|

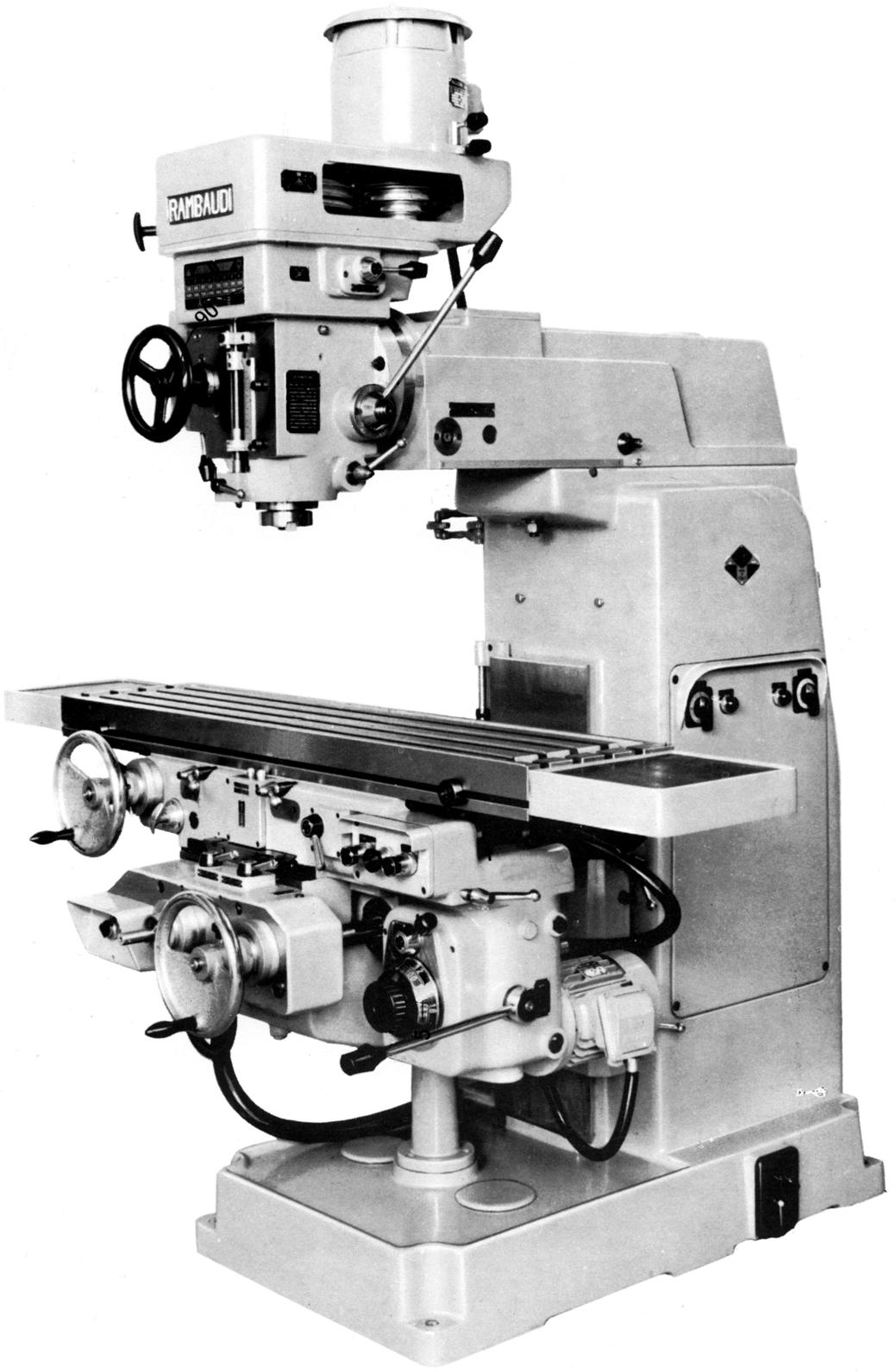

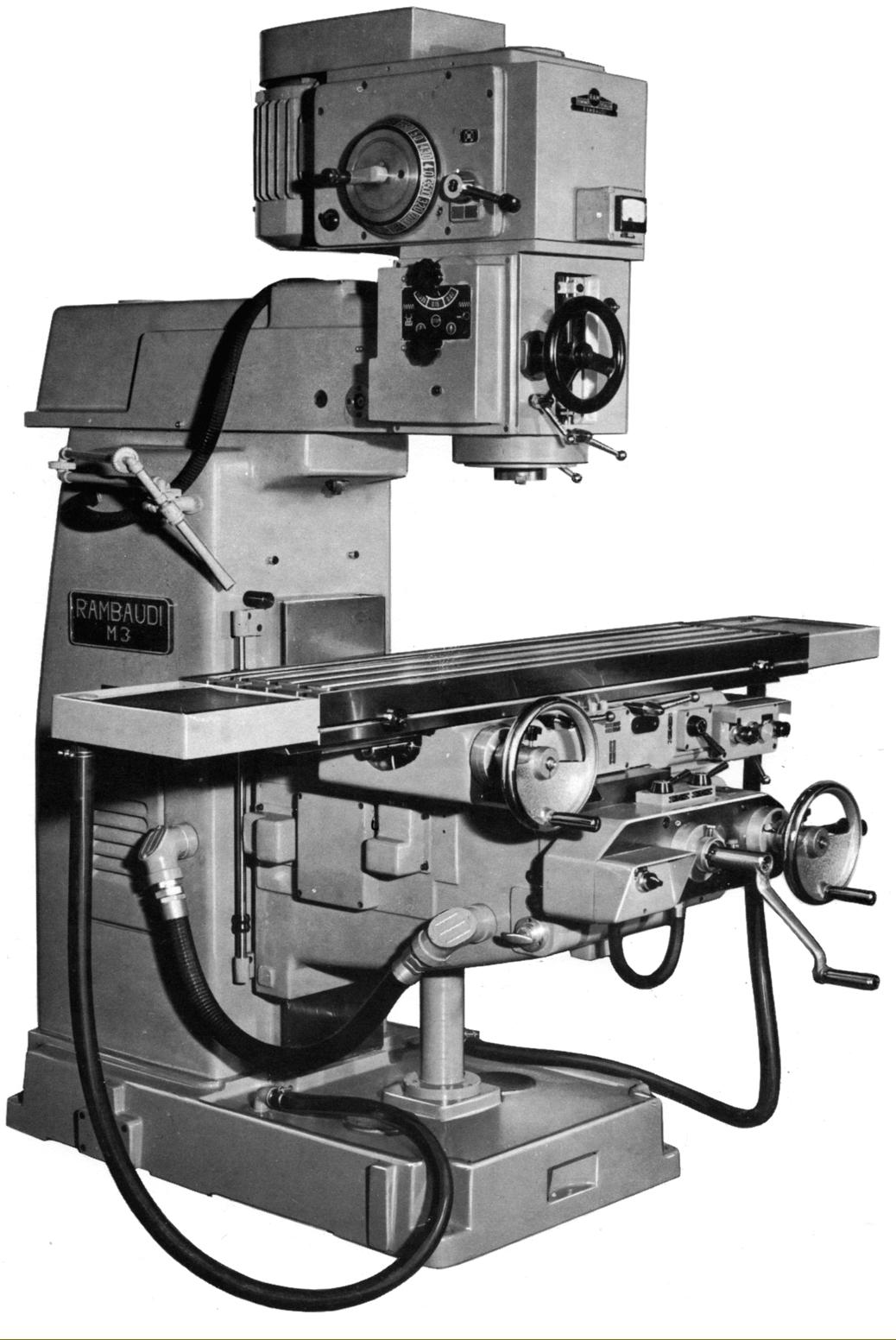

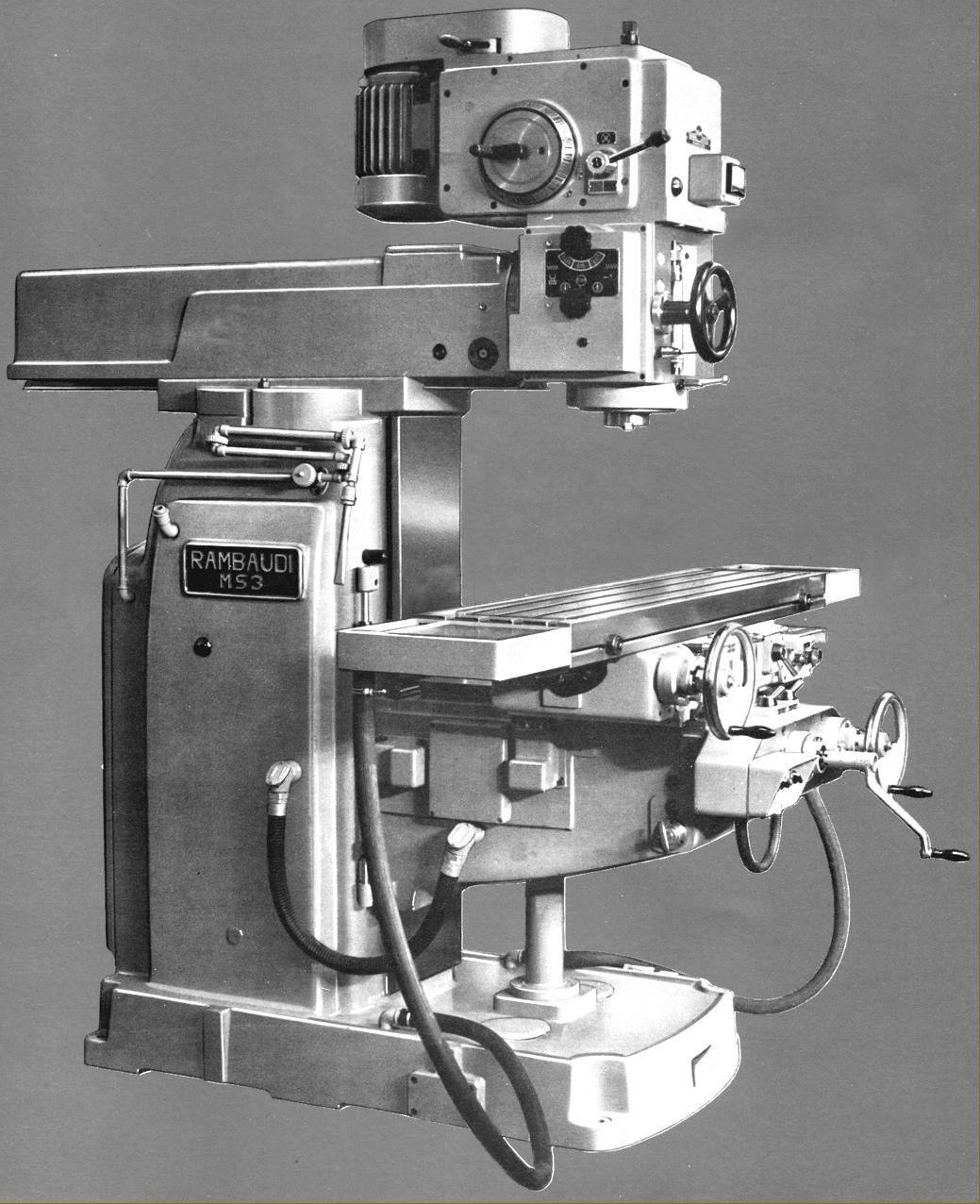

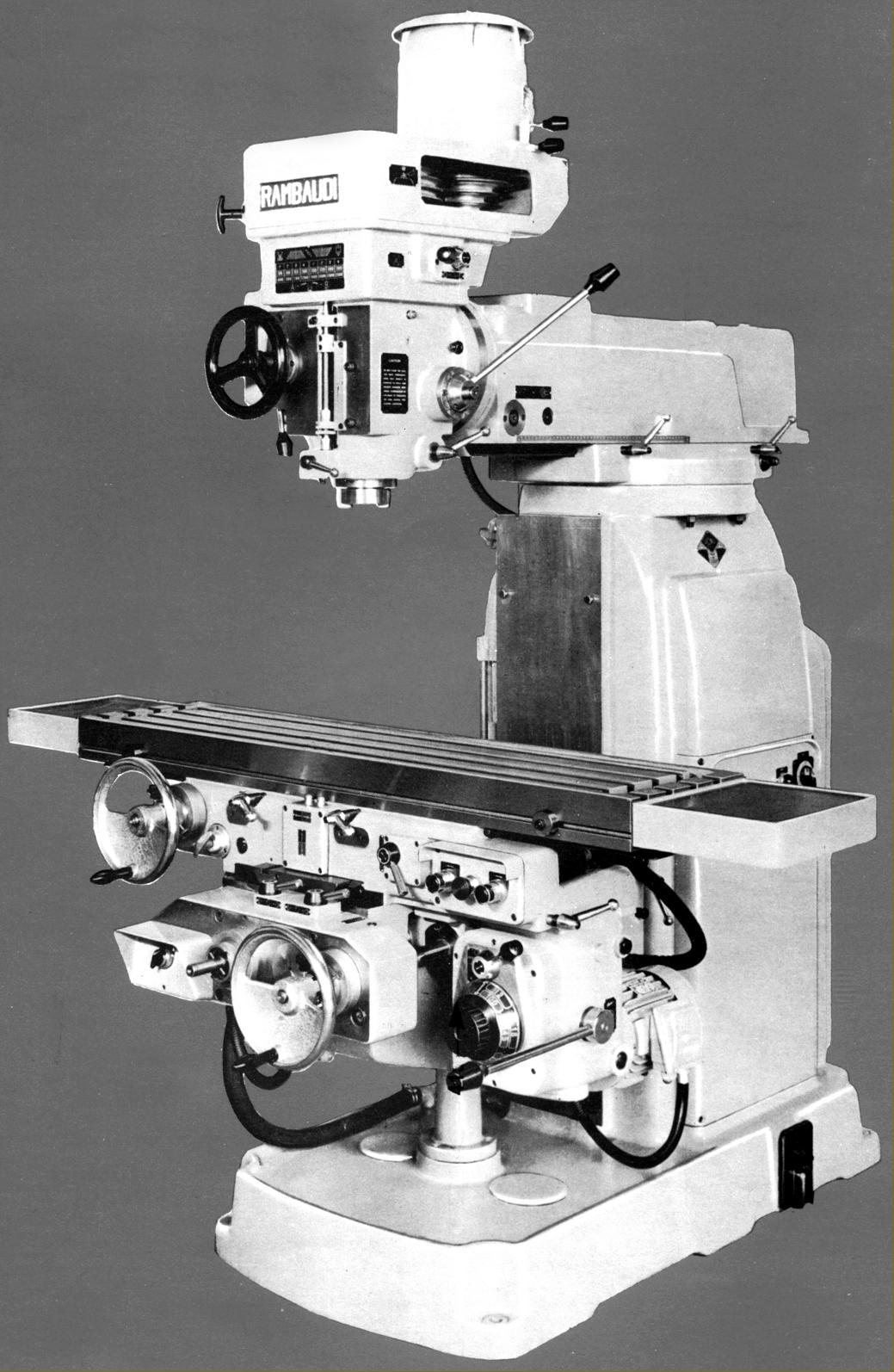

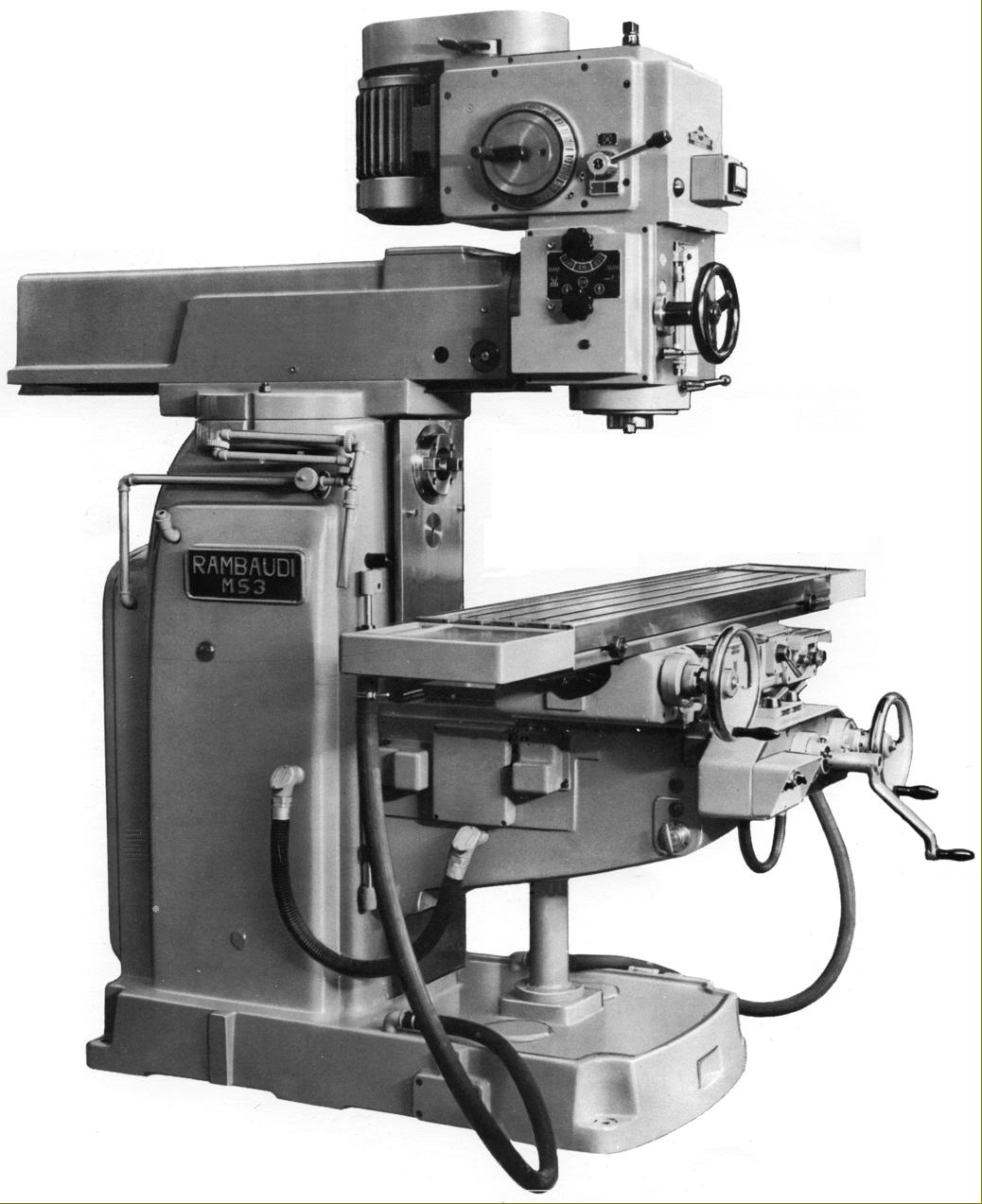

Introduced in the early 1970s (to replace the V2 and V3 models of the 1960s), the M-Series was final version of Rambaudi's well made and highly respected ram-head milling machine, a type that dated back to the VR-Series of 1955. The new range omitted the smaller "2" Series machines and concentrated on the larger "3" versions, these being heavier with new or improved vertical heads and longer tables with power feed in all directions. Like the original early types, the basic versions (M3 and M3P), had a ram that slide forwards and backwards only while those with a "G" in their description (MG3-P and MG3) had a swivel base that allowed the whole head assembly (as on a Bridgeport) to be rotated through 360° degrees. Although the ability to rotate the ram adding greatly to the versatility and functionality, it necessarily added to the number of surfaces (and hence flexibility) between cutting tool and the main machine body. If the letter "S" appeared in the title (MS3 and MS3-P) this indicated a miller of a combination type fitted with a motor and 18-speed gearbox within the main column that drove a horizontal milling spindle. The opposite end of the dovetail ram to that mounting the vertical head was pressed into service as an overarm to hold one or more drop brackets that supported a horizontal milling arbor.

Just one table size was offered, 51" x 12" (1300 x 300 mm), with four 11/16" (18 mm) T-slots. Longitudinal travel under power feed was 37" (950 mm), but 38" (970 mm) by hand, this being by a single, forwards facing handwheel working through bevel gears - an arrangement that operators used to table-end handle found strange at first acquaintance but soon accepted as very convenient. Cross travel was 10.5" (270 mm) under power and 12" (300 mm) by hand, the respective figures for vertical being 16.5" (415 mm) and 17.5" (445 mm)

Driven by a 1.5 h.p. motor through an oil-bath gearbox located on the right-hand side of the knee, twelve rates of longitudinal cross feed were available spanning 9/16" to 22" (12 to 550 mm) and the same number vertically from 1/4" to 11" (6 to 275 mm) per minute.

Selection of feed rates was by a combination of a short lever and a front-facing dial with engagement by a second, longer lever - pressing down the latter from its central (neutral) position engaged the feed (and started the spindle) while lifting it up (against spring pressure) caused the rapid feed, at a rate of 40" per minute to engage (a rapid feed was only available on the vertical drive).

As on all Rambaudi machines, the table feed screws were hardened and ground with that for the longitudinal drive running in an oil bath and made in two short sections, left and right and spring loaded against each other. The screws, around 3" (80 mm) in diameter, engaged against a long, semi-circular nut (a helicoidal rack) fastened to the underside of the table - this ingenious and beautifully constructed arrangement (adjustable to eliminate backlash) giving a huge surface area to slow down the rate of wear. Of conventional design, the cross-feed screw ran through two opposed bronze nuts, this arrangement also being adjustable to eliminate play. Lubrication of the table and knee ways was by a hand-operated single-shot oil pump positioned on the left-hand face of the knee.

Fitted on the end of a rack-and-pinion driven ram having 13.5" (335 mm) of travel on the M3 and MP3 and 21.5" (550 mm) on the MG3-P and MG3) two vertical heads were available, the less impressing being the earlier 16-speed V-belt and backgeared type as fitted to the V3 with a 2-speed 2.5/3.2 h.p. motor, 16 speeds from 50 to 2500 r.p.m. and an ISO40 spindle nose. Quill diameter was 4 3/8" (110 mm) with a travel of 5" (125 mm) and three rates of power up and down feed of 0.0015", 0.003" and 0.006" per rev. The head, whose slow-speed gearing was hardened and ground, could be swivelled through 90° each side of vertical by a crank handle working through worm-and-wheel gearing and was locked to the ram not by the expected four bolts but with a split ring formed with a conical periphery, the vertical position being obtained by a tapered pin of hardened and ground steel fitted at the 3 o'clock position on the head's right-hand side.

As an option a much-improved head, the NV3, was available; this had the same type of mounting as the V3 (though limited to a tilt of 45° each side of vertical), an ISO40 spindle nose, a 5.5 h.p. motor and all-gear drive with 18 dial-selected speeds spanning 40 to 35000 r.p.m. While the quill was the same diameter as V3 type and the power feed rates identical, the stroke was lengthened to 6" (150 mm).

Both heads had a lever-operated quick-action drilling quill and a handwheel giving a fine feed through worm and wheel gearing to a precision-ground helical rack on the hardened and ground quill assembly. A typical micrometer-dial/ruler depth-control stop was provided on the front of the housing, this being arranged to automatically release the power feed when working (either up or down) to an accuracy of within 0.001". To protect against a damaging overload, a slipping clutch was fitted to the power feed, the disengagement load being adjustable by the operator.

None of the Rambaudi ram-head millers was fitted with a "nodding" head as standard, instead this was a facility offered as an option. However, in place of the usual very simple clevis assembly (that always introduced an unwanted element of flexibility into the assembly together with the added difficulty of getting back to a zero setting), the assembly consisted of a ram-end adapter formed as a semi circle to which a matching casting on the back of the vertical head was clamped. With a huge contact face spread over 180° rigidity was much improved and the head held firmly despite its considerable mass.

For all types of the Rambaudi M-Series millers a range of extras was offered including: a self-contained power vertical rapid feed (usually at the rate of 31" per minute); a horizontal grinding attachment (with a vertically disposed wheel) complete with magnetic chuck, table-mounted shields and even a wheel-balancing spindle; a 600 x 300 mm universal swivelling and tilting table able to be moved through 30° each way in traverse and 15° each way longitudinally; rectangular and round raiser blocks to raise the ram; a "universal" swivelling table; a 6-speed slotting attachment driven from the horizontal spindle with stroke rates from 32 to 410 per minute; a 6-inch centre height universal dividing head (with tailstock and an optional gear train driven from the table feed screw to allow spiral milling); a 24-division indexing head; horizontal and vertical rotary tables; a right-angle drive attachment; fixed and swivel-base machine vices; high-precision optical table-travel readers; length-rod and DTI holders; a centring microscope; a handy 3x1 rectangular magnifying class on an articulated arm; collet chucks, shell-mill holders, precision drill chucks and boring heads; collet sets to fit the various spindle noses and a number of hydraulic copying attachments..

|

|