|

Manuals Machine Tool Catalogues Belts Accessories Books South Bend Series 20 Lathe South Bend Home Page South Bend 9-inch Workshop South Bend Model 5 |

||

|

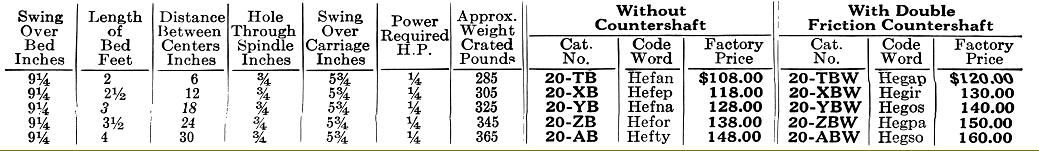

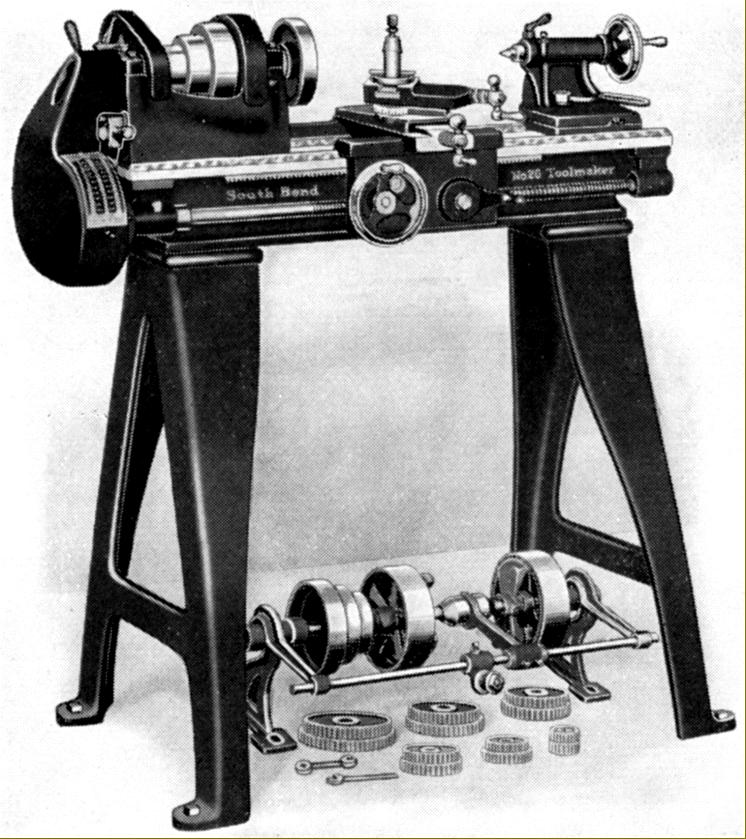

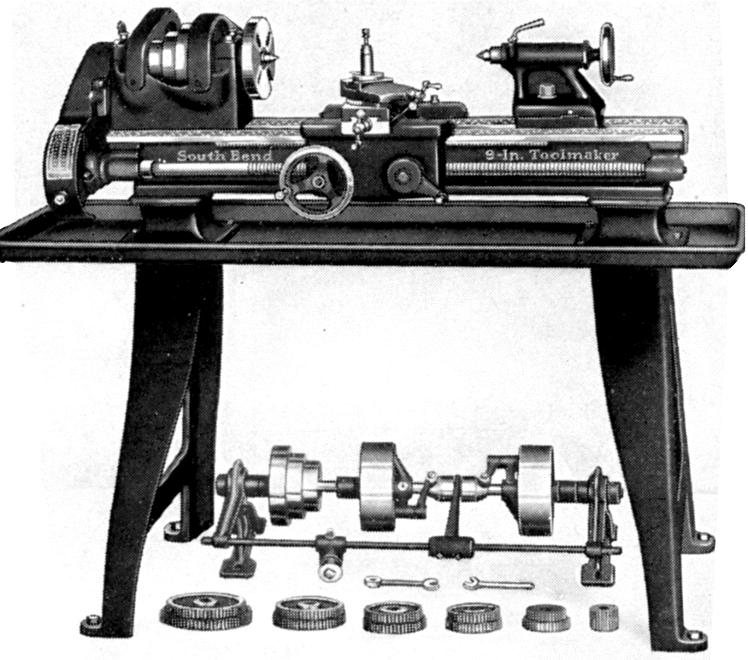

At around the time that the precursor to the most successful South Bend lathe of all was being launched, the Model 5, Type 405, the Company were also working on a new small lathe, the Series 20 Toolmaker. When introduced in early 1934, under Catalog No. 520, this new machine was priced at $158, this being twice the cost of an equivalent capacity if basic 405 that was listed at $75. Although the Toolmaker was shown in the 1934 Year Catalogue, by the middle of 1935 it had disappeared, perhaps setting a record for the shortest production run of any South Bend model. Cataloged as a rather special and expensive little lathe, it was, in fact, of absolutely conventional South Bend design and really little more than a copy of the regular 8-inch Model produced from 1931 until 1933 - though increased in size by around 20%. In addition to an identical design, the two lathes also shared the same changewheels, these being of 18 pitch although, oddly, the stud gear on the output of the tumble reverse had a 1/2" bore instead of the 9/16". As the ordinary changewheels could not be used (as on other models), the Company providing a set of three with each lathe of 16t, 32t and 64t. Like the Model 5, the Series 20 had no option of a power cross feed, nor a screwcutting gearbox, carriage travel for both threading and feed being by engaging and wearing out the leadscrew half-nuts. |

|

Continued: |

|

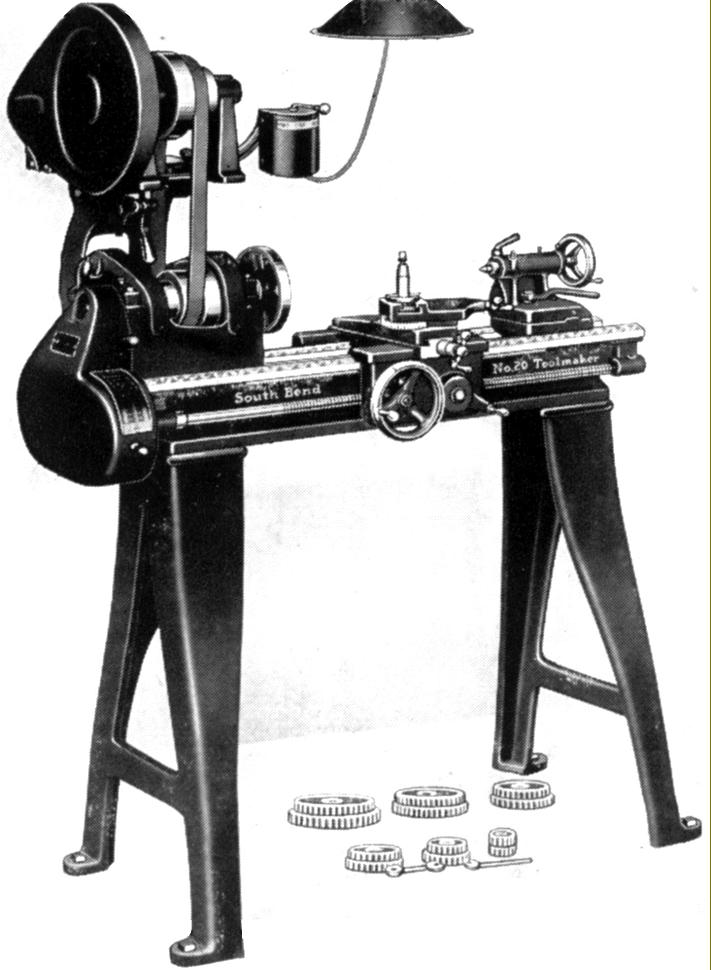

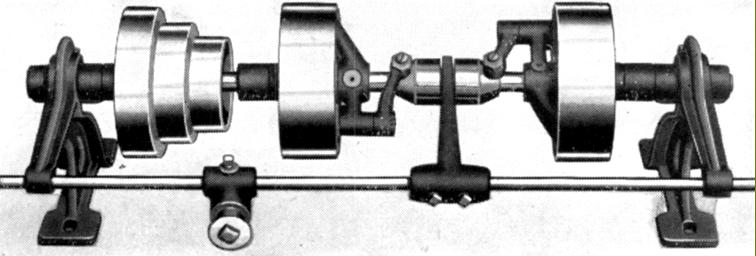

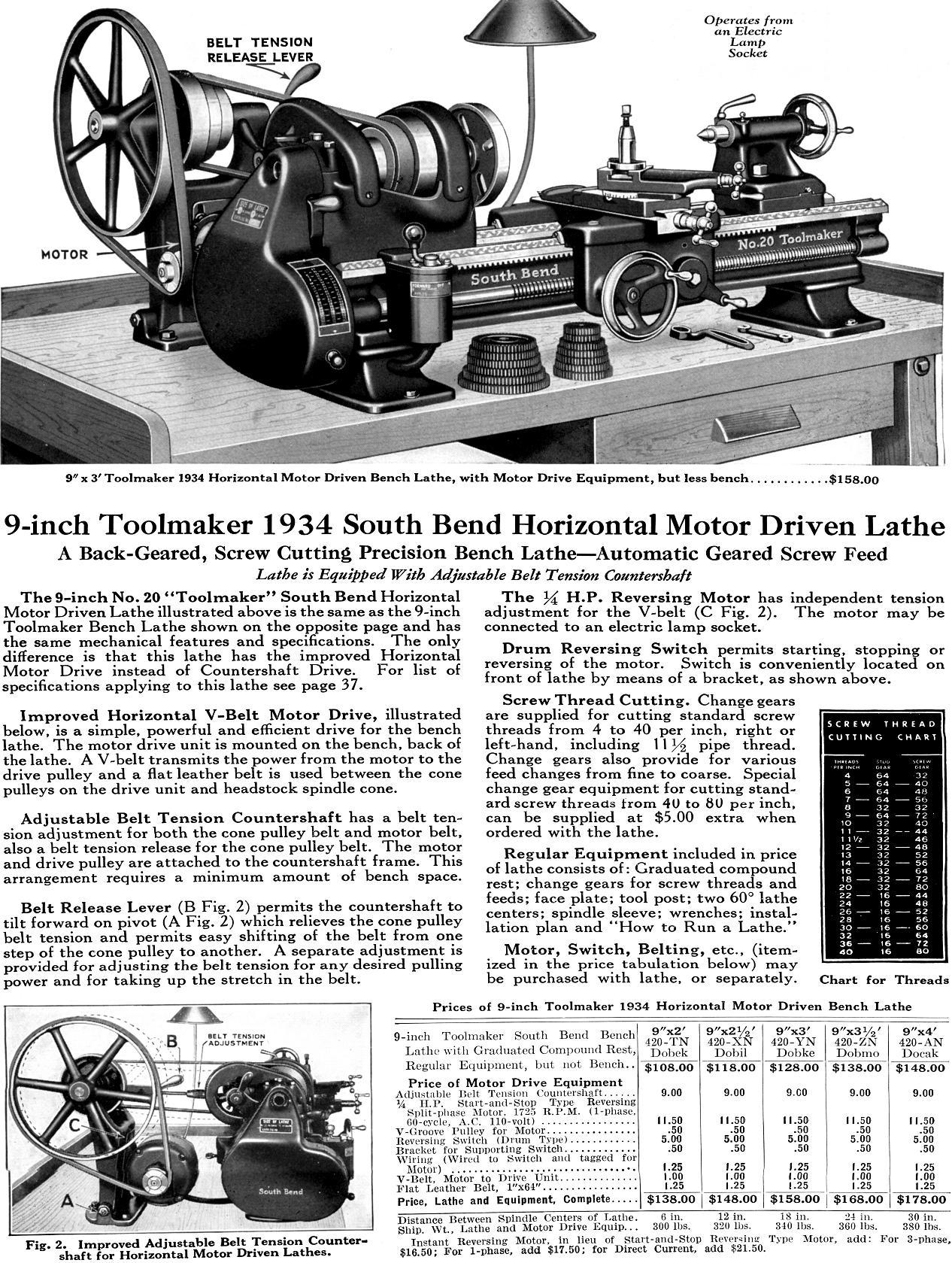

The South Bend Silent V-Belt Motor Driven countershaft as used on the Series 20 Toolmaker and also available for other lathes in the Company's range. The V-belt referred to was only from motor to countershaft, the final drive being by flat belt. This model was listed at $190 complete with Regular Equipment that included: 1/4 h.p. motor wired to a reversing switch with a V-pulley; the necessary belt; a graduated compound rest (top slide),; faceplate; toolpost; two 60° centres; an adaptor to sleeve down the spindle nose; a set of screwcutting changewheels; wrenches; lag screws; washers; installation plan - and copy of the South Bend Book "How to Run a Lathe" |

|

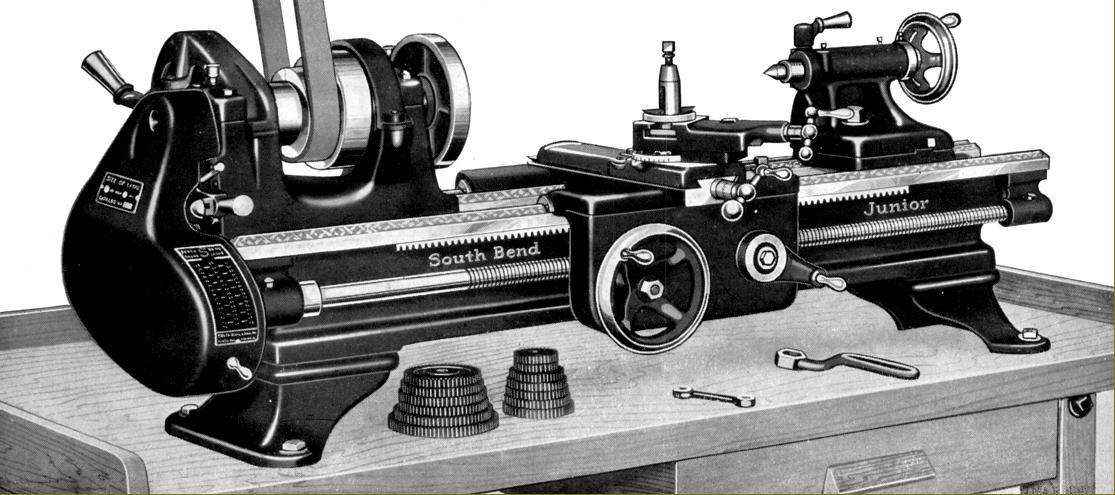

Simplex Motor Driven Bench Lathe with standard equipment - priced at $156 in 1934 with "Regular Equipment". "Simplex" referred to the fact that this was the simplest form possible of a remote countershaft available |

||

|

|

|

|

||

|

|

||

|

|

||

|

|

||

|

South Bend Series 20 Lathe E-Mail Tony@lathes.co.uk Manuals Machine Tool Catalogues Belts Accessories Books |

||