|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

C.&E. Marshall, Moseley, Peerless, Marco

& Little Giant Watchmakers' Lathes

C.E.Marshall Marco Lathe Marshall, Moseley, Peerless & Little Giant Page 2

Copies of the rare Moseley Lathe Booklet are available

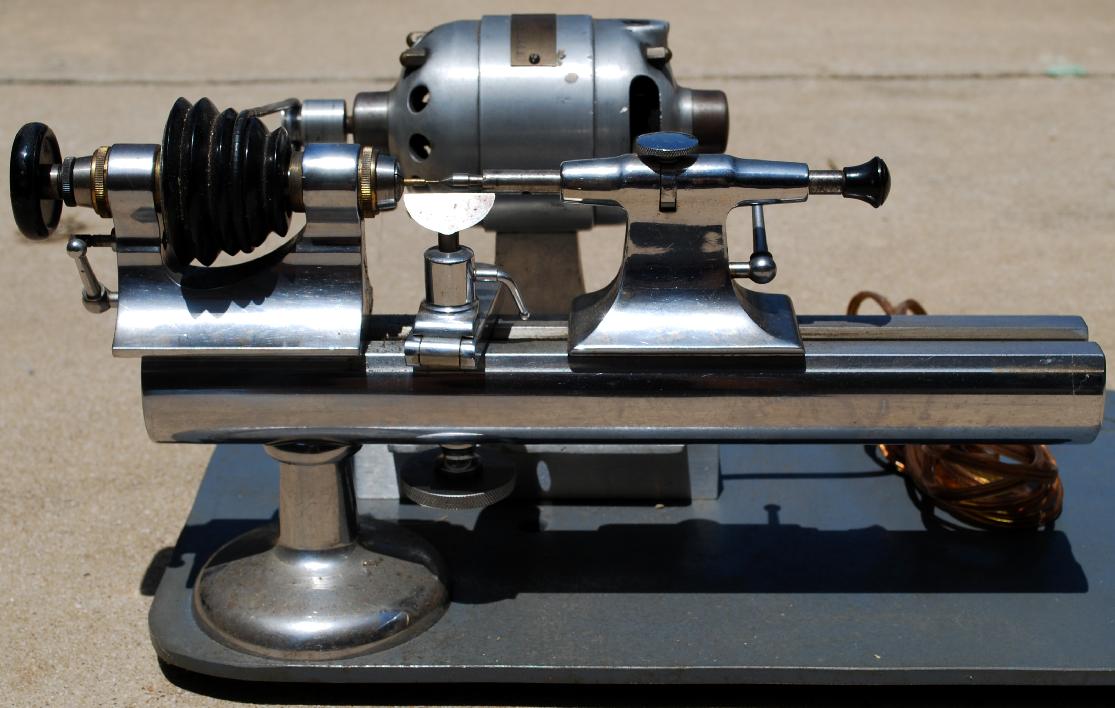

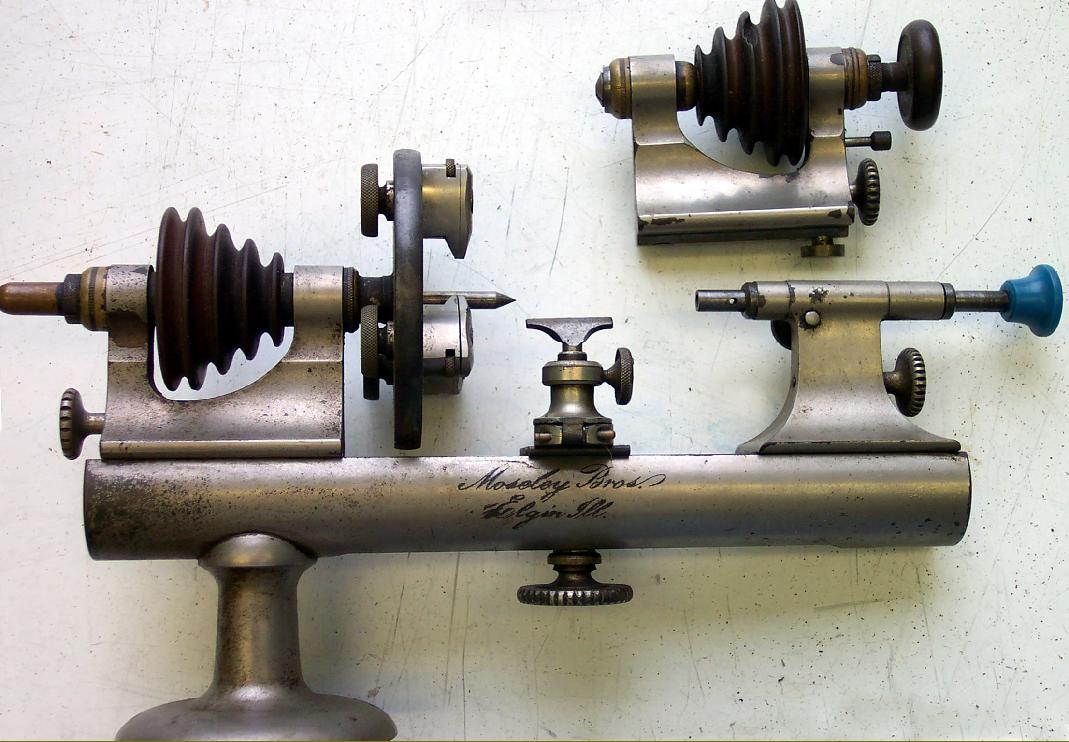

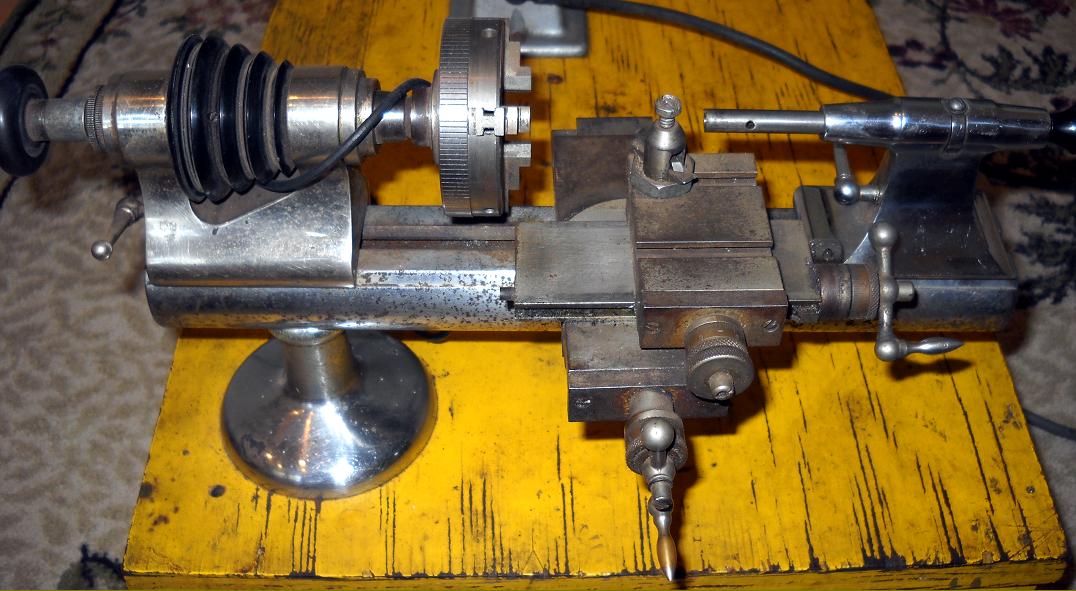

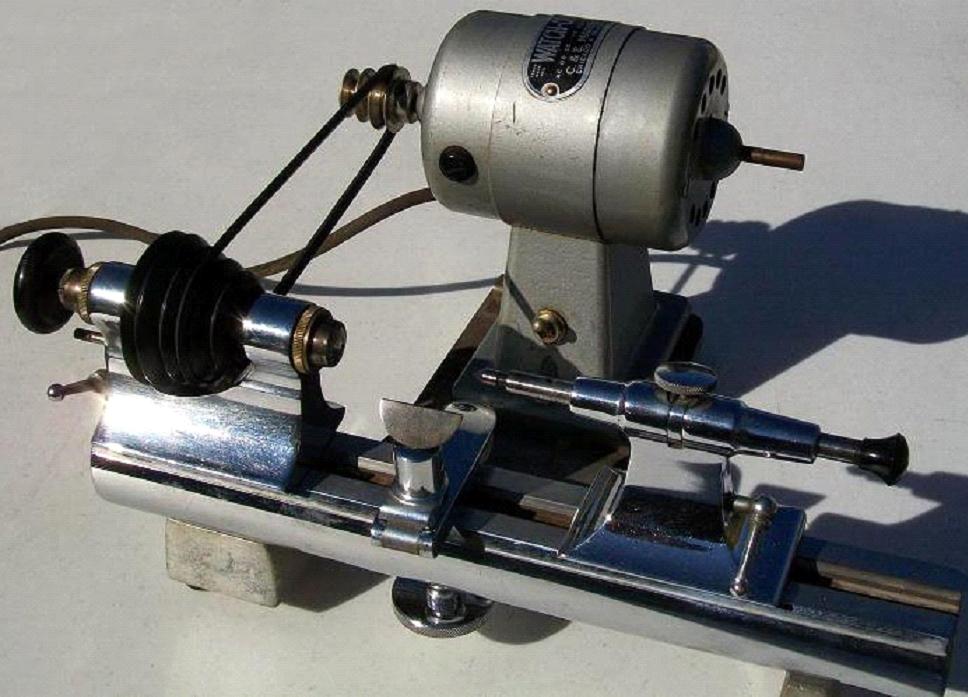

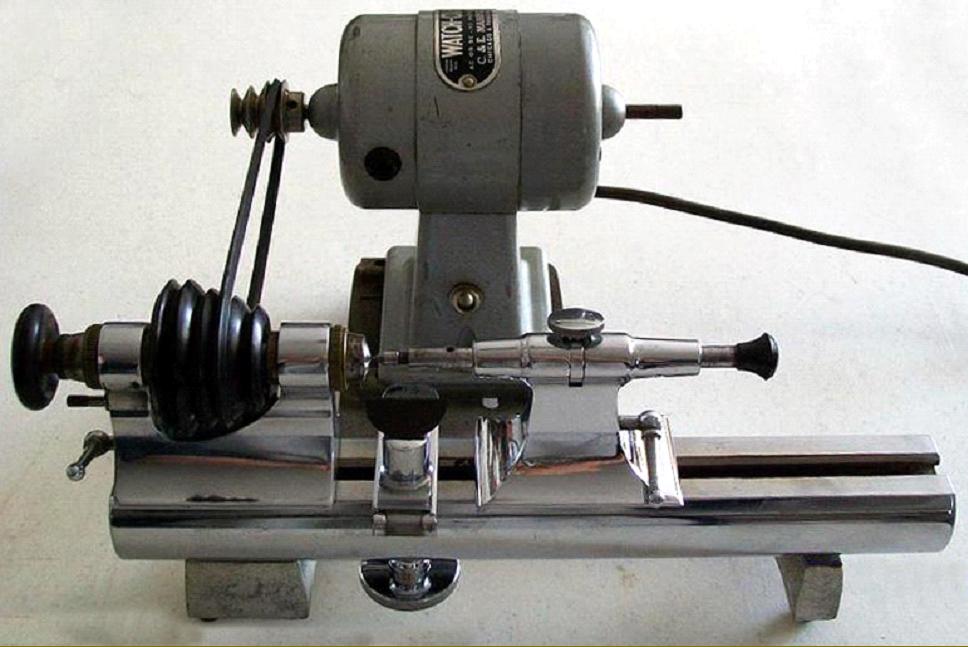

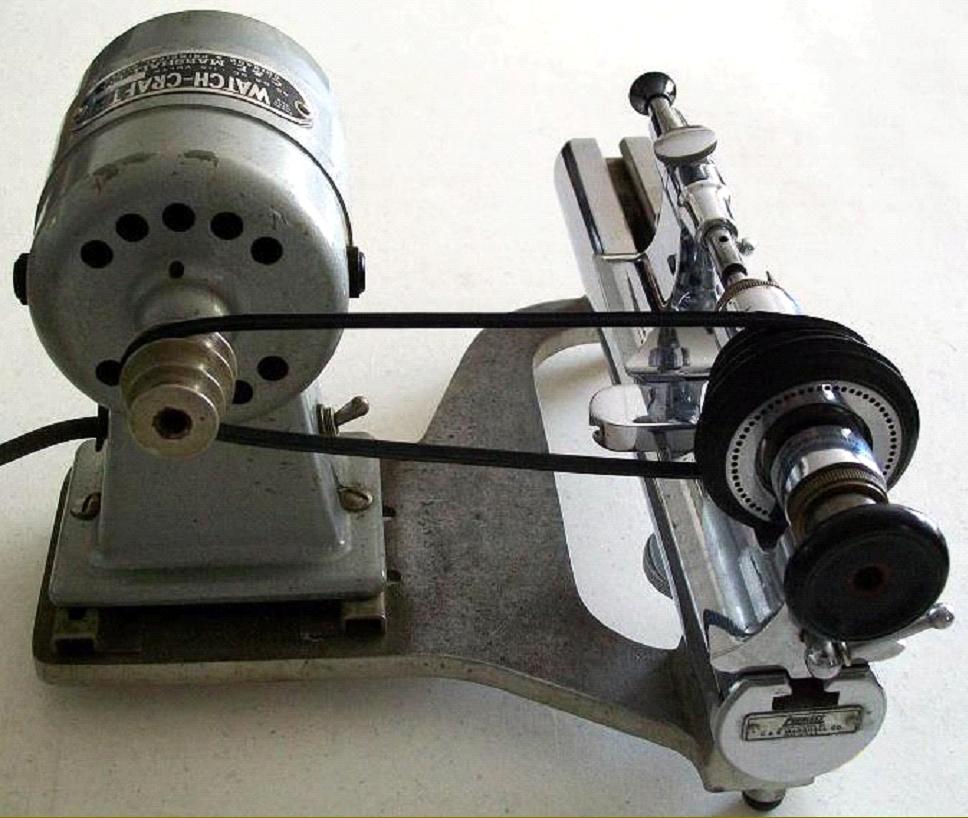

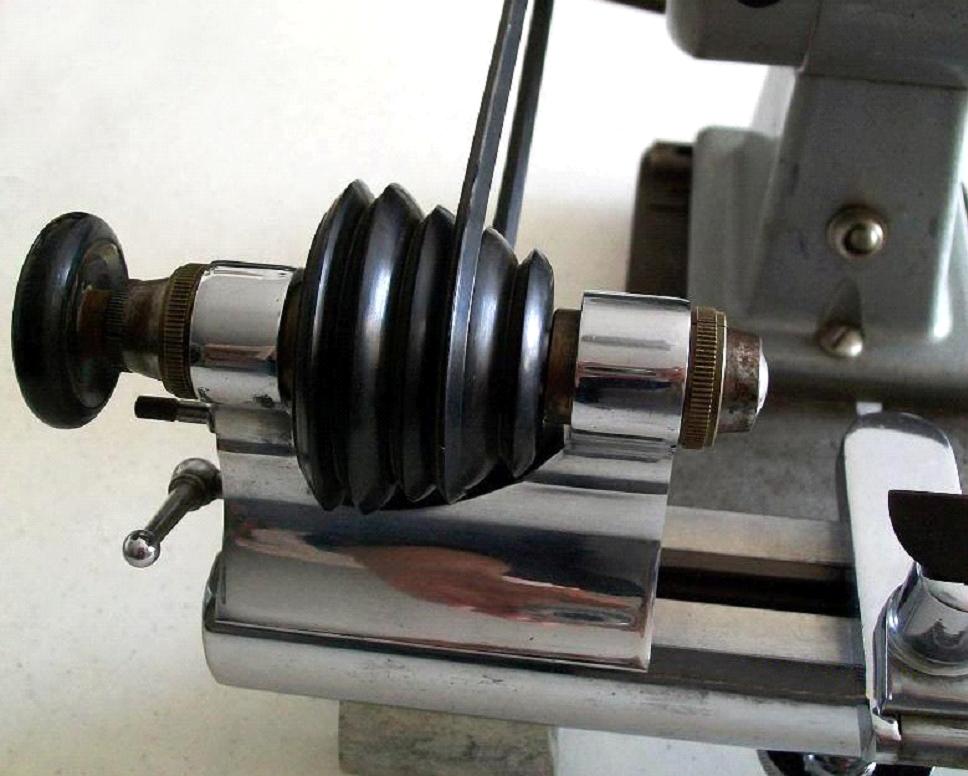

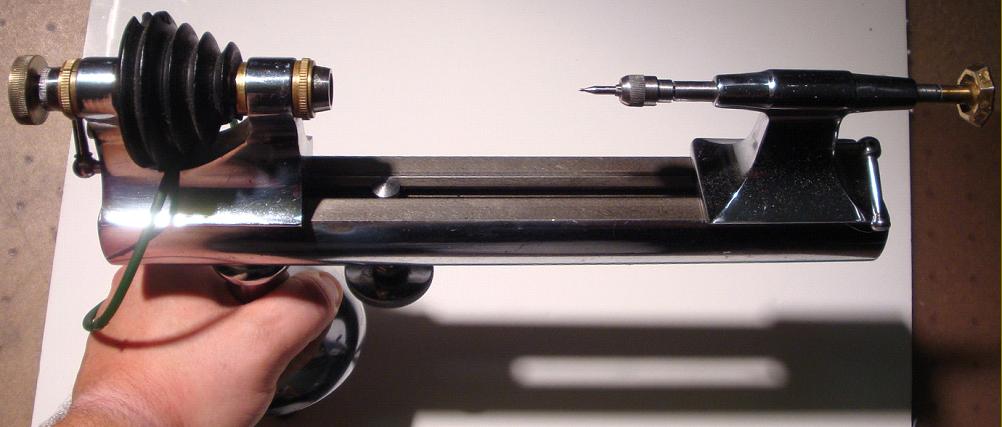

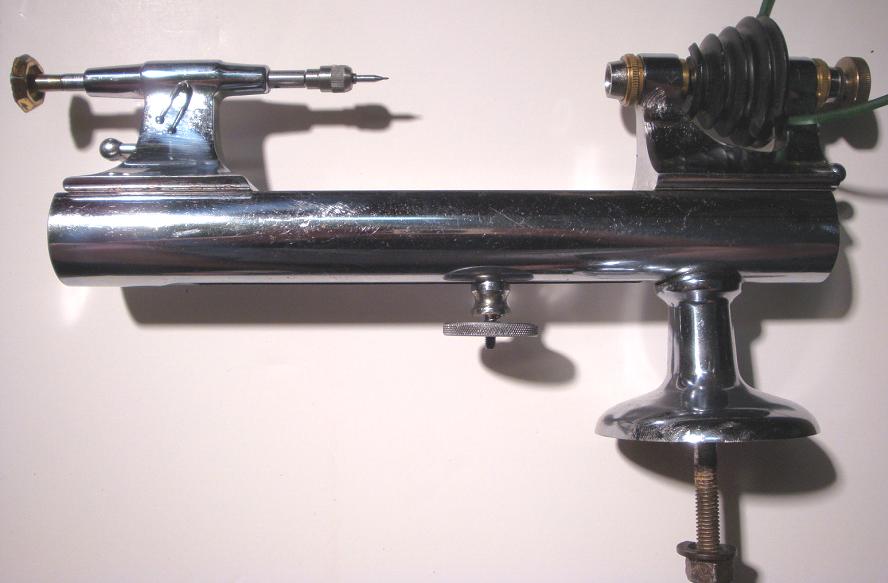

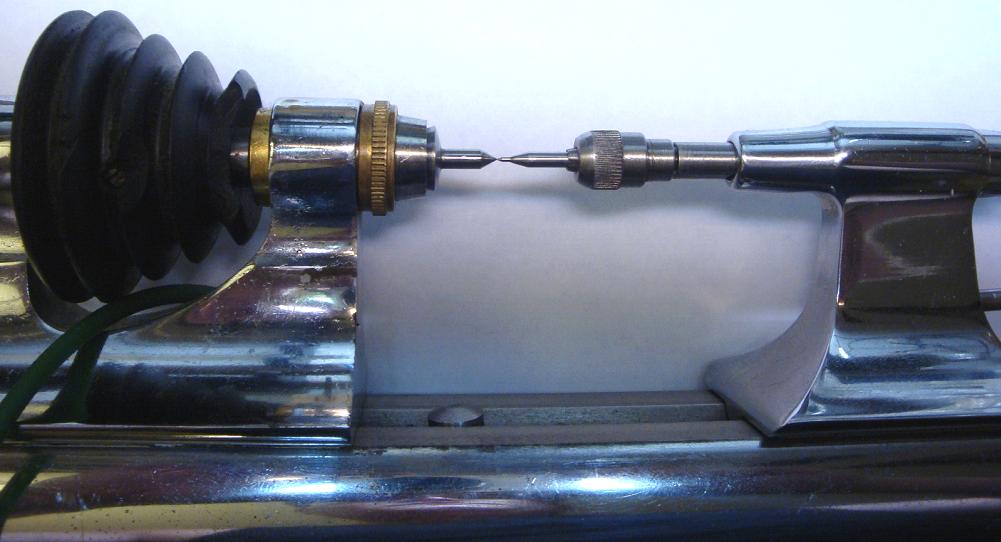

Dealers C. & E. Marshall Co., of 1445 West Jackson Boulevard, Chicago, Ill. U.S.A. branded five lathes as their own: the Marshall, the Peerless, the less-common Marco, the even rarer "Little Giant" and the Moseley. The latter was once being an independent company who had been absorbed by Marshall (an article about them is here). The "Little Giant" (shown on this page) was a very short-bed model, finished in a dark paint and perhaps sold at a lower price. All four lathes had a centre height of 2 inches and followed the robust, well-established and very popular WW (Webster-Whitcombe) design. On most, two spindles were offered to take either 8 mm or 6 mm collets and, as these were not the same length, two different draw bars were used as well. The 6 mm collet was by far the more common - and the most-used size on this class of lathe. A conventional WW-type bed with its heavy, half-round form and a flat top with bevelled edges was used by all models - but it was only the headstock that was located by the bed's outside bevels. The slide-rest, tool-rest and tailstock were pulled down into a single central "T-slot" but with sloping slides - a similar arrangement being used on some Rivett watchmakers' lathes (unfortunately, fittings for many Marshall lathes will not interchange with the Moseley and Peerless, the former having a different bed design). Although the forces involved in using a tiny lathe are slight - and, in practice, the V-slot would have made no discernable difference to the performance of the lathe - the design had the disadvantage that components from other WW-type models (which are often interchangeable make-to-make) could not be used.

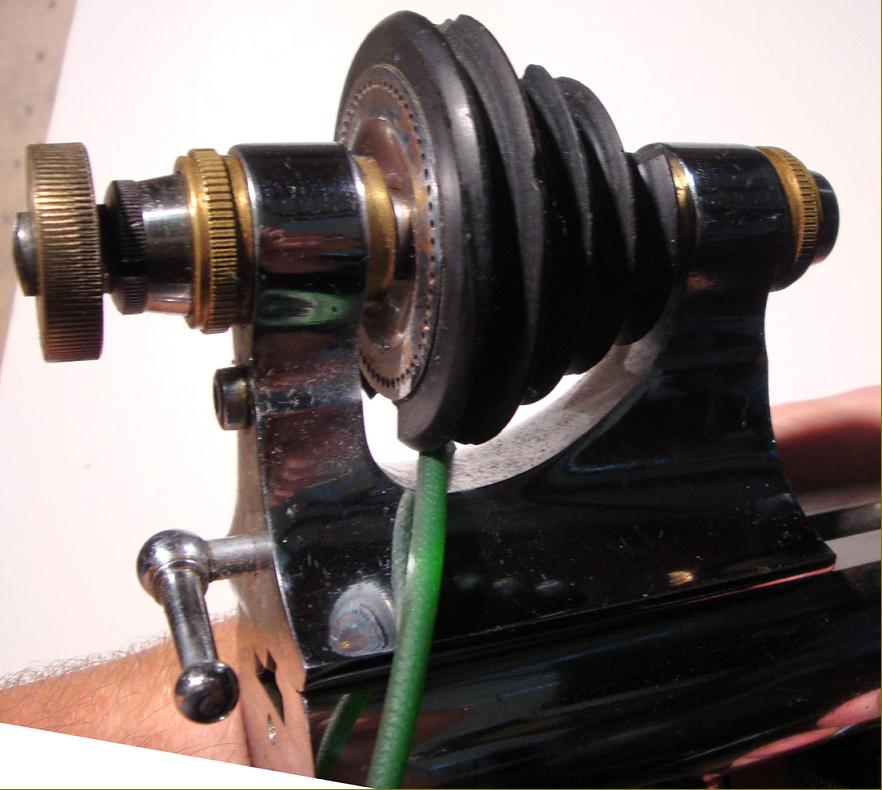

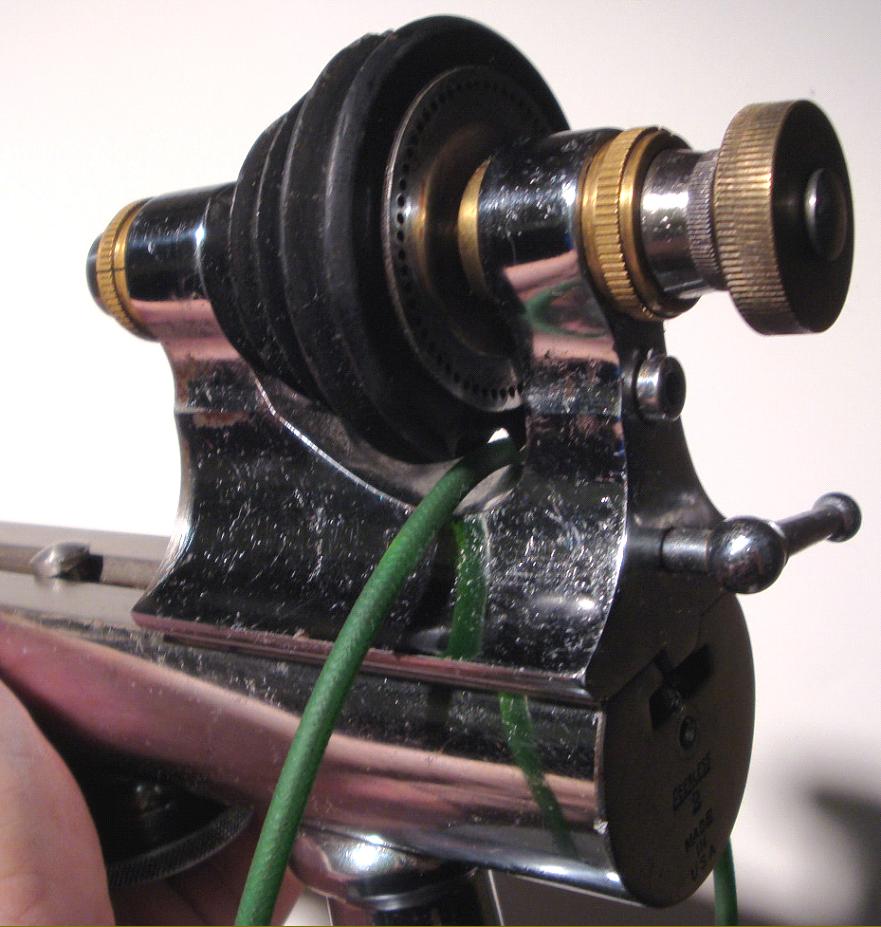

While the Marshall used a rather special headstock spindle assembly, with pre-loaded super-precision ball bearings (usually supplied by the Norma Company) the Peerless and Moseley both stuck to the tried and tested plain-cone type with hardened and lapped steel components that were guaranteed to give very high speeds with complete reliability together with a long and trouble-free life. It appears that Marshall-Moseley lathes have a centre height at variance with the standard 50 mm of a "true" WW lathe, their measurement being an exact 2 inches (50.8 mm).

One interesting addition to late-model Marshall machines was the incorporation of a rather finely proportioned Y-shaped base plate, supported on three rubber-tipped feet, that extended rearwards to carry the 115V AC/DC motor - in this respect it mirrored some versions of the contemporary Leinen and Lorch models of the early 1950s.

Like most other watchmakers' lathes, the Marshall, Moseley, Marco and Peerless brands were given the usual (and very pleasing) dull nickel-plated finish - though towards the end of production those branded Marshall and Moseley were in chrome (with the possibility that some Peerless versions were as well); this finish, though attractive in a cosmetic sense, caused unwanted reflections that could interfere with the operator's view of the job and, in addition, based on surviving examples, appears to have exacerbated rusting of the bed.

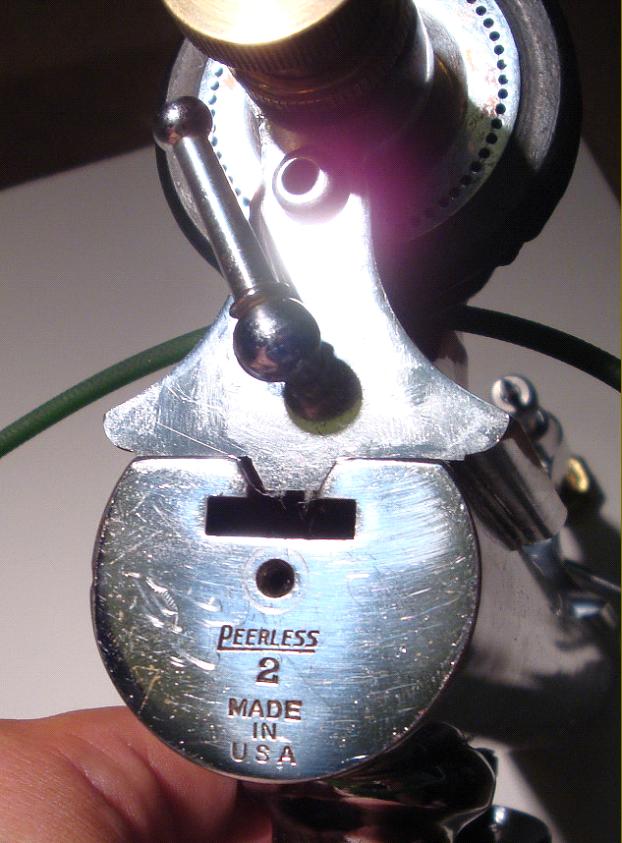

Late-model Peerless lathes have been found stamped "Peerless 2" - the digit signifying that the lathe had been adapted to accept the longer collets used in the Moseley (lathes with Marshall stamped into one end of the bed and Peerless into the other was standard practice). Older "classic" Mosely lathes had what was known as an invert "connoidal" collet (chuck) this being changed to a slightly longer one with a 20° head angle - the change perhaps coinciding with an alteration to the bed where an alignment bevel was provided along the front edge. These later style models have been found stamped "Moseley-Marshall".

If any reader has literature on Marco and "Little Giant" brands, the writer would be very interested to hear from you..

|

|

|

|