Rosemoor Lathe

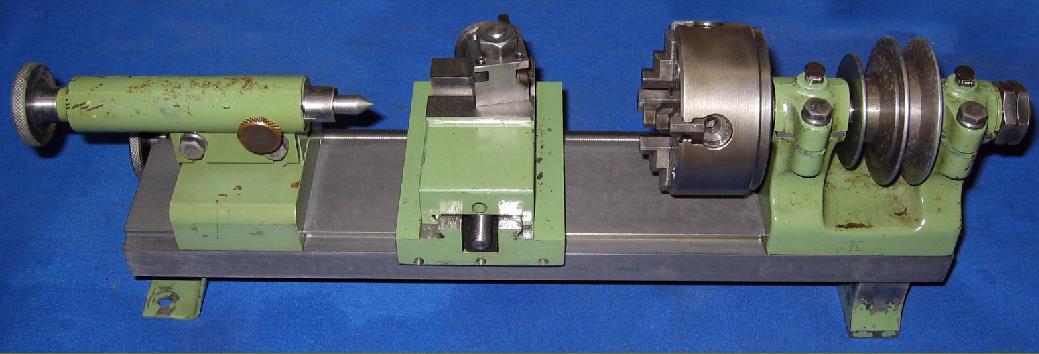

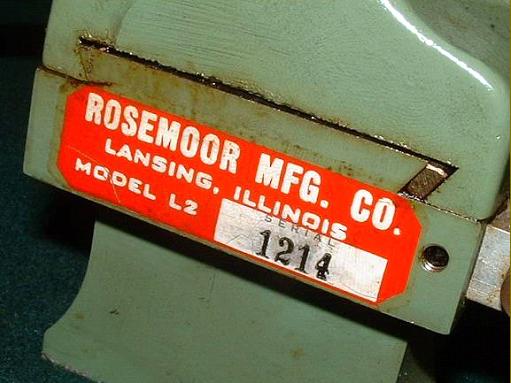

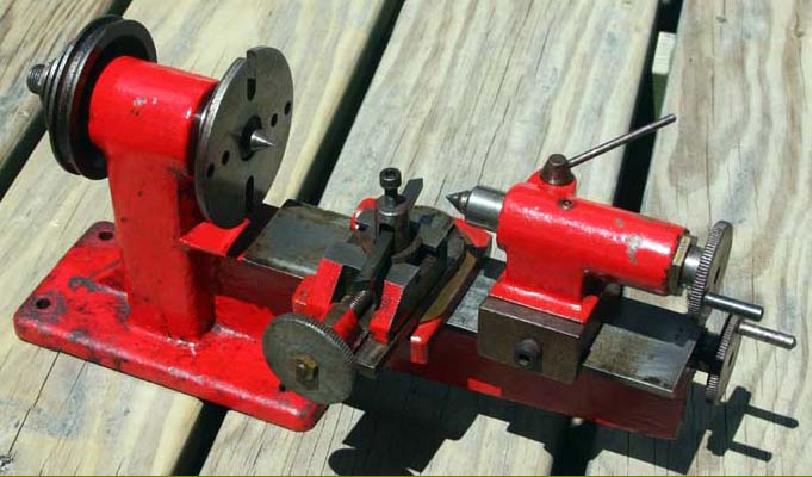

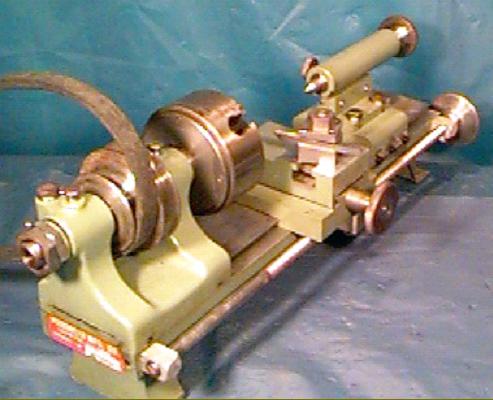

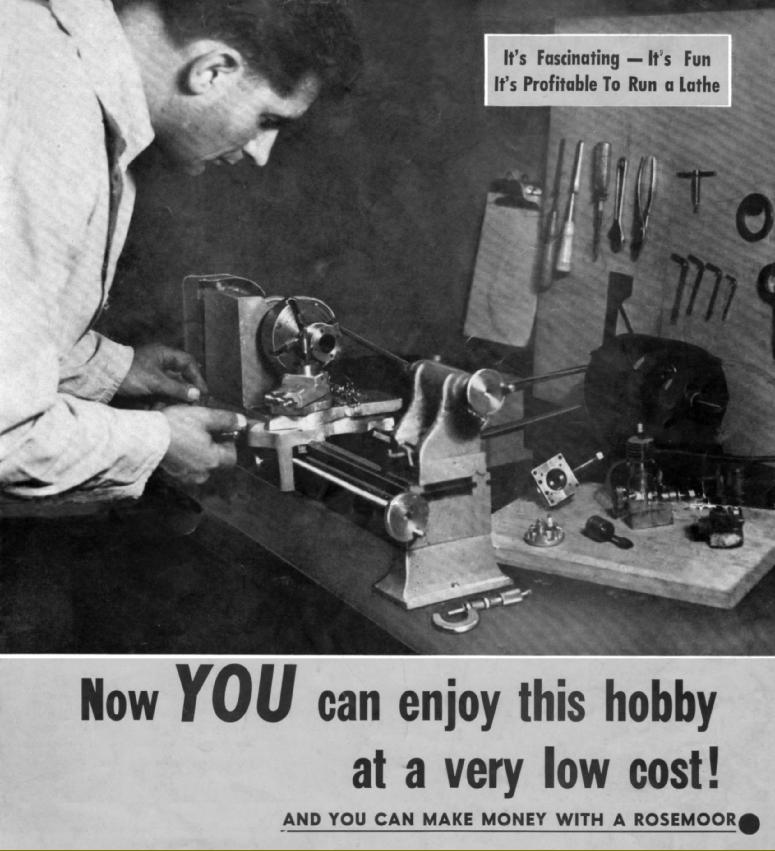

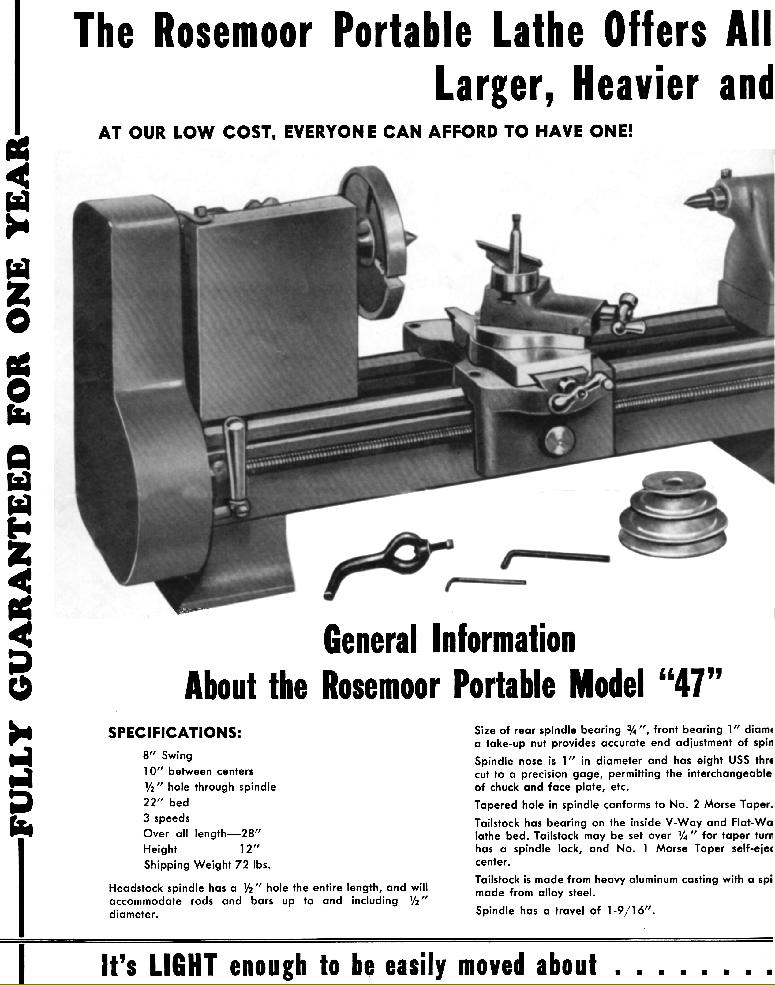

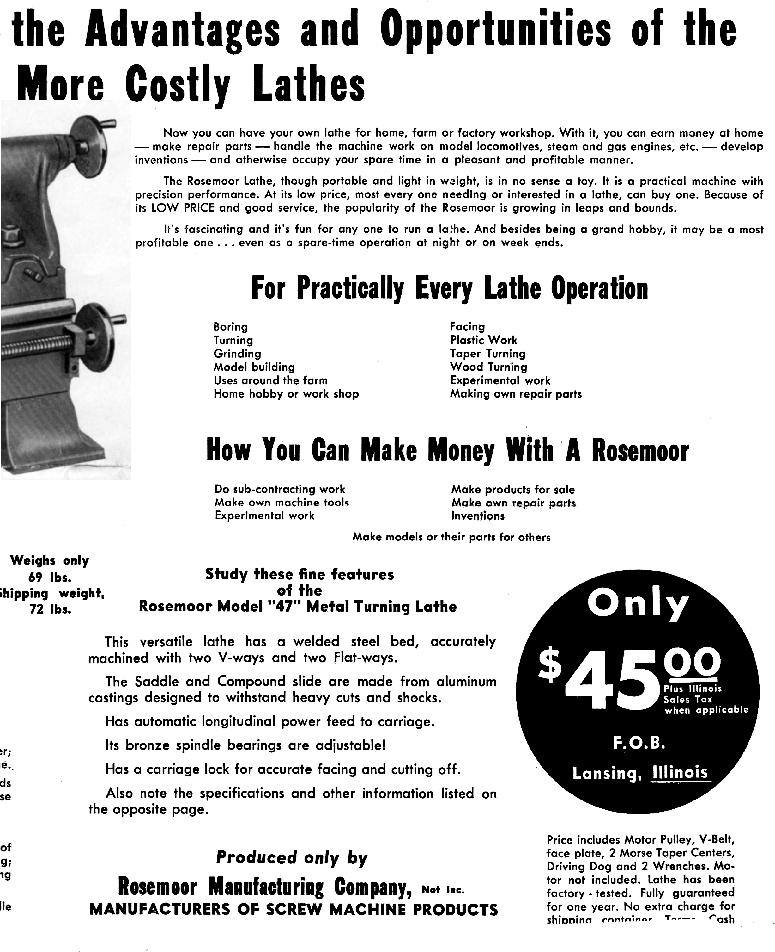

A simple, plain-turning lathe - and so lacking both a speed-reducing backgear and screwcutting - the little known, seldom encountered and rather prosaic 2.25-inch centre height by 7-inches between centres Rosemoor L2 was built by Rosemoor Mfg. of Lancing, Illinois, a company whose lathe production spanned from the mid-1940s until the late 1950s. Although Rosemoor produced other models - including the properly backgeared and screwcutting "Portable Model 47" - numbers of these must have been tiny as the robustly constructed L2 appears to be the only one that is, very occasionally, advertised for sale on the second-hand market.

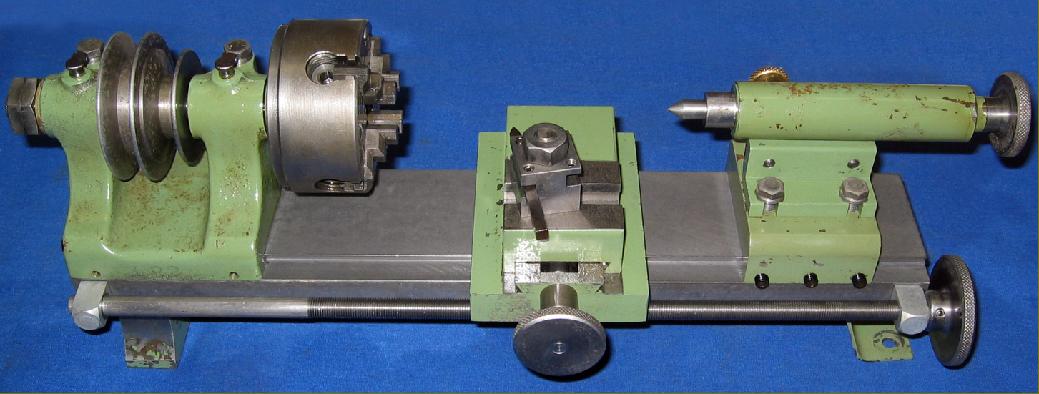

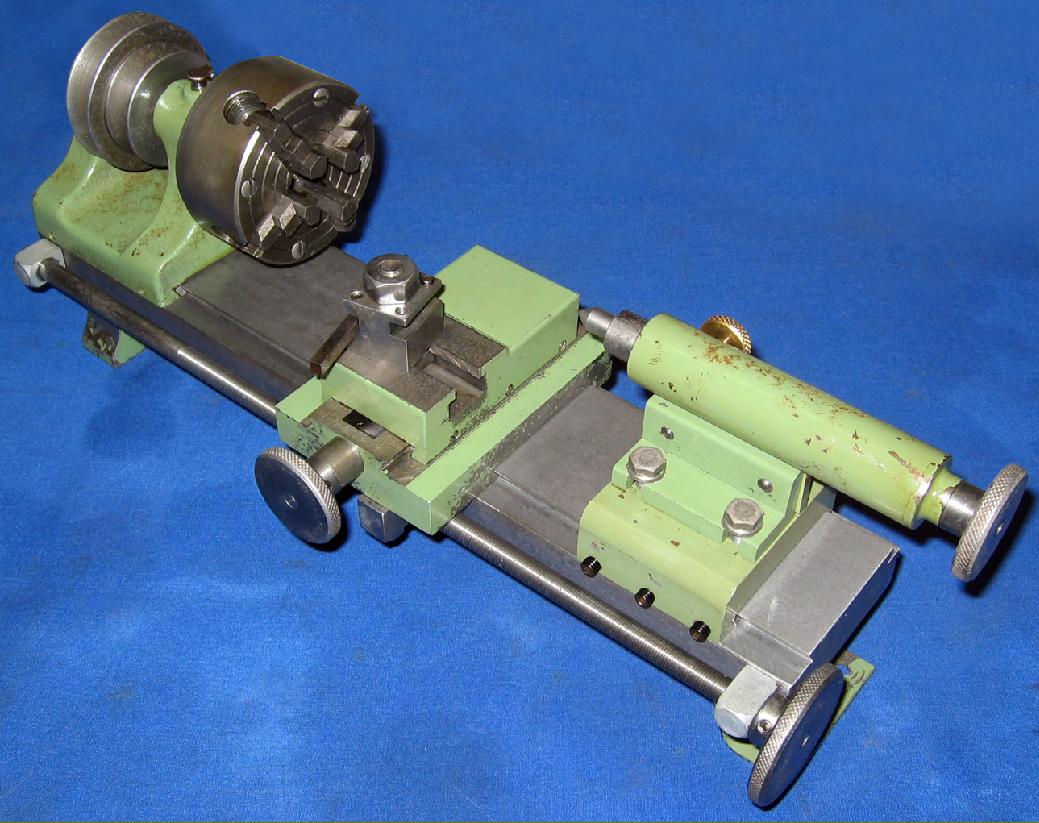

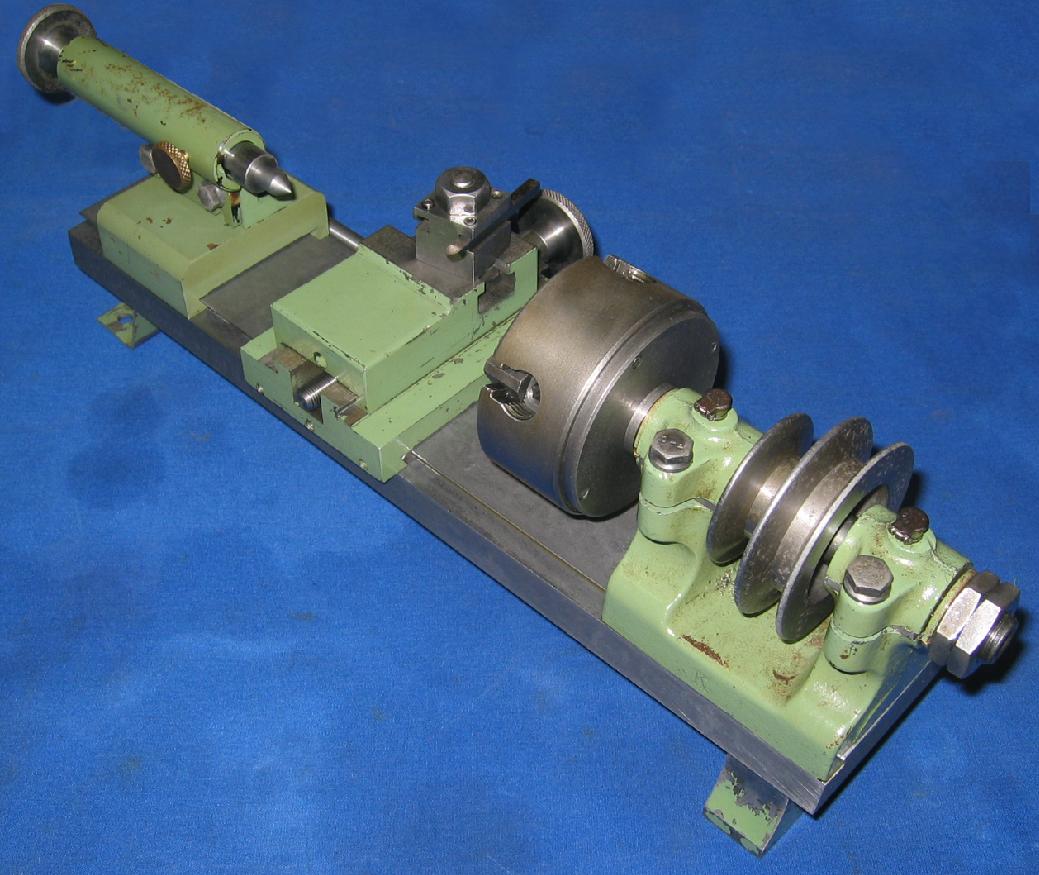

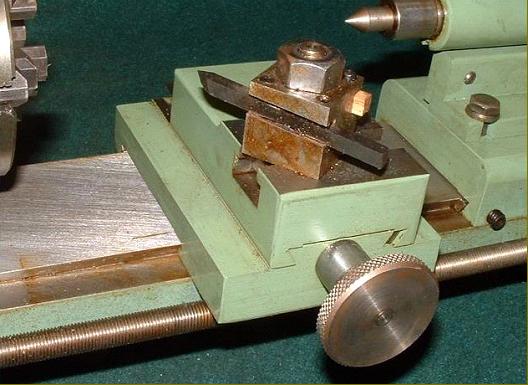

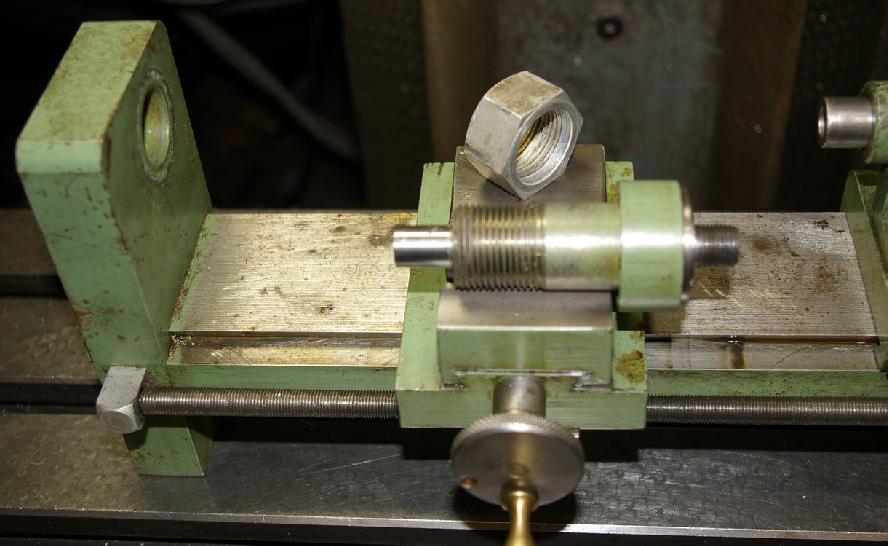

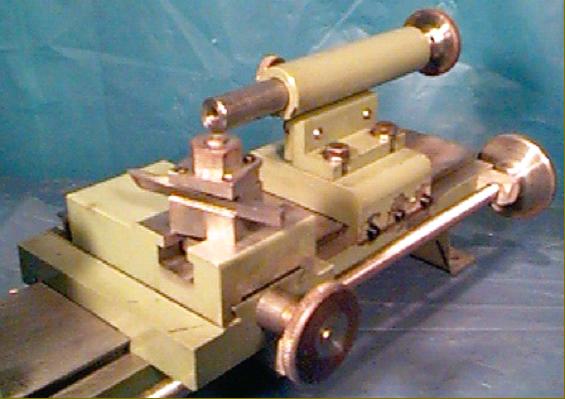

Of considerable width for so small a lathe (but at the same time rather shallow in depth), the bed had a completely flat top (just like the Myford ML10 and Hardinge HLV) with V-edges to guide the carriage. At the headstock end a cast-in foot was used - but under the tailstock a simple, rather crude folded sheet-steel support was deemed sufficient. Drive to the carriage was by feed-screw turned by a handle at the leadscrew end and supported in bearings at each end. However, there was no means of adjustment for end-play other than by pushing the screw handle at the tailstock end of the screw tightly against the screw support housing and tightening a set-screw. The carriage was topped by a single, non-swivelling tool slide fitted with a knurled-edge feed handle that lacked a micrometer dial. Unfortunately, this arrangement was a serious drawback as it failed to allow for the turning of short tapers and, as both design and dimensions appear to have excluded further modification, the possibility of mounting a top slide to produce a more useful, fully-compounded assembly was ruled out.

Running in plain bearings, the headstock spindle carried just a 2-step pulley which, from its appearance, looks to have been unnecessarily wide - many lathes of a similar size managing to fit a 3-speed pulley using a 6 mm wide V-belt.

Fitted with a No. 1 Morse taper spindle with a decent travel, the tailstock could be set over slightly for the turning of tapers--but was locked to the bed's front V-way by a pair of Allen socket-headed screws protruding through its front face, an almost impossibly simple yet crude solution.

Like all such simple lathes, the Rosemoor L2 was, in its standard form, of limited use for model and experimental engineering - though this did not stop companies marketing them, similar examples manufactured in England including the EW, Corbett "Little Jim" the aptly named Lineker & Winfield Utility, Wakefield and Super Adept (the latter also sold in the United States). However, unlike many of the mentioned examples (as well as those from other makers), the L2 was not offered with the option of backgear, screwcutting or the especially desirable swivelling or compounded tool slide (in this respect the English EW was exceptionally well designed, with all the upgrades simply bolting on to a basic machine). Having purchased a new lathe, the Rosemoor owner would first have required a motor and then a speed-reducing countershaft unit - if the lathe had been driven directly from the motor speeds would have been far too high (unless only very small diameter work was contemplated). Even then the user would have quickly discovered that, with a lack of proper gear-driven slow speeds, jobs would have been limited to those of the most basic kind.

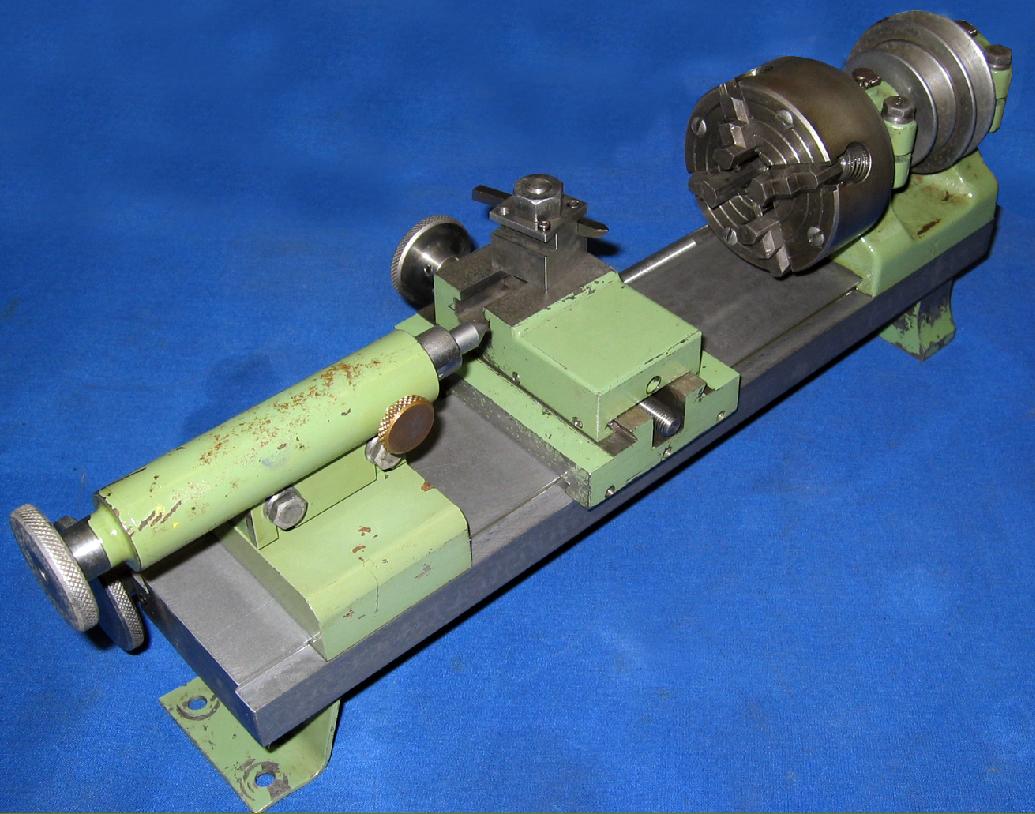

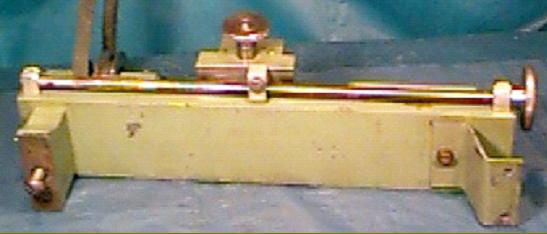

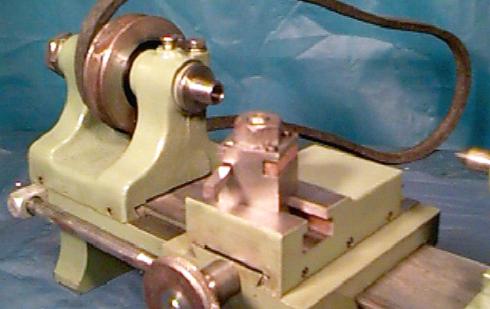

Now, if you think the foregoing is bad enough, you might be astonished to learn and even cheaper and more poorly made version of the Rosemoor was offered. This had a single upright support bolted to the end of a bed, both of which were machined from cold-rolled steel.

The spindle bearings were housed in a simple "quill" that, if it had been machined on a taper to fit in a matching taper in the single upright "headstock" support, may have had some hope of being secure and able to maintain alignment. However the "quill" was just a straight turned piece - with a large flange at one end to house a double-row bearing and threaded at the other, the whole being drawn into the headstock 1" x 14 t.p.i. Clamp. The drive pulley, a 3-step V-belt type, was overhung on the pulley's outer end, One wonders how many innocent, impecunious enthusiasts were tempted into buying a Rosemoor…but, should you have one of any type, the writer would be very interested to hear from you..