Makers of similar bench precision lathes listed here

By a previously unknown maker, until an example was found in England during December 2106, the 80 mm-centre height STB lathe was of very high quality construction with an appealing fit and finish to its components. Certainly the equal of, for example, similar lathes from the Swiss makers Schaublin and Mikron, the German G.Boley and Lorch and American Levin and Derbyshire, the lathe almost certainly dates from the late 1940s into the 1950s. For its type, the STB had a bed of rather unusual configuration, the casting being made virtually full depth along its entire length with just a small recess along the middle section of the underside face allowing a pair of feet to be formed at the headstock and tailstock ends. Arranged in a traditional bench-precision way, the bed's ways were flat on the top with each having a bevelled outer edge that provided an accurate location for the headstock, slide rest and tailstock.

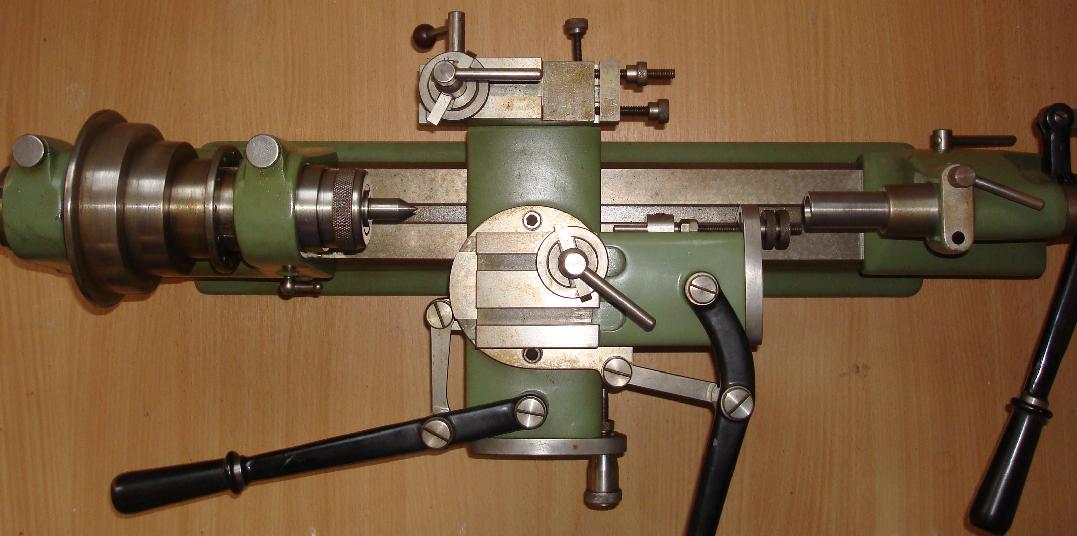

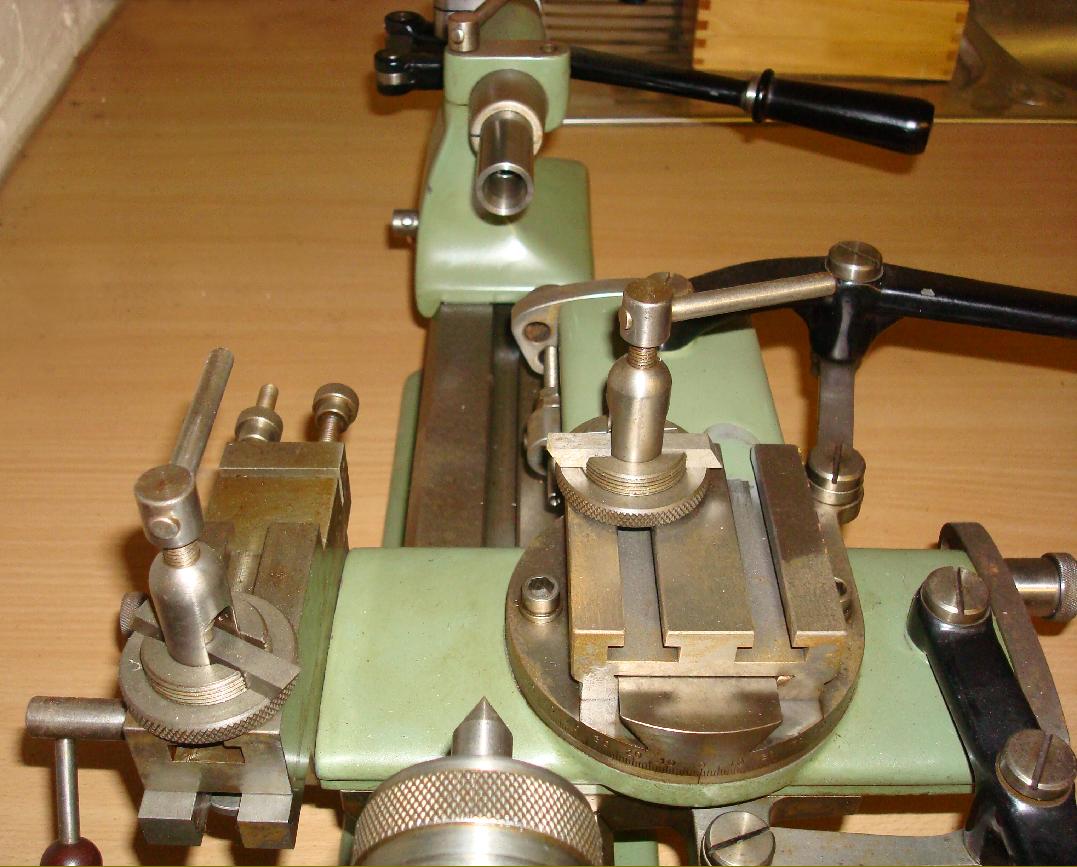

As found the lathe had full lever action control to both slides, the tool slide having a casting very like the twin T-slot design found on the Schaublin 102. The cross slide was fitted with dual tool posts, that at the front being of conventional arrangement but at the rear carried on a slideway having a degree of screw-driven independent longitudinal adjustment. The use of a rear toolpost on bench precision lathes was common practice; for example, the accessory list for the French Jenny lathe showed a variety of screw and lever-operated slides with this facility.

Precision plain turning lathes could, generally, be arranged to perform in the three distinct roles:: toolmaker, second-operation and production capstan. The toolmaker's type, intended for one-off precision jobs by a skilled turner, was equipped with a screw-feed compound slide and tailstock (and often a collet draw tube for collet holding), while the second-operation version (sometimes called a "finishing lathe") had slides, tailstock and collet closer driven by screws, quick-action levers- or a combination of the two. Production models were usually equipped with a bed-mounted 6-station capstan unit and had a choice of lever or screw-operated cut-off slide rests and a quick-action collet closer - the latter sometimes of the foot-operated kind. By the simple means of changing the fittings mounted on the bed, any version (or combinations of versions) could be assembled in a matter of minutes and pressed into service with a minimum loss of time. Whether the makers of the STB offered such a range of accessories is not known - but it's highly likely that they did.

Fitted with a nose able to take standard draw-in Schaublin collets, the headstock spindle ran in plain bearings, oil reservoirs being provided for each with, doubtless, feed by spring-loaded wicks dipping into wells beneath the bearings. Surviving with the STB shown below was a drawtube and a single collet with integral centre.

Of ordinary design and with its spindle locked by closing down a split in the casting, the tailstock was operated by a long lever through a double swivel joint. Unfortunately it lacked the cut-out in the casting often found on this type of tailstock whereby the ruler graduations were exposed.

Should any reader have an STB lathe - or literature from the Company, the writer would be interested to hear from you..