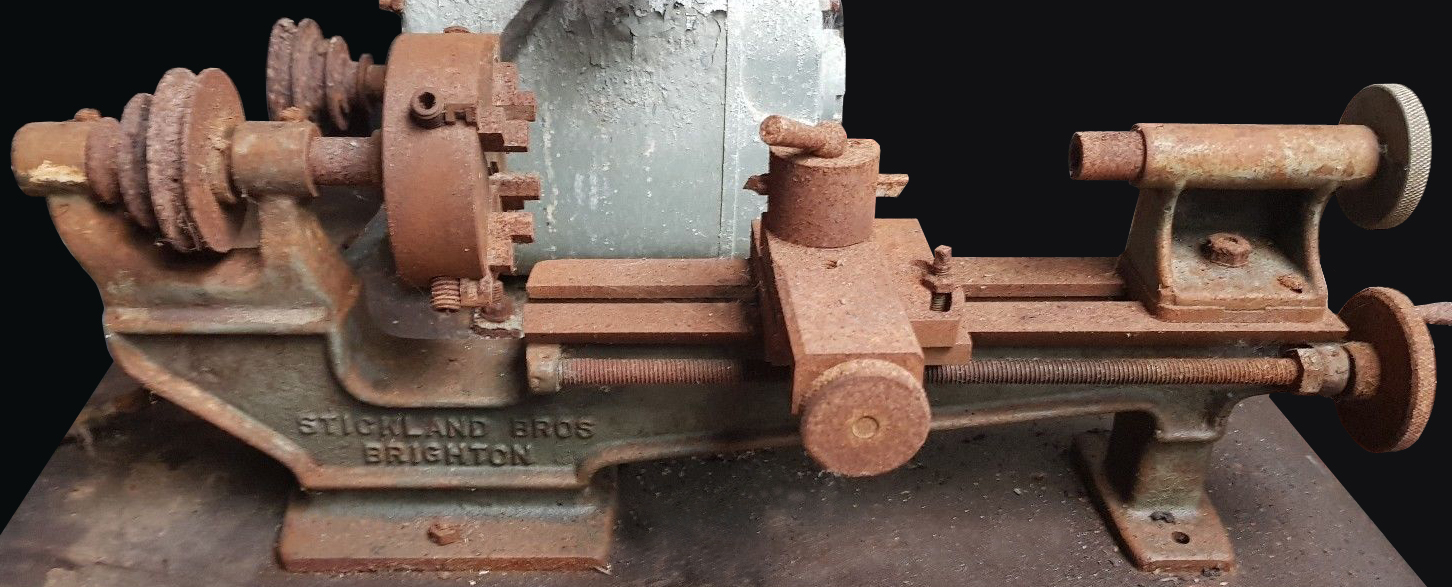

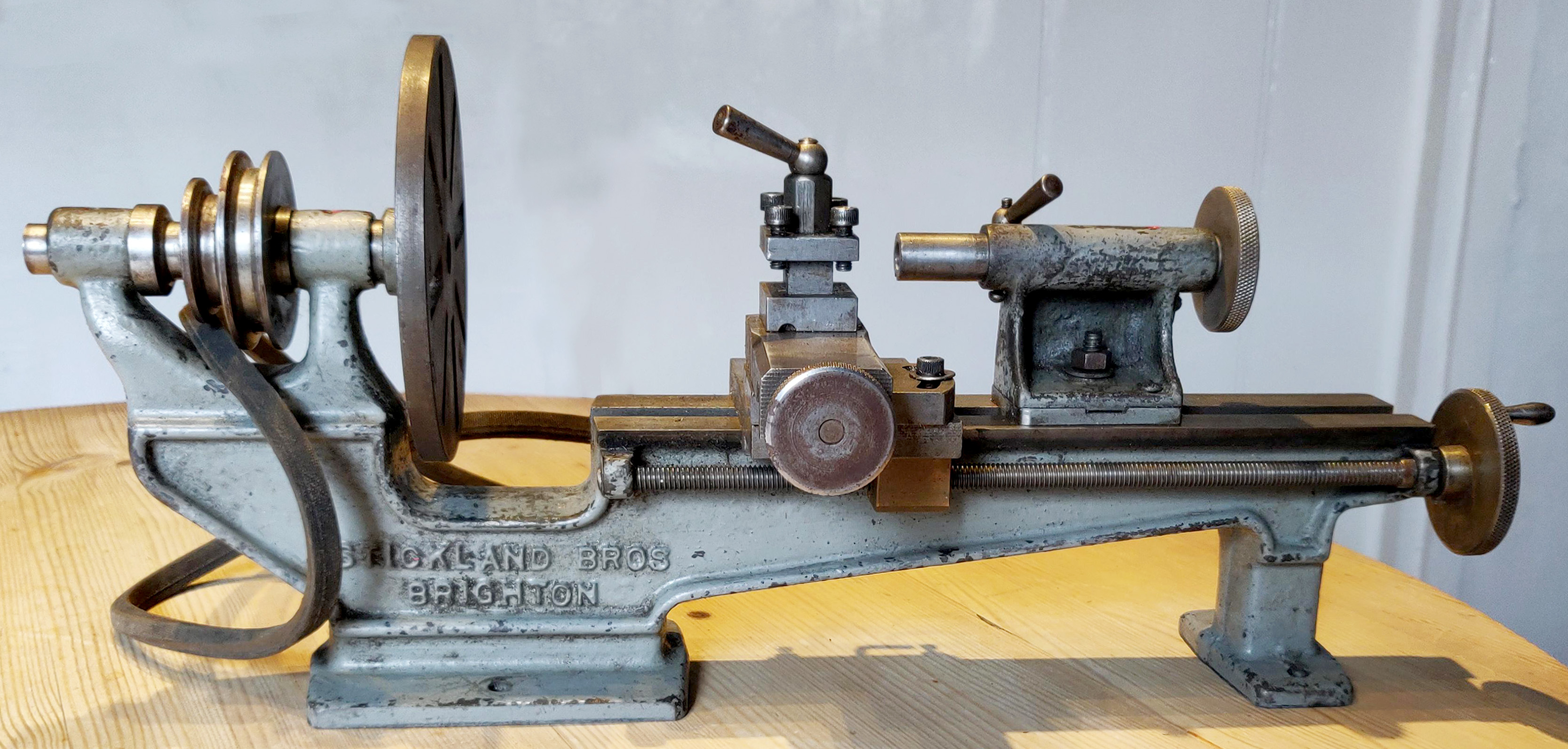

Stickland Brothers Lathe

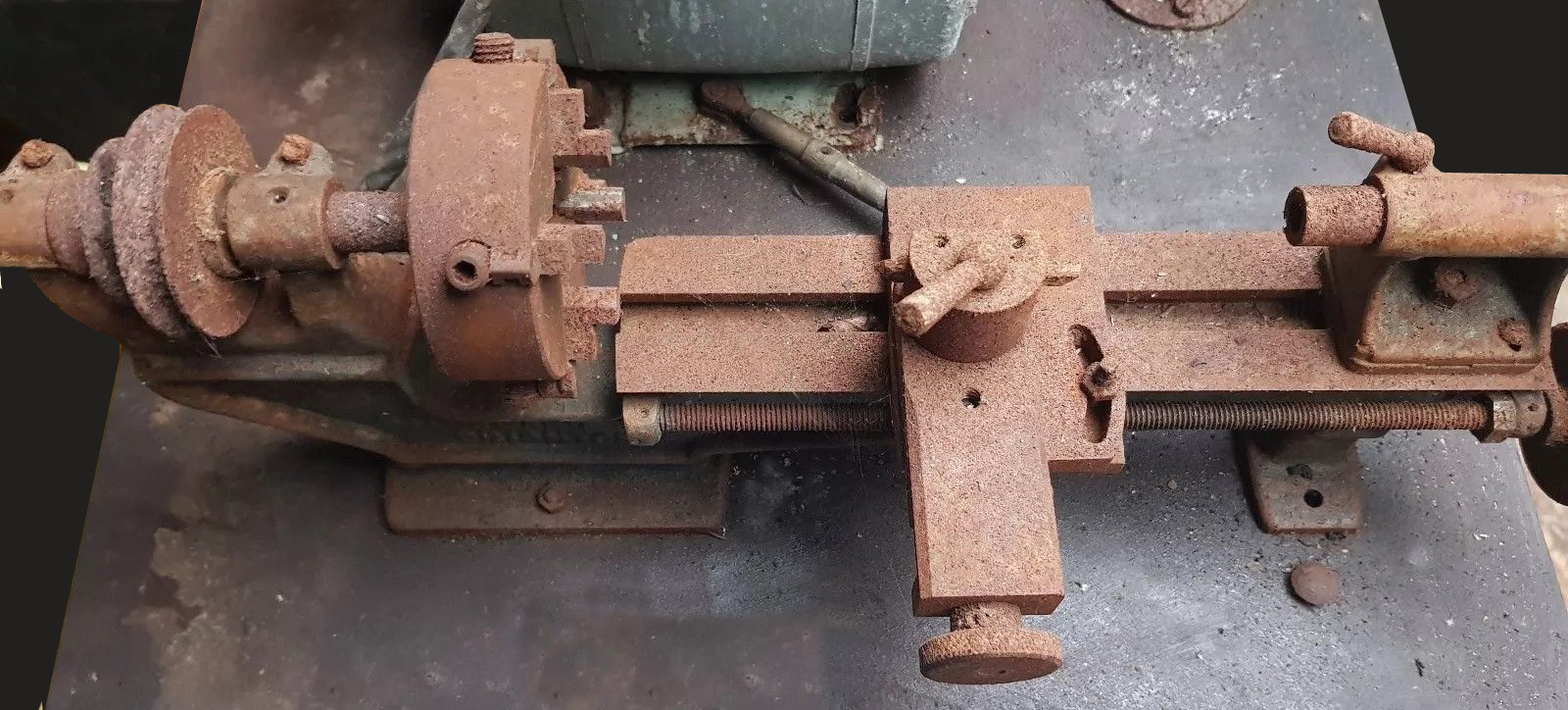

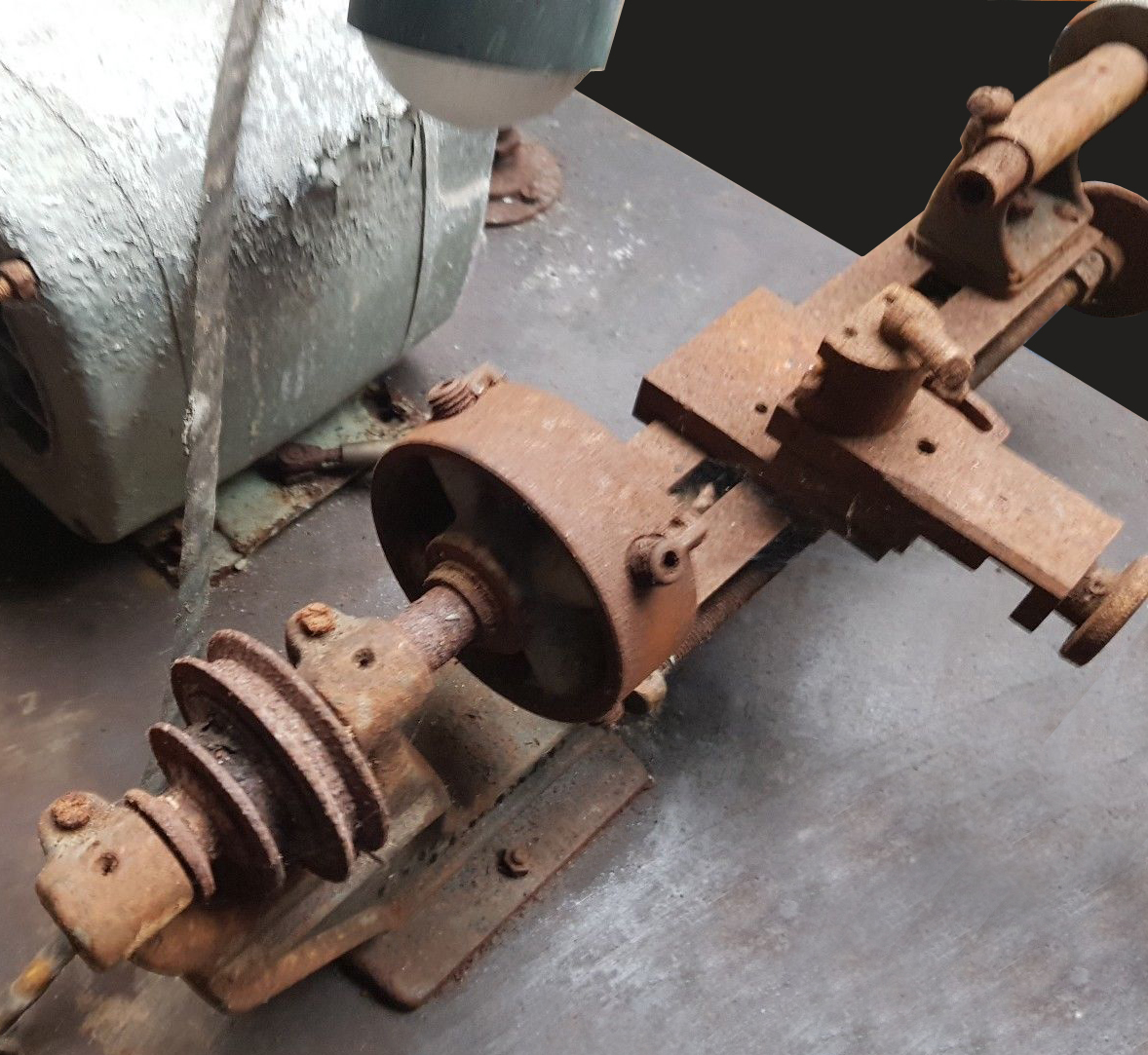

Manufactured in the coastal town of Brighton, England, the Stickland Brothers lathe is rare with just two examples coming to light. One, a very rusty example encountered by the writer and the other, carefully preserved in original condition and believed to have been bought new, in the 1920s or 1930s, by the owner's grandfather, a foreman toolmaker who worked for Sperryn in Birmingham from 1909 to 1964.

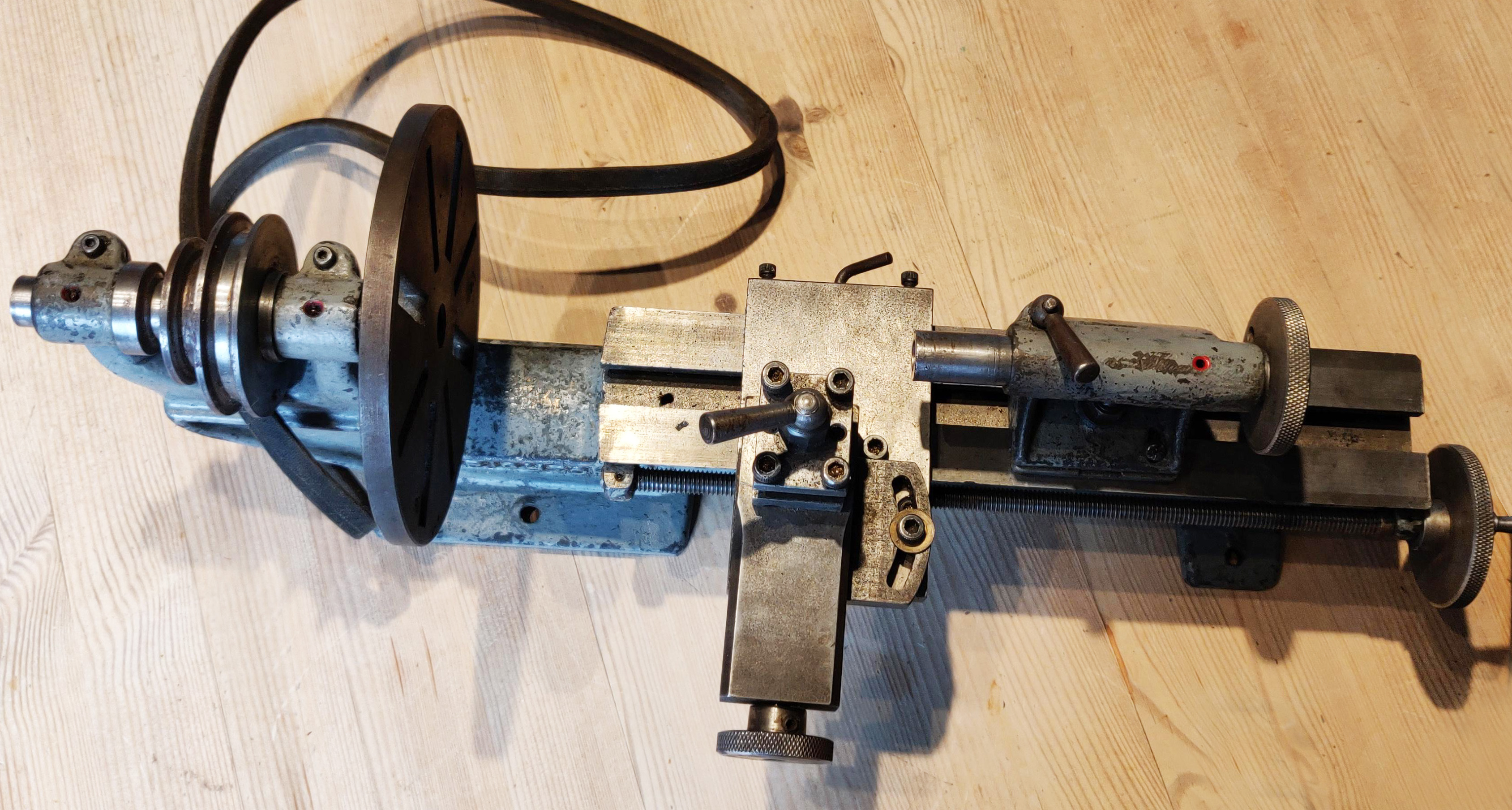

Of the simplest kind intended for use by amateurs, the Stickland would have been made for a short time from the late 1920s into the early 1930s--and was the same sort of machine also made - though in much greater quantities - by Portass in Sheffield. Long-established in Sheffield, Portass was well known for selling machines to be branded as other makes for sale by distributors and dealers and so a suspicion arouses that this might have been such an example. However, in this case, the design exhibits no Portass trade-mark styling features and is certainly a genuine product of a now long-disappeared company.

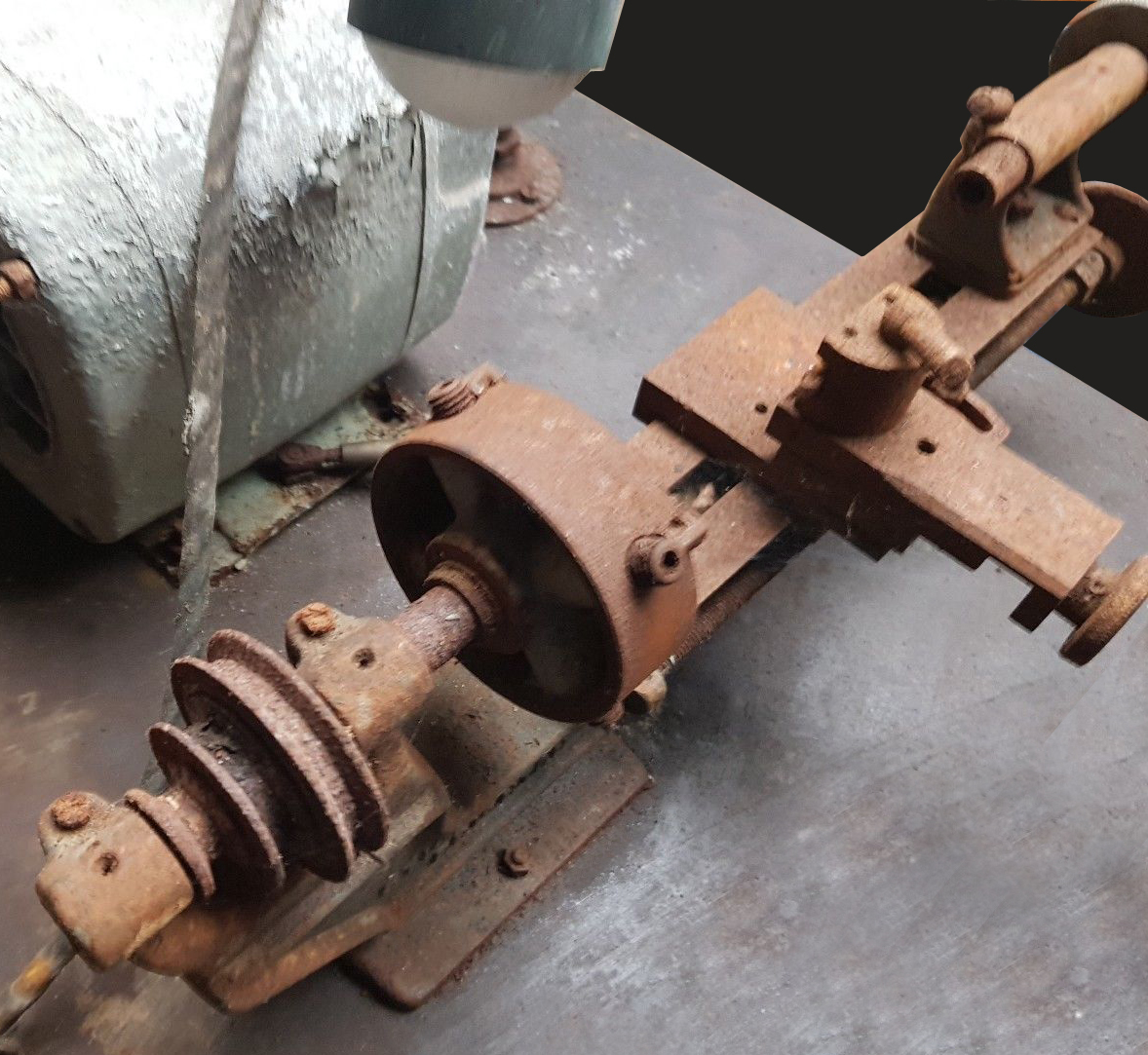

As an early and lighter English-made lathe, the 3-step headstock pulley might originally have been driven by a round leather rope, though the width of the pulleys is unusually generous for this type. Hence, it may well have been intended to take a modern-style narrow V-belt - as first became available for use on small machine tools from around 1930.

While many similar lathes economised by having just a single plain bearing inboard of the headstock spindle nose - and the other end supported against an adjustable, hardened point - the Strickland had two conventional, plain split bearings, these able to be adjusted by clamp bolts set to the rear. Oddly, the whole headstock was canted to the left, requiring the headstock spindle to stick out a long way to bring the chuck out over the gap in the bed; needless to say, this arrangement did little to promote either rigidity or accuracy.

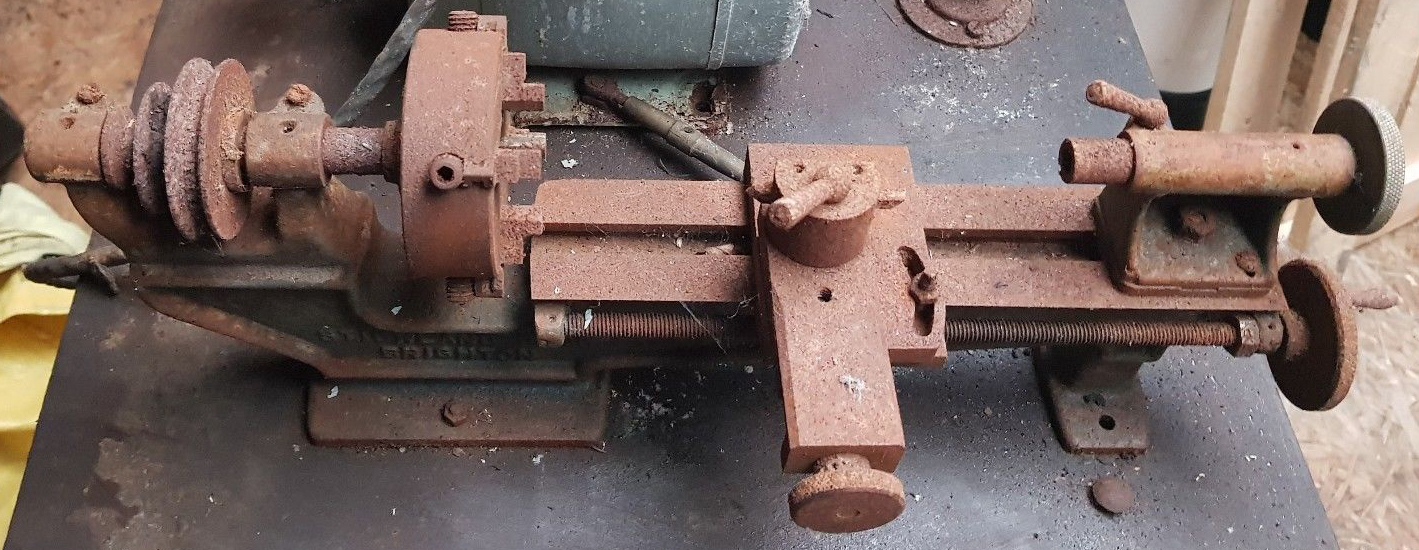

Of typically English design, the lathe had a flat-topped bed with V-shaped edges and a carriage driven by a hand-turned leadscrew - both ends of the latter supported in bearings; again, this was in contrast to many models in the same class where the screw was overhung for cheapness and speed of construction; examples of the lathes using the latter system include the Coronet Diamond and Jewel, the first Flexispeed, Centric Micro, Corbett's Little Jim, several Portass models, the American Childs - and even the high-class Csepel from Hungary.

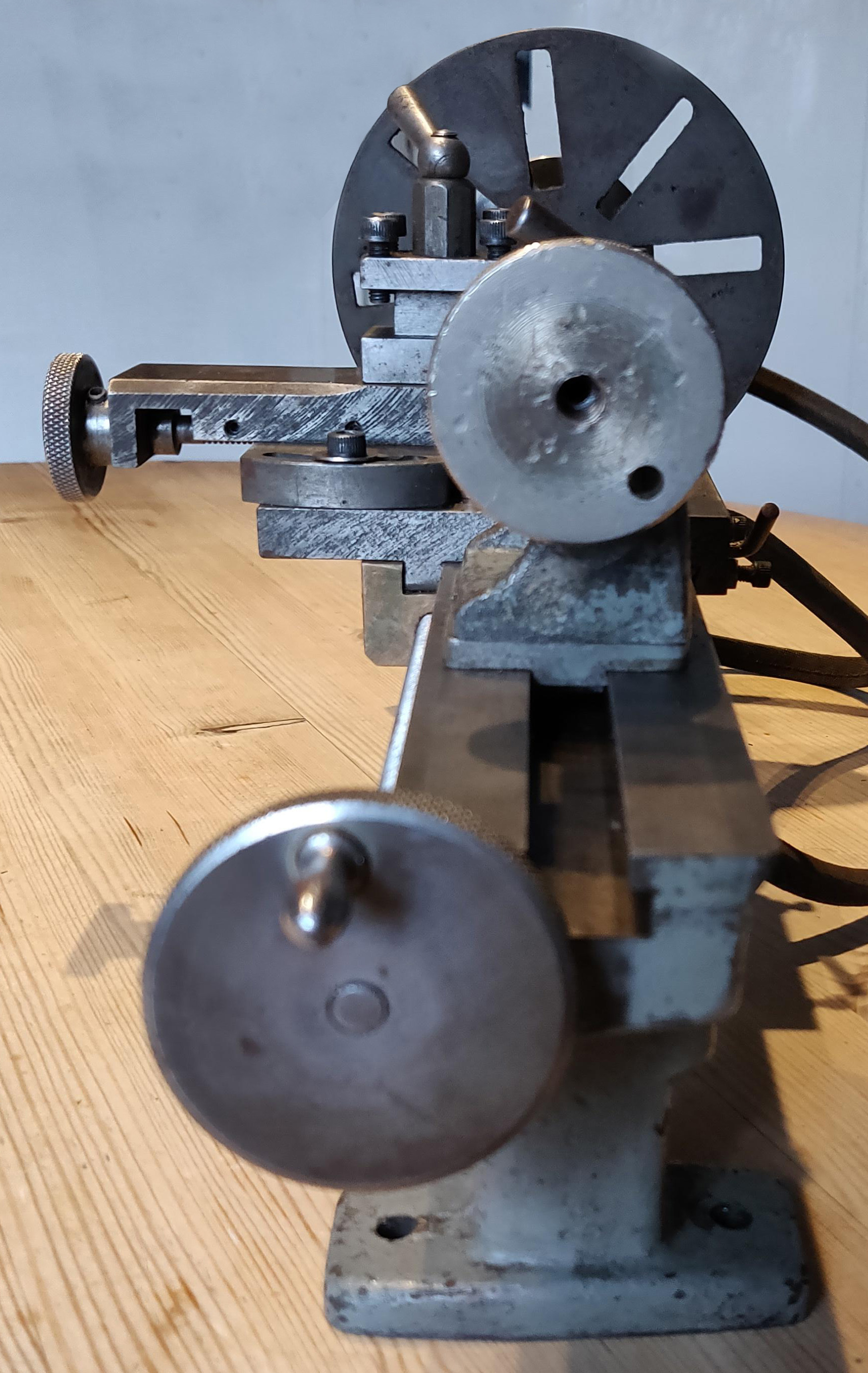

Just a single tool slide was fitted, this being locked by a bolt passing through a curved slot on the slide's right-hand side; the slide could be swivelled, but through a very limited range - though a second tapped hole appears to have been provided on the other side of the saddle allowing the slide to be repositioned and other angle settings obtained.

Able to be set-over for the turning of slight tapers, the tailstock spindle looks likely to have been machined with a No. 1 Morse centre.

One pleasing touch was the use of relatively large, full-circle handwheels on all the feed screws, these having diamond-knurled edge faces for improved grip (just like the Centric Micro and some models of the Perris miniature lathe) - though all lacked micrometer dials.

If you have a Stickland lathe, the writer would be interested to hear about it.