|

Shepard, Lathe & Co. was founded in 1845, as S. C. Coombs & Co. (a joint venture by Samuel C. Coombs, Russell R. Shepard and Martin Lathe - yes, he really was called Mr Lathe...)In 1853, when Mr Coombs left, the Company was reorganised as Shepard, Lathe & Co. and then, in 1864, when Shepard retired, as Lathe & Morse.

As a point of interest, another Company with a similar name (and not connected with Shepard, Lathe & Co.) was H. L. Shepard & Co. of Cincinnati, Ohio. This concern had been founded in 1875 and then reorganized in 1898 as the Shepard Lathe Co.; production of their lighter lathes under the brand Shepard continued until, it is believed, the mid 1920s. One lathe known to have been manufactured by them was the treadle-powered Sterling, a model introduced in 1919 and exported to the UK where machinery and tools dealers such as Burton, Griffiths & Co. offered it for sale as a relatively low-cost item.

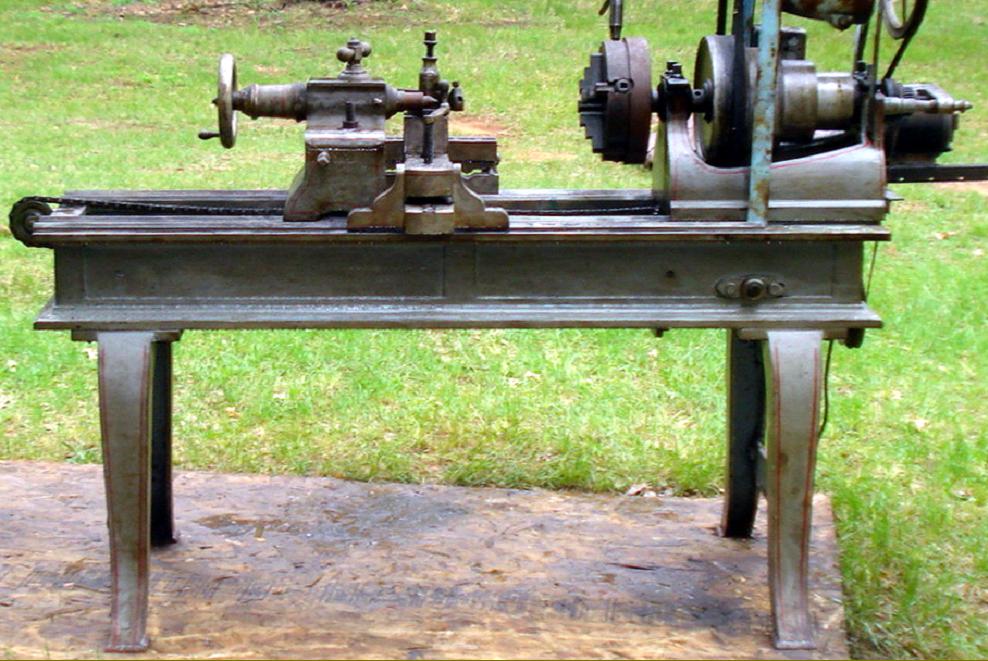

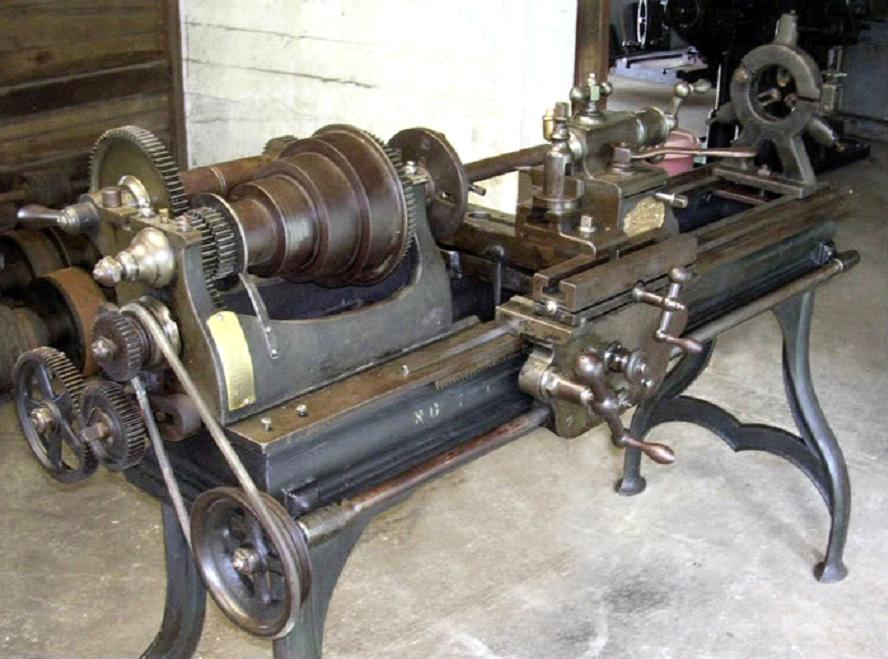

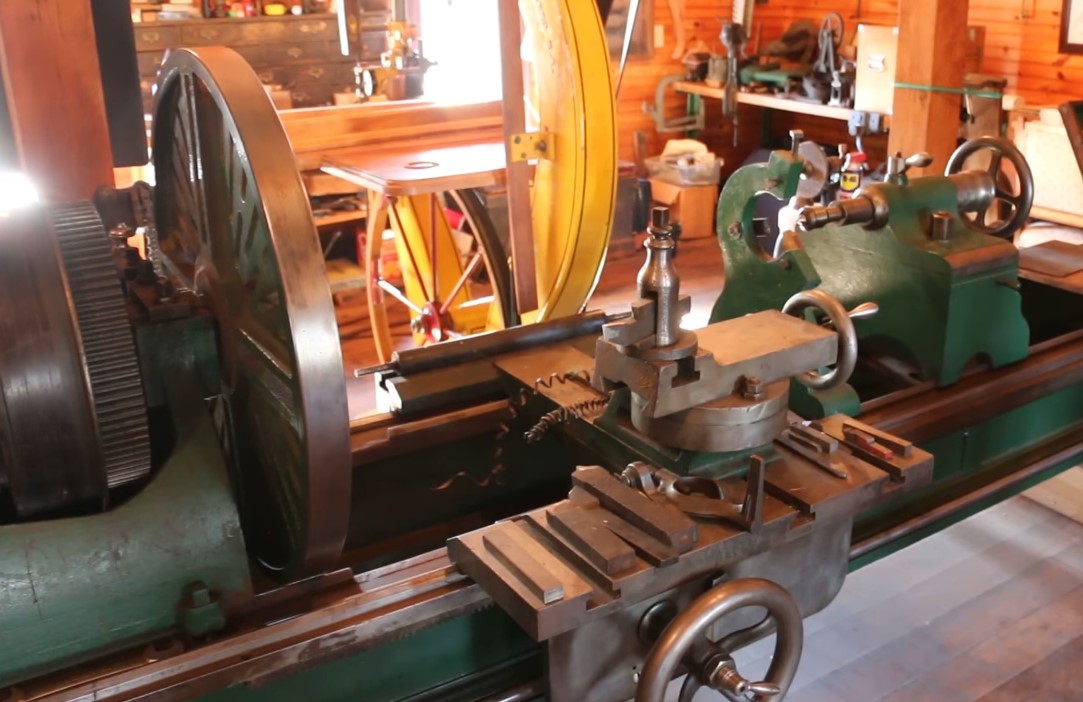

Shown below is a Shepard, Lathe & Co. lathe with a chain to pull the carriage to and fro and a typical-for-the-time elevating cross-slide - while these features hint at a pre-1853 design, manufacture could have been at any date during the company's active years. In 1853, at the Worcester Mechanics Association Annual Show, two engineers, Thayer & Houghton, appeared with an important development that superseded the chain mechanism - carriage feed by a rod engineered to give a variable-speed drive.

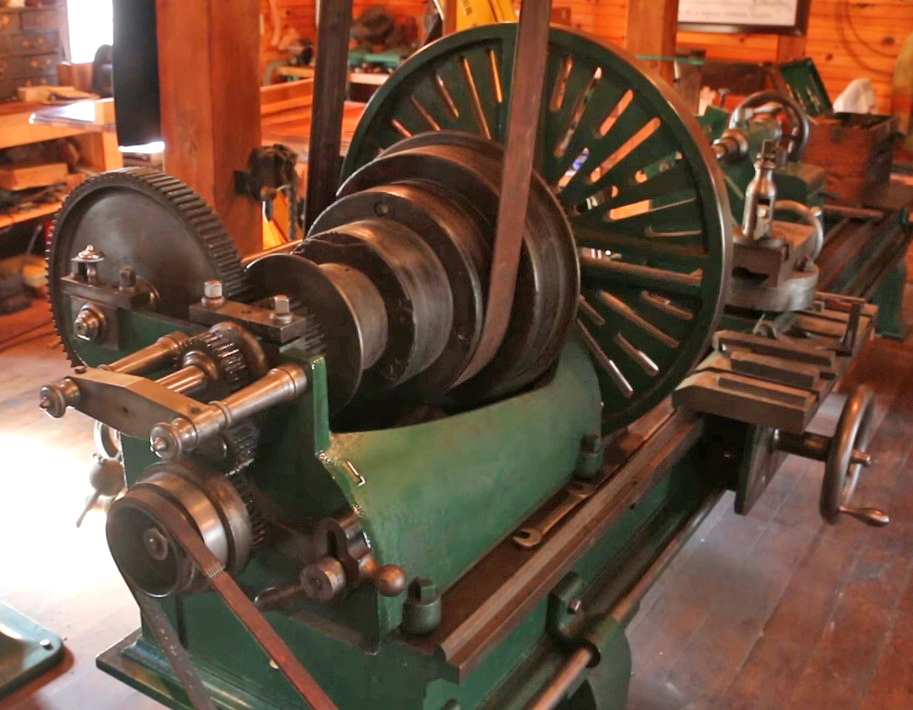

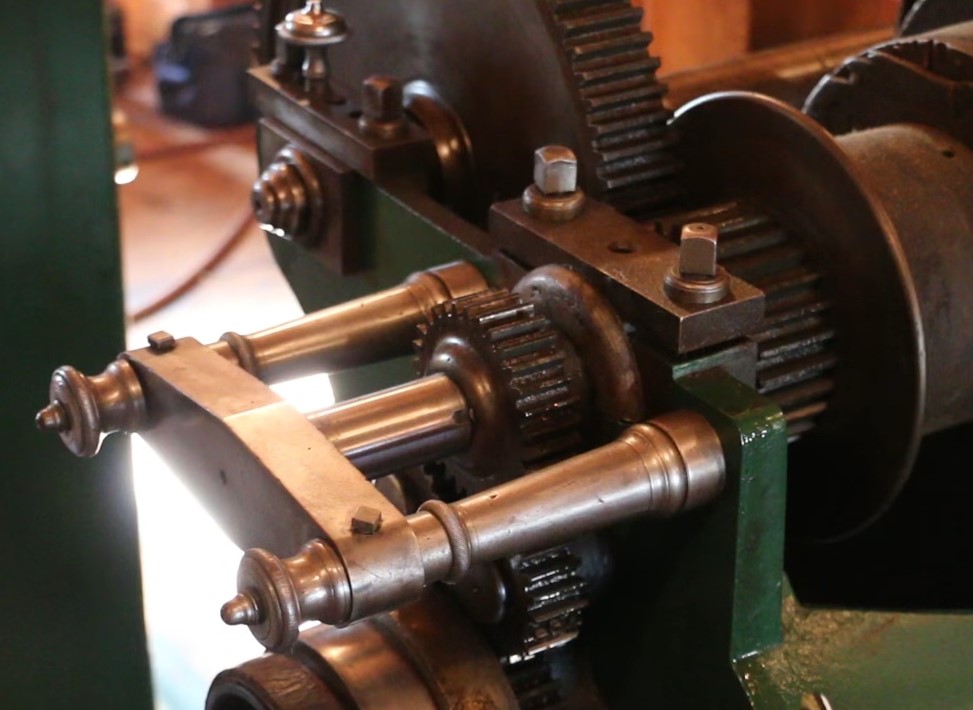

Although details of Shepard's chain drive are not clear from the photographs, it may have incorporated simplified elements of a rather complex dual-worm drive as employed on the Baxter D. Whitney lathe of 1854 (and described in the American Machinist of 14 March 1908.) On the Shepard, drive to the chain began with a 2-step round-rope pulley, turned from the headstock spindle, that rotated a shaft set horizontally below the line of the bed at the headstock end. Fastened to the shaft was a pair of worm gears, separated by a short plain section, with one gear cut left-hand pitch and the other right-hand. The worms could mesh with a large worm wheel (set just inboard of a plain handwheel used for manual feed) and whose mounting shaft passed through the bed to carry a sprocket at its far end. By using a lever, the operator could slide the horizontal shaft left or right to engage either set of worm teeth (or leave in the middle for neutral) and so cause the worm wheel to rotate clockwise or anti-clockwise. As the chain was in the form of an endless loop and fastened to the carriage, it caused the latter to be moved either towards or away from the headstock. In other respects, the lathe has elements of design still in use today including a very wide, straight (gapless) V-way bed with the headstock secured on an inner V-pair shared by the tailstock and the carriage running on an outer pair. The latter arrangement allowed of course, for the continued correct alignment of tailstock and headstock even though the carriageways might have worn in service.

Could the largest diameter of the headstock pulley contain an epicyclic backgear? The writer hopes to find out.

Should any reader have one of these now very rare lathes and would like to contribute photographs and their observations, the writer would be very interested to hear from you.

|

|