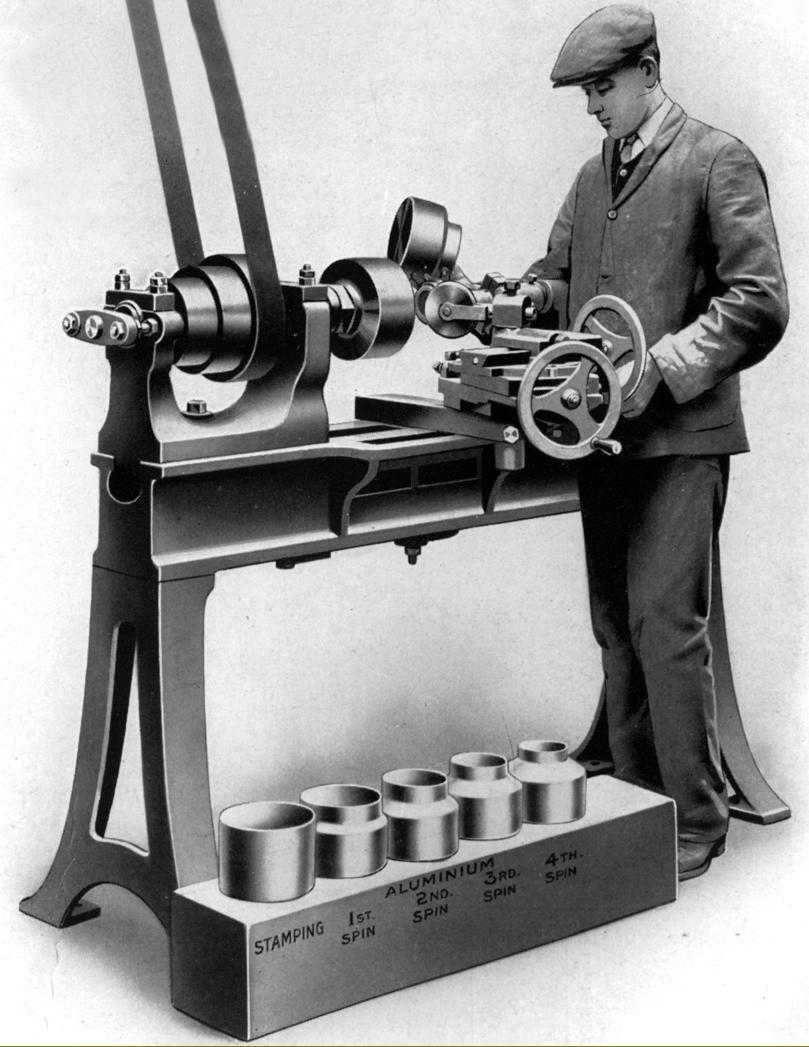

9-inch spinning lathe Model 866. The operator is producing, using the special production attachment shown below, bottle necked articles - job progress can be seen arranged on the floor stand.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

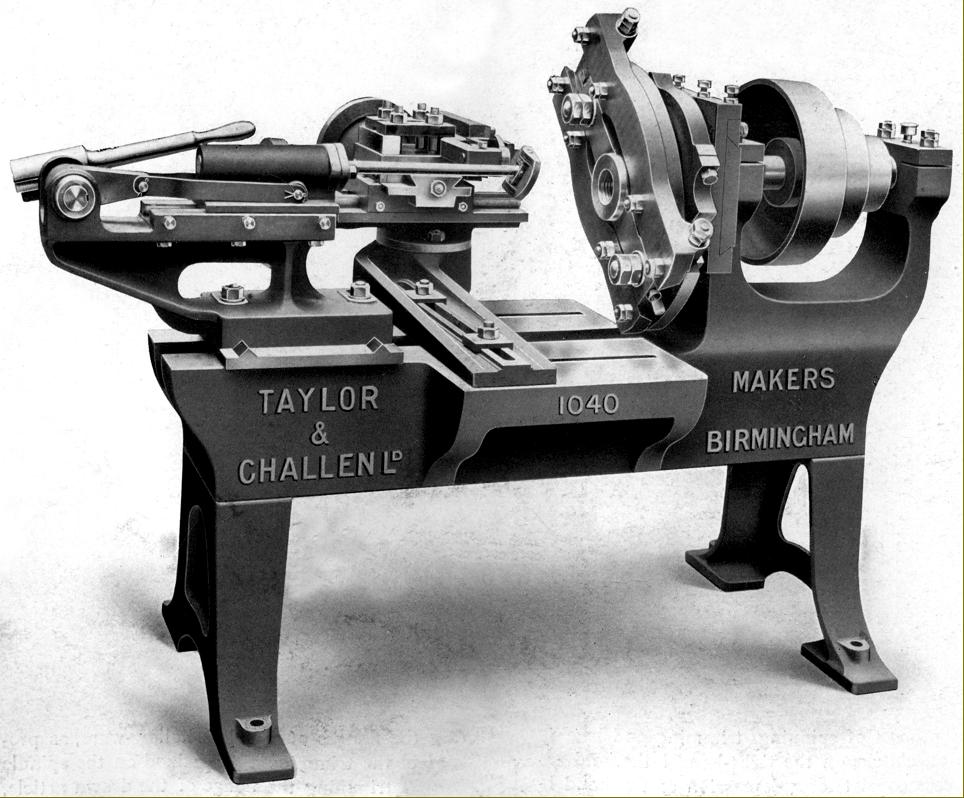

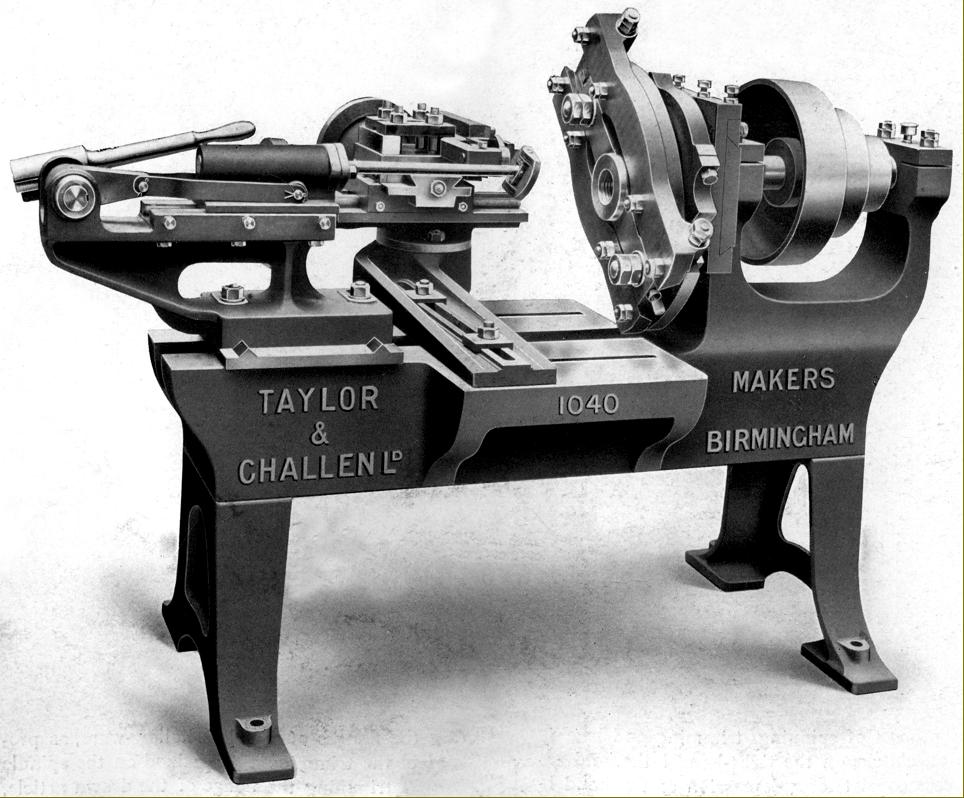

12-inch centre height lathe Model 1040 for oval spinning, trimming and beading. Using the same bed, legs and headstock as the Model 371 this version was fitted with a faceplate-cum-chuck arranged to give an eccentric motion - much like those employed on ornamental-turning lathes. The tailstocks was also specially arranged with the ability to be off-set to line up with the workpiece and its spindle fitted with a ball-thrust bearing and engaged against the job by a powerful spring held within a horizontal cylinder. The lathe was intended for the manufacture (or finishing of press work) of such items as oval frying and stew pans, bowls, basins and general sheet-metal work.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

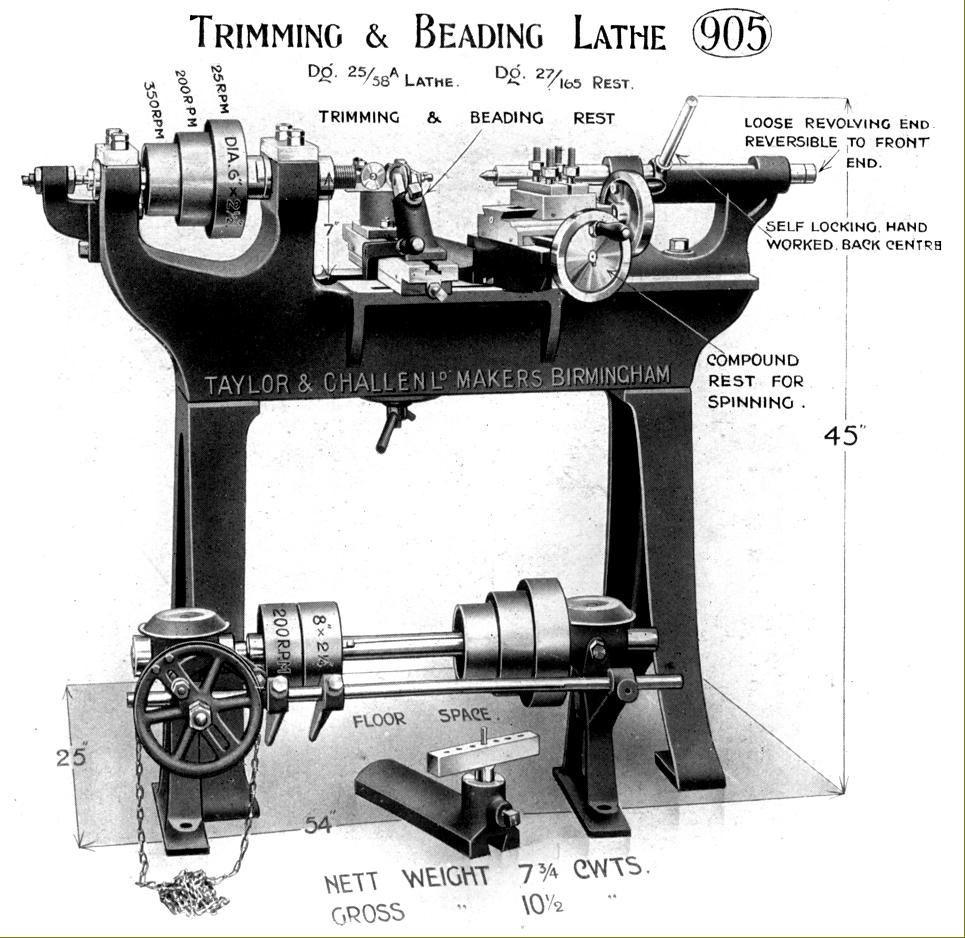

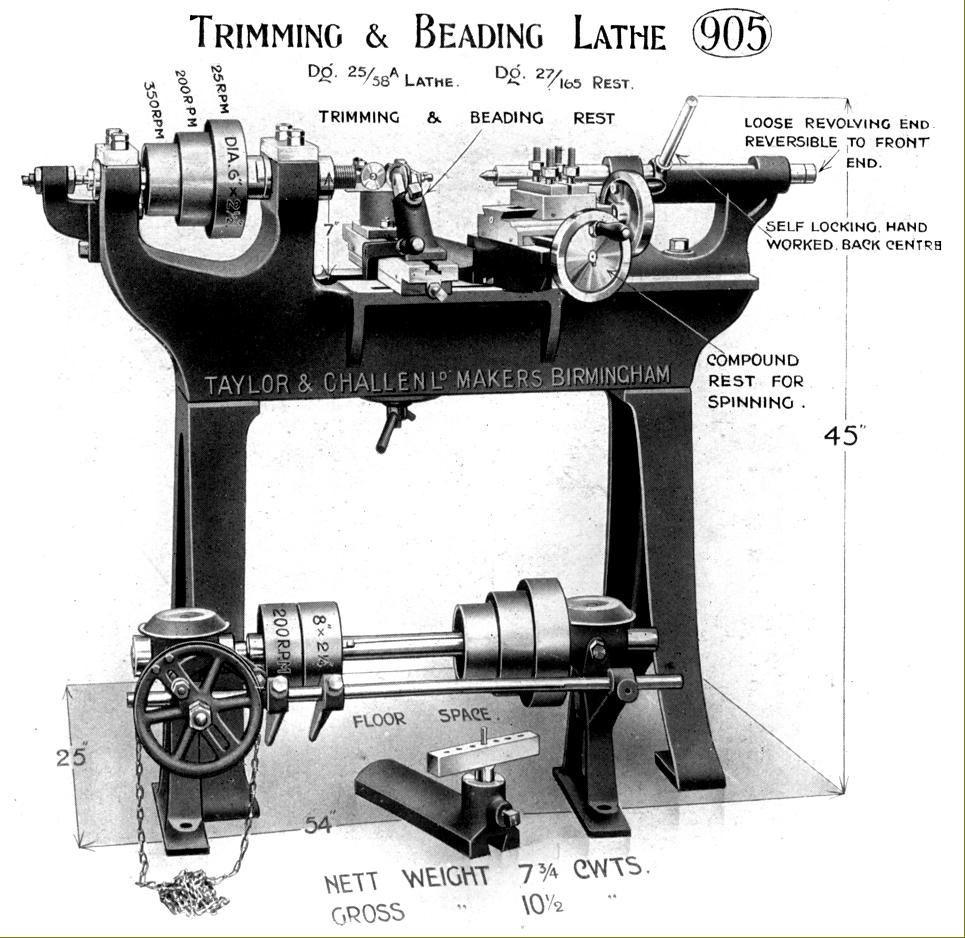

7-inch centre height Trimming and Beading lathe Model 905. The aim of this lathe was to smooth, by the action of a revolving roller, stamped articles with a tapered form produced in a drawing press. It could also, with the right attachment (No. 782) be used to trim off excess or uneven material on the rim by shearing (not turning) and then rolling over edge to give strength, rigidity and smooth, safe-handling form. It could also, using a technique called beading, include a stiffening wire in the rolled edge of the rim. A number of other attachments were available including a compound slide rest and the usual type of spinning rest with peg holes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

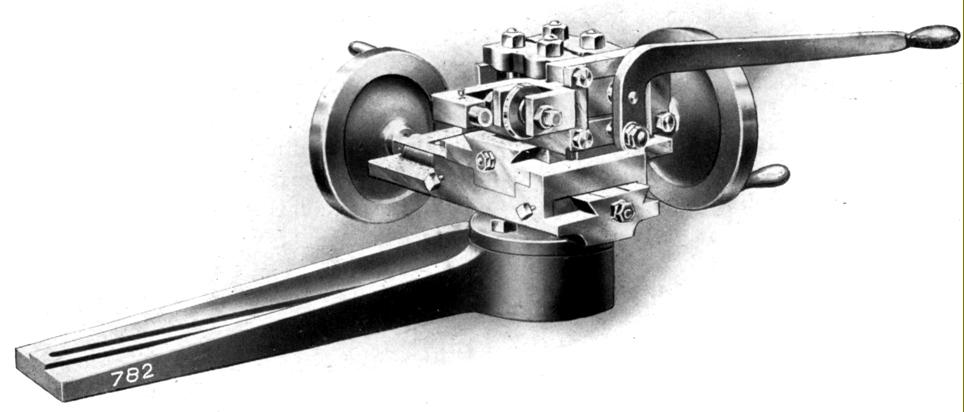

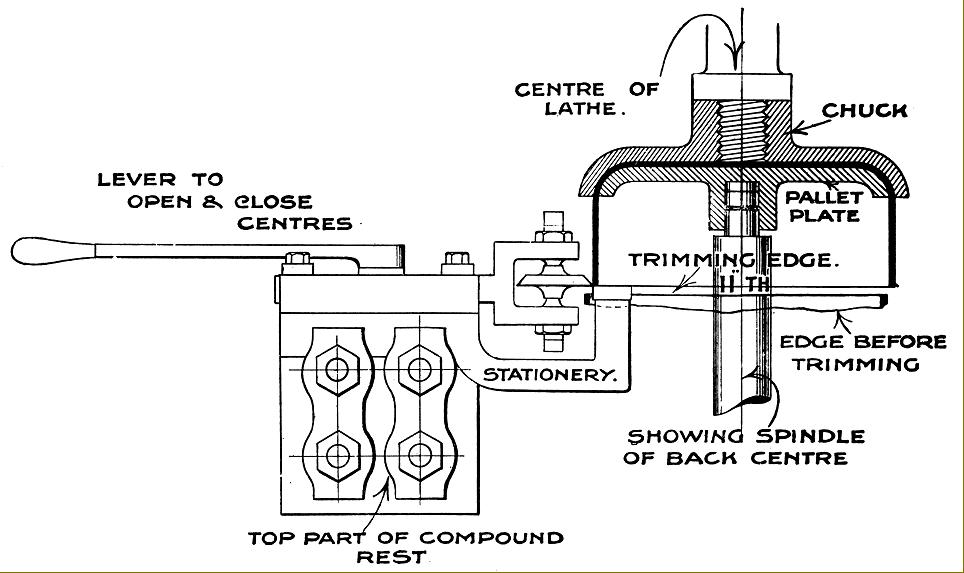

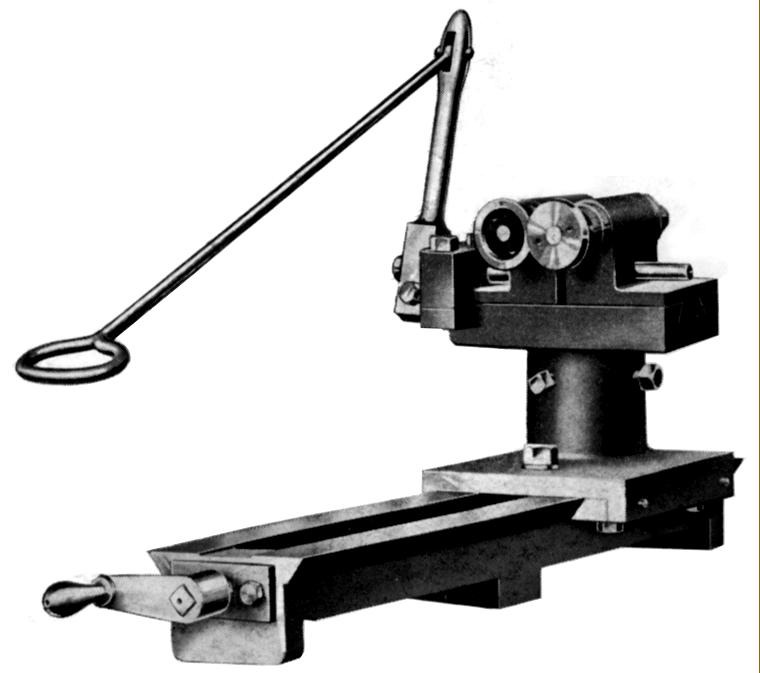

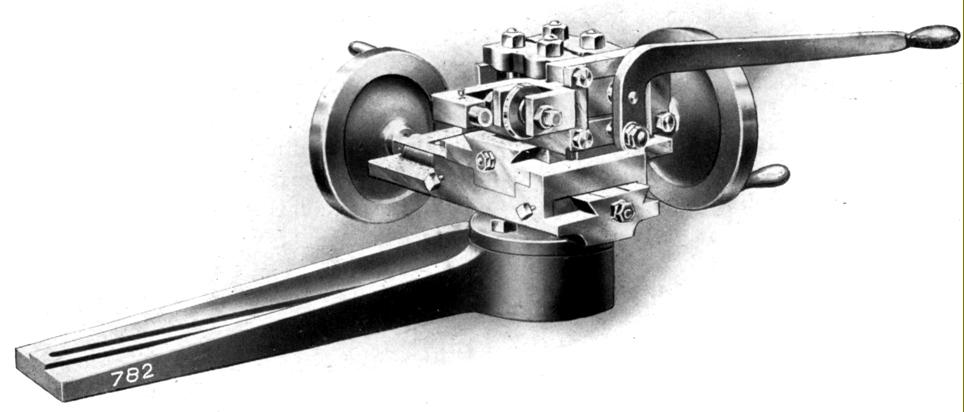

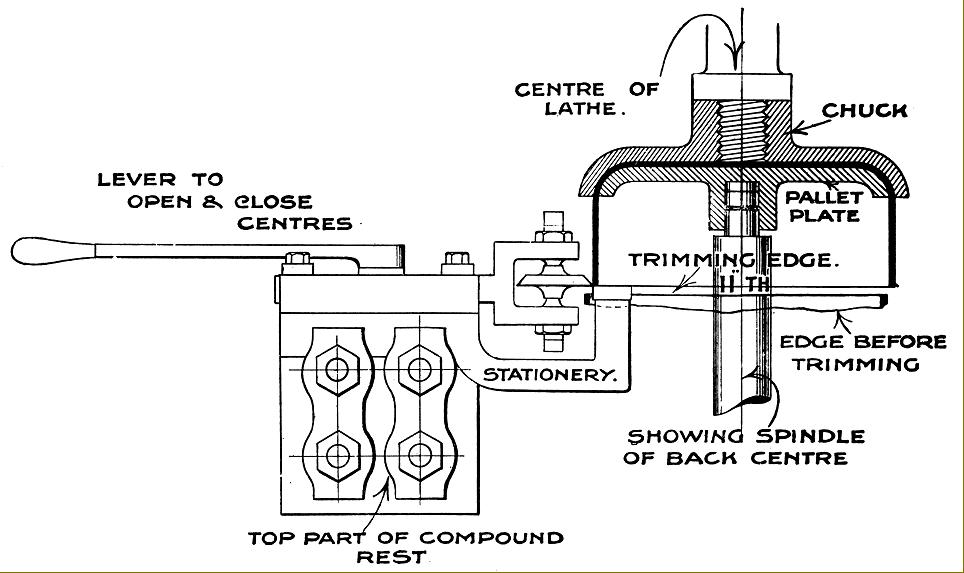

Trimming Attachment No. 782 for use on the 12-inch lathe Model 371 and 15-inch lathe Model 953. A similar but smaller version was also made for the 7-inch Model 905. The unit could handle cylinders and cups up to 16 I.W.G. steel. The arrangement diagram below shows the unit in plan and the method of operation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Trimming Attachment No. 782

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

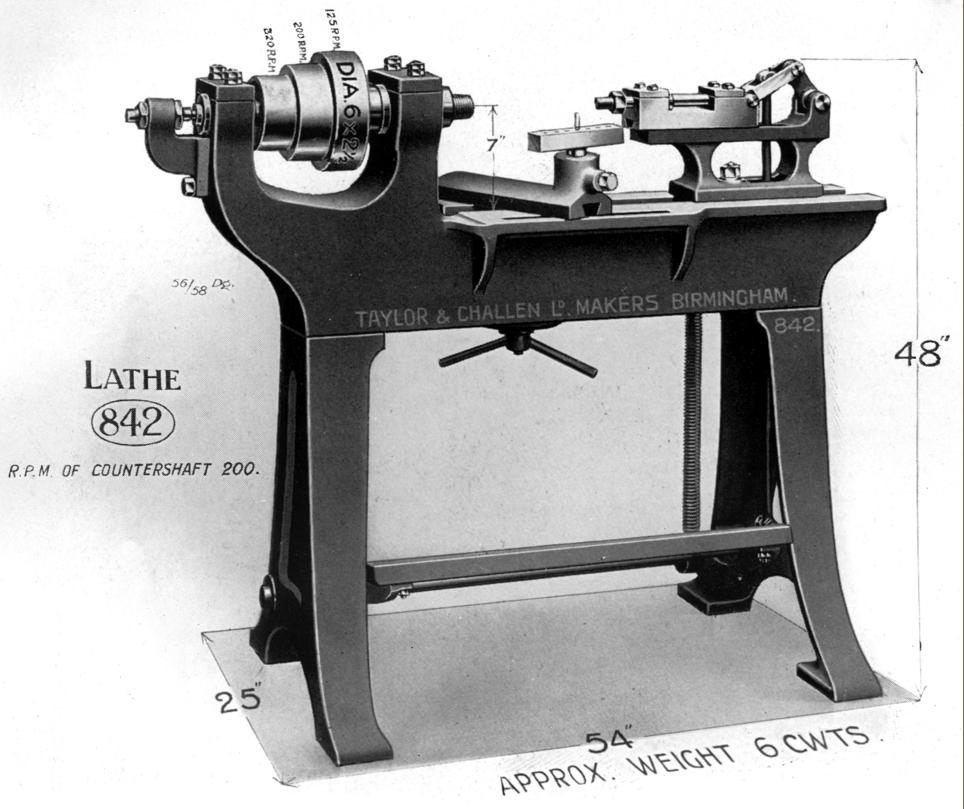

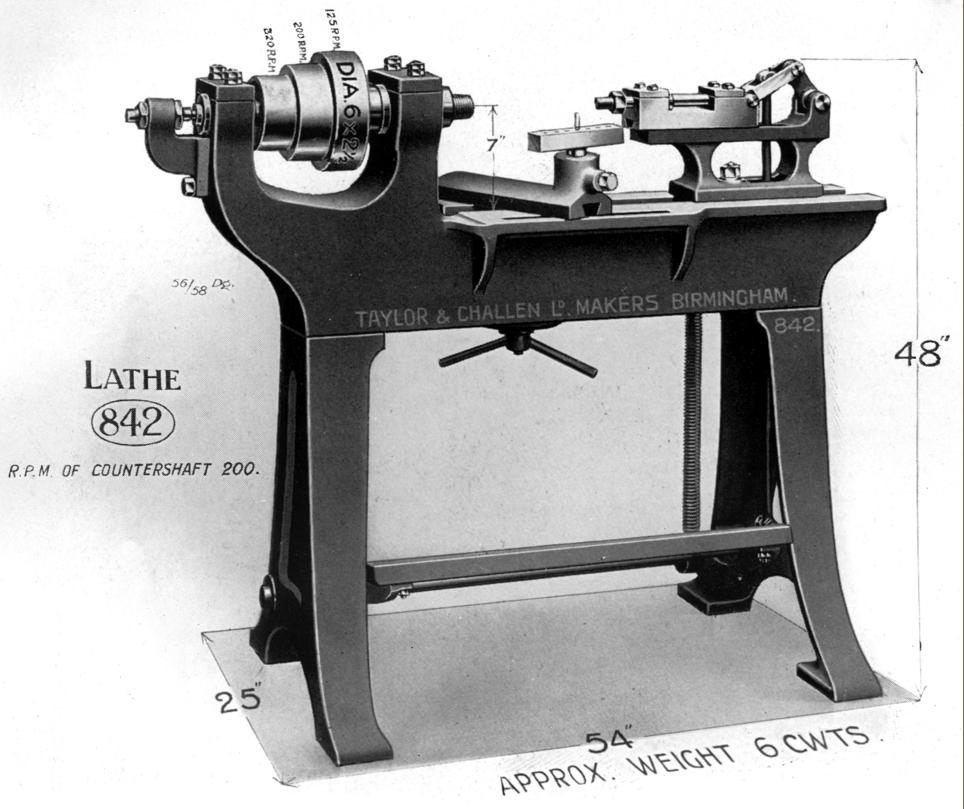

7-inch Spinning lathe No. 842. Intended for ordinary metal spinning the lathe could also be fitted with a trimming and beading rest as used on the Models 371 and 953. A foot-pedal was fitted to operate the tailstock spindle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7-inch and 12-inch Spinning, Trimming and Wiring Lathe Models 201 and 371. Designed for the finishing of seamless bowls, basins and pans after the drawing process, A hardened steel roller was fitted for spinning, a pair of hardened steel trimming cutters for trimming and a hardened steel grooved roller for wiring work. The lathe could also mount the special Trimming and Beading Rest No. 582 and Trimming Rest No. 583 - both accessory designed specially for this pair of models

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

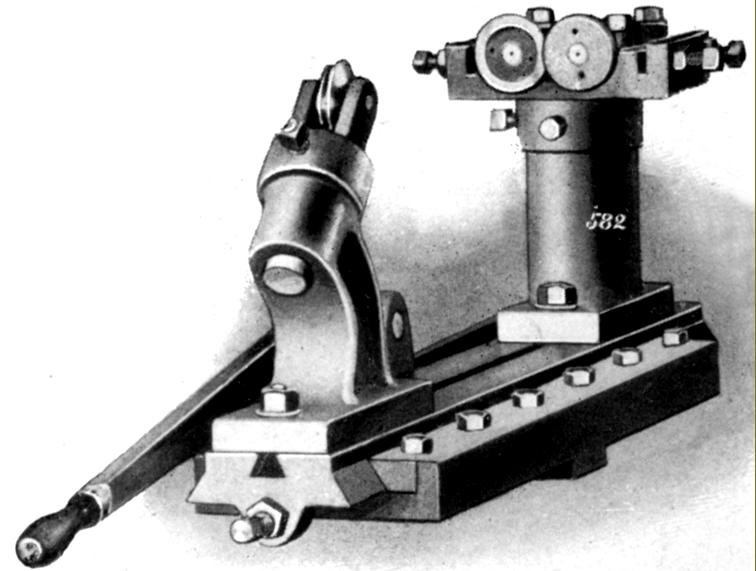

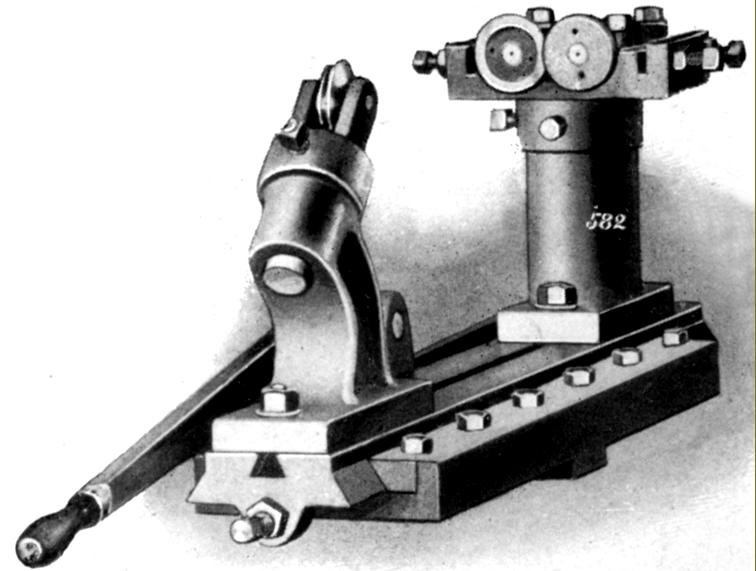

Trimming and Beading Rest No. 582 - a heavy (130 lb) accessory specially designed for the Taylor & Challen 7 and 12-inch lathes

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

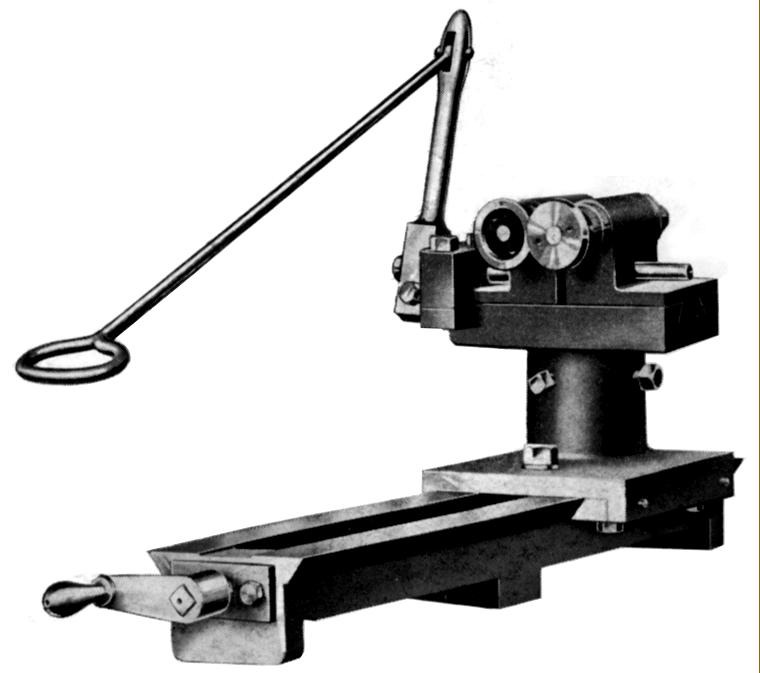

Trimming Rest No. 583 for the 7 and 12-inch lathes. Operated by the long handle, the pair of cutters opened and closed and could trim stampings with either straight sides or flanges at any angle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

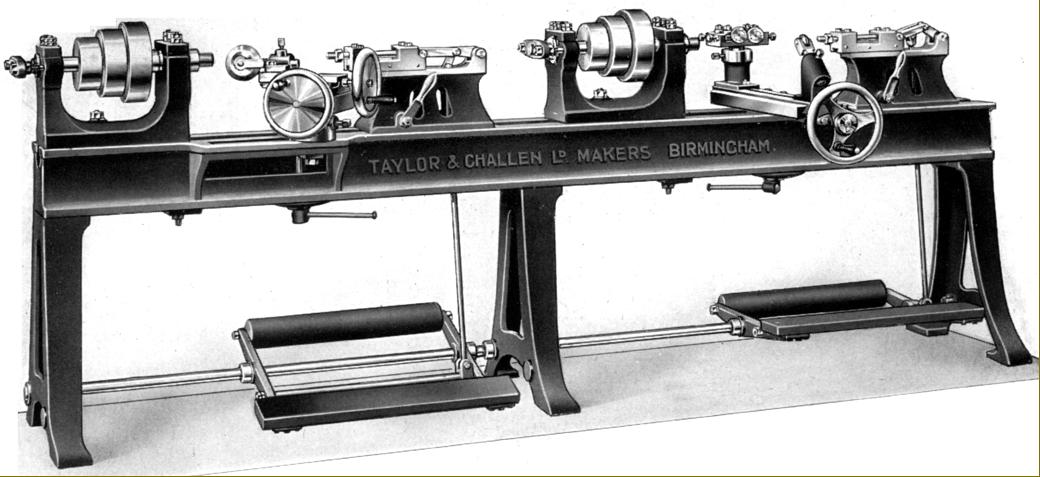

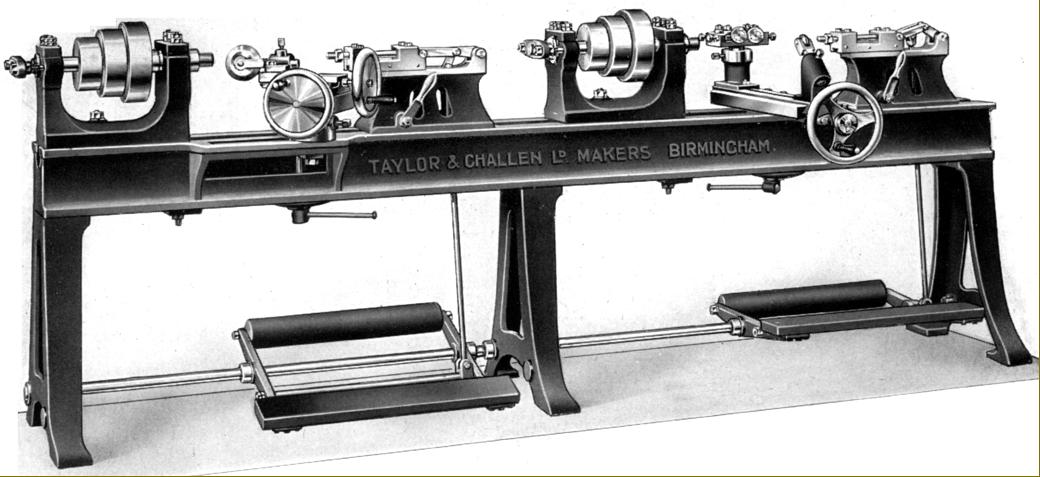

9-inch Double Spinning, Trimming and Wire Beading lathe Model 842. Weighing one ton, this lathe made economical use of one bed to allow two operators to work side by side. Spinning was carried out on the right-hand side with the work being passed to an operator on the left who trimmed and wired the job. A group of such lathes, suitably equipped, could be tooled to process a more complex job from start to finish. For even greater efficiency, the lathe was fitted with foot-pedal controls to operate the tailstock spindle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

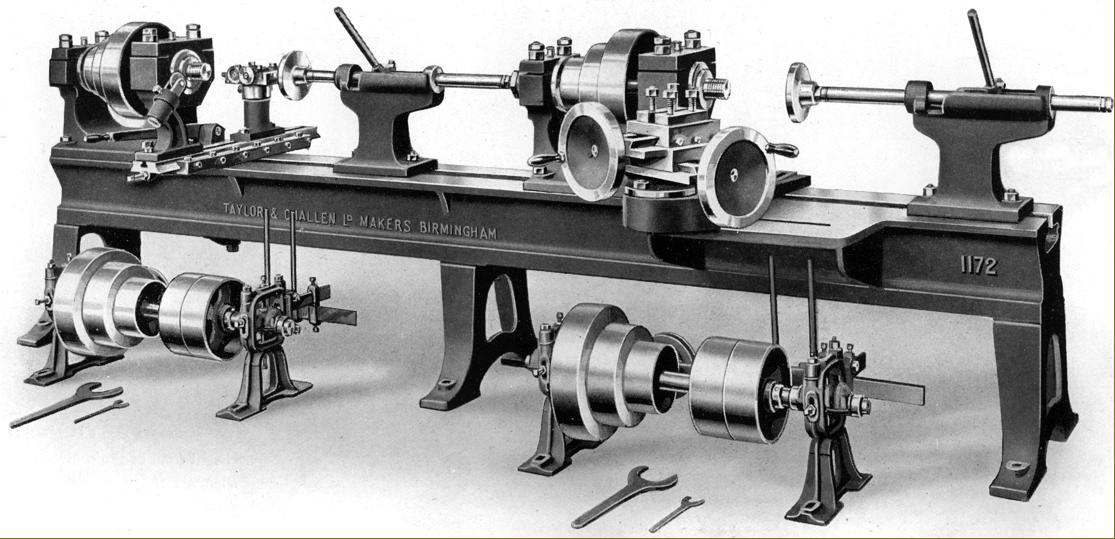

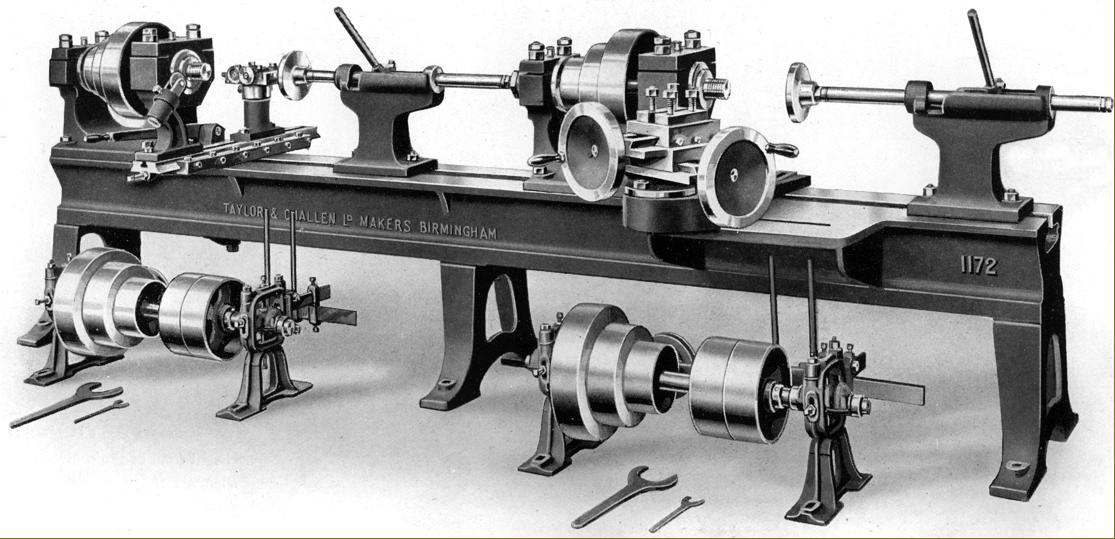

12-inch Double Spinning, Trimming and Beading lathe Model 1172. This was intended as a complete, heavy-duty unit - it weighed 2.2 tons - for continuous spinning on the right-hand side followed by trimming, beading or wiring on the left. The latter operation was carried out by a downward upward movement of the front-facing hand lever to trim the flange followed by an upward movement to advance the bending roller that curled over the flange to the required shape.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

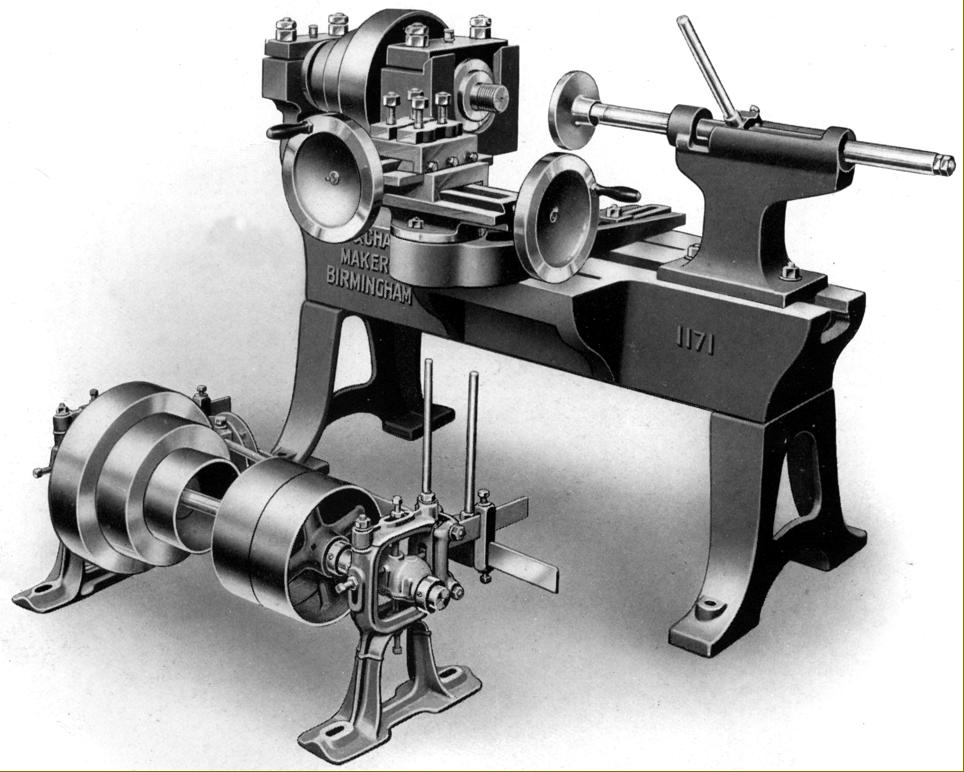

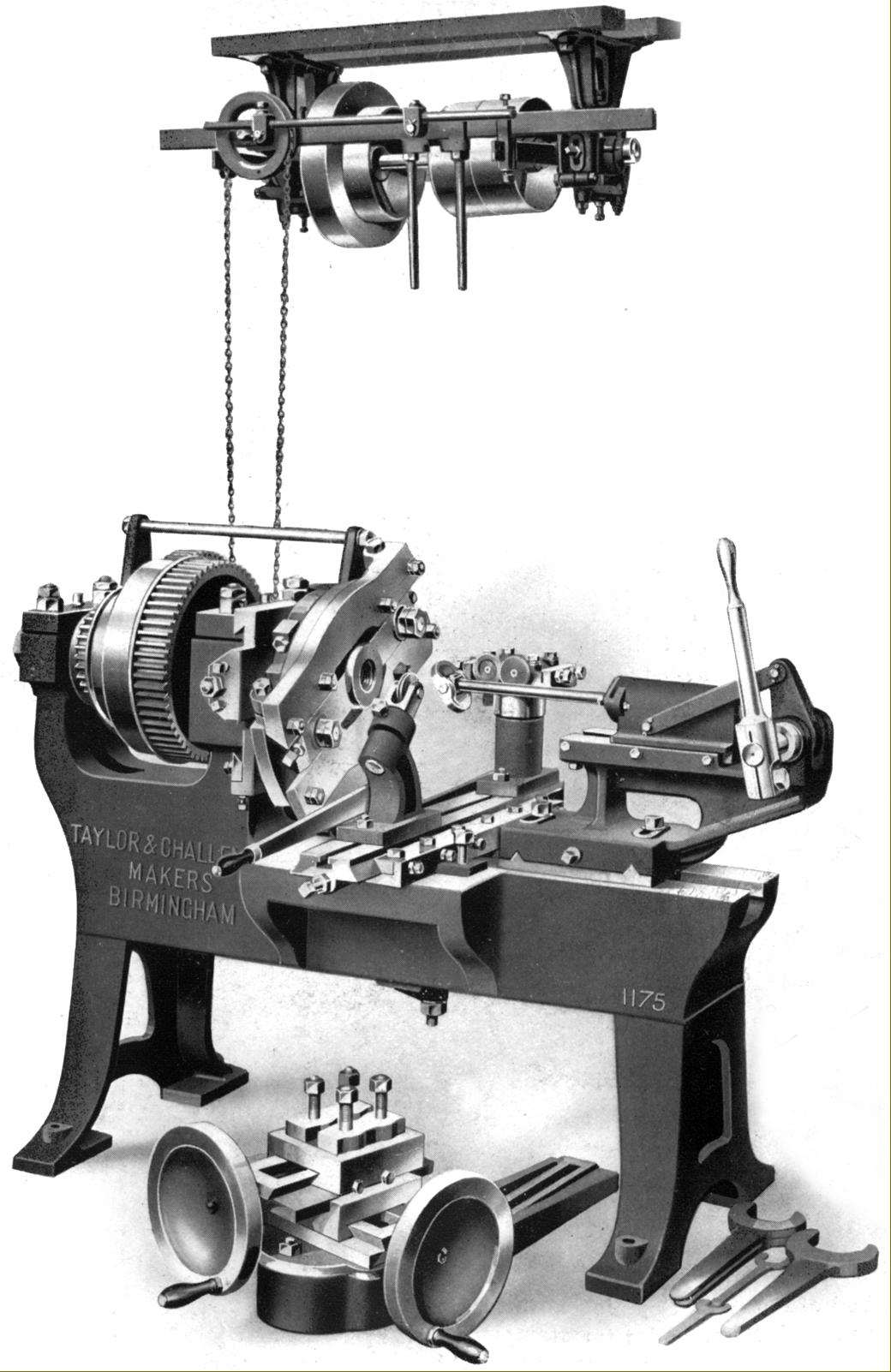

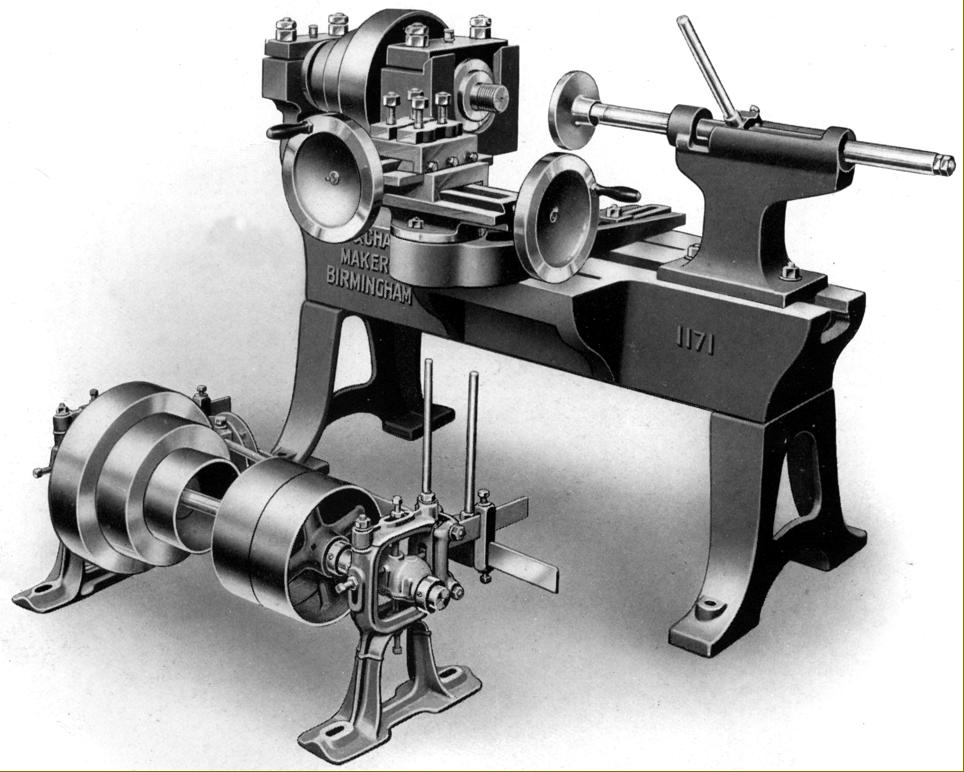

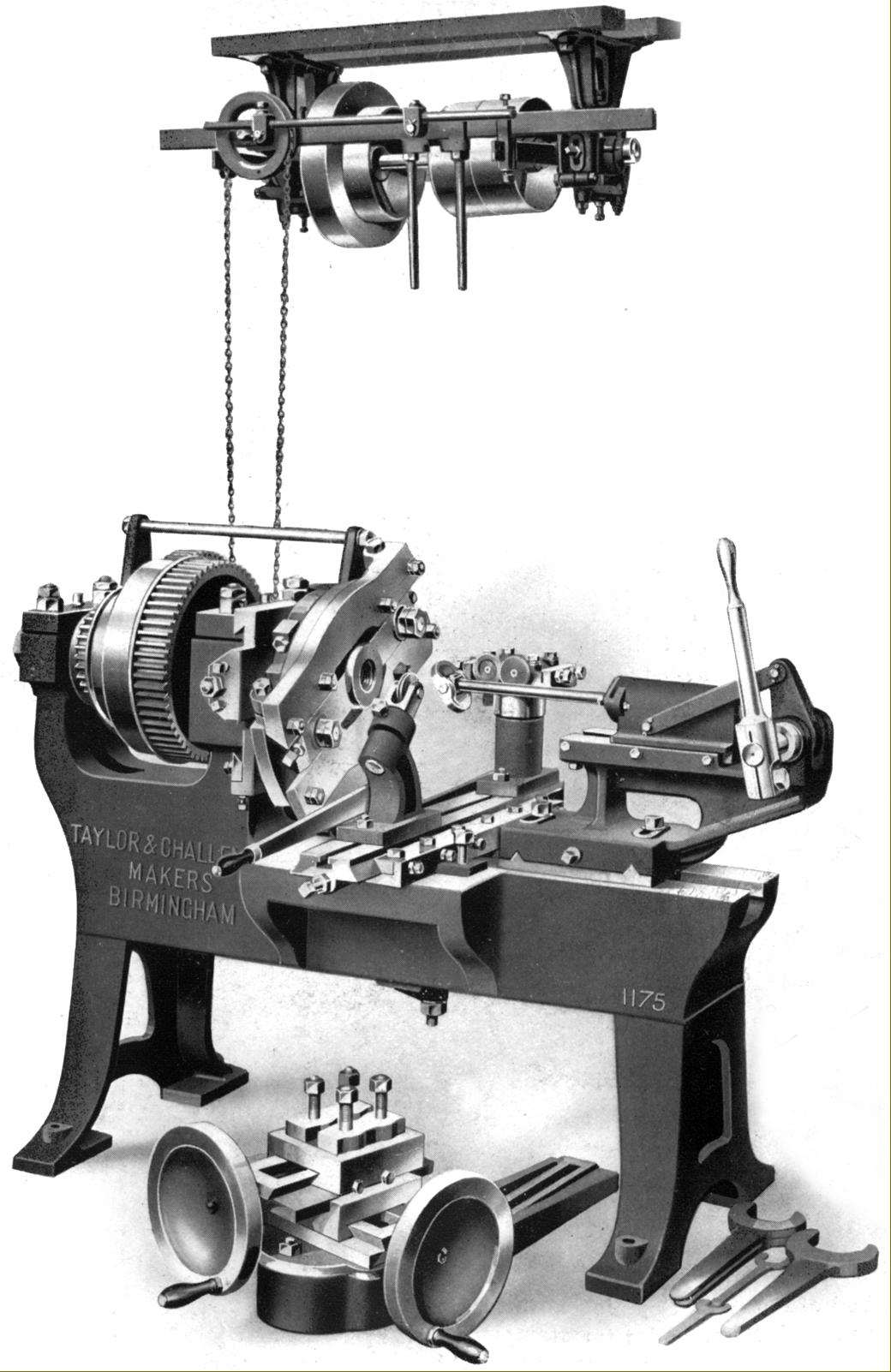

9-inch and 12-inch Backgeared Spinning, Trimming and Beading lathes Models 1178 and 1175. Shown fitted with an oval chuck, lever-operated tailstock spindle, a trimming and beading rest and a compound slide assembly. On this model the spindle was strengthened and fitted with backgear for slow speed, high-torque working. Including their heavy fast-and-loose countershafts and slide rests, the two lathes weighed 1178 and 2688 lbs respectively

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|