|

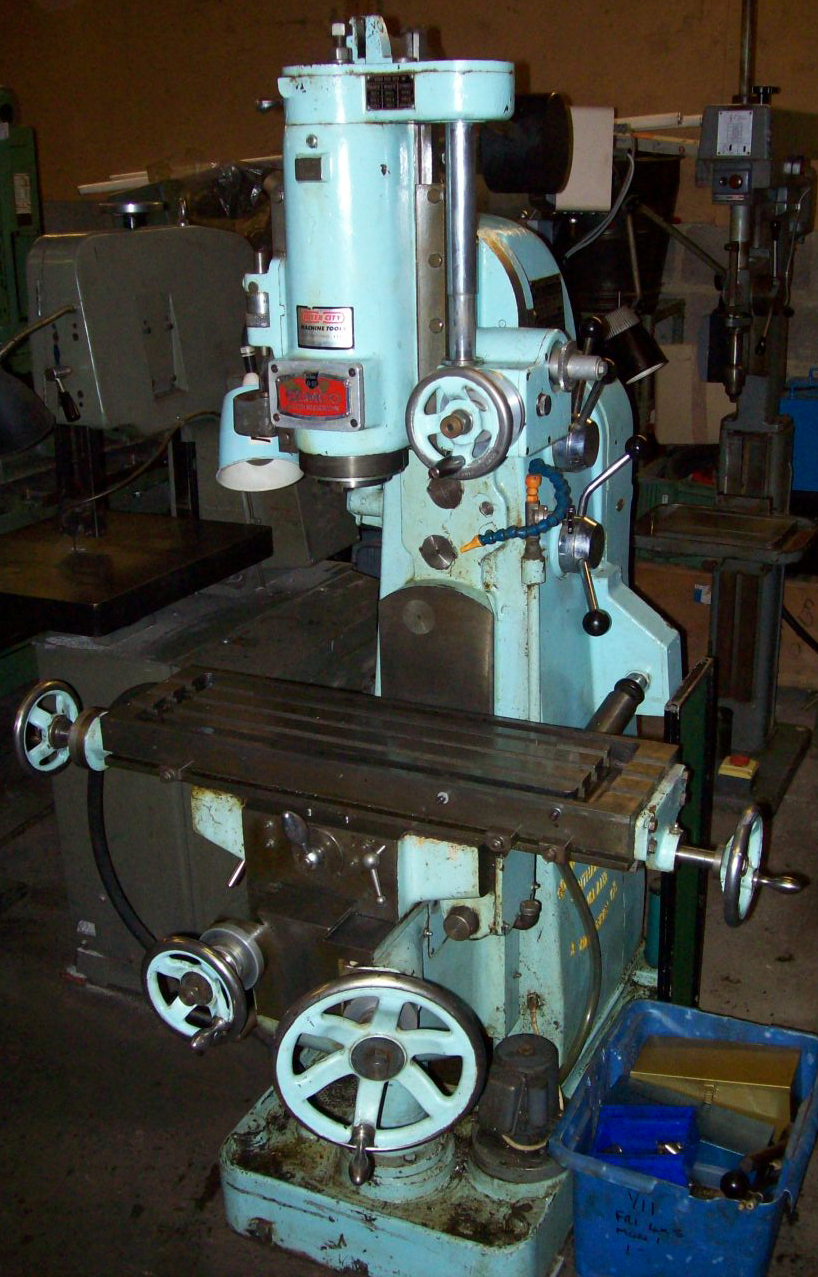

Founded in 1938 to rebuild and repair machine tools (with war work on Spitfire components) SEMCO (the letters come from its name "Southern Engineering & Machinery Co.") was based in the Connaught Buildings on Millbrook Road, Southampton. The Company was taken over by Ajax Machine Tools in 2005 and the name disappeared - though in 2023 it was revived and trades today under its original name: www.semco.co.uk

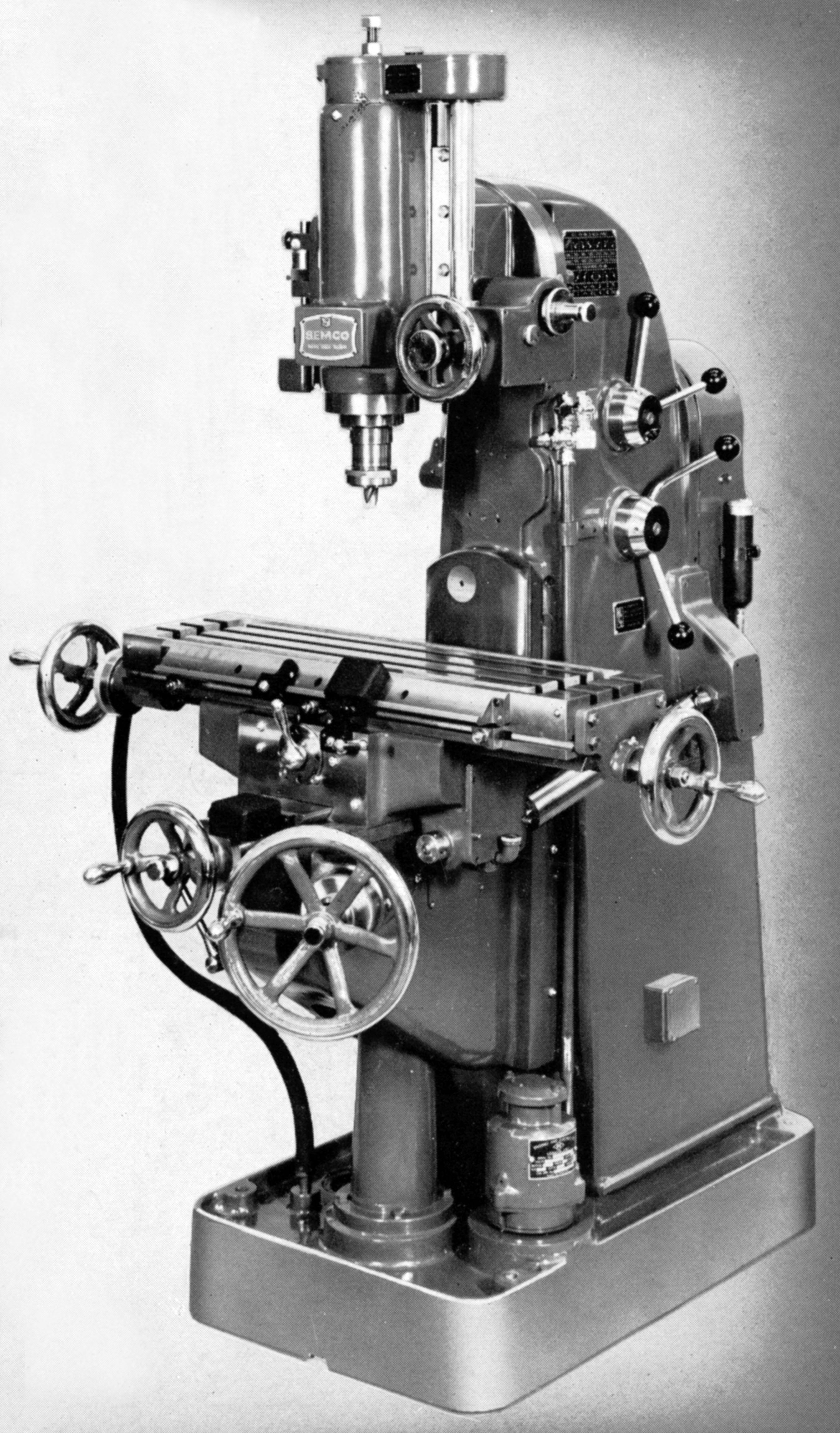

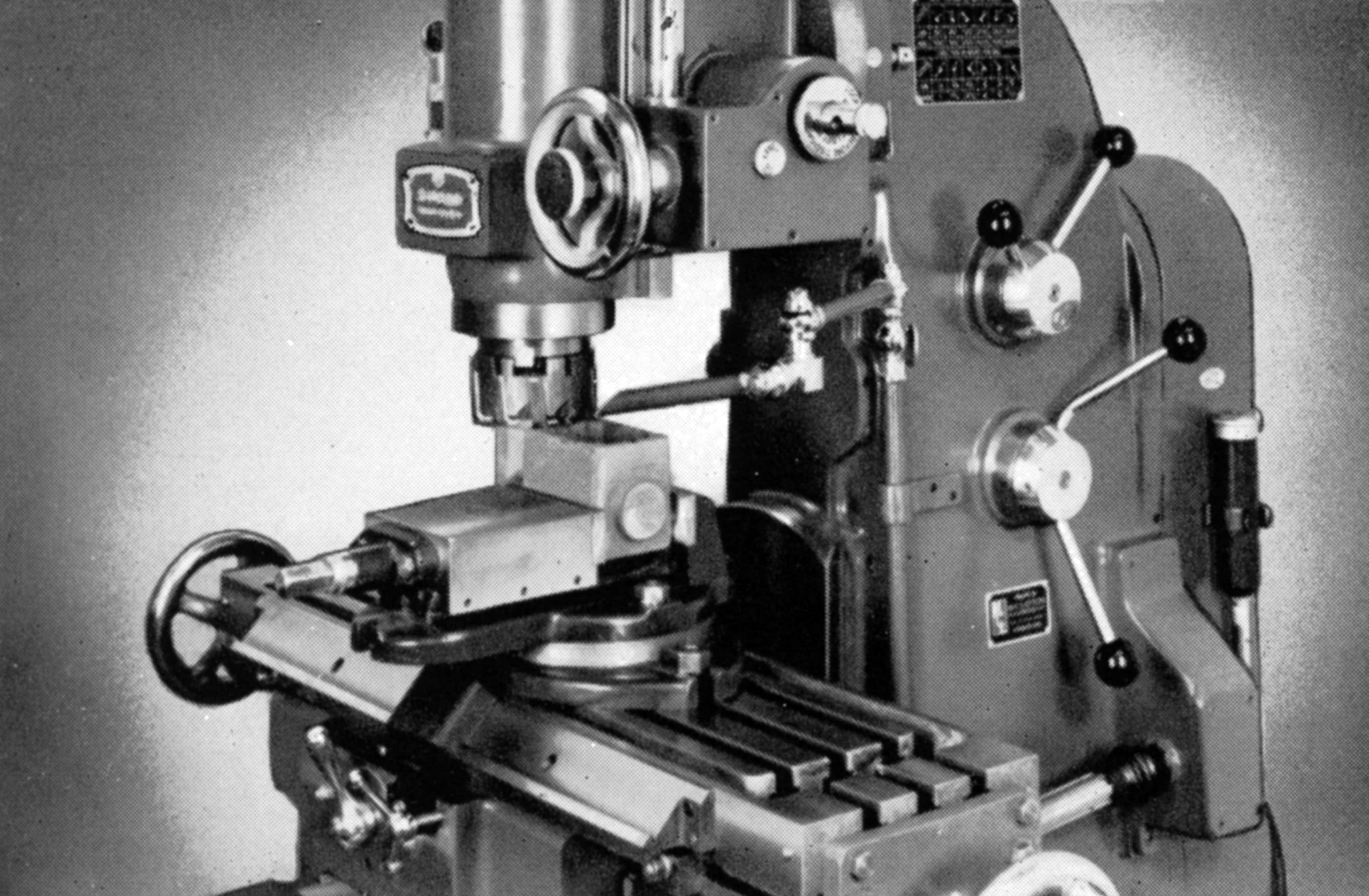

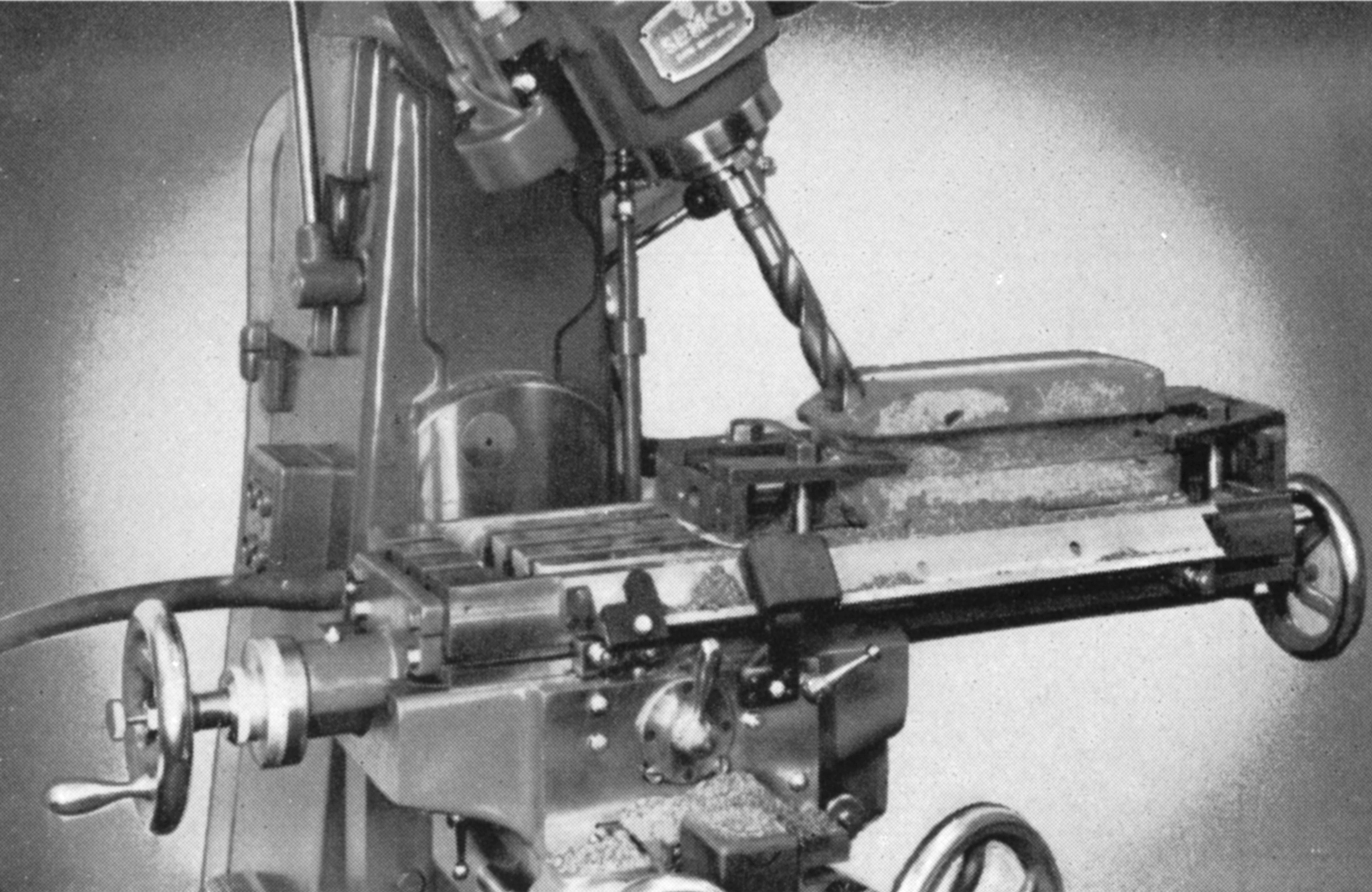

The background to the SEMCO 0-DF vertical milling machine is uncertain. While the publicity literature - dated circa late 1950s to early 1960s - claims that hundreds are already in use and shows parts of the machine under construction and during testing, there was no claim that it was manufactured by Southern Engineering - and that's because it wasn't, it was by Henry Milnes of Bradford. There was, possibly, some small differences in specification, but the following refers exclusively to the model sold by Southern.

In addition to the 0-DF, an improved model, 1-DF was also produced, this having a number of significant differences including a top speed raised from 1000 to 1650 r.p.m. and a table ten inches longer. Further details of this model are, hopefully, in the pipeline…,

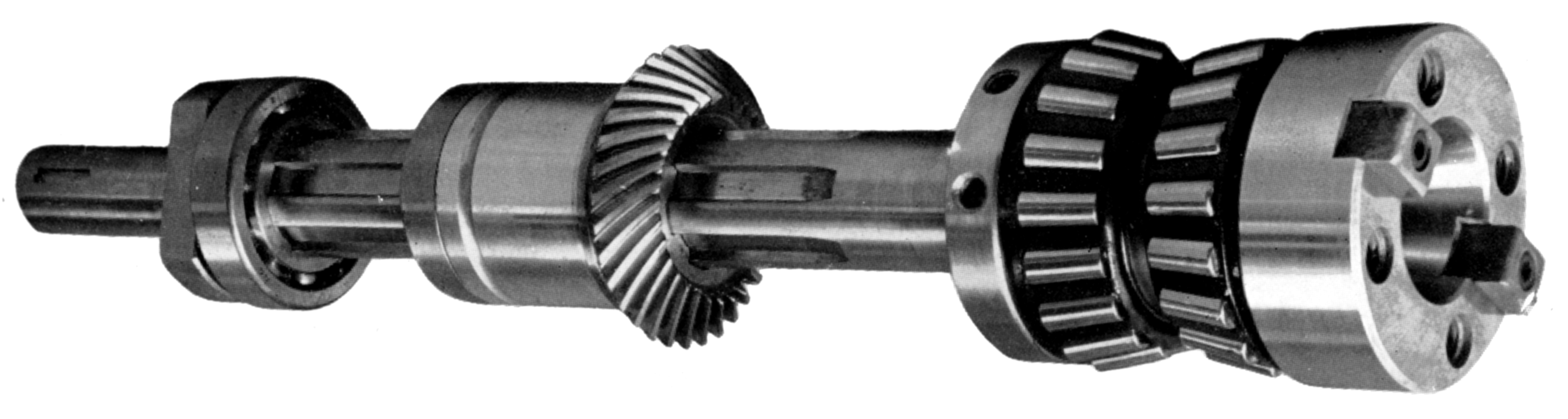

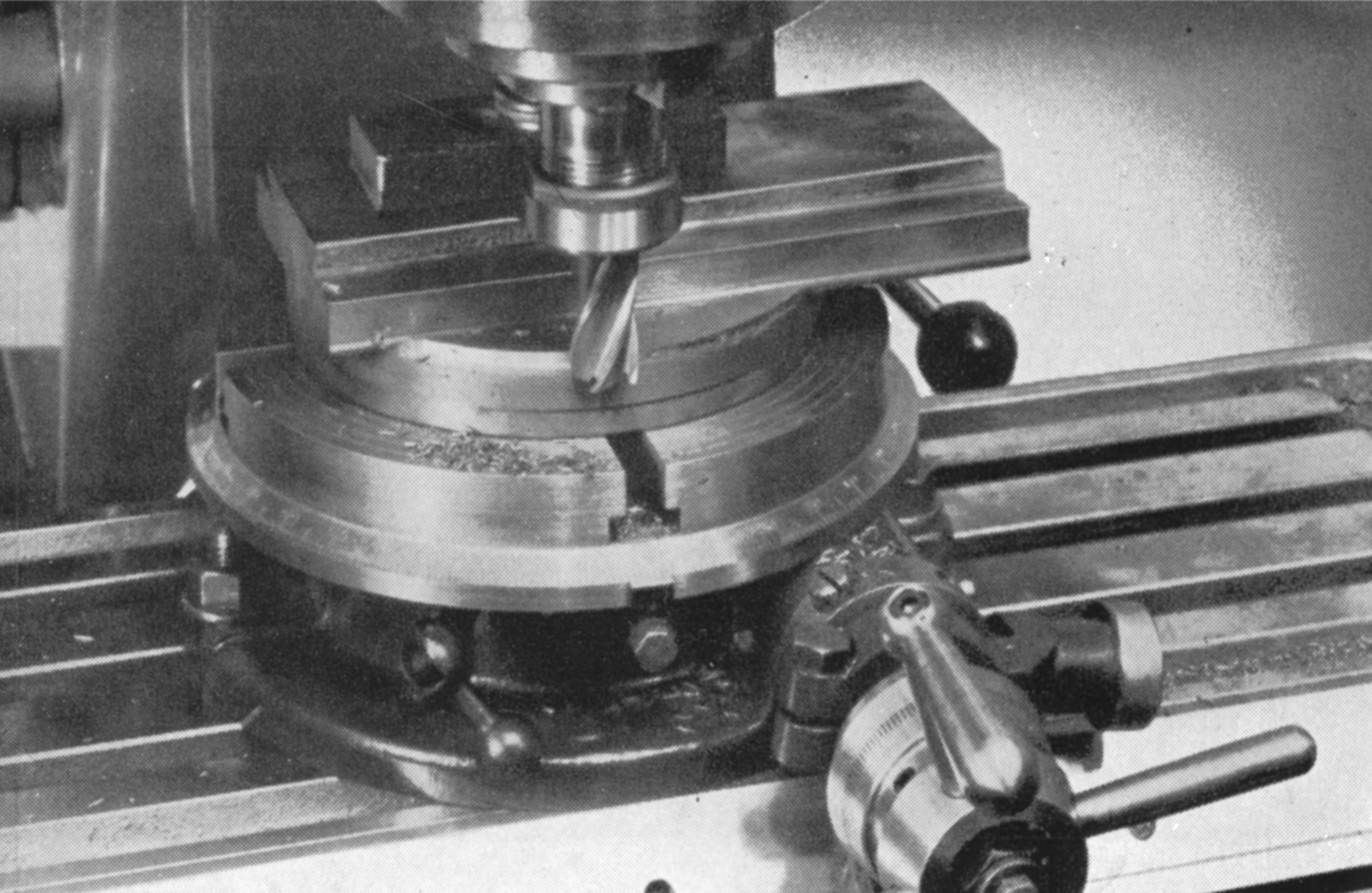

Built to pass the contemporary "1st Grade Acceptance Checks" as published by the Institution of Mechanical Engineers and the Institution of Production Engineers, the 0-DF was a heavy, (2000 lb) compact and strongly-built machine. It was powered by a 1500 r.p.m. 3 h.p. 3-phase motor, held in the lower section of the main column, with drive direct to the spindle and also though a 6-speed, oil-sump lubricated gearbox mounted above it; final drive to the vertical head was by a pair of bevel gears that turned the drive through 90°. With its vertical axis set 10.5" from the inside face of the column, the head could be swivelled through 360° and held a hardened and ground 40 INT spindle running in a pair of pre-loaded, back-to-back precision-class Timken taper roller bearings at the front and a single ball race at the back. Quill travel, at 3 inches, was just about adequate and could be engaged either by hand (using a fine-feed handwheel or quick-action lever) or under power, three rates of the latter being provided at 0.001", 0.002" and 0.004" per revolution of the spindle. Fitted to the left-hand side of the head was a large and finely engraved micrometer barrel, the setting of which could automatically trip the power down-feed. With the massive knee set to its lowest position, the maximum clearance under the spindle nose was 15" and, when lifted as high as possible, 0".

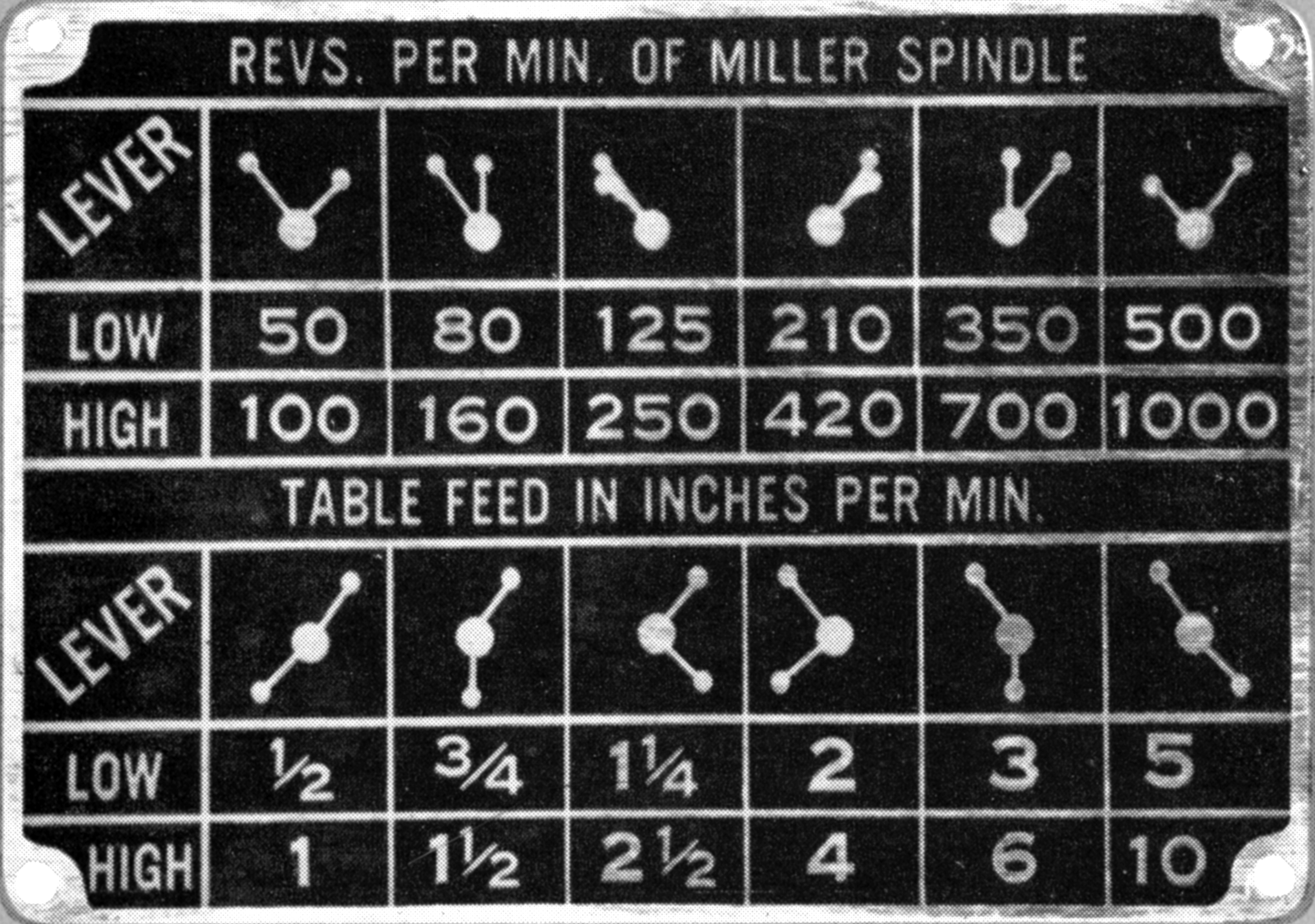

A useful range of twelve spindle speeds was provided running from 100 through 160, 250, 420, 700 to 1000 r.p.m. in direct belt drive and from 50, 80, 125, 210, 350 to 500 r.p.m. through the speed-reduction gearbox.

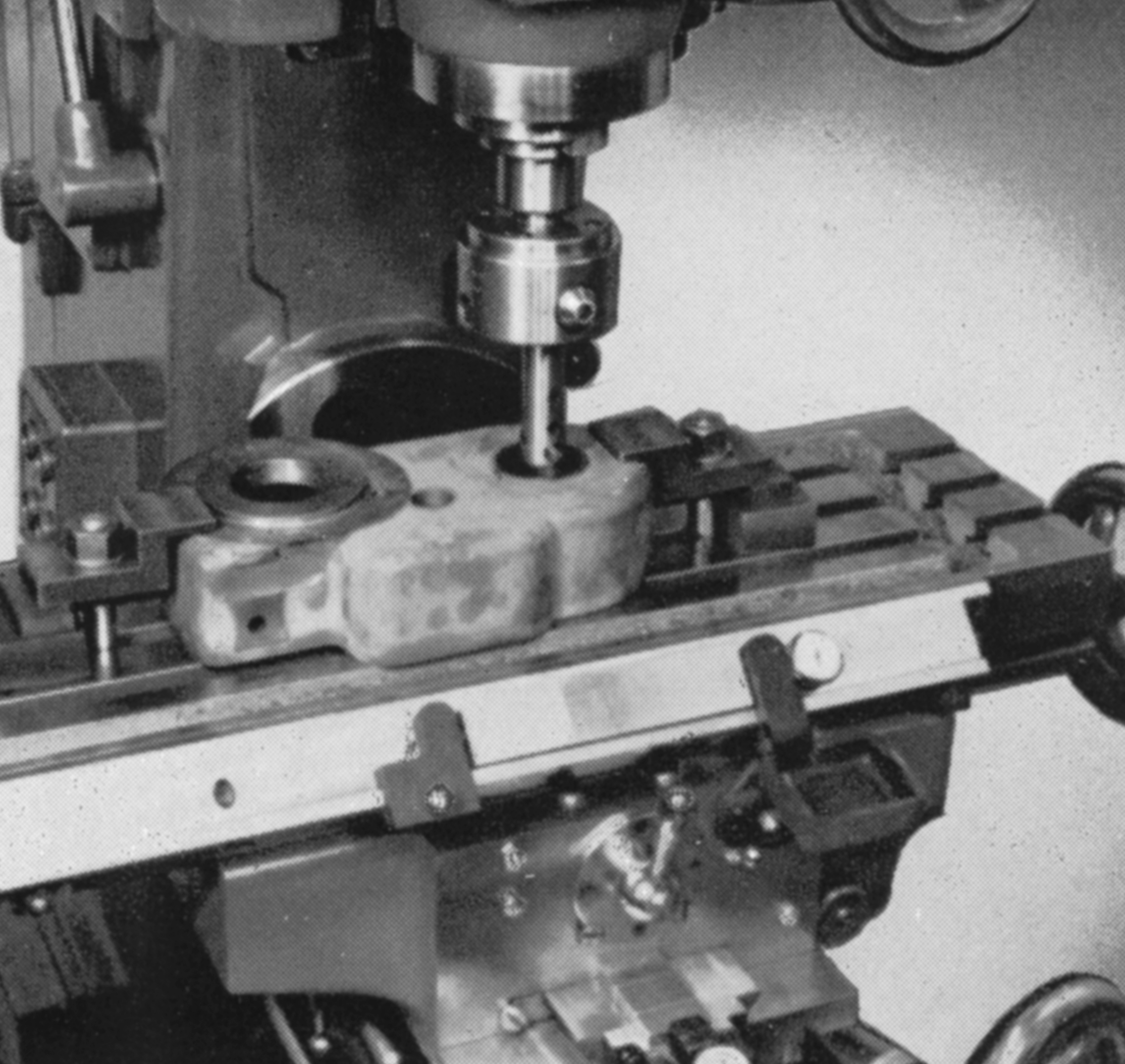

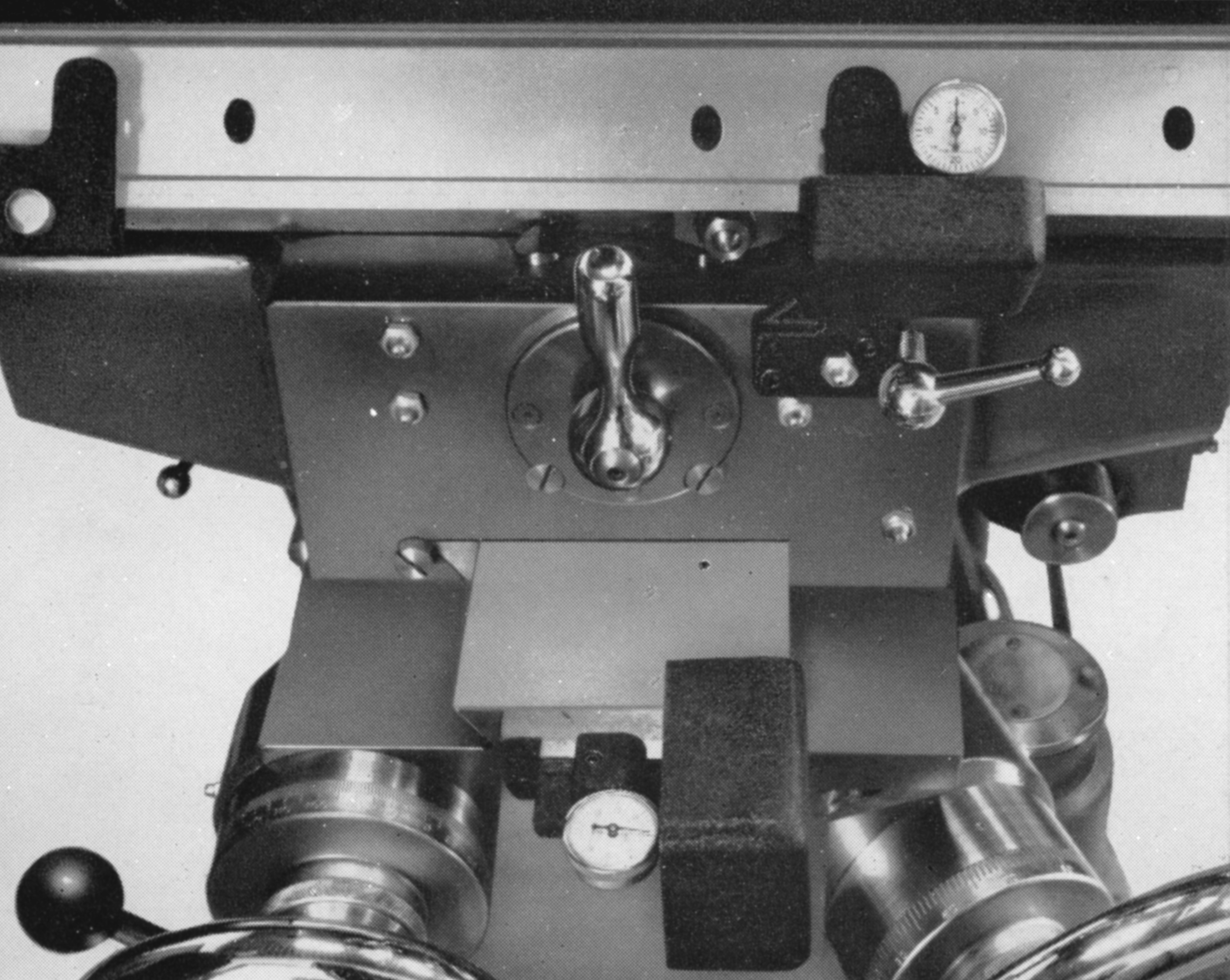

Mounted on very deep saddle that ran on a relatively narrow pair of V-edged ways, the 30" x 8.5" table had three 5/8" T-slots on a spacing of 17/8", a longitudinal travel of 18" under power and, by hand only, 6.5" across and 14.5" vertically. Available as an extra-cost option was a fitting, to mount, on the front face of the table, that could be used to mount gauge blocks and dial indicators, by which means jobs could be set with great accuracy; a similar fitting also being available for the cross feed. Power feed for the table came an extension of the main input pulley, this driving a splined carden shaft that turned a worm-and-wheel gear assembly surrounding the table's longitudinal feed screw. Selection and engagement of power feed was by a single, centrally-mounted "directional" lever with adjustable knock-off stops at each side. As the table power feed came from the spindle drive, the same numbers of rate (twelve) were possible, these ranging from 1/2" to 5" with the drive running through the gearbox and from 1" to 10" in direct belt drive. Full-circle handwheels were fitted at both ends of the table though only one large micrometer dial, this being on the left with the right-hand side perhaps left without to more easily accommodate a powered indexing attachment of some type. While all the micrometer dials were usefully large, on some examples of the 0-DF the finish was a bright, reflective chrome rather than the usual and easier-to-read, dull satin. Of high quality, the table feed screws had ground threads and were supported in ball races where they passed through the table-end brackets.

Bolted to a separate 33" x 21" base that doubled as a coolant storage tank, the miller stood 71" high and required, for comfortable operation, a floor space of 72" x 48"..

|

|