|

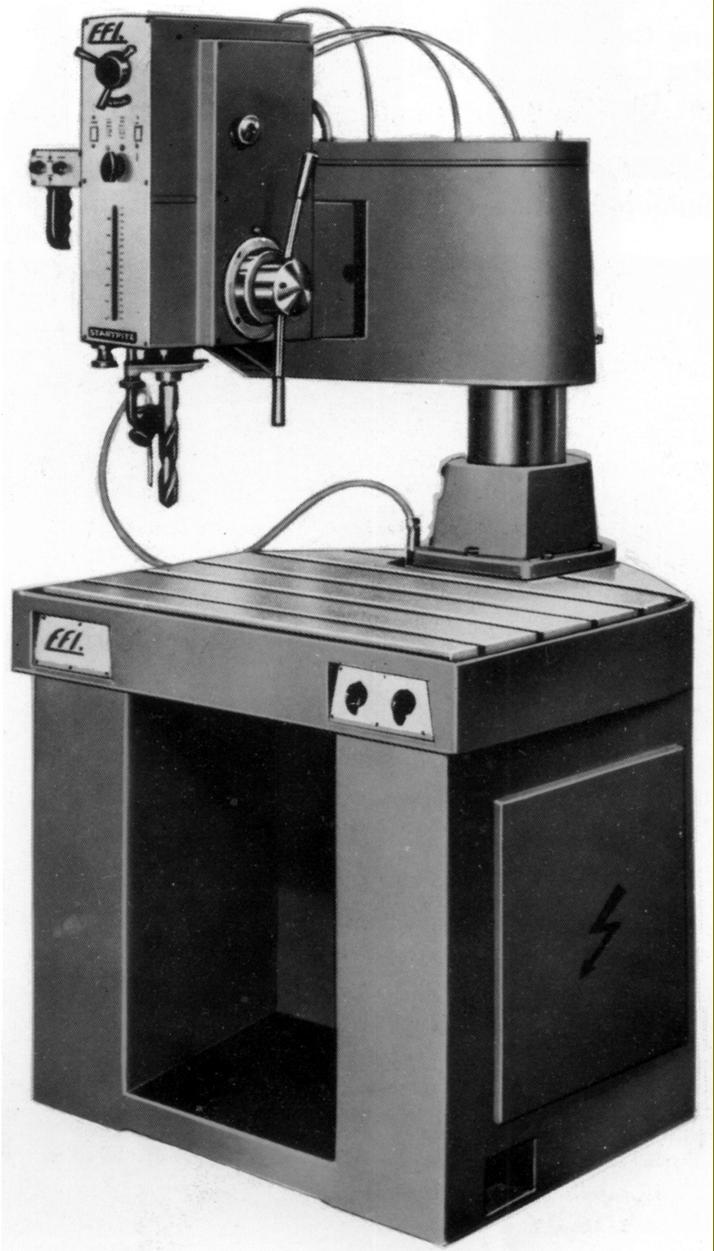

Built with several different specifications, the Startrite EFI drills were heavy, geared-head industrial machines with a generous specification and intended for heavy-duty work.

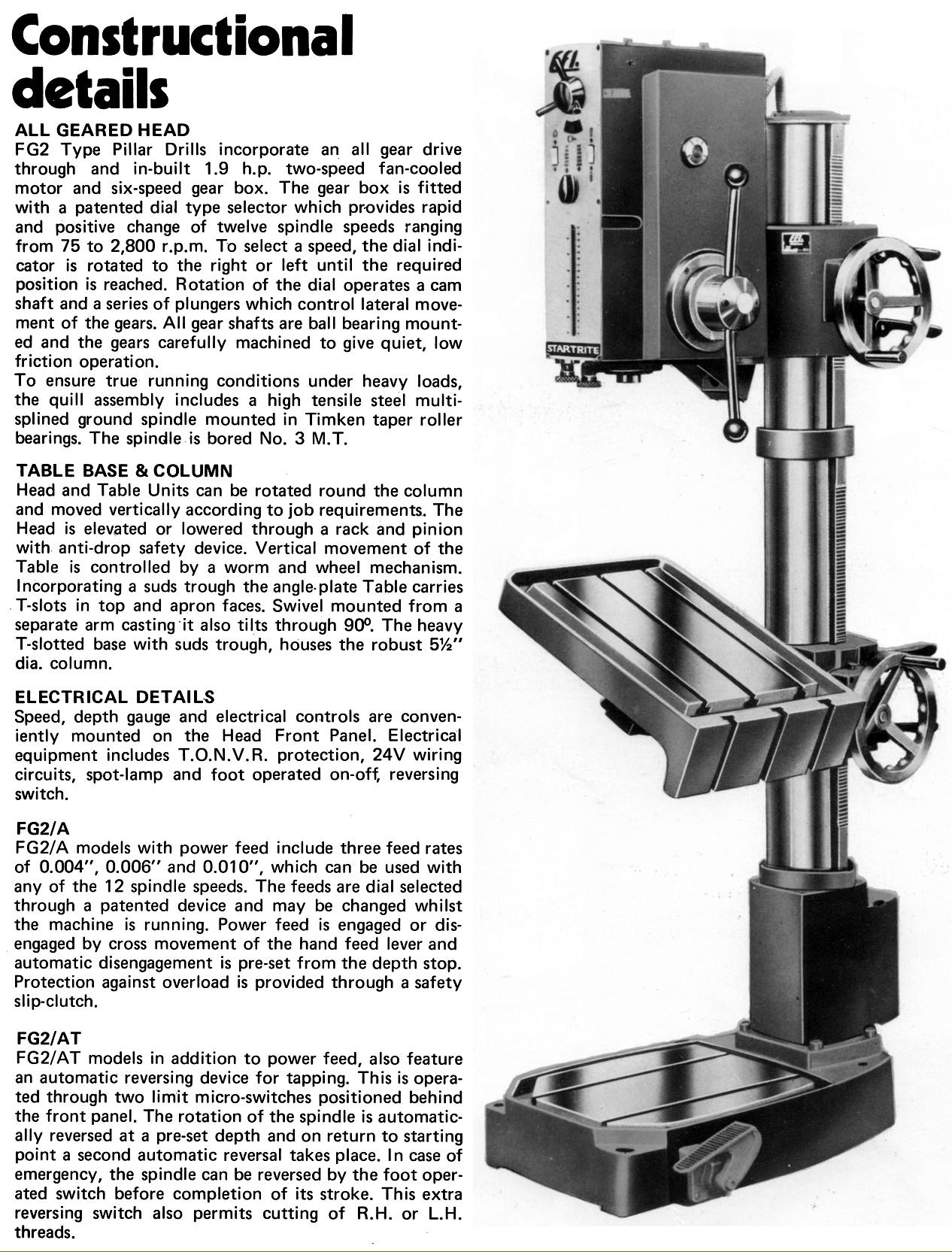

Equipped with hand down-feed only the basic model was the FG2 fitted, like all the other versions with a 2-speed fan-cooled 3-phase motor rated at 1.9 h.p. A dial-type selector enabled any of twelve speeds from a low of 75 to a high of 2800 r.p.m. to be selected - the control operating a camshaft that bore against a series of plungers to control the lateral movement of the hardened and ground gears on their splined shafts. Running in Timken taper roller bearings the multi-splined, ground-finished No. 3 Morse taper spindle was manufactured from a high-tensile steel.

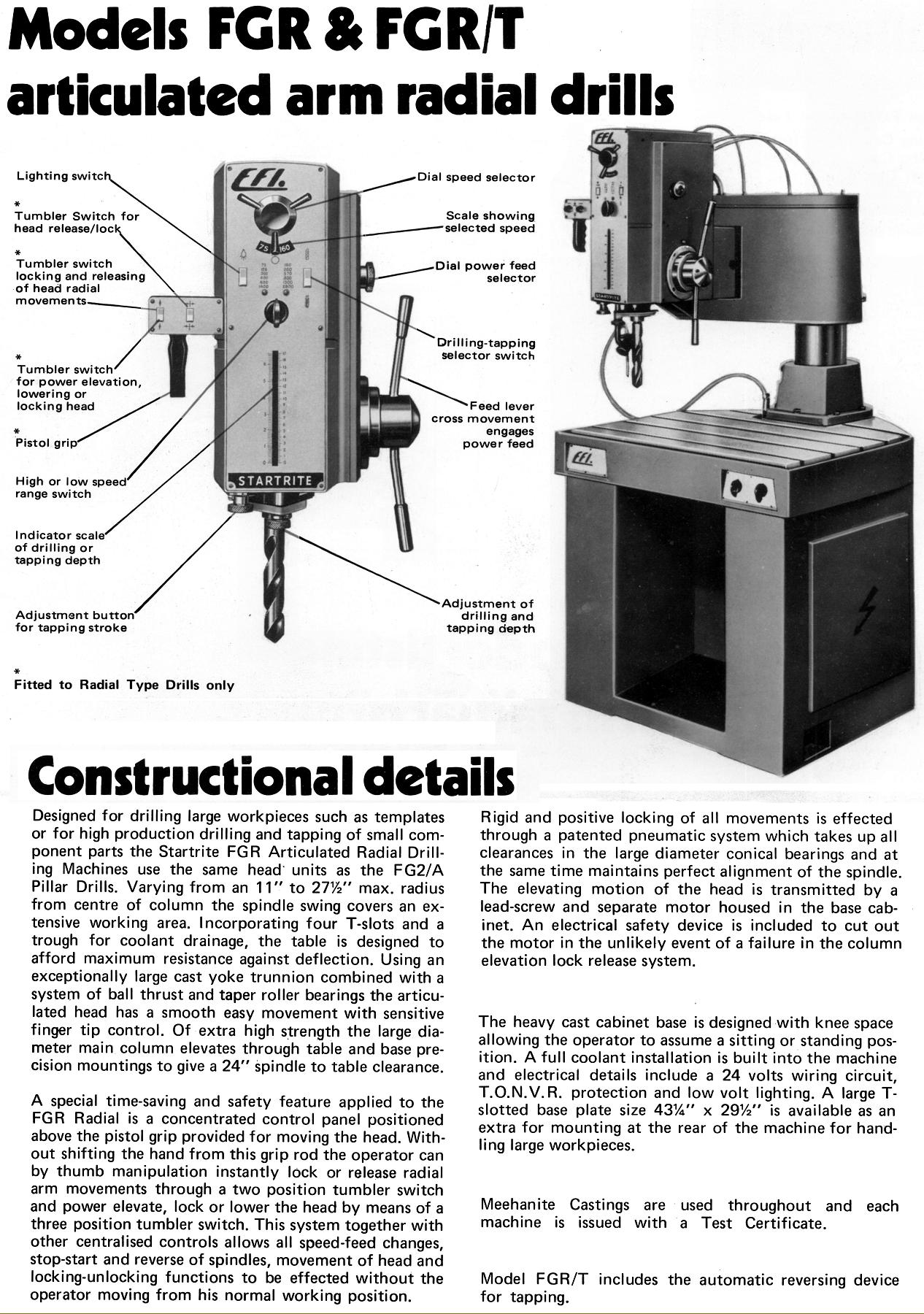

Carried on a round column, the entire swivelling head assembly could be moved up and down the upper one-third section of its round support column by means of a handwheel working through rack-and-pinion gearing. The lower two-thirds of the column carried a tilting table, also moved in the same manner as the head, and equipped with three T-slot on its top surface and three on a short section of its right-hand face. As an optional extra a screw-feed compound table could be fitted; with a top carrying three T-slots, this 18" x 6" unit had a longitudinal travel of 11.75" and across of 5.875" and was intended for co-ordinate drill and light milling operations.

If power down-feeds were needed, the makers offered the Model FG2/A with three rates of 0.004", 0.006 and 0.010" and, if both down-feed and an automatic reverse for tapping were required, buyers could choose the Type FG2/AT.

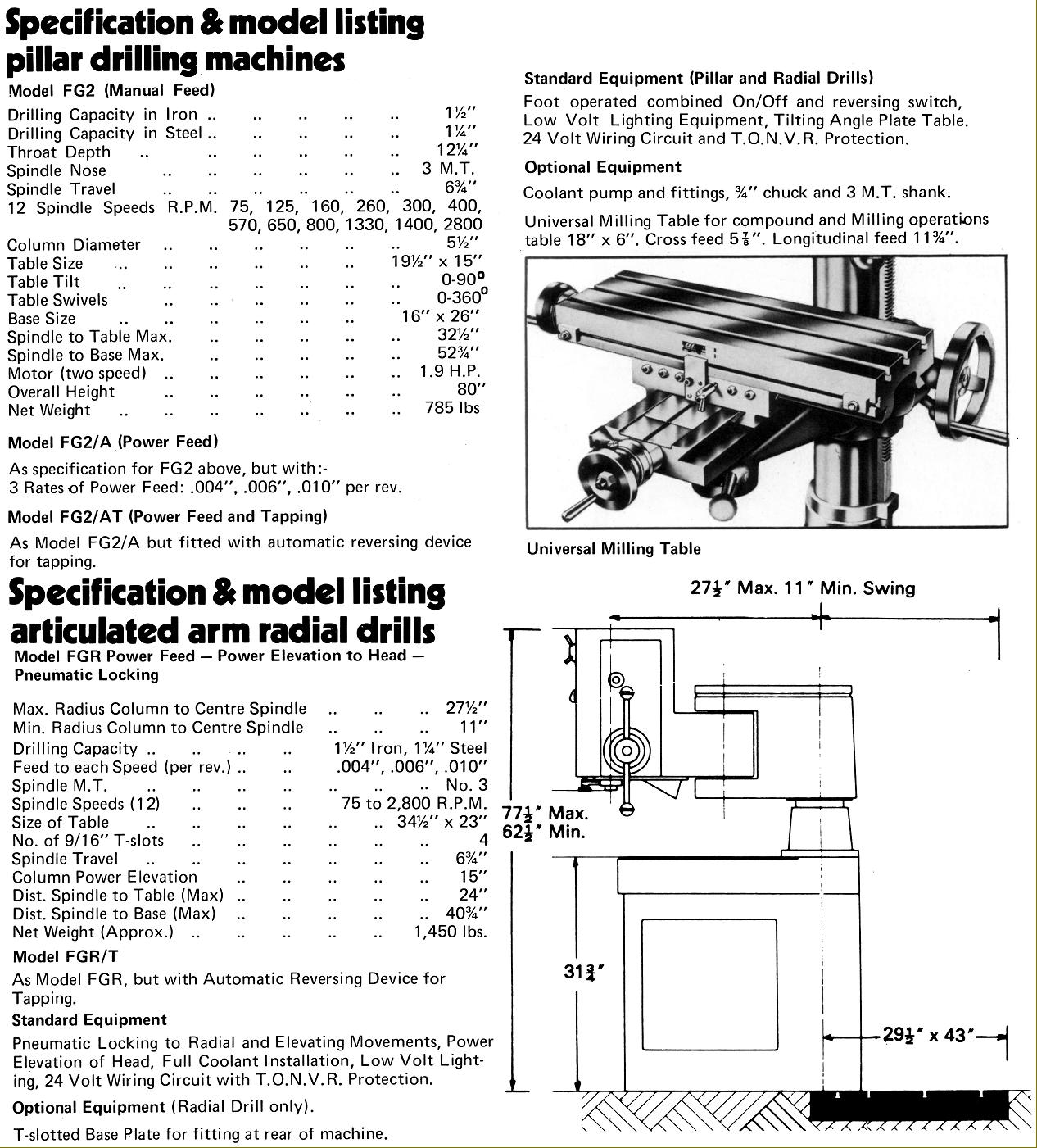

For workshops handling awkward or large jobs, an articulated-arm version was also manufactured, the FGR and FGR/T. This drill was carried on a very substantial cast-iron box-section base in Meehanite with a 34.5" x 23" top machined with three T-slots; the front face of the box was open to allow space for the operator's knees when working in a sitting position. As an option, when even bigger sections of material needed to be supported, a large, rear-mounted 43.25" x 19.52" auxiliary table could be fitted. This drill was especially well-thought out, with the swing head supported on ball thrust and taper roller bearings to give an easy, finger-tip control of its movements. In order to save time locking and unlocking the head -,and so causing it to elevate and descend - a control panel, that the operator used to control the swing movement, was positioned immediately above the pistol grip Without releasing his grip it was possible, by thumb manipulation, to lock or release radial movements and raise, lower and lock the head under power.

Full details of the various models and their specifications can be found below..

|

|