|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E-MAIL Tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sales & Wants

Manuals Catalogues Belts Books Accessories

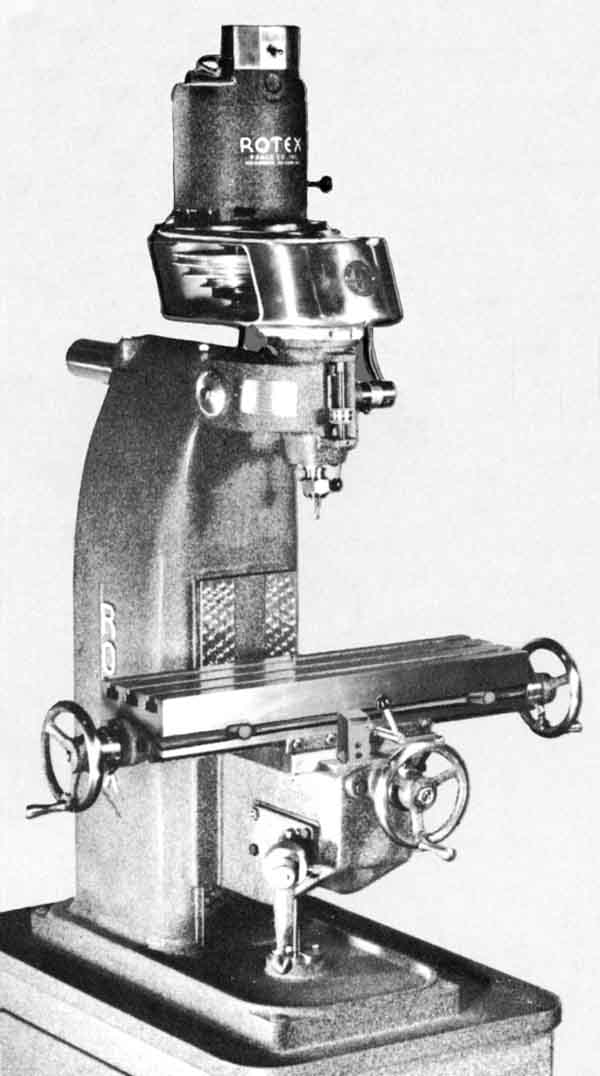

Rotex Milling Machines

& Machine Tools - USA

If you have a Rotex miller or Planer - or any of the manufacturer's

publicity literature - the author would be pleased to hear from you

A maker's literature is available for these machines

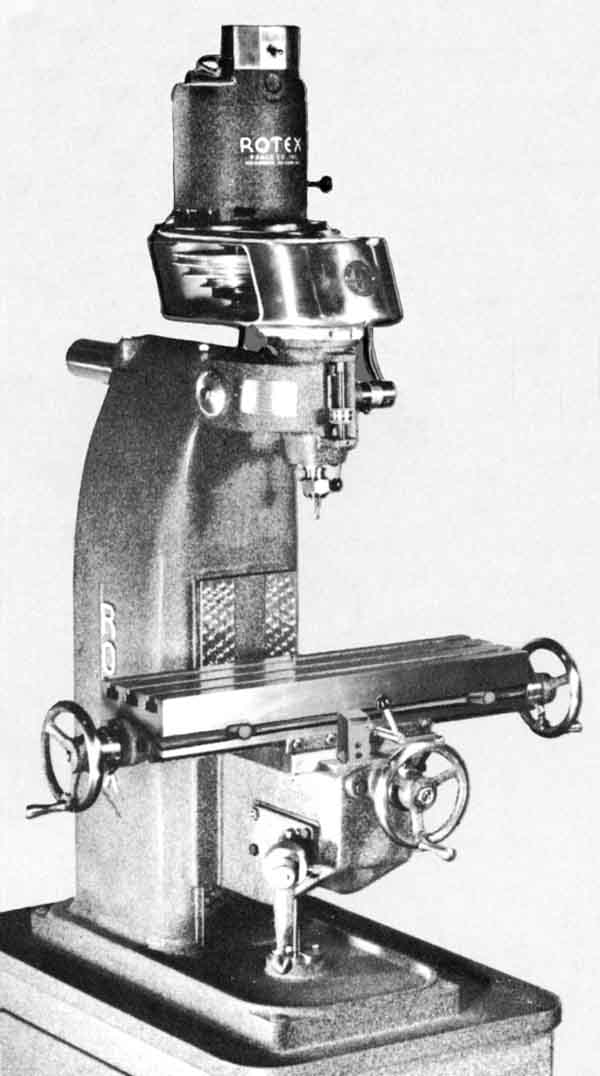

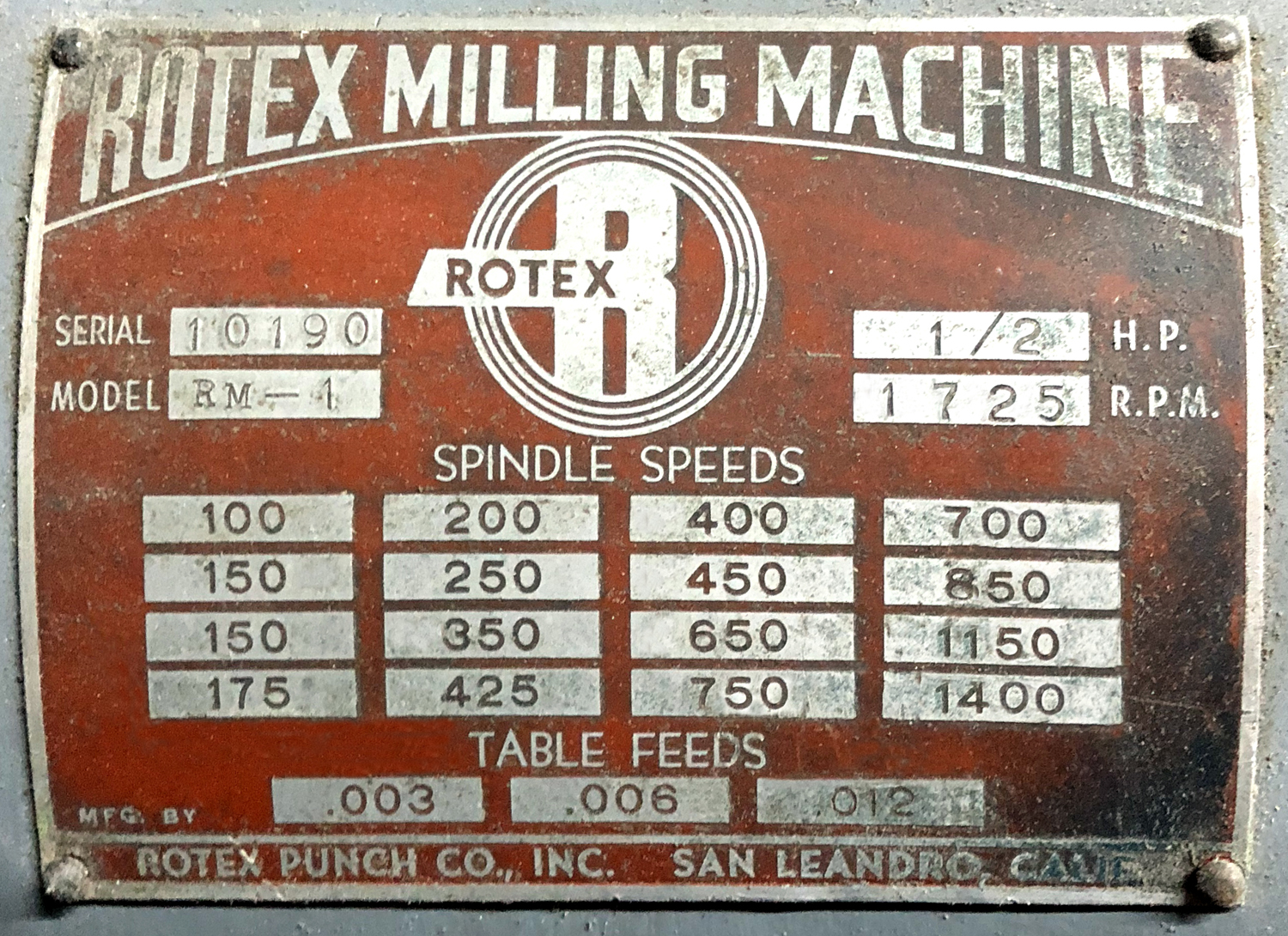

Owned by one Earl Pearson, the American-based Rotex Punch Co. Inc. was based in San Leandro, California and manufactured a range of entirely conventional small horizontal, universal millers and vertical millers - as well as an unusual (for the 1950s) hydraulically operated bench-top planer. All the Company's machine tools had something of the appearance of the early English-made Tom Senior designs - solidly built, very well finished and with careful attention to detail - with users reporting silky-smooth controls and a pleasing attention to detail in the design and finish of smaller components.

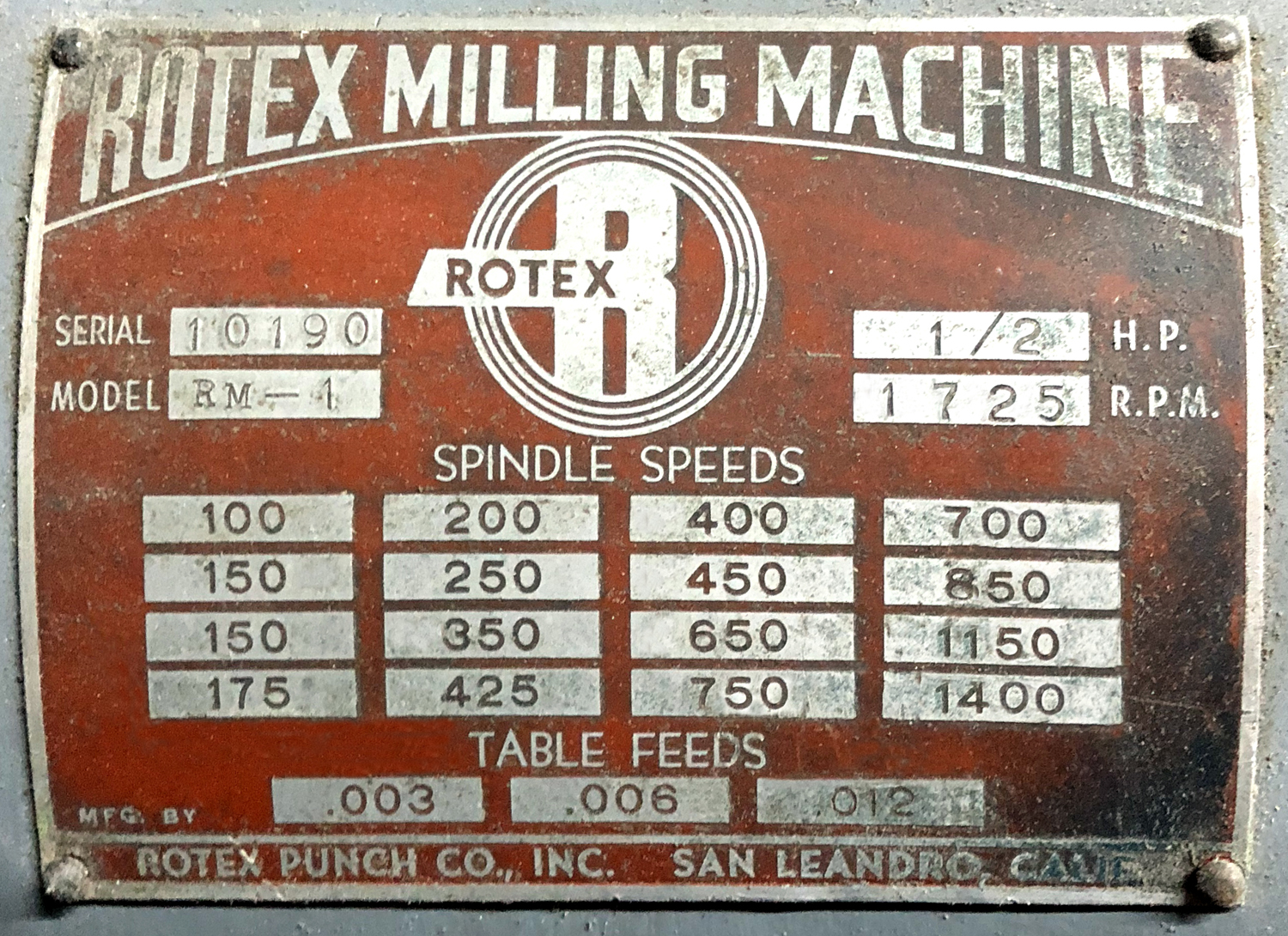

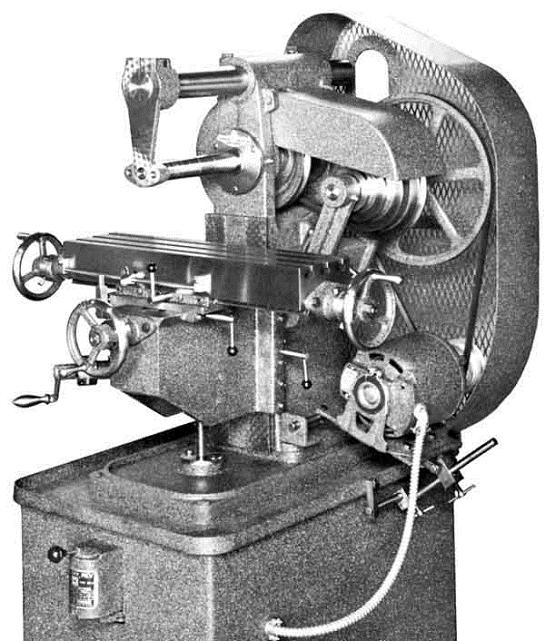

Fitted out for bench mounting, the standard horizontal miller had an integral, side-mounted V-belt drive countershaft that gave a range of 4 speeds. The spindle (bored through 0.75") was of a generous size for so compact a machine and the customer had a choice of either No. 4 Morse taper or Brown and Sharpe No. 9 and 10 fittings.

Reasonably sized for a smaller miller at 20" x 5", the exceptionally deep and robust table (with two, or optionally three, T slots) was powered along its 12 inches of longitudinal travel by a universally joined shaft driven from a pulley mounted on an extension to the rear of the taper-roller bearing spindle; three rates of feed were available:- 0.003", 0.006" and 0.012" per revolution. The traverse feed was five inches and the vertical movement of the knee 9 inches.

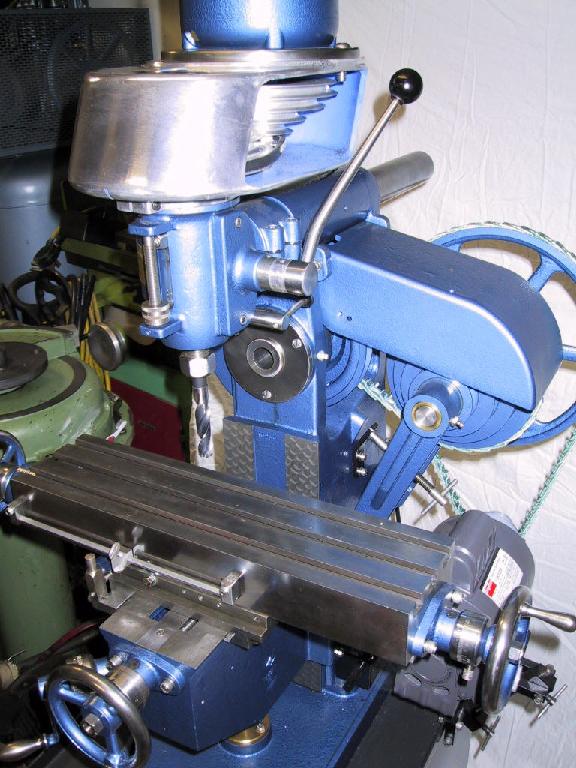

For the horizontal millers a simple non- quill feed vertical head (Type VH-255) was offered that mounted onto the front end of the round overarm; the head appears to have been driven by a shaft passing through the overarm to a 5-step V pulley, mounted at the back and driven from the same pulley cluster that powered the horizontal spindle. The machine occupied a box 36" front to back x 36" wide by 31" high - and weighed approximately 450 lb.

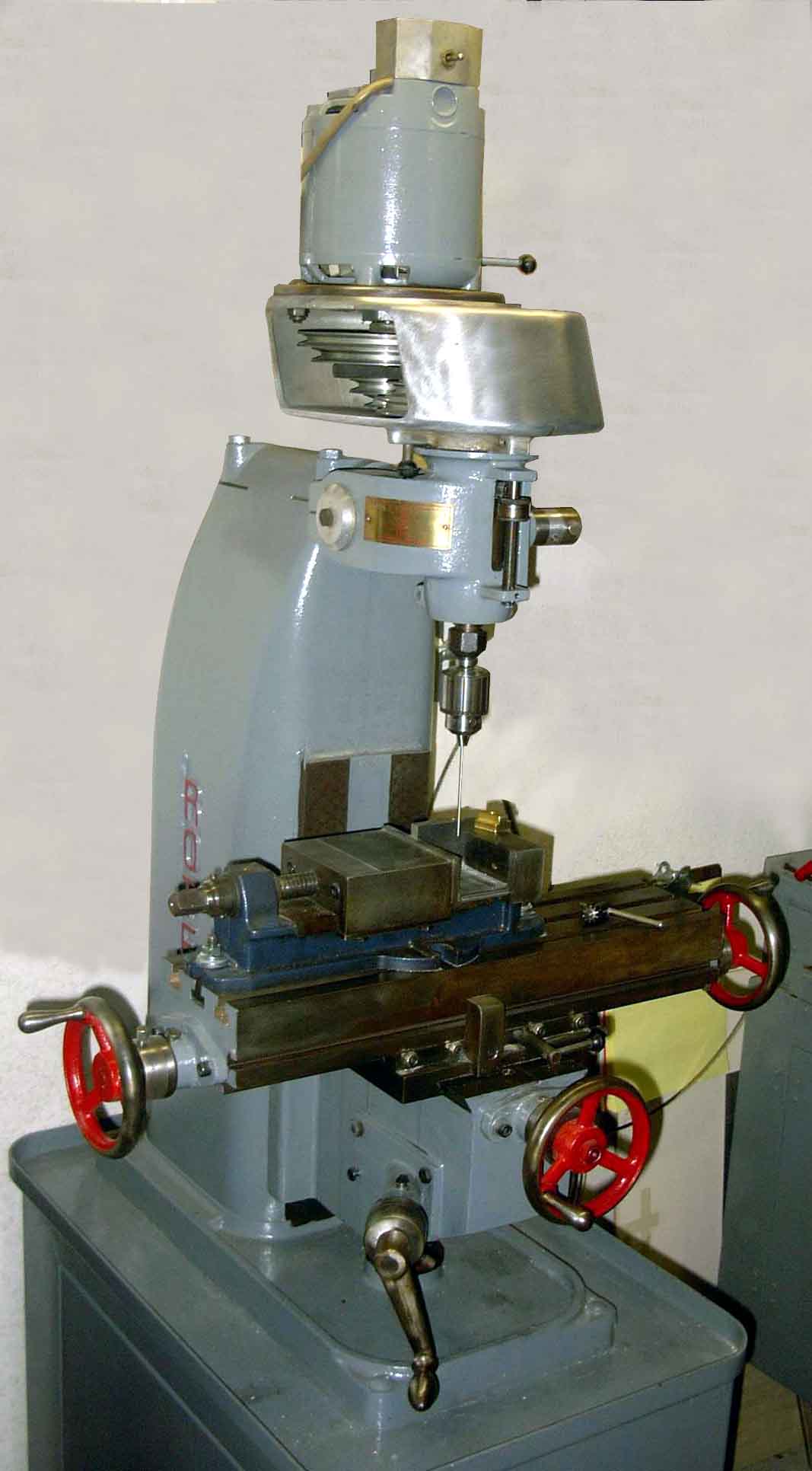

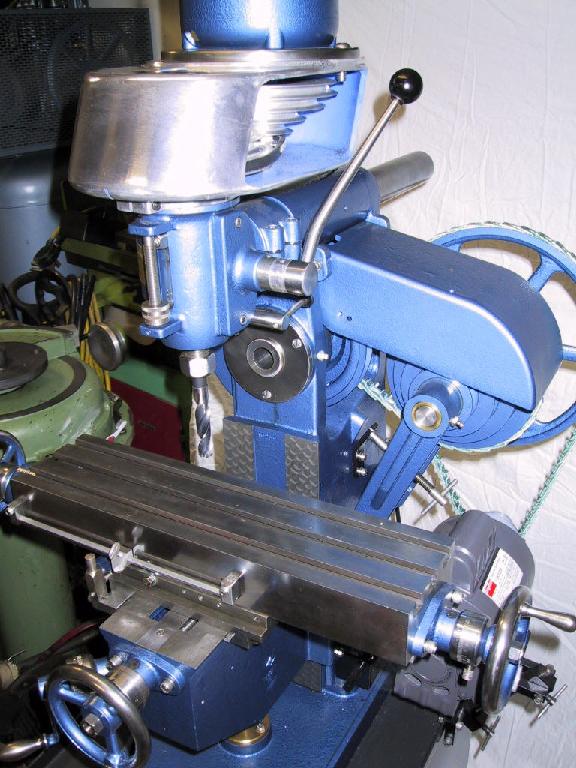

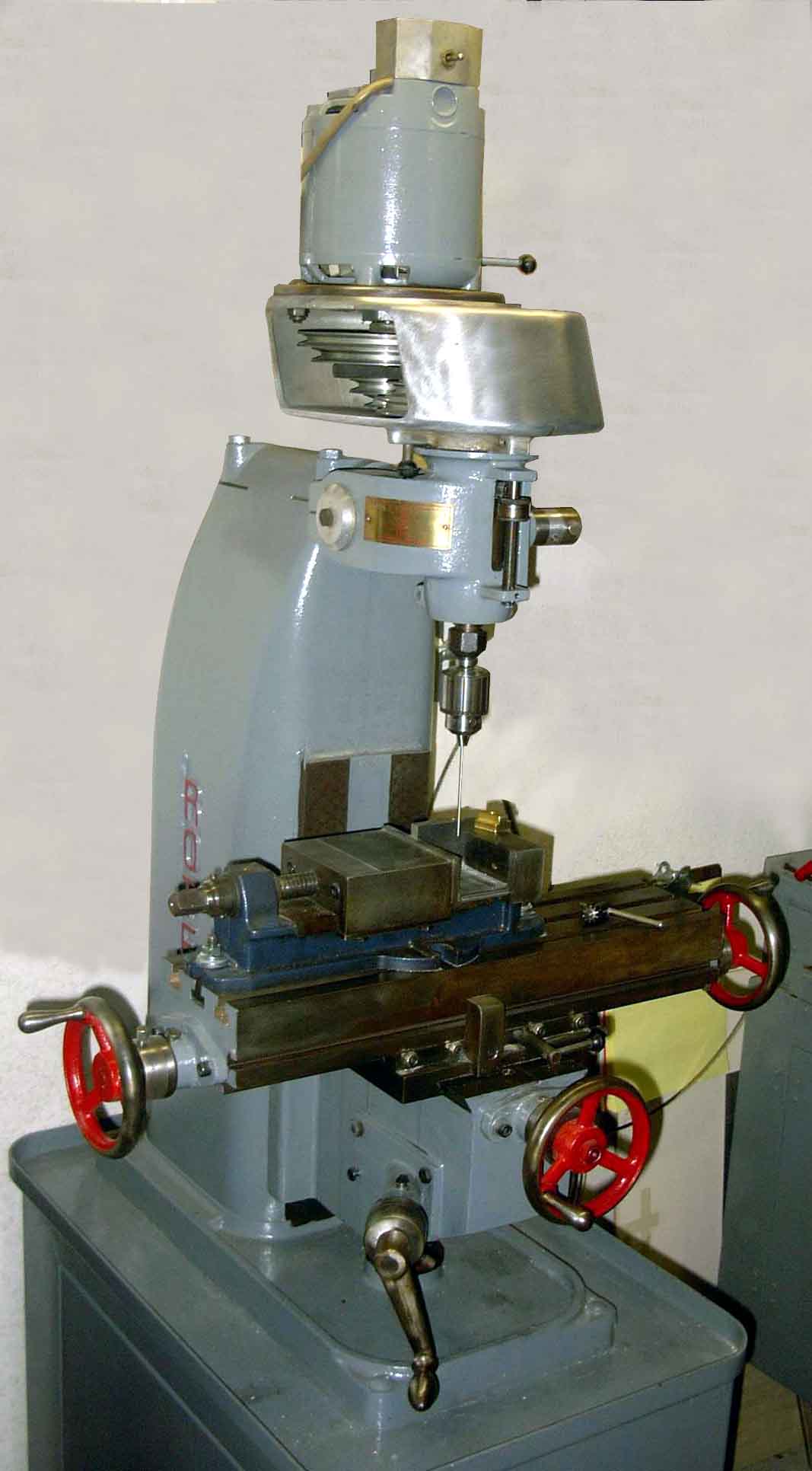

Dedicated Rotex vertical millers are rarely seen, and few can have been sold - though the machine was an ideal size for the smaller workshop with a self-contained, V-belt-drive, lever-action quill-feed head that could be both swivelled and nodded - the arrangement being rather along the lines of the neat little Rusnok head (the later being found as an attachment on some Rotex models). Cutting tools were held by double-taper collets - though instead of the powerful clamping force found on modern types, those on the Rotex have been reported as inadequate, with flex apparent under only moderate cuts. Apart from the head, in all other respects the vertical appears to have been identical to the horizontal models (with the usual deep and robust table) though of course, without the horizontal spindle and associated drive gear.

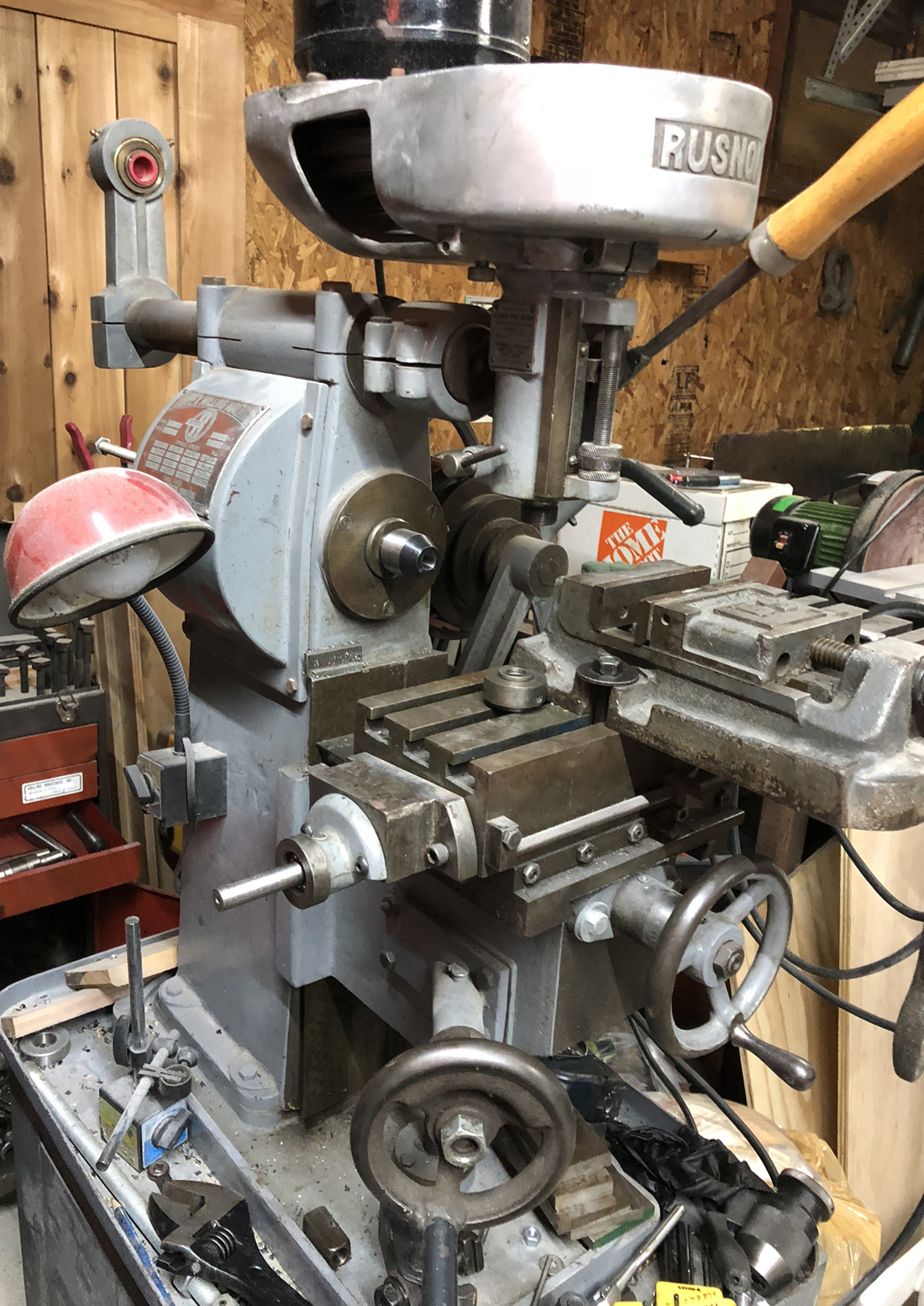

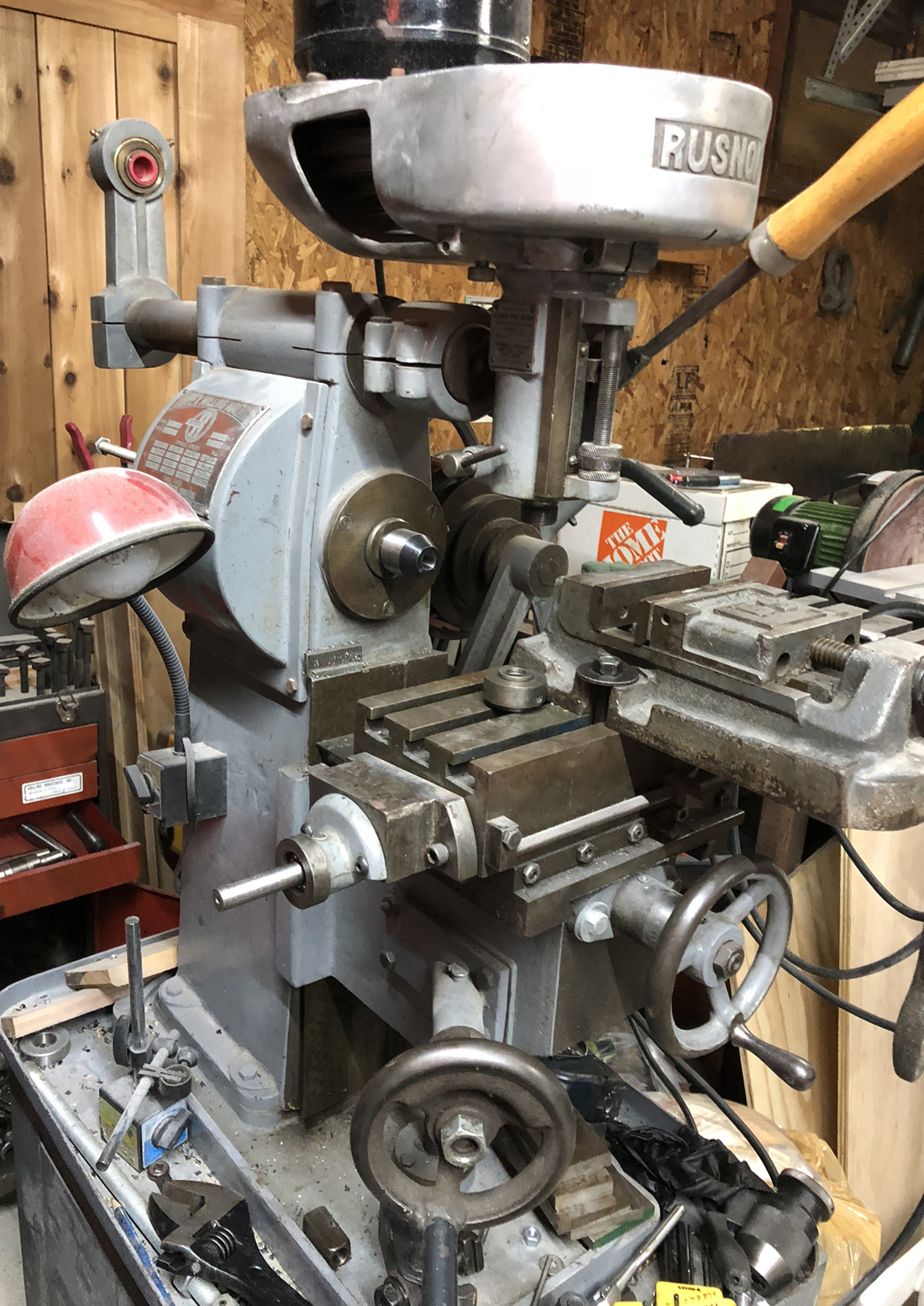

Illustrated at the bottom of this page is the company's unusual - though effective - planer with a hydraulically-driven table and a standard Rotex with a Rusnok head..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

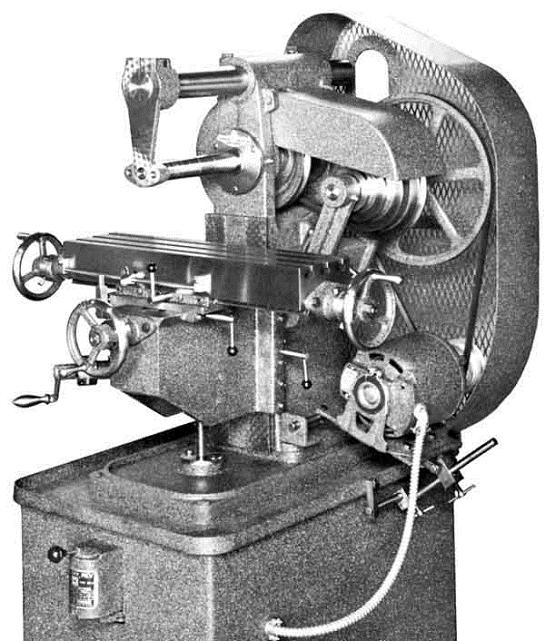

Rotex Production Miller Model PM-6 with hydraulically-powered longitudinal table travel.

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotex Standard Miller Model RM-1 on the optional cabinet stand.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

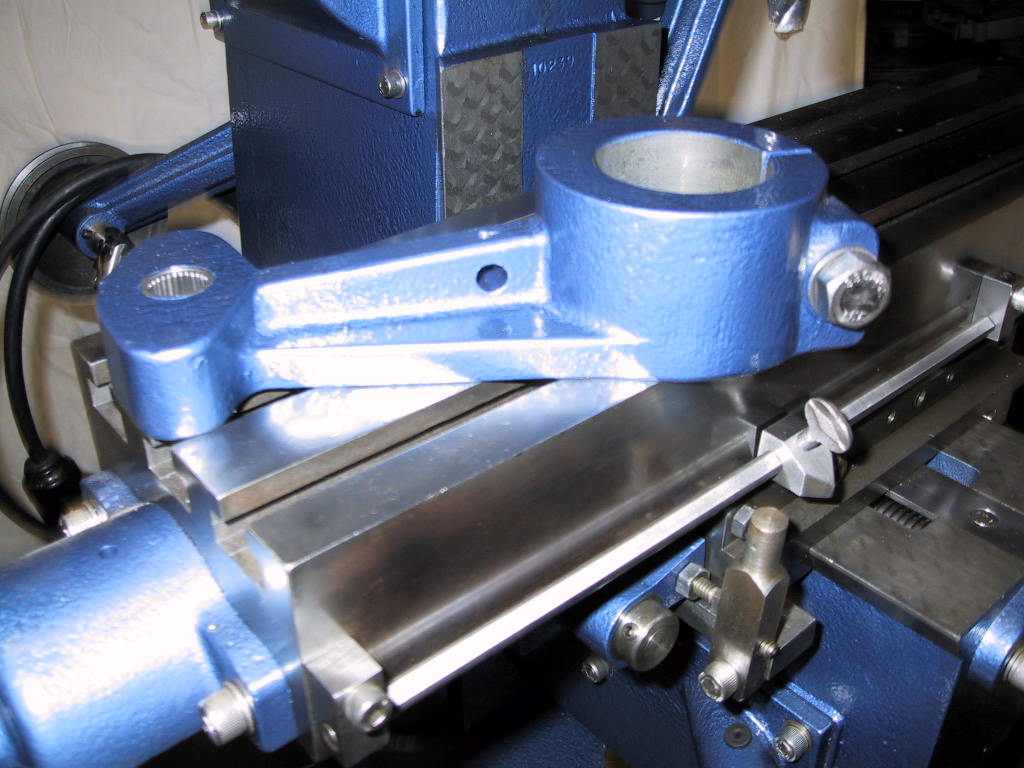

By the early 1950s small planers where almost impossible to find in any manufactures' catalogue - and Rotax offered what must have been of of the very last - a compact, up-to-date version with a neatly-installed hydraulic table drive.

Simply constructed (witness the simple braced, round uprights) but heavy at 800 lbs, it was fitted with a useful 24" x 9.25" table with 3 T slots each 1/3" wide.

Eight rates of cross feed were fitted - 0.003, 0.006, 0.009, 0.12, 0.15, 0.18, 0.21 and 0.24 inches per minute, whilst the table feed rate could be altered to provide cutting speeds which varied between 28 and 48 feet per minute.

The overall height was 53" , the length 48" and the width 30".

Planers make an extraordinarily versatile and cheap-to-run tool, capable of machining large components in a very restricted area and a Rotax Hydraulic would be a wonderfully entertaining addition to any enthusiast's workshop.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The rare dedicated Rotex vertical - an ideal size for the smaller workshop - with a self-contained V-belt-drive quill-feed head that could be swivelled and nodded

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The very useful - but rare - Rotex vertical milling machine

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

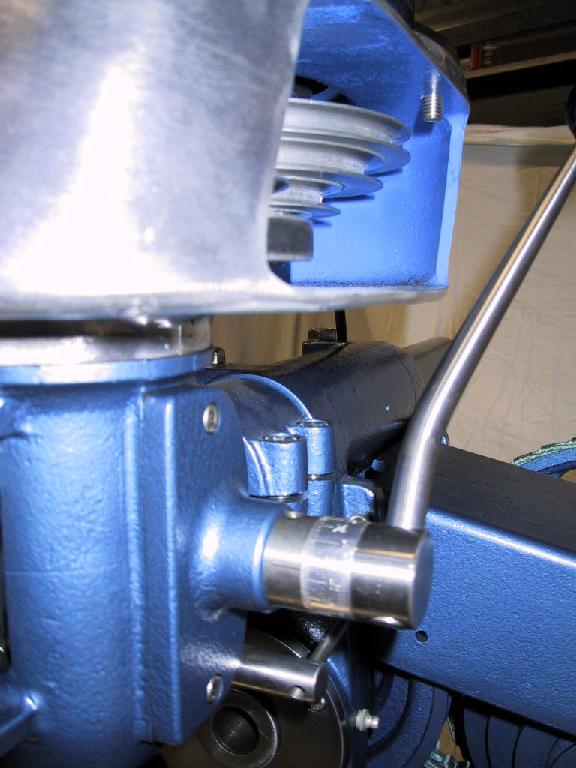

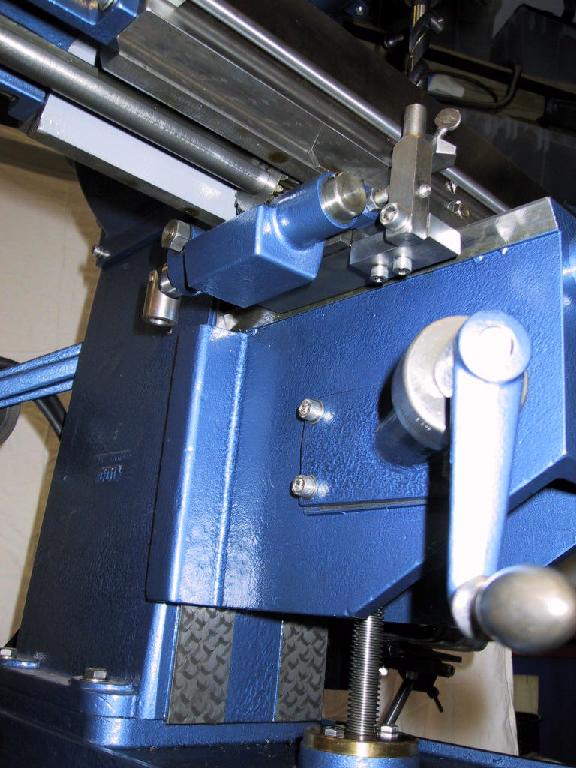

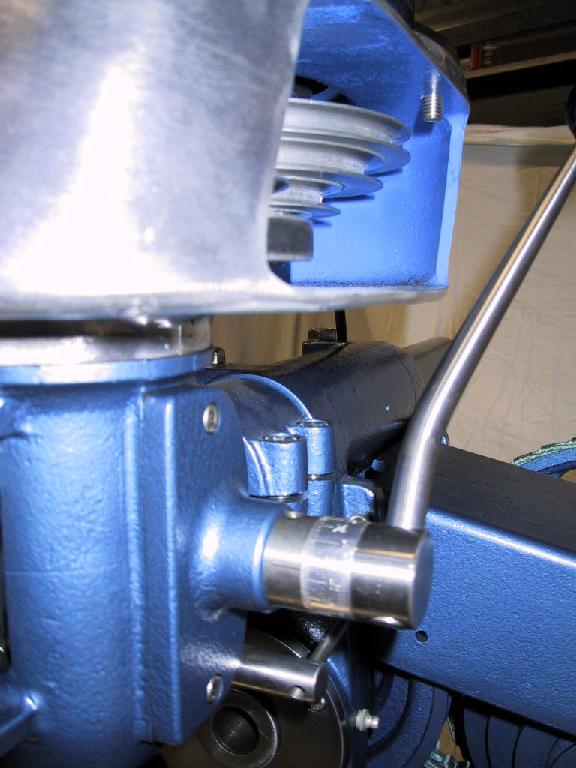

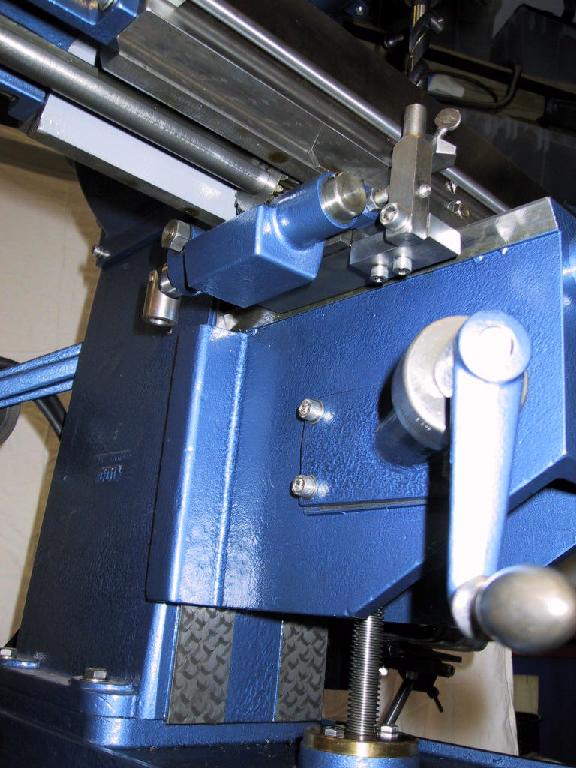

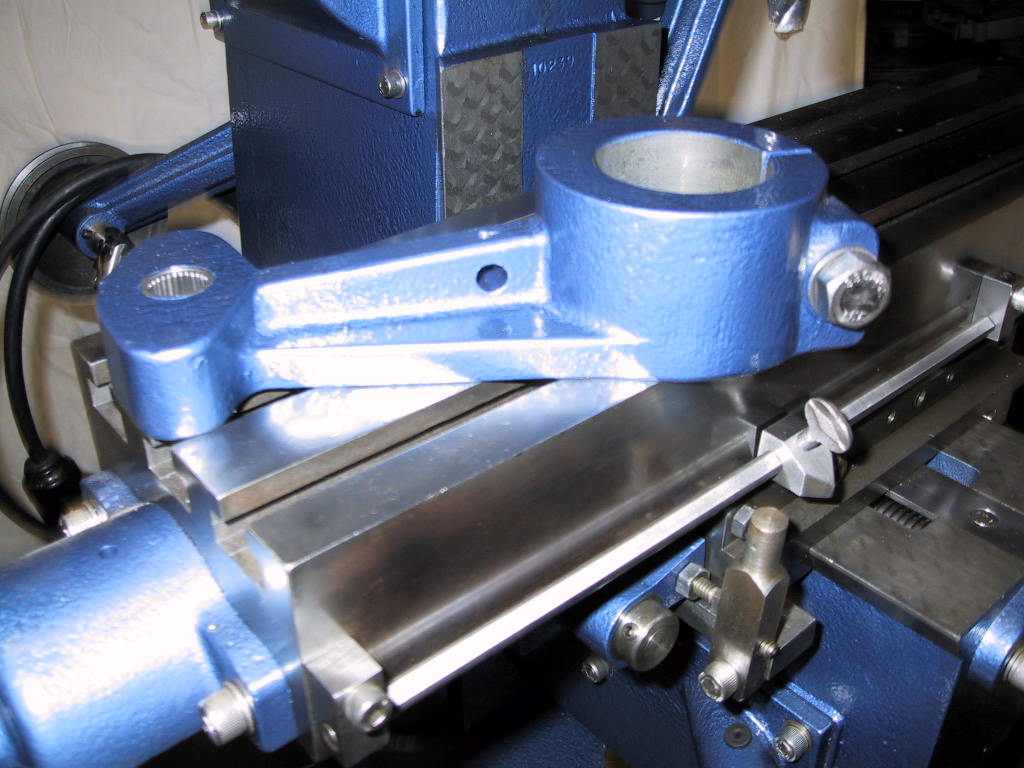

A beautifully restored Rotex horizontal complete with very useful multi-angle swivel and tilt vertical head

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Badge from the Rusnok vertical head

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|