|

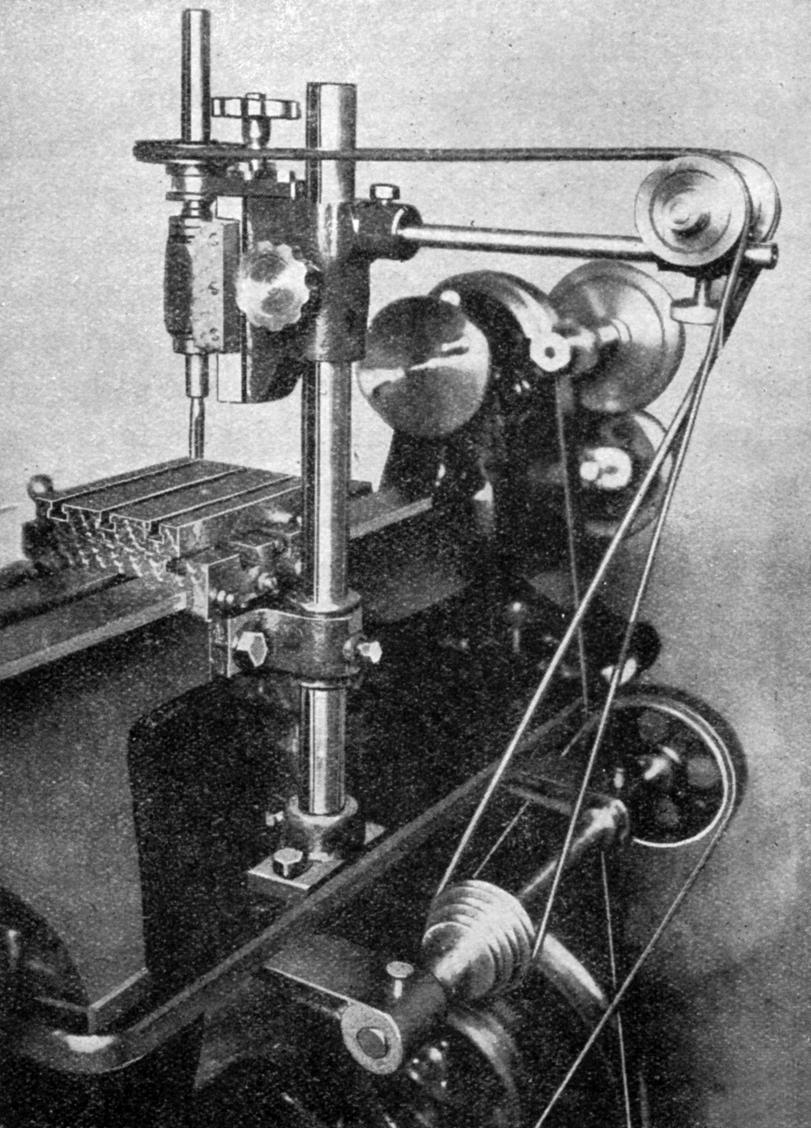

Home Machine Tool Archive Machine-tools Sale & Wanted "Relmil" Vertical Milling and Drilling Attachment Manufactured during the 1920s, the "Relmil" vertical attachment was designed to bolt against the back face of a lathe bed with a bracing foot secured to a stout (preferably cast-iron) chip tray. Ground to size, the round column carried a casting, located by a keyway, that could be elevated by hand into the desired working position - the clamping screw being fitted with a brass pad to prevent damage to the pillar. Mounted on the rise-and-fall casting was the vertical head, its No. 2 Morse, draw-bar spindle driven through its 2 inches of travel by a screw thread and its handwheel equipped with a micrometer dial. The drive was intended to take advantage of a lathe's existing foot-operated treadle mechanism with an auxiliary countershaft, driven from the main flywheel, fitted with a 3-step pulley over which ran a round leather belt. Like the system used on many simple, light drills intended for amateur use (and also employed on watch and clockmakers' drills) the drive rose vertically from the countershaft and, before wrapping round the spindle pulley, passed over pair of jockey pulleys, these being adjustable along the length of a horizontal bar socketed into the back of the head casting; by this means the head could be elevated or lowered and the belt tension quickly adjusted to compensate. |

|

|

||