|

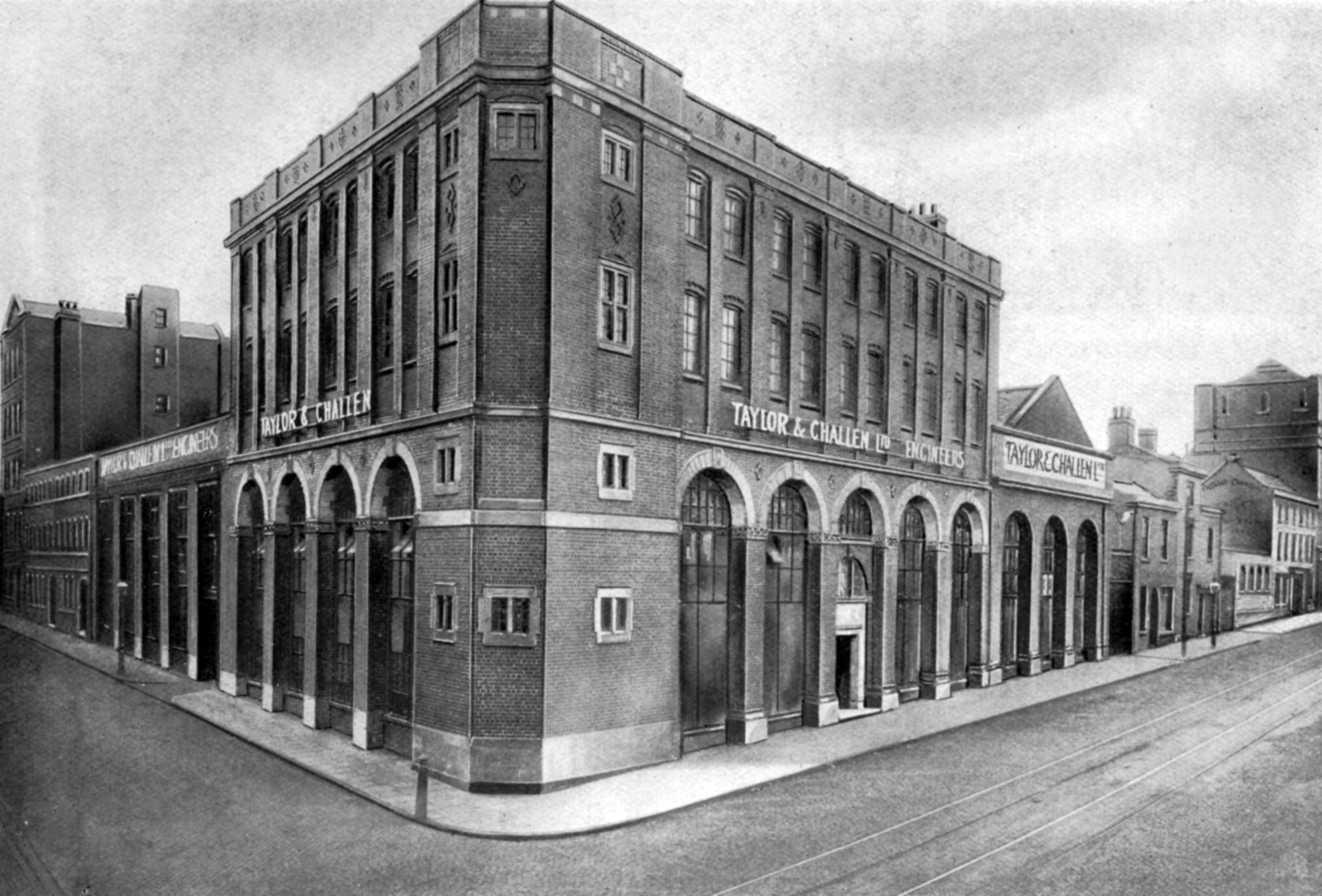

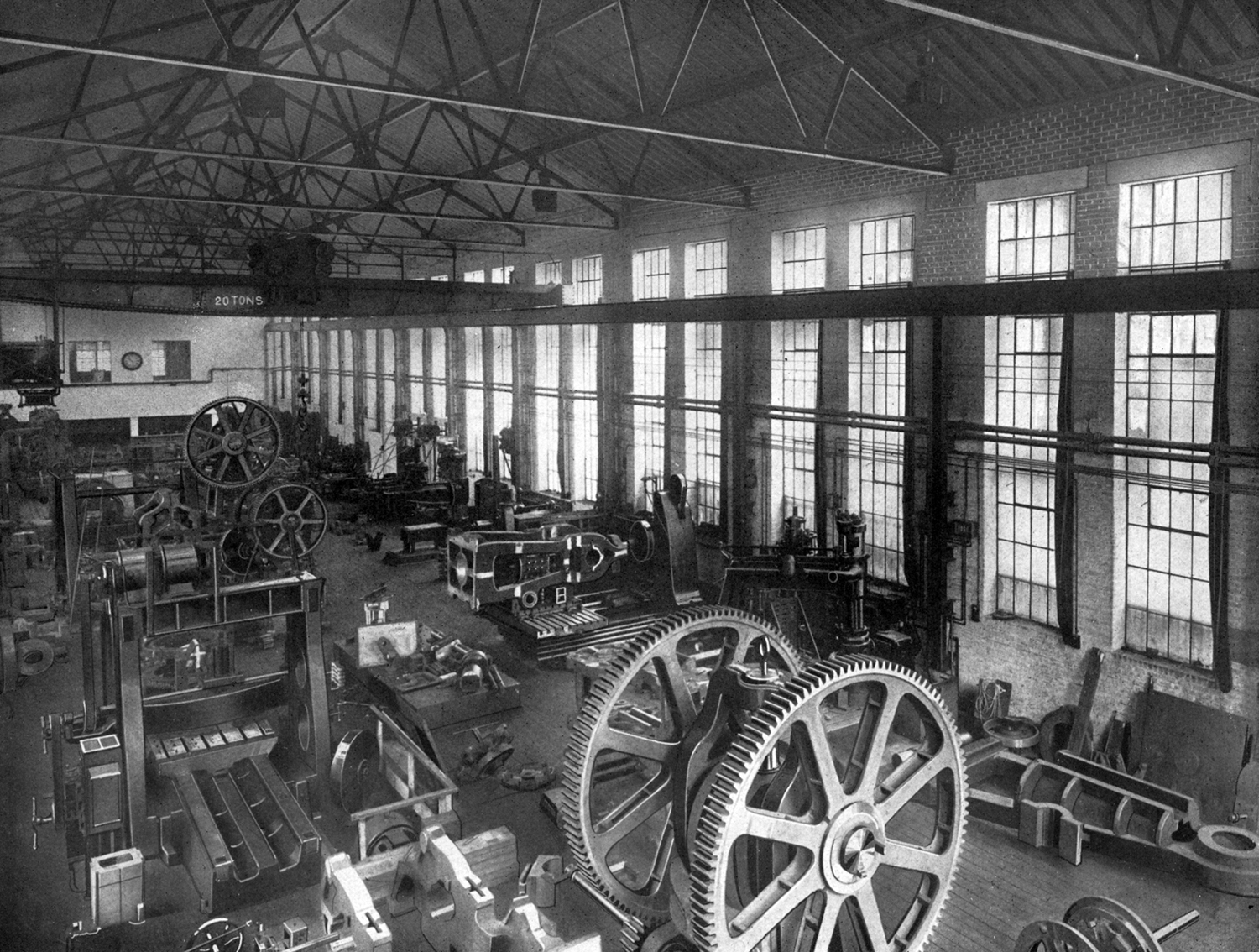

Taylor & Challen were not known as makers of lathes but for presses of all kinds and sizes, for which they became world famous. Founded in Birmingham by Joseph Taylor during 1849 and working at first from a cramped workshop in Brasshouse Passage, the Company thrived and moved regularly to larger premises, the main factories and offices eventually including the Derwent Works on Constitution Hill and, across the road, a large factory on the corner of Livery and Mary Anne Streets with a foundry in a separate building at the Water Street end. The foundry was erected circa 1913/16 and designed by the well-known architects Ewen Harper & Bro. who appear to have been influenced by Peter Brethen's Kraftwerk Union Factory Hall in Berlin. Today, 2017, the buildings still stand with the Derwent works (extended in 1938) being Grade 11 Listed (though with the fašade horribly disfigured by modern signage) and the foundry building converted to housing.

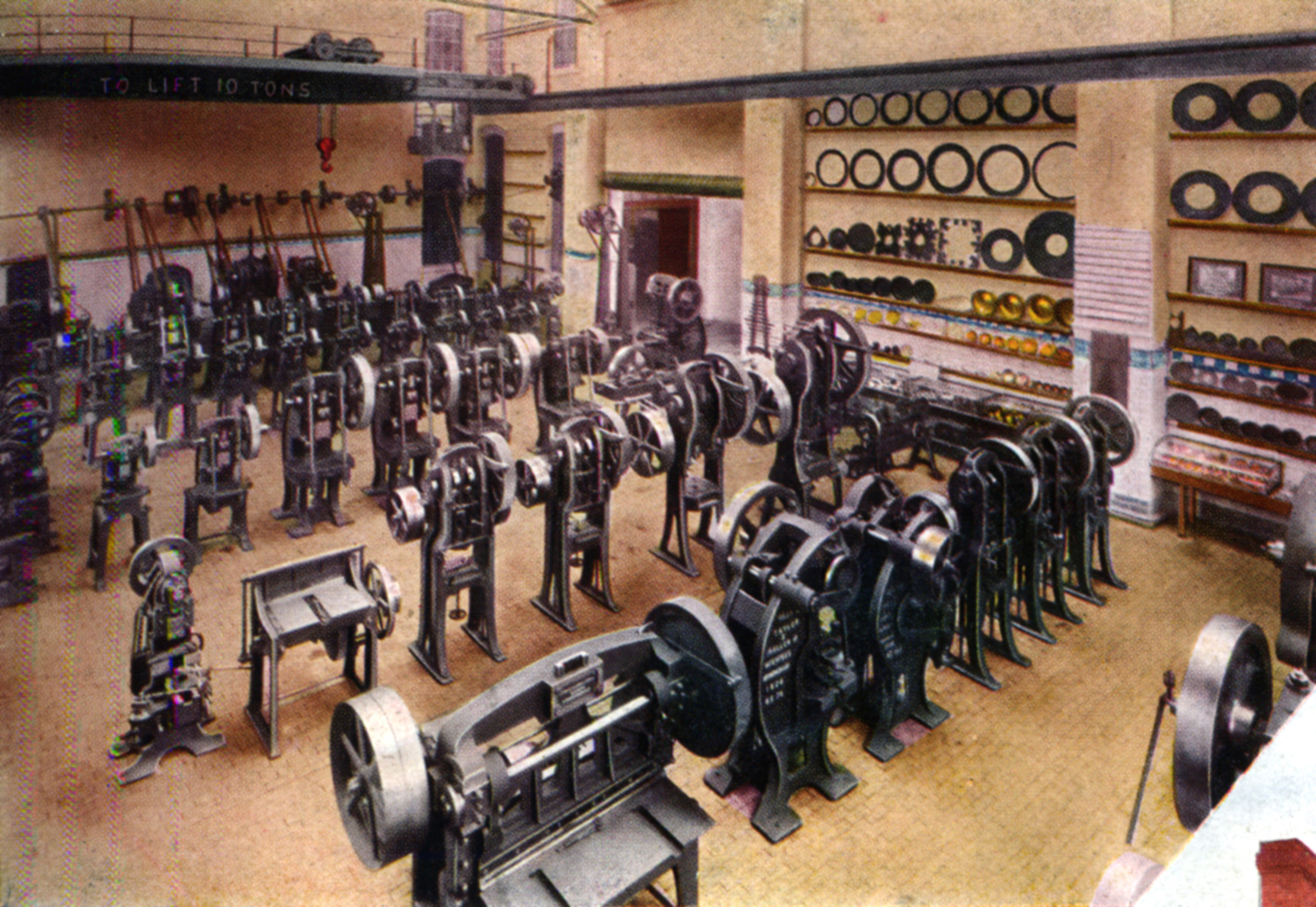

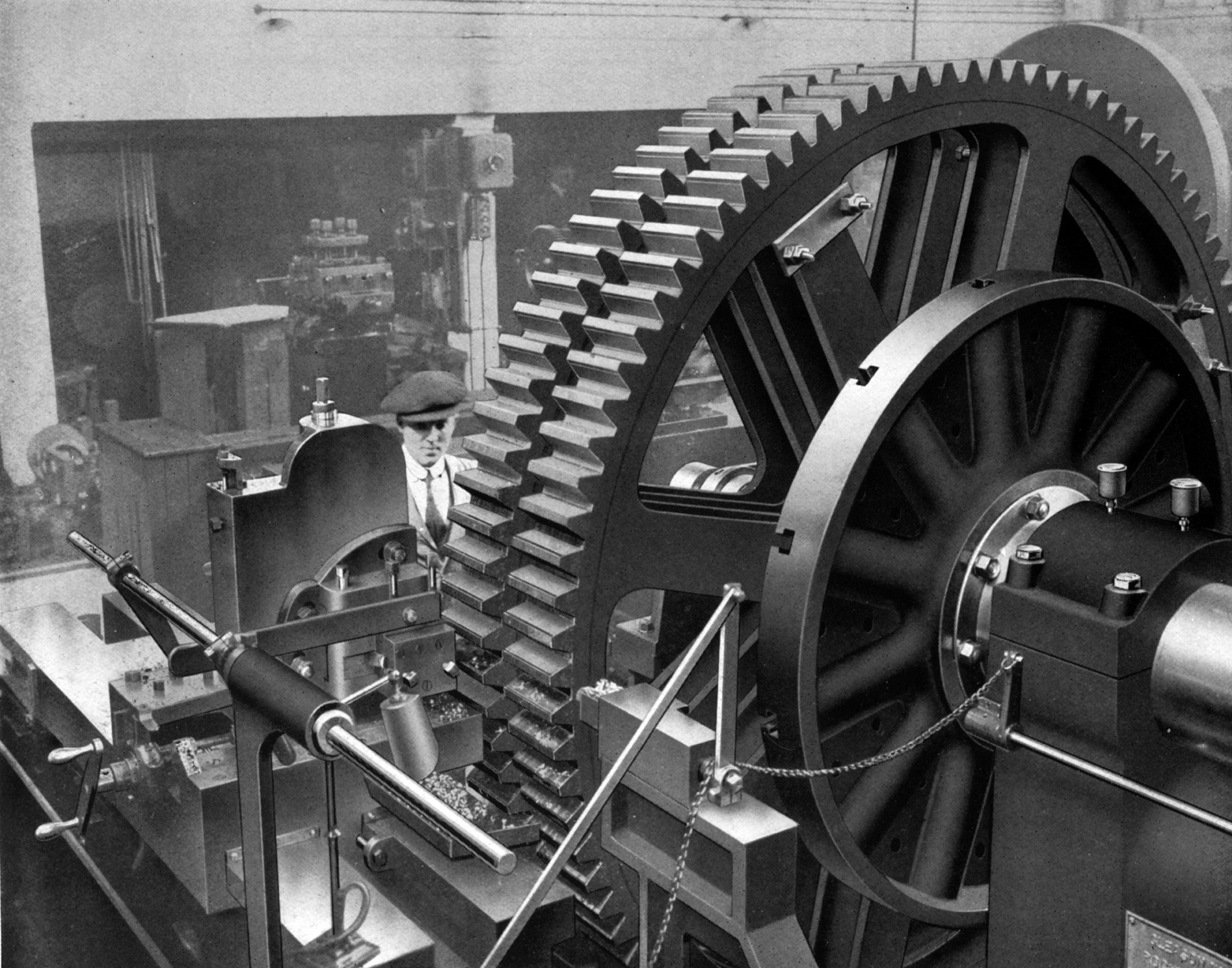

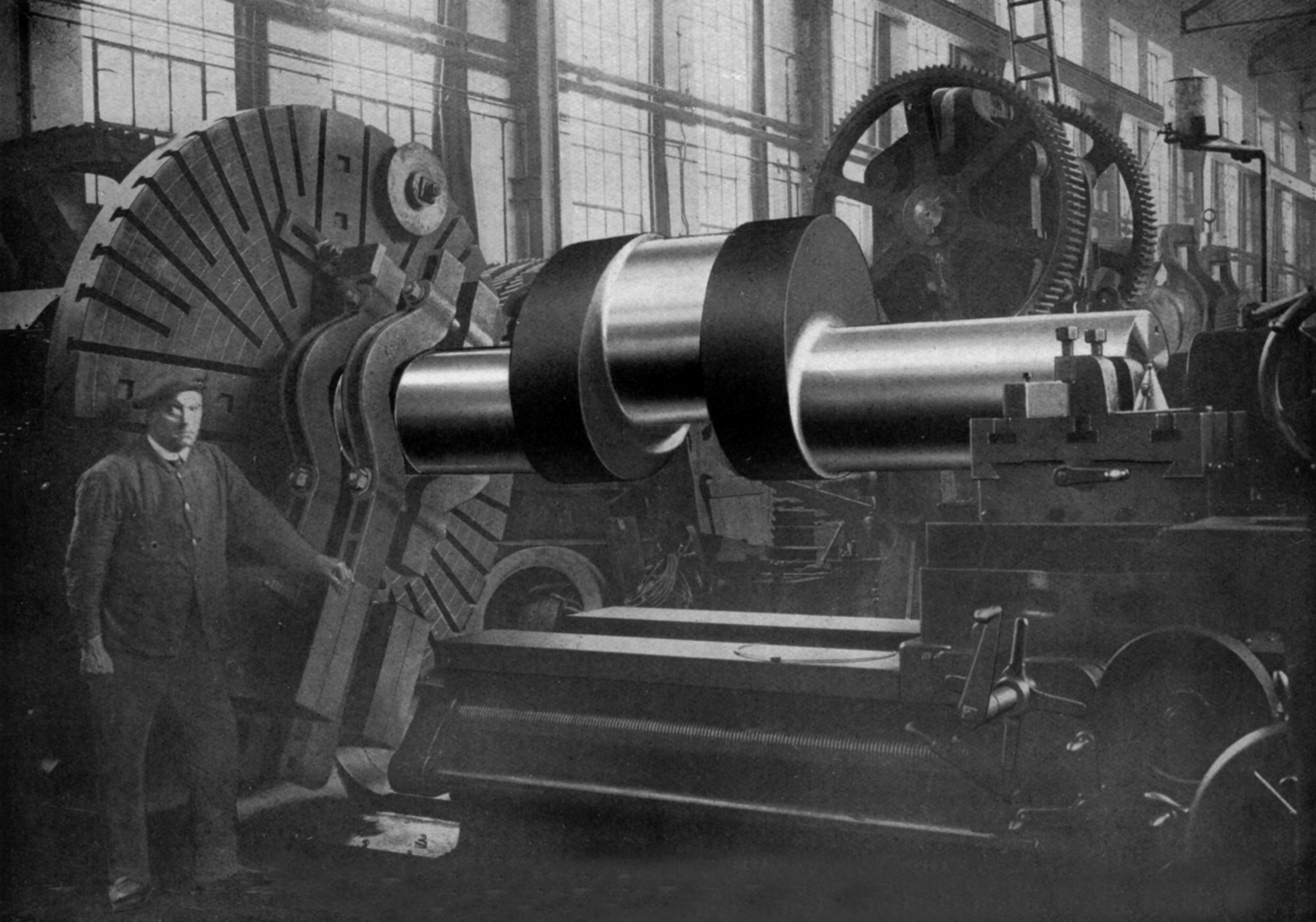

With a vast product range, from simple hand-operated to giant 2000 ton power presses, machines for the stamping of coins, shears, rolling mills and draw-benches, nut and bolt machines and even complete installations to grind, mix and mould gunpowder and manufacture cartridges, it seems as though nothing was beyond the remit of Taylor & Challen.

While metal pressing and stamping remains an important industry, before the introduction of plastic and injection moulding techniques it played an even larger role in providing the many hundreds of every-day objects for domestic, industrial and military use such as saucepans, bowls, cups, boxes, baths, gas and electricity meter cases, hinges, buttons, cistern balls, scoops, shovels, food tins, scale pans, sheet-metal flanges, cartridge cases, bullet clips, shell cases together with a myriad of other items including parts for cars, aeroplanes, motorcycles, cycles and boats, etc. While some of the formed items could be used straight from the press others, especially those with tapered or curved sides, needed either cosmetic or further engineering work (or both) to make them ready for sale - and it was for this reason that Taylor and Challen offered a range of spinning, trimming and beading lathes to complete the manufacturing process. At its simplest the lathe work might have involved a spinning process, to smooth out the stretch marks caused by the press and then the removal of excess or uneven material on the rim by shearing (not turning) and then curling over the edge - a process called beading - to give strength and rigidity and safe handling. As a further step, the beading action sometimes included the insertion of a stiffening wire to give additional rigidity.

In interestingly, one of the Taylor & Challen's former patternmakers was Fred Baier, a contemporary renowned British furniture designer:

https://www.artworkersguild.org/media/4456/pn-2023.pdf

"...whenever he could, he returned to Birmingham and worked in the wooden pattern shop at Taylor and Challen, manufacturers of presses for industry. Fred spoke of how much the monumental forms produced there fuelled his creative imagination. Vast warehouses were filled with redundant patterns, and since the firm wanted to sell off the land, he was free to find imaginative uses for the monoliths abandoned there".

Taylor & Challen Lathes - Page 2

Taylor & Challen Lathes - Page 3

|

|