|

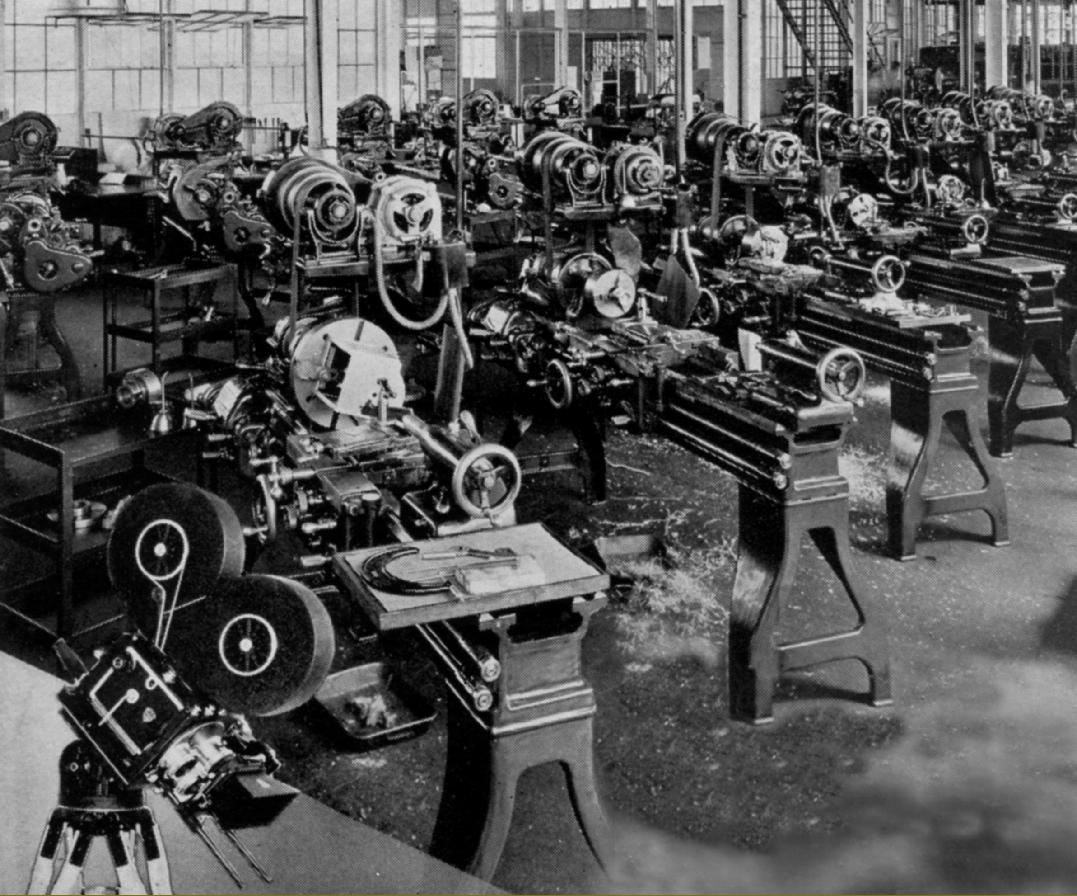

Long a maker of lathes and milling machines, the history of the Rockford Company stretches back to the closing years of the 19th century. Non of their machine tools were ever ambitious, or of unusual design, instead they concentrated on honest-to-goodness quality, the use of decent materials and simplicity of construction. Their main lathe market was always the middle ground - no giant or precision bench types ever being made - just regular "Engine" types suitable for use in production and repair shops (rather along South Bend lines but without the variety of models). A surprising number of these lathes have survived and, even if neglected and abused, their straightforward construction enables them to be brought back into working order by the enthusiastic amateur.

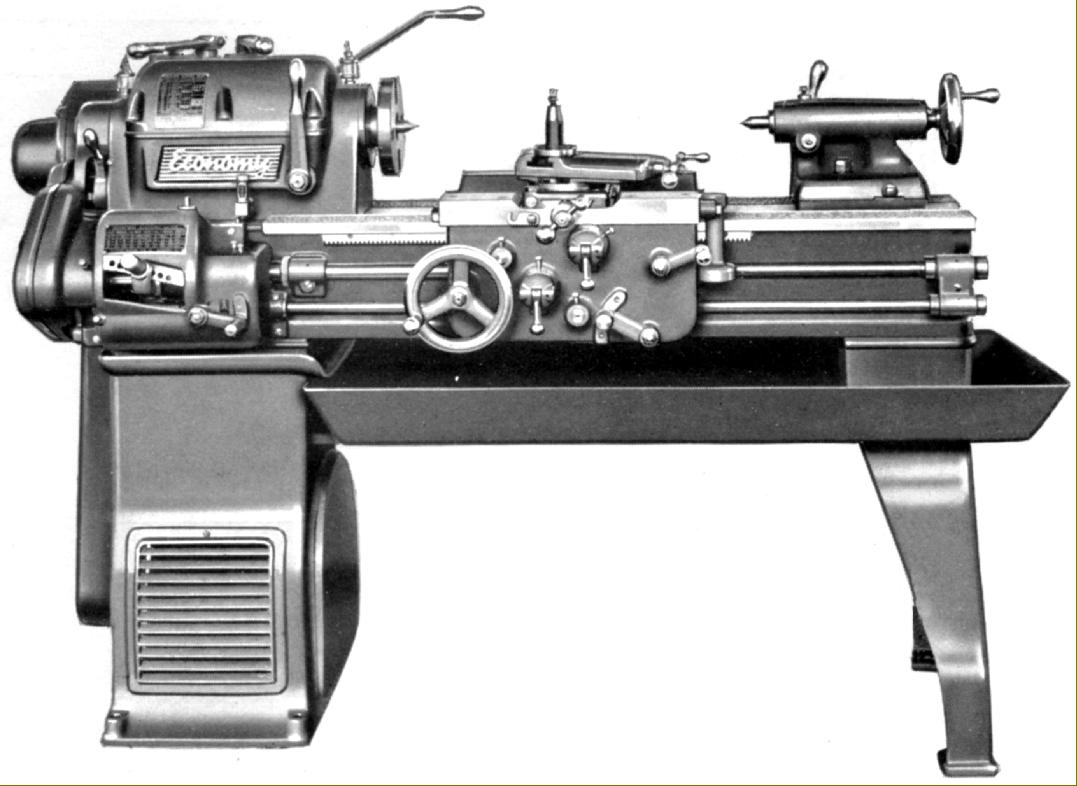

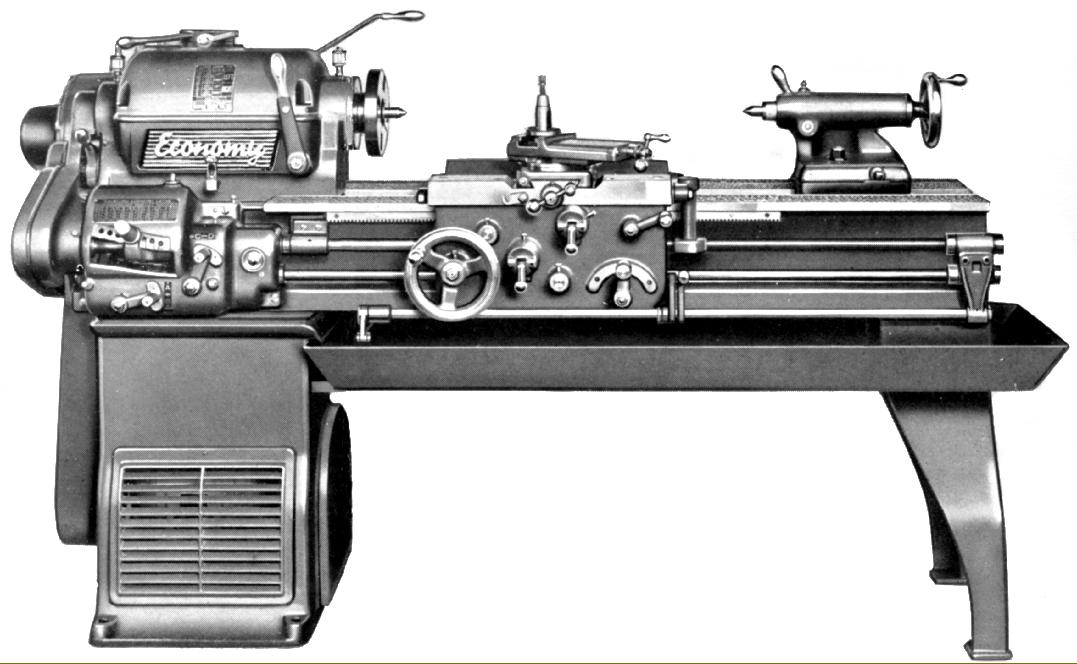

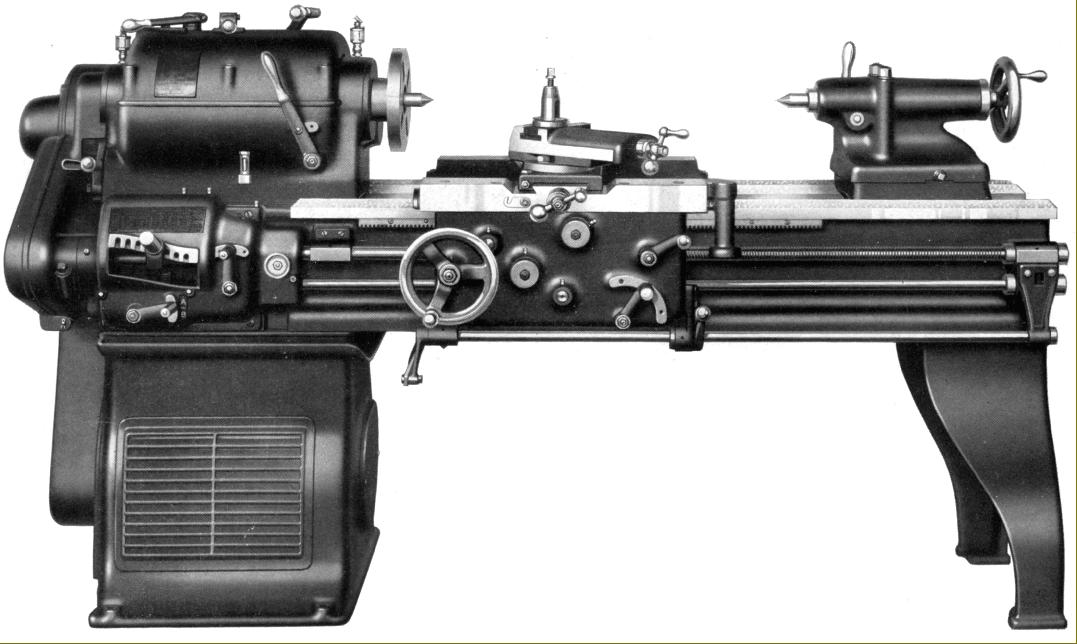

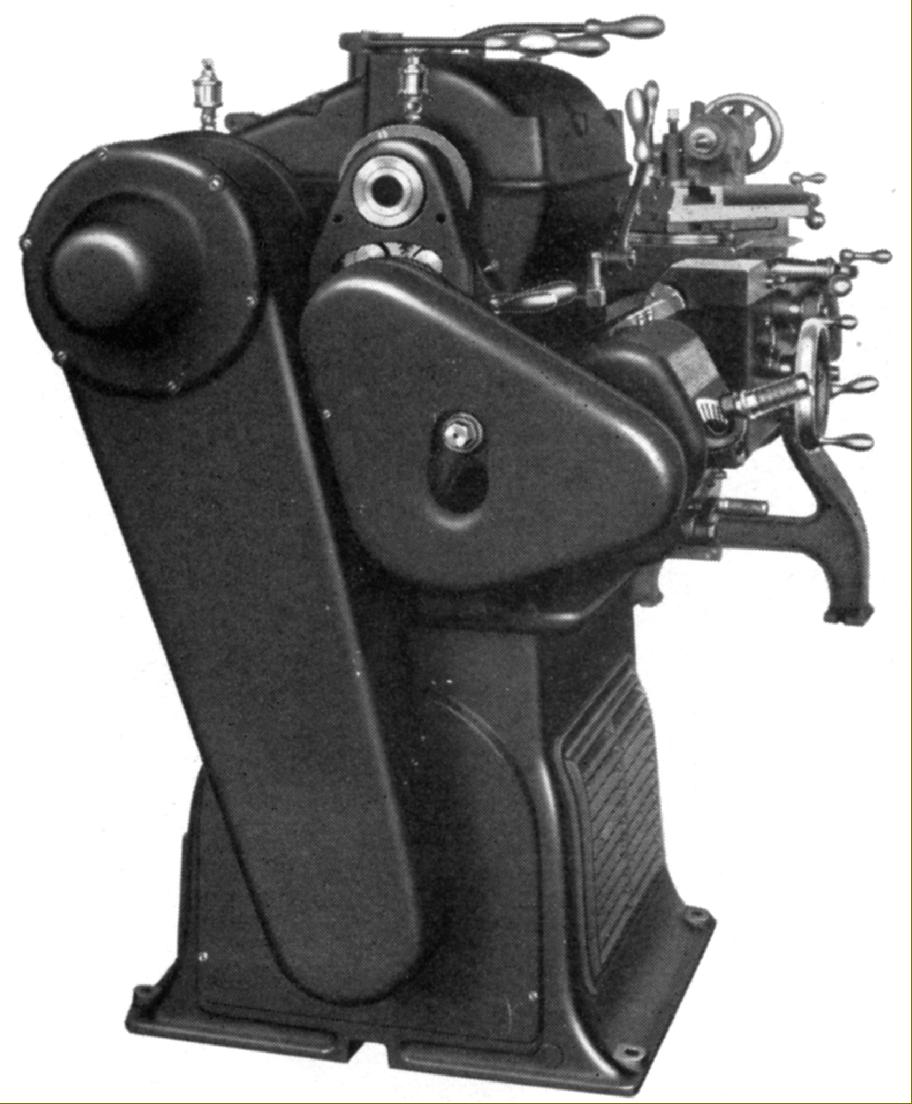

By the late 1930s and early 1940s the range offered was typical of the company: just three models, all branded Economy and all little changed from those of twenty years earlier. The main advance had been to offer, as an alternative to the increasingly unpopular flat-belt drive, a fully geared headstock with a motor drive enclosed within the headstock-end plinth. All sizes were of almost identical mechanical design yet each engineered specifically for its intended task and capacity. Offered as 12", 14" and 16" models the actual swings were, respectively, 13.0625", 13.635" and 17.75". A number of between-centre capacities was available with each slightly changed depending upon whether a geared or cone headstock was fitted. The cone head range ran from 27" to 37" and 51" (respectively as to the centre heights) whilst the geared head models lost a little capacity at 26", 36" and 49". Almost any bed length could be ordered, in intervals of 12 inches on the smallest machine and 24 inches on the larger.

Of deep section - and without the option of a gap - the bed was the same depth for its full length and strengthened by widely spaced webs between the walls. The flat and V-ways ran on past the front and back of the headstock, so allowing the carriage to have the cross slide in the best position for support, placed centrally, and the toolpost able to be run right up to the spindle nose. Saddle lengths were changed for each model starting with 18" for the smallest machine and then 20.25" and 24.375 respectively for the two larger examples.

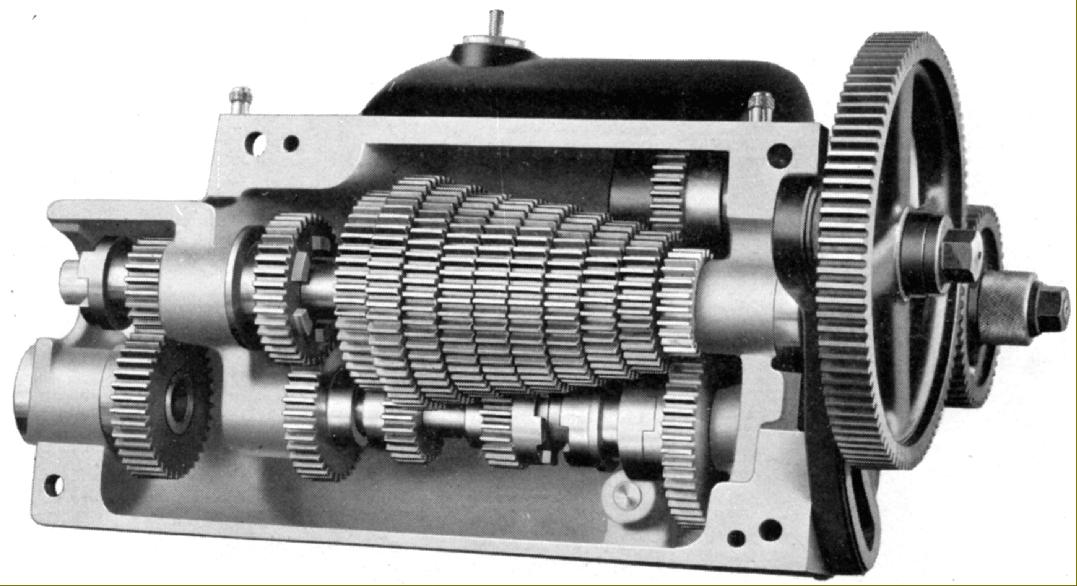

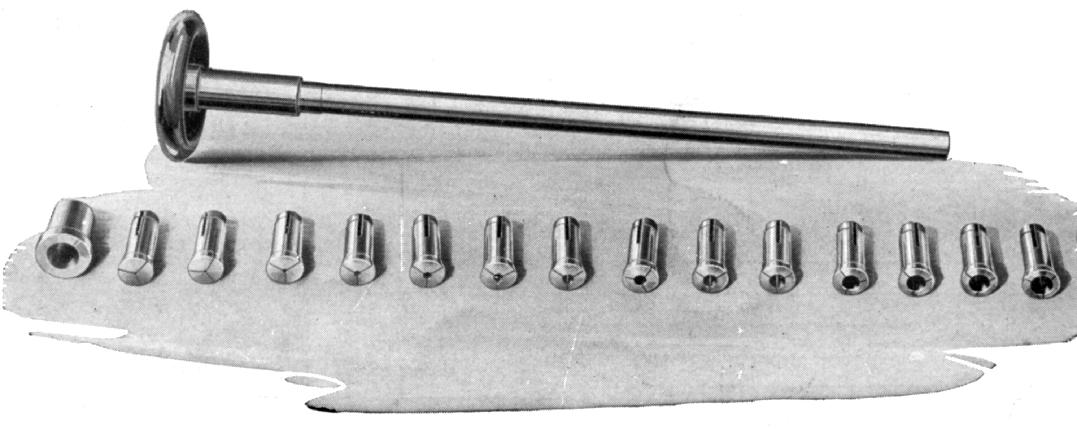

Controls on the geared head models were simple: twin spindle-speed levers on top of the headstock and a high/low range lever on the front. The headstock reflected early geared-type design where, instead of a box-like structure that rose above and enclosed the bearings in a stiff shell, the top was cut away at the front to allow access to the plain bronze bearings and their cap nuts. For the 12 and 14-inch models this was acceptable, the bearings were indeed bronze, but the 16-inch version had Timken taper roller bearings and would have benefited from a more rugged design, as exemplified by the final Economy model produced in the 1950s as single 17-inch version only. All headstock gears were hardened and ground, lubricated by splash from an oil sump in the base and ran on roller or ball races - even on the two versions with the spindle bearings in bronze. The main spindle, manufactured from a carbon-steel forging, was a different size on each model with a spindle nose of 2.125" x 8 t.p.i. on the 12-inch, 2.5" x 6 t.p.i. on the 14-inch and 2.75" x 5 t.p.i. on the 16-inch. spindle bores were, for the time, of average generosity being, respectively: 1.0625", 1.3125" and 1.5".

Although a motor was not supplied as standard, the makers recommended one running at 1200 r.p.m. and sized at from 1 to 1.5 h.p. for the smallest model up to 3 h.p. for the largest. Whilst the two smaller geared-head versions had twelve speeds from a low of 16 to a top of 402, the largest had a range from just 15 to 385 r.p.m. - rather slow, even by standards of the time. The situation with the cone-head models was more complicated with the smallest machine carrying a 4-step headstock pulley with a single conventional backgear assembly at an 8 : 1 reduction whilst the two larger had wider 3-step pulleys and (in order to transmit sufficient power on large jobs) double backgears with reductions of 3.42 : 1 and 9.07 : 1. Speeds, naturally depended upon the type of countershaft employed - the makers recommending a multi-step one that ran at 250 r.p.m. on the smallest model, at 285 r.p.m. on 14-inch and at 250 r.p.m. on the largest - but the end result would have been a range much like that found on the geared-head versions, though with more speeds to choose from - sixteen on the smallest lathe and eighteen on the others. One significant advantage of the Rockford geared-head models over many competitors was the fitting as standard of a combined twin-disc spindle clutch and brake unit. At first this was operated by a single lever on top of the headstock but later versions of the 14 and 16-inch were given a "third-rod" system, with a lever pivoting from the right-hand face of the apron - a 1930s development that did much to make controlling a medium to large lathe so much easier.

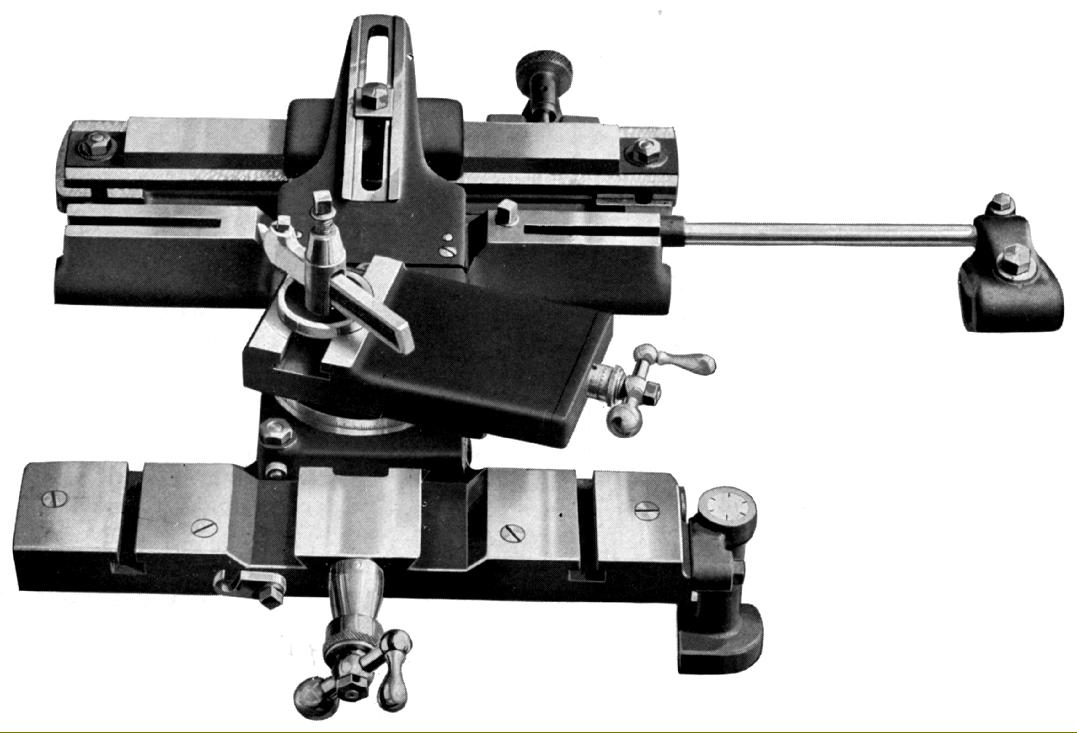

Of rather slender proportions, the cross and top-slides were fitted with taper gib strips and conventional balanced handle wheels. The micrometer dials were, of course, rather small, though precisely engraved, fitted with a knurled ring for grip and, on machines from the late 1930s onwards, given a non-glare satin-chrome finish. To allow the fitting of a taper-turning unit, the cross slide was of the short-type, a design that would have caused the ways to wear more in their mid section - though the rear of the feed screw was protected by a removable cover. Late machines had plain saddle wings, it appearing to be the case that, after the mid 1930s, most manufacturers began to question the usefulness of equipping them with T-slots.

A conventional Norton-type tumbler gearbox provided screwcutting and power feeds with, on the 12 and 14-inch models a 1.125" diameter. 6 t.p.i. Leadscrew, 32 English pitches from 4 to 56 t.p.i. were available and sliding feeds from 0.004" to 0.056" per revolution of the spindle. The 16-inch was somewhat beefed up with a 1.25" x 4 t.p.i leadscrew, 32 pitches from 3 to 46 t.p.i. and sliding feeds also coarsened and ranging from 0.04 to 0.064" per revolution of the spindle. Either the leadscrew of separate powershaft could be selected for drive, a lever on the gearbox making the change.

Unchanged in basic design from 1920 (or earlier), the apron was doubled-walled, with all shafts supported at both ends and an oil sump in the base with lubrication by splash. Selection of longitudinal or cross feed was by one quadrant lever and engagement, with a safe and instant snap-in-and-out action, by separate levers for each direction. The latter system was a considerable improvement on that fitted to earlier machines, where a handwheel had to be turned to engage and disengage the feed.

Heavily built, the set-over tailstock on the smaller pair had a 1.75-inch diameter spindle with a No. 3 Morse taper and 5" of travel on the 12-inch and 5.5" on the 14-inch. The 16-inch model had a more robust unit with a 2-inch diameter spindle with a No. 4 Morse taper and 7 inches of travel.

If you have a Rockford lathe of any age, or any technical or sales literature about them, the writer would be very interested to hear from you.

|

|